Professional Documents

Culture Documents

Scheduled Oil Sampling Report: Customer Information Unit Information

Scheduled Oil Sampling Report: Customer Information Unit Information

Uploaded by

KorneliusCopyright:

Available Formats

You might also like

- Bachs Suites For Solo Cello BWV 1007 101 PDFDocument289 pagesBachs Suites For Solo Cello BWV 1007 101 PDFLuca Franceschelli100% (1)

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech0992000% (1)

- 7test Report of Petroleum Coke Dated 13.07.2020Document1 page7test Report of Petroleum Coke Dated 13.07.2020Abhinav BansalNo ratings yet

- Painting Inspection Report Final CoatDocument3 pagesPainting Inspection Report Final Coatabdulgafoor54100% (1)

- TAMU EssaysDocument7 pagesTAMU EssaysAnakin Skywalker100% (2)

- Sos Sampling ReportDocument2 pagesSos Sampling Reportomar solimanNo ratings yet

- SOS Sampling ReportDocument2 pagesSOS Sampling ReportAsaisan AsaisanNo ratings yet

- A20J120618 Valuable Customer 0Document2 pagesA20J120618 Valuable Customer 0Chandra Hermanto SinagaNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationMuhammad AriefNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationDharmaNugrahaNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationARI WIJAYANTONo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationHeri KiswantoNo ratings yet

- B14B052339 - Hanurata Ahmad Zarkasi (A) - 0Document1 pageB14B052339 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiNo ratings yet

- PT Petrolab Services: Grease Analysis ReportDocument1 pagePT Petrolab Services: Grease Analysis Reportvictor josuaNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- Interstellar Testing Centre Pvt. LTD.: Test ReportDocument2 pagesInterstellar Testing Centre Pvt. LTD.: Test ReportDemon barberNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- Multi-Point BET Data Reduction Parameters DataDocument1 pageMulti-Point BET Data Reduction Parameters DataWempic Aulia FauziNo ratings yet

- Indian Oil Corporation Limited: ASTM/IP/IS1448)Document3 pagesIndian Oil Corporation Limited: ASTM/IP/IS1448)Arvind DhakaNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDocument1 pageAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghNo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- Aggregate Crushing Value (STP 7.7.1) 10% Fines Value (STP 7.7.2)Document1 pageAggregate Crushing Value (STP 7.7.1) 10% Fines Value (STP 7.7.2)Shoyeeb AhmedNo ratings yet

- CCR Engine Detonation PHKT Lawe-Lawe Gs1411b 8500215139Document12 pagesCCR Engine Detonation PHKT Lawe-Lawe Gs1411b 8500215139Sidik NopiansyahNo ratings yet

- Aes Laboratories (P) LTD.: Analyzing Today FR An A.csured TomorrowDocument1 pageAes Laboratories (P) LTD.: Analyzing Today FR An A.csured TomorrowShreyansh SinghNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- PlatDocument1 pagePlatSitorus DevisNo ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- 10 MM AS0480104Document1 page10 MM AS0480104mamdouhNo ratings yet

- Battery 17 AhDocument1 pageBattery 17 AhBroh UtunNo ratings yet

- Scheduled Oil Sampling Report: Eval CodeDocument1 pageScheduled Oil Sampling Report: Eval Codedwiatmi1312No ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- Layout Inspection Report: M/s Pricol LTDDocument35 pagesLayout Inspection Report: M/s Pricol LTDPrakash kumarTripathiNo ratings yet

- BH MT 199 2022 T&aDocument1 pageBH MT 199 2022 T&aDeanz KmcNo ratings yet

- Steam Blowing ProcedureDocument119 pagesSteam Blowing ProcedureshashinaganurNo ratings yet

- Daily Report 18 Juin 2020Document150 pagesDaily Report 18 Juin 2020Salim82 LKNo ratings yet

- 43-Utm Load Cell Tensile Calibration CartificateDocument1 page43-Utm Load Cell Tensile Calibration CartificateCustomer SupportNo ratings yet

