Professional Documents

Culture Documents

Table of Contents

Table of Contents

Uploaded by

Satheesh Kumar NatarajanCopyright:

Available Formats

You might also like

- Practical MEMS: Ville KaajakariDocument9 pagesPractical MEMS: Ville Kaajakarioniruddha4No ratings yet

- bs7671 Iee On Site GuideDocument184 pagesbs7671 Iee On Site Guidemigzx95% (19)

- Power+Electronics+for+Technology+By+Ashfaq+Ahmed+ 1 PDFDocument438 pagesPower+Electronics+for+Technology+By+Ashfaq+Ahmed+ 1 PDFAbdullah Mahsud100% (5)

- (C. Christopoulos, A. Wright (Auth.) ) Electrical PDFDocument619 pages(C. Christopoulos, A. Wright (Auth.) ) Electrical PDFNicolás Cáceres García100% (2)

- J and P Transformer Book 14th Edition by Martin Heathcote and Ray Arnold Table of ContentsDocument3 pagesJ and P Transformer Book 14th Edition by Martin Heathcote and Ray Arnold Table of Contentskennedy100% (1)

- Electrical Installation Design Guide PDFDocument15 pagesElectrical Installation Design Guide PDFJack So0% (3)

- Passat W8 Engine Management, Motronic ME 7.1.1Document56 pagesPassat W8 Engine Management, Motronic ME 7.1.1sheba1023100% (1)

- Minor Electrical Installation Works - GreenDocument2 pagesMinor Electrical Installation Works - GreenPopescuLaurentiuNo ratings yet

- Transformers and Inductors For Power Electronics: Theory, Design and ApplicationsDocument6 pagesTransformers and Inductors For Power Electronics: Theory, Design and ApplicationsAKHIL VINAYAK RNo ratings yet

- E-HandBook On High Voltage Circuit Breakers, Edition 1.0, September'2021Document261 pagesE-HandBook On High Voltage Circuit Breakers, Edition 1.0, September'2021Saran Kumar100% (1)

- Electrical Power System Protection PDFDocument18 pagesElectrical Power System Protection PDFAlberto José Bermúdez AriasNo ratings yet

- Preface and Acknowledgements Preface To 2nd Edition Xi: ° ° ° XillDocument6 pagesPreface and Acknowledgements Preface To 2nd Edition Xi: ° ° ° XillDara HengNo ratings yet

- EM-I BookDocument141 pagesEM-I BookAnnapoorana EEENo ratings yet

- ContentsDocument5 pagesContentsJeans GonzalezNo ratings yet

- Gas-Insulated Medium Voltage Switchgear: Manual For Installation and Operation HB 601/01 EDocument85 pagesGas-Insulated Medium Voltage Switchgear: Manual For Installation and Operation HB 601/01 EGeorgi NikolovNo ratings yet

- J&P-TF Book PDFDocument957 pagesJ&P-TF Book PDFCtl JvvnlNo ratings yet

- Power Electronics and Motor Control PDFDocument563 pagesPower Electronics and Motor Control PDFAnonymous qdJOxst100% (3)

- Philips ApplicationBook IndustrialTriacsApplications 1975-02Document144 pagesPhilips ApplicationBook IndustrialTriacsApplications 1975-02hidalgobNo ratings yet

- ElECTRONIC CKTSDocument544 pagesElECTRONIC CKTSNavaraj BaniyaNo ratings yet

- Transformer Design Principles With AppliDocument9 pagesTransformer Design Principles With AppliCHUKARONo ratings yet

- Manual DanfossDocument212 pagesManual DanfossEduardo LegorretaNo ratings yet

- About The Authors Xiii Preface XV Acknowledgements Xix List of Symbols XxiDocument7 pagesAbout The Authors Xiii Preface XV Acknowledgements Xix List of Symbols XxiJhon Edwin OcampoNo ratings yet

- KAVR Series - Manual PDFDocument214 pagesKAVR Series - Manual PDFtunghtdNo ratings yet

- Flexible Power Transmission: The HVDC OptionsFrom EverandFlexible Power Transmission: The HVDC OptionsRating: 5 out of 5 stars5/5 (1)

- Introduction and Philosophy of A Protective Relaying System 1Document6 pagesIntroduction and Philosophy of A Protective Relaying System 1J Naveen KumarNo ratings yet

- Electricity Training Association. - Institution of Electrical Engineers-Power System Protection (Vol 2 - Systems and Methods) - Institution of Electrical Engineers (1995) PDFDocument331 pagesElectricity Training Association. - Institution of Electrical Engineers-Power System Protection (Vol 2 - Systems and Methods) - Institution of Electrical Engineers (1995) PDFMiguel CbNo ratings yet

- 10 18 IndiceDocument9 pages10 18 IndicebryanNo ratings yet

- 6 Table of ContentsDocument4 pages6 Table of ContentsCho Lin MaungNo ratings yet

- 04.02.008.002-11204 Compact 100 Touch Serv Man-Intermed - 01-08-12Document167 pages04.02.008.002-11204 Compact 100 Touch Serv Man-Intermed - 01-08-12Юрий ЧередничокNo ratings yet

- Modern Power Transformer Practice2Document3 pagesModern Power Transformer Practice2amulya sNo ratings yet

- Power Electronics Devices Circuits and I PDFDocument1,017 pagesPower Electronics Devices Circuits and I PDFama001100% (1)

- High-Speed Digital System DesignDocument14 pagesHigh-Speed Digital System DesignaylonsNo ratings yet

- Fundamentals of ELectrical Enginneering 1Document5 pagesFundamentals of ELectrical Enginneering 1Natali MonizNo ratings yet

- IEE On-Site GuideDocument179 pagesIEE On-Site GuideMahmud Sied100% (5)

- Manual Distribution Network Operation ManualDocument113 pagesManual Distribution Network Operation ManualJorge Cáceres0% (1)

- Second Edition: An Introduction ToDocument16 pagesSecond Edition: An Introduction ToanujNo ratings yet

- Chapter No Description Page No: 1. 1-4 2. Transformer Basic Theory 5-28Document3 pagesChapter No Description Page No: 1. 1-4 2. Transformer Basic Theory 5-28kniight23No ratings yet

- Electrical Model of Thermal Power PlantDocument81 pagesElectrical Model of Thermal Power PlantMahesh KumbharNo ratings yet

- Concepts Engineering: ApplicationsDocument11 pagesConcepts Engineering: ApplicationsGS AryaNo ratings yet

- EEE 1101 - NewDocument165 pagesEEE 1101 - Newদেবব্রত সেনNo ratings yet

- Selection of Switchyard EquipmentDocument64 pagesSelection of Switchyard EquipmentkrcdewanewNo ratings yet

- I Cellular Mobile CommunicationDocument110 pagesI Cellular Mobile Communicationavinash00000No ratings yet

- Applied Industrial Electricity 1591728448Document460 pagesApplied Industrial Electricity 1591728448Ervis GegaNo ratings yet

- Basics of Circuit Breakers RockwellDocument102 pagesBasics of Circuit Breakers RockwellThanh KieuNo ratings yet

- Electrical Craft Principles Volume 2 5th Edition PDFDocument429 pagesElectrical Craft Principles Volume 2 5th Edition PDFRafael olivaresNo ratings yet

- S.No Content Chapter I Magnetic Circuits and Magnetic MaterialDocument141 pagesS.No Content Chapter I Magnetic Circuits and Magnetic MaterialROHIT SINGHNo ratings yet

- Electrical Machines and Drives An Introduction To Principles and CharacteristicsDocument267 pagesElectrical Machines and Drives An Introduction To Principles and CharacteristicsJules Nikko Dela Cruz67% (3)

- NXPLUS C 24 SpecificationDocument21 pagesNXPLUS C 24 SpecificationRoni Pardamean SijabatNo ratings yet

- Physics 1Document6 pagesPhysics 1joekeery86020100% (1)

- High Voltage Direct Current Transmission: 2nd EditionDocument296 pagesHigh Voltage Direct Current Transmission: 2nd EditionYagnesh ParmarNo ratings yet

- Application Guidelines Medium Voltage E01 1HC PDFDocument86 pagesApplication Guidelines Medium Voltage E01 1HC PDFAnonymous kdFzbQ4jfNo ratings yet

- Wave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsFrom EverandWave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsNo ratings yet

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- IGARD IEEE 1584 Based Arc Flash Calculator REV2 05dec2009Document9 pagesIGARD IEEE 1584 Based Arc Flash Calculator REV2 05dec2009Satheesh Kumar NatarajanNo ratings yet

- Check With Athi For Interpretation of The SameDocument3 pagesCheck With Athi For Interpretation of The SameSatheesh Kumar NatarajanNo ratings yet

- Cable Connected Secondary SwitchgearDocument17 pagesCable Connected Secondary SwitchgearSatheesh Kumar NatarajanNo ratings yet