- Customer Engineering ApprovalDocument28 pagesCustomer Engineering Approvalgagandeep isherNo ratings yet

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- 2 Turbin 0511 Ob2123174Document1 page2 Turbin 0511 Ob2123174BennyNo ratings yet

- G2206070002 0001 Test ReportDocument12 pagesG2206070002 0001 Test Reportrakesh kumarNo ratings yet

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- MTC 16.08.2023Document2 pagesMTC 16.08.2023OMARDIBNo ratings yet

- A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0Document2 pagesA44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0m.shehreyar.khanNo ratings yet

- Tube Comp J00Document1 pageTube Comp J00Dudi SolehudinNo ratings yet

- Ultratech Cement 7 Days Test Report Week 37Document3 pagesUltratech Cement 7 Days Test Report Week 37Venkatesh VictoryNo ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- Compressive Strength of Cement Grout/Mortar Mix (Cubes)Document30 pagesCompressive Strength of Cement Grout/Mortar Mix (Cubes)Mohamed RamadanNo ratings yet

- Oil Sample S315Document1 pageOil Sample S315yudhaperkasa92No ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Dhi LM43 F200 MTBFDocument1 pageDhi LM43 F200 MTBFAntónio LeitãoNo ratings yet

- Pt. Riodi Jaya Medan Oj02944 Uo 24 QRDocument1 pagePt. Riodi Jaya Medan Oj02944 Uo 24 QRdotaaja222No ratings yet

- Interstellar Testing Centre Pvt. LTD.: Test ReportDocument2 pagesInterstellar Testing Centre Pvt. LTD.: Test ReportDemon barberNo ratings yet

- Modified BitumensDocument6 pagesModified BitumensDonNo ratings yet

- 1.11111 Hyu Flo Flu Steel: Tensile Test Impact Test (L) Chemical Composition Yield Bend MN S Cu Ni Mo CR NB SNDocument1 page1.11111 Hyu Flo Flu Steel: Tensile Test Impact Test (L) Chemical Composition Yield Bend MN S Cu Ni Mo CR NB SNyugandharNo ratings yet

- Purchase Request: Qualitycontrol DepartmentDocument2 pagesPurchase Request: Qualitycontrol DepartmentValipireddy NagarjunNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Daily Report Juillet 2020Document165 pagesDaily Report Juillet 2020Salim82 LKNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Content and Contextual Analysis of The Parisian LifeDocument7 pagesContent and Contextual Analysis of The Parisian LifeSowla sidoNo ratings yet

- World's Famous NewspapersDocument8 pagesWorld's Famous NewspapersgopiganjaNo ratings yet

- Basso Wisdom+Sits+in+PlacesDocument22 pagesBasso Wisdom+Sits+in+Placeshello motoNo ratings yet

- Lesson 1 Principles and TheoriesDocument11 pagesLesson 1 Principles and TheoriesJoycee BoNo ratings yet

- 2nd Bimonth Test 7th FORMDocument7 pages2nd Bimonth Test 7th FORMFranco AleNo ratings yet

- McDonald Family History v35Document45 pagesMcDonald Family History v35David McDonaldNo ratings yet

- Pakistan (1964) Government Servants (Conduct) Rules, (EN)Document11 pagesPakistan (1964) Government Servants (Conduct) Rules, (EN)Imran Khan SharNo ratings yet

- 01 Reinforcement Material AnswersDocument5 pages01 Reinforcement Material Answerspicoleta2No ratings yet

- Abbotsford Law Court Provincial AdvanceDocument108 pagesAbbotsford Law Court Provincial Advancesampv90No ratings yet

- Zaid Letter To DNI Acting DirectorDocument2 pagesZaid Letter To DNI Acting DirectorNational Content Desk100% (2)

- Challenges Facing GraduateDocument95 pagesChallenges Facing GraduateGetu DeleluNo ratings yet

- Chapter 5 - Probability and Counting Rules IIDocument13 pagesChapter 5 - Probability and Counting Rules IIJanice NarcisoNo ratings yet

- Bidding Docs For DBWD Nlif May Final 2013projectDocument158 pagesBidding Docs For DBWD Nlif May Final 2013projectrain06021992No ratings yet

- SNAKE PLANT (Sansevieria Trifasciata) FIBER AS A POTENTIAL SOURCE OF PAPERDocument38 pagesSNAKE PLANT (Sansevieria Trifasciata) FIBER AS A POTENTIAL SOURCE OF PAPERandrei100% (1)

- Transfusion Reaction Algorithm V 2 FINAL 2016 11 02 PDFDocument1 pageTransfusion Reaction Algorithm V 2 FINAL 2016 11 02 PDFnohe992127No ratings yet

- Assignement 2Document3 pagesAssignement 2Ma Vanessa Rose TacuyanNo ratings yet

- Concerto in C Minor - Johann Christian Bach - CelloDocument24 pagesConcerto in C Minor - Johann Christian Bach - CellojosianeNo ratings yet

- The Crucial Difference Between Creativity and InnovationDocument14 pagesThe Crucial Difference Between Creativity and InnovationTamara KlicekNo ratings yet

- WLC UpgradeDocument13 pagesWLC Upgradeapi-3703368No ratings yet

- Azu TD 3132236 Sip1 MDocument218 pagesAzu TD 3132236 Sip1 MXi LinNo ratings yet

- Bible Greek VpodDocument134 pagesBible Greek VpodEmanuel AlvarezNo ratings yet

- Westbourne Baptist Church NW CalgaryDocument4 pagesWestbourne Baptist Church NW CalgaryBonnie BaldwinNo ratings yet

- Smith, K. B. & Pukall, C. F. (2009) - An Evidence-Based Review of Yoga As A Complementary Intervention For Patients With CancerDocument12 pagesSmith, K. B. & Pukall, C. F. (2009) - An Evidence-Based Review of Yoga As A Complementary Intervention For Patients With CancerDerly ObtialNo ratings yet

- Eating Disorder PPT by Shreyasi MittalDocument35 pagesEating Disorder PPT by Shreyasi MittalPrachi gattaniNo ratings yet

- Phoenix Curriculum - Science (Biology) .150899589Document2 pagesPhoenix Curriculum - Science (Biology) .150899589CanioNo ratings yet

- My PastorDocument3 pagesMy PastorPastor Emma MukisaNo ratings yet

- Managerial EconomicsDocument15 pagesManagerial EconomicsAditi WaliaNo ratings yet

- Practice Test Cao Hoc 2012Document9 pagesPractice Test Cao Hoc 2012SeaBlueNo ratings yet

Scheduled Oil Sampling Report: Customer Information Unit Information

Scheduled Oil Sampling Report: Customer Information Unit Information

Uploaded by

KorneliusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scheduled Oil Sampling Report: Customer Information Unit Information

Scheduled Oil Sampling Report: Customer Information Unit Information

Uploaded by

KorneliusCopyright:

Available Formats

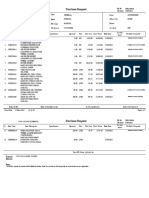

PT.

Trakindo Utama S•O•S Fluids Analysis Laboratory

Scheduled Oil Sampling Report

JI. Cilandak KKO Raya No. 1, Jakarata 12560, PO Box 2282/JKT - Indonesia

Tel: (62-21) 7822373, Fax. (62-21) 7822357, 7822379

Customer Information Unit Information

MANGGALA USAHA MANUNGGAL PT. Category : Oil Equip Make : Caterpillar Received Date : 7/26/2019 4:00:00PM

ATTN: Manggala Usaha Manunggal / Kornelius David (A) Lab No : A19G270201 Equip Model : C15 Lab Process Date : 07/26/2019 4:00PM

GRAHA BIP LT,11 JL.JEND.GATOT SUBROTO

Unit Number : TXY04636/DYNOTES Sample Site/Location : DYNOTES PALEMBANG Sample Note : SO : 8600038469 - OVERHAUL BESAR MESIN

KAV 23,SEMANGGI SETIABUDI

JAKARTASELATAN, SANGATTA ,Indonesia 12930 Equip Serial : TXY04636 Jobsite : 22 - PALEMBANG Reported Date : 7/28/2019 1:08:59PM

Compartment : Engine Job No :

Sample Point : Label No : 22 Evaluation Code B Monitor Compartment.