- Distribution Switchgear: Stan StewartDocument2 pagesDistribution Switchgear: Stan StewartSatheesh Kumar NatarajanNo ratings yet

- PDF PCC LP No 2 DTD 15march 2016Document9 pagesPDF PCC LP No 2 DTD 15march 2016Satheesh Kumar NatarajanNo ratings yet

- References: & Power Journal, February 1979Document1 pageReferences: & Power Journal, February 1979Satheesh Kumar NatarajanNo ratings yet

- High-Voltage Fuse-LinksDocument11 pagesHigh-Voltage Fuse-LinksSatheesh Kumar NatarajanNo ratings yet

- Index Terms LinksDocument15 pagesIndex Terms LinksSatheesh Kumar NatarajanNo ratings yet

- The FutureDocument5 pagesThe FutureSatheesh Kumar NatarajanNo ratings yet

- Fault Level CalculationsDocument11 pagesFault Level CalculationsSatheesh Kumar NatarajanNo ratings yet

- GXT MT 6 - 10 - 20 KvaDocument4 pagesGXT MT 6 - 10 - 20 KvaSatheesh Kumar NatarajanNo ratings yet

- Techniques For Estimation of Hot Spot Temperatures in TransformersDocument4 pagesTechniques For Estimation of Hot Spot Temperatures in TransformersSatheesh Kumar NatarajanNo ratings yet

- Battery Size Calculator (22.8.12)Document3 pagesBattery Size Calculator (22.8.12)Satheesh Kumar NatarajanNo ratings yet

- Assignment DGADocument5 pagesAssignment DGASatheesh Kumar NatarajanNo ratings yet

- School of Electrical, Electronics and Computer EngineeringDocument7 pagesSchool of Electrical, Electronics and Computer EngineeringSatheesh Kumar NatarajanNo ratings yet

- D.G Size Calculation (22.8.12)Document1 pageD.G Size Calculation (22.8.12)Satheesh Kumar Natarajan100% (1)

- L&T MLCP East Block HVAC Heat Load SUMMARYDocument3 pagesL&T MLCP East Block HVAC Heat Load SUMMARYSatheesh Kumar NatarajanNo ratings yet

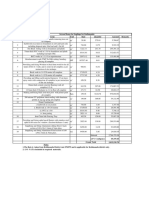

- Bus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)Document6 pagesBus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)Satheesh Kumar NatarajanNo ratings yet

- Time Allowed - 2 Hours: (Turn OverDocument3 pagesTime Allowed - 2 Hours: (Turn OverSatheesh Kumar NatarajanNo ratings yet

- LMS - Design PhilosophyDocument2 pagesLMS - Design PhilosophySatheesh Kumar NatarajanNo ratings yet

- Fault Level CalculationsDocument18 pagesFault Level CalculationsSatheesh Kumar NatarajanNo ratings yet

- Final Load SheetDocument25 pagesFinal Load SheetSatheesh Kumar NatarajanNo ratings yet

- Atys & Sircover: Transfer Switch Equipment For Your Power AvailabilityDocument20 pagesAtys & Sircover: Transfer Switch Equipment For Your Power AvailabilityMesseňger HệŢhốngNo ratings yet

- Arc CC cdq2 - en PDFDocument5 pagesArc CC cdq2 - en PDFShashidhar C NNo ratings yet

- UPS Clearances: Size Unit A3 MM Scale NTSDocument8 pagesUPS Clearances: Size Unit A3 MM Scale NTSFarshad MahmoudiNo ratings yet

- BOQ of Screen House For Saplings For KathmanduDocument1 pageBOQ of Screen House For Saplings For Kathmanduavs kfleNo ratings yet

- Stafford 301kiln ControllerDocument4 pagesStafford 301kiln ControllerJamie HerschelNo ratings yet

- 43ff-TGard Part Number Book - DigitalDocument21 pages43ff-TGard Part Number Book - DigitalAlan David Rojo HernandezNo ratings yet

- Questions & Answers On Synchronous MotorsDocument28 pagesQuestions & Answers On Synchronous Motorskibrom atsbha100% (1)

- IACO Komponenty 2014Document448 pagesIACO Komponenty 2014Gesiel SoaresNo ratings yet

- A4989 Demo Board SchematicDocument6 pagesA4989 Demo Board SchematicmontolinNo ratings yet