Phone 0215258211

Interpreted by : Interpreter / Basuki Rachmat - EM ext.1092 (A)

Element Reading (mg/kg = ppm) - ASTM D-5185

Lab No. Sample Process Eval CMU SMU HOO Oil Added Fluid Filter Oil Type Oil Grade

Wear Metal Contaminant Additives

Date Date Chg Chg

Cr Pb Fe Cu Al Sn Ni B K Na Si Ca P Zn Mg Mo

A19G270201 20/Jul/19 26/Jul/19 B 3 3 0 Y DEO SAE 15W-40 0 0 7 36 1 1 0 2 2 0 3 938 1057 1256 901 45

Element Reading (mg/kg = ppm) Oil Condition (JOAP) ASTM E2412 Physical / Chemical Test Particle Count (Counts / ml) - ASTM D 4464

Lab No Ba * Ti * Ag * V* ST OXI NIT SUL FP (P/N) DF (%) V100 V40 VI TBN TAN W (P/N) W(%) PQ Visual PC 04 PC 06 PC 14 ISO 04 ISO 06 ISO 14

(cSt) (cSt) (idx)

A19G270201 0 9 4 14 N 13.0 9.0 N 7.0 -

Lab No. Tendency (5' Tendency (5' Tendency (5' Stability (10' Stability (10' Stability (10' Milipore Sludge

aeration) Seq 1 aeration) Seq 2 aeration) Seq 3 aeration) Seq 1 aeration) Seq 2 aeration) Seq 3 Test

A19G270201

Glossaries

Elements Ag=Silver P=Positive (0.5 - 0.8%) Visual

(ASTM D 5185) Note: Results = 0 < LoD (Limit of Detection) T=Trace (Cloudy but < 0.5%) LQ = Low Quantity

Si=Silicon (LoD=0.26) ppm=Parts Per Million E=Excessive (> 0.8%) MQ = Medium Quantity

AI=Aluminum (LoD=0.12) Particle Count Physical / Chemical HQ = High Quantity

Cr=Chromium (LoD=0.12) (ASTM D7647 & ASTM D7596) PQ=Particle Quantifier (Idx=Index) Met = Metallic

Fe=Iron (LoD=0.11) PC04=Particle Count at 4 micron TBN (mg KOH /g)=Total Base Number - ASTM D 4739 Non Met = Non Metallic

Pb=Lead (LoD=0.82) PC06=Particle Count at 6 micron TAN (mg KOH /g) =Total Acid Number - ASTM D664 F = Fine

Cu=Copper (LoD=0.01) PC14=Particle Count at 14 micron V100=Viscosity 100 °C - ASTM D445 C = Coarse

Sn=Tin (LoD=0.25) ISO4=ISO Code 4 V40=Viscosity 40 °C - ASTM D445 Granul = Granular

Ni=Nickel (LoD=0.38) SO6=ISO Code 6 cSt=Centistokes

Mg=Magnesium (LoD=0.01) ISO14=ISO Code 14 VI=Viscosity Index

Ca=Calcium (LoD=0.05) Oil Condition W(%)=Water Percentage

K=Potassium (LoD=0.64) ST=Soot FP Criteria Approved by

Na=Sodium (LoD=0.42) OXI=Oxidation FP=Flash Point (ASTM D 3828 - Method A)

P=Phosphorus (LoD=0.74) NIT=Nitration P=Positive

B=Boron (LoD=0.40) SUL=Sulfation N=Negative

Mo=Molybdenum (LoD=0.20) Water Criteria DF(%)=Dilution Fuel - ASTM D 3524

Zn=Zinc (LoD=0.17) W=Water - ASTM D6304 / ASTM D4377

Ti=Titanium % =Percentage

V=Vanadium N=Negative

Ba=Barium Mukhlisin

Manager S•O•S Laboratory

* Not Include Acreditation Scope

A19G270201 Page 1 of 2

PT. Trakindo Utama S•O•S Fluids Analysis Laboratory

JI. Cilandak KKO Raya No. 1, Jakarata 12560, PO Box 2282/JKT - Indonesia

Tel: (62-21) 7822373, Fax. (62-21) 7822357, 7822379

Customer Information Unit Information

MANGGALA USAHA MANUNGGAL PT. Category : Oil Equip Make : Caterpillar Received Date: : 7/26/2019 4:00:00PM

ATTN: Manggala Usaha Manunggal / Kornelius David (A) Lab No : A19G270201 Equip Model : C15 Lab Process Date : 07/26/2019 4:00PM

GRAHA BIP LT,11 JL.JEND.GATOT SUBROTO Unit Number : TXY04636/DYNOTES Sample Site/Location : DYNOTES PALEMBANG Sample Note : SO : 8600038469 - OVERHAUL BESAR MESIN

KAV 23,SEMANGGI SETIABUDI Equip Serial : TXY04636 Jobsite : 22 - PALEMBANG Reported Date: : 7/28/2019 1:08:59PM

JAKARTASELATAN, SANGATTA ,Indonesia 12930 Compartment : Engine Job No :

Sample Point : Label No : 22

Evaluation Code B Monitor Compartment.

Phone 0215258211 Interpreted by : Interpreter / Basuki Rachmat - EM ext.1092 (A)

Recommendation** Rekomendasi**

CU IS HIGH.PROBABLY CAME FROM NEW PART/ASSEMBLY CONTAMINATION. THE UNIT STILL BREAK-IN ELEMEN CU TINGGI.KEMUNGKINAN BERASAL DARI KONTAMINASI PART/ASSEMBLY YANG BARU. UNIT MASIH

PERIOD.TAKE OIL SAMPLES AT 250 HOUR INTERVALS TO MONITOR CONDITION.MORE SAMPLES ARE NEEDED DALAM BREAK-IN PERIOD.AMBIL SAMPEL OLI PADA INTERVAL 250 JAM UNTUK MEMONITOR KONDISI.LEBIH

TO ESTABLISH A TREND. BANYAK SAMPEL DIBUTUHKAN UNTUK MEMBUAT TREN.

Wear Metal Contaminant

7 3.2

2.8

6

2.4

5

2

Al K

4

Cr Na

Fe 1.6

Si

Pb ST

3

PQ

1.2

2

0.8

1 0.4

0 0

7/20/2019 7/20/2019

Oil Condition Viscosity

14 14

12 12

10 10

8 NIT 8

OXI

V100

SUL

6 TBN 6

4 4

2 2

0 0

7/20/2019 7/20/2019

If you need further information & dicussion, please kindly advised to contact us prior 7 days after report released (Jika di perlukan informasi & diskusi lebih lanjut dengan sample ini, hubungi kami sebelum 7 hari setelah laporan di kirim)

This analysis is indicative and base on sample information received and quality of sample supplied. Any decision relating to component repair is entirely discretion of customer

(Analisa ini bersifat indikasi, berdasarkan informasi dari label & sample yg di kirimkan. Jika ada keputusan perbaikan component sepenuhnya kebijakan customer).

**The evaluation & Recommendation made by Equipment Management PT. Trakindo Utama

A19G270201 Page 2 of 2

You might also like

- Bachs Suites For Solo Cello BWV 1007 101 PDFDocument289 pagesBachs Suites For Solo Cello BWV 1007 101 PDFLuca Franceschelli100% (1)

- Mill Test Certificate: Jindal Stainless (Hisar) LimitedDocument1 pageMill Test Certificate: Jindal Stainless (Hisar) Limitedhemantmech0992000% (1)

- 7test Report of Petroleum Coke Dated 13.07.2020Document1 page7test Report of Petroleum Coke Dated 13.07.2020Abhinav BansalNo ratings yet