- POP POS DisplaysDocument18 pagesPOP POS DisplaysMarilyn AriasNo ratings yet

- MM FCU 4F Wiring Diagram v1.0Document1 pageMM FCU 4F Wiring Diagram v1.0alexNo ratings yet

- WEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTDocument2 pagesWEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTLuanNo ratings yet

- Schema Electrica Passatb5 ComfortDocument16 pagesSchema Electrica Passatb5 ComfortAnda PleseaNo ratings yet

- 10.0 IS 1127 (1970) Recommendations For Diamensions and Workmanship of Natural Building Stones For Masonary WorkDocument11 pages10.0 IS 1127 (1970) Recommendations For Diamensions and Workmanship of Natural Building Stones For Masonary WorkShabbir LokhandwalaNo ratings yet

- 54-K Model Town-Final SUBMISSIONDocument1 page54-K Model Town-Final SUBMISSIONSohail AshrafNo ratings yet

- Mil STD 1913 - CHG - Notice 1Document2 pagesMil STD 1913 - CHG - Notice 1Red BeardNo ratings yet

- Elevator Lighting Controls PDFDocument1 pageElevator Lighting Controls PDFTai Nguyen DucNo ratings yet

- QOCircuit Breakers 2005Document5 pagesQOCircuit Breakers 2005Sanjeev KumarNo ratings yet

- MDB Specs PDFDocument9 pagesMDB Specs PDFAbdElrahman AhmedNo ratings yet

- Hi-Line Hippo ConnectorsDocument6 pagesHi-Line Hippo ConnectorsTonyNo ratings yet

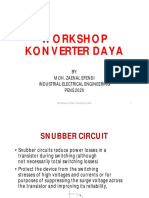

- Snubber Circuit Workshop-DikompresiDocument22 pagesSnubber Circuit Workshop-DikompresiNafila WidyaNo ratings yet

- DC Inverter Forming PDFDocument2 pagesDC Inverter Forming PDFFrancisco TorresNo ratings yet

- List of ComponentsDocument2 pagesList of ComponentsRainwin TamayoNo ratings yet

- Incubadoras Manual Operacion Dni-Series-300Document4 pagesIncubadoras Manual Operacion Dni-Series-300déborah_rosalesNo ratings yet

- Pioneer SA-410 Service ManualDocument6 pagesPioneer SA-410 Service ManualSofei Adrian FlorinNo ratings yet

- Inst RocaW12 533145Document4 pagesInst RocaW12 533145Nes Choque SolizNo ratings yet

- DSU MaintenanceDocument26 pagesDSU MaintenancedamirNo ratings yet

- Clicker ChamberlainDocument2 pagesClicker ChamberlainFrancisco HerreraNo ratings yet

Table of Contents

Table of Contents

Uploaded by

Satheesh Kumar NatarajanOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Table of Contents

Table of Contents

Uploaded by

Satheesh Kumar NatarajanCopyright:

Available Formats

Contents

Foreword xiii

Acknowledgements xv

1 Basics and general principles 1

1.1 Why do we have switchgear? 1

1.2 What is the difference between a circuit breaker and

a switch? 1

1.2.1 Disconnectors 2

1.2.2 Earth switches 2

1.2.3 Fuses 2

1.3 Components of switchgear 2

2 Interruption techniques 9

2.1 Arc interruption 9

2.2 Interruption mediums and techniques 9

2.3 Oil switchgear 10

2.4 Vacuum switchgear 14

2.5 SF6 switchgear 20

2.5.1 Gas pressure 22

2.5.2 Contact design 23

2.5.3 Gas dryness 23

2.5.4 Choice of materials 24

2.6 Interrupter types 24

2.6.1 Rotating arc SF6 interrupters 24

2.6.2 The SF6 puffer interrupter 27

2.6.3 The relative merits of vacuum and SF6 interrupters 29

3 Fault level calculations 31

3.1 Impedance resolution within complicated networks 36

3.2 Problems 41

viii Contents

4 Symmetrical and asymmetrical fault currents 43

4.1 The rate of decay of the d.c. component 46

4.2 Decrement factor 48

4.3 Problems 52

5 Electromagnetic forces and contact design 55

5.1 Contact loading 62

5.2 Electromagnetic forces in three-phase faults 64

5.3 Arcing contact tips 65

5.4 Contact entry profiles 66

5.5 Pre-arcing and contact burning 67

5.6 Contact misalignment and fault making capacity 67

5.7 Sliding frictional resistance of contacts 68

5.8 Problems 70

6 Switching transients 71

6.1 The influence of system earthing on the transient

recovery voltage 72

6.2 The interruption of load current 73

6.3 The interruption of inductive current 74

6.4 The interruption of small inductive currents 77

6.5 Capacitor switching 80

6.6 Back-to-back capacitor switching 82

6.7 Reignition surges 84

7 Insulation 87

7.1 Electrical stress 87

7.2 Electrical discharge 89

7.3 Discharges in oil and gases 89

7.4 Discharge in solid insulation 90

7.5 Discharge level design practice 90

7.6 Voids in moulded insulation 91

7.7 Flashover caused by indirect discharge 92

7.8 Breakdown voltage and gas pressure 94

7.9 Solid insulation 95

7.10 Composite insulation 98

8 Operating mechanisms 103

8.1 Materials 103

8.2 Operating features 104

8.3 Energy for operation 104

8.4 Spring operating mechanisms 105

8.5 Three-link kinematic chains 108

8.6 Magnetic actuators 111

Contents ix

9 Primary switchgear 119

9.1 Changes in technology 121

9.2 Current and voltage transformers 123

9.3 The architecture of primary switchgear 124

9.3.1 Horizontal transfer earthing 124

9.3.2 Horizontal isolation with separate earthing switches 125

9.3.3 Horizontal isolation with internal earthing via vertical

transfer 126

9.3.4 Horizontal isolation with internal earthing via top

contact stem rotation 130

9.3.5 Gas-insulated primary switchgear 132

10 Cable connected secondary switchgear 135

10.1 T-off circuit protection 142

10.1.1 150 per cent transformer over-rating 144

10.1.2 The transformer inrush current 144

10.1.3 Discrimination with fuses on the low-voltage side 144

10.1.4 No tripping due to spillage current from the time-fuse

circuit 145

10.2 Time-fuse operating characteristics 145

10.3 The Falcon protection scheme 146

10.4 Protection where a low-voltage source is available 148

10.5 Secondary distribution switchboards 148

11 Overhead conductor connected secondary switchgear 153

11.1 Introduction 153

11.2 Standards 153

11.3 Historical background 153

11.4 Pole mounted autoreclosers 154

11.5 Technical terms 157

11.6 Discussion on autoreclosers with HV internal solenoid

mechanisms 158

11.7 Hydraulic control 159

11.8 The short-circuit fault level of overhead lines 159

11.9 Advances in interrupter technology 160

11.10 Sectionalisers 161

11.11 Protection 163

11.12 Magnetic actuators and their impact on

the design of autoreclosers 165

11.13 Remote monitoring and operation 166

11.14 Islands of intelligence 166

11.15 Autoreclosers with integral series disconnectors 170

11.16 A summary of the development of autoreclosers 171

11.17 Significant trends 172

x Contents

12 High-voltage fuse-links 175

12.1 Construction 175

12.2 Operation in service 177

12.3 Fuse characteristics 179

12.3.1 Time–current characteristics 179

12.3.2 Cut-off characteristics 179

12.3.3 The I 2 t fuse-link characteristic 180

12.4 Types of high-voltage HRC fuse-links 180

12.4.1 British Standard oil-tight fuse-links 180

12.4.2 British Standard air-insulated HV fuses 181

12.4.3 DIN Standard air-insulated HV fuses 181

12.4.4 Motor circuit fuses 182

12.4.5 Instrument voltage transformer fuses 182

12.5 Full range HV fuses 182

12.6 Fuse standards 182

12.7 Distribution applications 184

12.8 Future trends 185

13 Switchgear type tests 187

13.1 Reports and certificates 187

13.2 National and International Standards 189

13.3 Development tests 189

13.3.1 Mechanical operations 191

13.3.2 Temperature rise 191

13.3.3 High-voltage tests 197

13.3.4 Short-circuit tests 200

13.3.5 Environmental tests 208

13.3.6 Electromagnetic compatibility tests 209

14 Product conformity, quality control and service problem

resolution 211

14.1 Serial numbers 211

14.2 Routine test 211

14.2.1 Power frequency voltage withstand tests on

the main circuit 212

14.2.2 Voltage withstand tests on the control

and auxiliary circuits 212

14.2.3 Measurement of the resistance of the main circuit 212

14.2.4 Mechanical operating tests 212

14.3 Automatic routine test facilities 214

14.4 Design and visual checks 215

14.5 Quality control 216

14.6 Design review meetings 217

14.7 Service problem resolution 217

14.8 Minimising the problem 217

Contents xi

15 Cost of ownership 221

16 The future 225

16.1 Technology 225

16.2 Specifications 226

16.3 Competition 227

16.4 Materials 227

16.5 Manufacturing 227

16.6 Size 228

16.7 Manufacturing base 228

16.8 The shape of things to come 228

17 Further reading 231

17.1 Books 231

17.2 Papers and published articles 231

18 National, International and customer Specifications 235

References 241

Index 243

You might also like

- Practical MEMS: Ville KaajakariDocument9 pagesPractical MEMS: Ville Kaajakarioniruddha4No ratings yet