- Painting Inspection Report Final CoatDocument3 pagesPainting Inspection Report Final Coatabdulgafoor54100% (1)

- TAMU EssaysDocument7 pagesTAMU EssaysAnakin Skywalker100% (2)

- Sos Sampling ReportDocument2 pagesSos Sampling Reportomar solimanNo ratings yet

- SOS Sampling ReportDocument2 pagesSOS Sampling ReportAsaisan AsaisanNo ratings yet

- A20J120618 Valuable Customer 0Document2 pagesA20J120618 Valuable Customer 0Chandra Hermanto SinagaNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationMuhammad AriefNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationDharmaNugrahaNo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationARI WIJAYANTONo ratings yet

- Scheduled Oil Sampling Report: Customer Information Unit InformationDocument2 pagesScheduled Oil Sampling Report: Customer Information Unit InformationHeri KiswantoNo ratings yet

- B14B052339 - Hanurata Ahmad Zarkasi (A) - 0Document1 pageB14B052339 - Hanurata Ahmad Zarkasi (A) - 0Ahmad ZarkasiNo ratings yet

- PT Petrolab Services: Grease Analysis ReportDocument1 pagePT Petrolab Services: Grease Analysis Reportvictor josuaNo ratings yet

- Inspection Report: IR No.: QETO/IR/SUD/110Document2 pagesInspection Report: IR No.: QETO/IR/SUD/110sudipta dasNo ratings yet

- DTHW 005Document1 pageDTHW 005Angga 99No ratings yet

- Interstellar Testing Centre Pvt. LTD.: Test ReportDocument2 pagesInterstellar Testing Centre Pvt. LTD.: Test ReportDemon barberNo ratings yet

- Pdf24 MergedDocument9 pagesPdf24 MergedauliaadyaksaNo ratings yet

- Multi-Point BET Data Reduction Parameters DataDocument1 pageMulti-Point BET Data Reduction Parameters DataWempic Aulia FauziNo ratings yet

- Indian Oil Corporation Limited: ASTM/IP/IS1448)Document3 pagesIndian Oil Corporation Limited: ASTM/IP/IS1448)Arvind DhakaNo ratings yet

- Inspection Report: Page 1 of 2 Vendor P.O. NODocument4 pagesInspection Report: Page 1 of 2 Vendor P.O. NOsudipta dasNo ratings yet

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDocument1 pageAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghNo ratings yet

- Mycom #1Document1 pageMycom #1Rifky Windya NNo ratings yet

- Aggregate Crushing Value (STP 7.7.1) 10% Fines Value (STP 7.7.2)Document1 pageAggregate Crushing Value (STP 7.7.1) 10% Fines Value (STP 7.7.2)Shoyeeb AhmedNo ratings yet

- CCR Engine Detonation PHKT Lawe-Lawe Gs1411b 8500215139Document12 pagesCCR Engine Detonation PHKT Lawe-Lawe Gs1411b 8500215139Sidik NopiansyahNo ratings yet

- Aes Laboratories (P) LTD.: Analyzing Today FR An A.csured TomorrowDocument1 pageAes Laboratories (P) LTD.: Analyzing Today FR An A.csured TomorrowShreyansh SinghNo ratings yet

- Failure Analysis Report: SIMS InformationDocument13 pagesFailure Analysis Report: SIMS InformationHasby PotterNo ratings yet

- PlatDocument1 pagePlatSitorus DevisNo ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- 10 MM AS0480104Document1 page10 MM AS0480104mamdouhNo ratings yet

- Battery 17 AhDocument1 pageBattery 17 AhBroh UtunNo ratings yet

- Scheduled Oil Sampling Report: Eval CodeDocument1 pageScheduled Oil Sampling Report: Eval Codedwiatmi1312No ratings yet

- MIghty Machine RejectDocument1 pageMIghty Machine RejectMohammad Shanawaz MNo ratings yet

- Layout Inspection Report: M/s Pricol LTDDocument35 pagesLayout Inspection Report: M/s Pricol LTDPrakash kumarTripathiNo ratings yet

- BH MT 199 2022 T&aDocument1 pageBH MT 199 2022 T&aDeanz KmcNo ratings yet

- Steam Blowing ProcedureDocument119 pagesSteam Blowing ProcedureshashinaganurNo ratings yet

- Daily Report 18 Juin 2020Document150 pagesDaily Report 18 Juin 2020Salim82 LKNo ratings yet

- 43-Utm Load Cell Tensile Calibration CartificateDocument1 page43-Utm Load Cell Tensile Calibration CartificateCustomer SupportNo ratings yet

- Customer Engineering ApprovalDocument28 pagesCustomer Engineering Approvalgagandeep isherNo ratings yet

- Integrated Oil Field Supply & Services LLC: Material Inspection ReportDocument1 pageIntegrated Oil Field Supply & Services LLC: Material Inspection ReportRajkumar ANo ratings yet

- HGR3100 Engine 23augDocument1 pageHGR3100 Engine 23augIndo BemlNo ratings yet

- 2 Turbin 0511 Ob2123174Document1 page2 Turbin 0511 Ob2123174BennyNo ratings yet

- G2206070002 0001 Test ReportDocument12 pagesG2206070002 0001 Test Reportrakesh kumarNo ratings yet

- FAR D6R LH Final Drive FailureDocument9 pagesFAR D6R LH Final Drive Failurealisa alainaNo ratings yet

- MTC 16.08.2023Document2 pagesMTC 16.08.2023OMARDIBNo ratings yet

- A44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0Document2 pagesA44-01-PRO-DAS-08 Datasheet For Inlet Gas Trim Cooler, Rev.F0m.shehreyar.khanNo ratings yet

- Tube Comp J00Document1 pageTube Comp J00Dudi SolehudinNo ratings yet

- Ultratech Cement 7 Days Test Report Week 37Document3 pagesUltratech Cement 7 Days Test Report Week 37Venkatesh VictoryNo ratings yet

- HGR3098 Engine 23augDocument1 pageHGR3098 Engine 23augIndo BemlNo ratings yet

- Compressive Strength of Cement Grout/Mortar Mix (Cubes)Document30 pagesCompressive Strength of Cement Grout/Mortar Mix (Cubes)Mohamed RamadanNo ratings yet

- Oil Sample S315Document1 pageOil Sample S315yudhaperkasa92No ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Dhi LM43 F200 MTBFDocument1 pageDhi LM43 F200 MTBFAntónio LeitãoNo ratings yet

- Pt. Riodi Jaya Medan Oj02944 Uo 24 QRDocument1 pagePt. Riodi Jaya Medan Oj02944 Uo 24 QRdotaaja222No ratings yet

- Interstellar Testing Centre Pvt. LTD.: Test ReportDocument2 pagesInterstellar Testing Centre Pvt. LTD.: Test ReportDemon barberNo ratings yet

- Modified BitumensDocument6 pagesModified BitumensDonNo ratings yet

- 1.11111 Hyu Flo Flu Steel: Tensile Test Impact Test (L) Chemical Composition Yield Bend MN S Cu Ni Mo CR NB SNDocument1 page1.11111 Hyu Flo Flu Steel: Tensile Test Impact Test (L) Chemical Composition Yield Bend MN S Cu Ni Mo CR NB SNyugandharNo ratings yet

- Purchase Request: Qualitycontrol DepartmentDocument2 pagesPurchase Request: Qualitycontrol DepartmentValipireddy NagarjunNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Condition ReportDocument2 pagesCondition ReportCarlos MNo ratings yet

- Daily Report Juillet 2020Document165 pagesDaily Report Juillet 2020Salim82 LKNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Content and Contextual Analysis of The Parisian LifeDocument7 pagesContent and Contextual Analysis of The Parisian LifeSowla sidoNo ratings yet

- World's Famous NewspapersDocument8 pagesWorld's Famous NewspapersgopiganjaNo ratings yet

- Basso Wisdom+Sits+in+PlacesDocument22 pagesBasso Wisdom+Sits+in+Placeshello motoNo ratings yet

- Lesson 1 Principles and TheoriesDocument11 pagesLesson 1 Principles and TheoriesJoycee BoNo ratings yet

- 2nd Bimonth Test 7th FORMDocument7 pages2nd Bimonth Test 7th FORMFranco AleNo ratings yet

- McDonald Family History v35Document45 pagesMcDonald Family History v35David McDonaldNo ratings yet

- Pakistan (1964) Government Servants (Conduct) Rules, (EN)Document11 pagesPakistan (1964) Government Servants (Conduct) Rules, (EN)Imran Khan SharNo ratings yet

- 01 Reinforcement Material AnswersDocument5 pages01 Reinforcement Material Answerspicoleta2No ratings yet

- Abbotsford Law Court Provincial AdvanceDocument108 pagesAbbotsford Law Court Provincial Advancesampv90No ratings yet

- Zaid Letter To DNI Acting DirectorDocument2 pagesZaid Letter To DNI Acting DirectorNational Content Desk100% (2)

- Challenges Facing GraduateDocument95 pagesChallenges Facing GraduateGetu DeleluNo ratings yet

- Chapter 5 - Probability and Counting Rules IIDocument13 pagesChapter 5 - Probability and Counting Rules IIJanice NarcisoNo ratings yet

- Bidding Docs For DBWD Nlif May Final 2013projectDocument158 pagesBidding Docs For DBWD Nlif May Final 2013projectrain06021992No ratings yet

- SNAKE PLANT (Sansevieria Trifasciata) FIBER AS A POTENTIAL SOURCE OF PAPERDocument38 pagesSNAKE PLANT (Sansevieria Trifasciata) FIBER AS A POTENTIAL SOURCE OF PAPERandrei100% (1)

- Transfusion Reaction Algorithm V 2 FINAL 2016 11 02 PDFDocument1 pageTransfusion Reaction Algorithm V 2 FINAL 2016 11 02 PDFnohe992127No ratings yet

- Assignement 2Document3 pagesAssignement 2Ma Vanessa Rose TacuyanNo ratings yet

- Concerto in C Minor - Johann Christian Bach - CelloDocument24 pagesConcerto in C Minor - Johann Christian Bach - CellojosianeNo ratings yet

- The Crucial Difference Between Creativity and InnovationDocument14 pagesThe Crucial Difference Between Creativity and InnovationTamara KlicekNo ratings yet

- WLC UpgradeDocument13 pagesWLC Upgradeapi-3703368No ratings yet

- Azu TD 3132236 Sip1 MDocument218 pagesAzu TD 3132236 Sip1 MXi LinNo ratings yet

- Bible Greek VpodDocument134 pagesBible Greek VpodEmanuel AlvarezNo ratings yet

- Westbourne Baptist Church NW CalgaryDocument4 pagesWestbourne Baptist Church NW CalgaryBonnie BaldwinNo ratings yet

- Smith, K. B. & Pukall, C. F. (2009) - An Evidence-Based Review of Yoga As A Complementary Intervention For Patients With CancerDocument12 pagesSmith, K. B. & Pukall, C. F. (2009) - An Evidence-Based Review of Yoga As A Complementary Intervention For Patients With CancerDerly ObtialNo ratings yet

- Eating Disorder PPT by Shreyasi MittalDocument35 pagesEating Disorder PPT by Shreyasi MittalPrachi gattaniNo ratings yet

- Phoenix Curriculum - Science (Biology) .150899589Document2 pagesPhoenix Curriculum - Science (Biology) .150899589CanioNo ratings yet

- My PastorDocument3 pagesMy PastorPastor Emma MukisaNo ratings yet

- Managerial EconomicsDocument15 pagesManagerial EconomicsAditi WaliaNo ratings yet

- Practice Test Cao Hoc 2012Document9 pagesPractice Test Cao Hoc 2012SeaBlueNo ratings yet