- bs7671 Iee On Site GuideDocument184 pagesbs7671 Iee On Site Guidemigzx95% (19)

- Power+Electronics+for+Technology+By+Ashfaq+Ahmed+ 1 PDFDocument438 pagesPower+Electronics+for+Technology+By+Ashfaq+Ahmed+ 1 PDFAbdullah Mahsud100% (5)

- (C. Christopoulos, A. Wright (Auth.) ) Electrical PDFDocument619 pages(C. Christopoulos, A. Wright (Auth.) ) Electrical PDFNicolás Cáceres García100% (2)

- J and P Transformer Book 14th Edition by Martin Heathcote and Ray Arnold Table of ContentsDocument3 pagesJ and P Transformer Book 14th Edition by Martin Heathcote and Ray Arnold Table of Contentskennedy100% (1)

- Electrical Installation Design Guide PDFDocument15 pagesElectrical Installation Design Guide PDFJack So0% (3)

- Passat W8 Engine Management, Motronic ME 7.1.1Document56 pagesPassat W8 Engine Management, Motronic ME 7.1.1sheba1023100% (1)

- Minor Electrical Installation Works - GreenDocument2 pagesMinor Electrical Installation Works - GreenPopescuLaurentiuNo ratings yet

- Transformers and Inductors For Power Electronics: Theory, Design and ApplicationsDocument6 pagesTransformers and Inductors For Power Electronics: Theory, Design and ApplicationsAKHIL VINAYAK RNo ratings yet

- E-HandBook On High Voltage Circuit Breakers, Edition 1.0, September'2021Document261 pagesE-HandBook On High Voltage Circuit Breakers, Edition 1.0, September'2021Saran Kumar100% (1)

- Electrical Power System Protection PDFDocument18 pagesElectrical Power System Protection PDFAlberto José Bermúdez AriasNo ratings yet

- Preface and Acknowledgements Preface To 2nd Edition Xi: ° ° ° XillDocument6 pagesPreface and Acknowledgements Preface To 2nd Edition Xi: ° ° ° XillDara HengNo ratings yet

- EM-I BookDocument141 pagesEM-I BookAnnapoorana EEENo ratings yet

- ContentsDocument5 pagesContentsJeans GonzalezNo ratings yet

- Gas-Insulated Medium Voltage Switchgear: Manual For Installation and Operation HB 601/01 EDocument85 pagesGas-Insulated Medium Voltage Switchgear: Manual For Installation and Operation HB 601/01 EGeorgi NikolovNo ratings yet

- J&P-TF Book PDFDocument957 pagesJ&P-TF Book PDFCtl JvvnlNo ratings yet

- Power Electronics and Motor Control PDFDocument563 pagesPower Electronics and Motor Control PDFAnonymous qdJOxst100% (3)

- Philips ApplicationBook IndustrialTriacsApplications 1975-02Document144 pagesPhilips ApplicationBook IndustrialTriacsApplications 1975-02hidalgobNo ratings yet

- ElECTRONIC CKTSDocument544 pagesElECTRONIC CKTSNavaraj BaniyaNo ratings yet

- Transformer Design Principles With AppliDocument9 pagesTransformer Design Principles With AppliCHUKARONo ratings yet

- Manual DanfossDocument212 pagesManual DanfossEduardo LegorretaNo ratings yet

- About The Authors Xiii Preface XV Acknowledgements Xix List of Symbols XxiDocument7 pagesAbout The Authors Xiii Preface XV Acknowledgements Xix List of Symbols XxiJhon Edwin OcampoNo ratings yet

- KAVR Series - Manual PDFDocument214 pagesKAVR Series - Manual PDFtunghtdNo ratings yet

- Flexible Power Transmission: The HVDC OptionsFrom EverandFlexible Power Transmission: The HVDC OptionsRating: 5 out of 5 stars5/5 (1)

- Introduction and Philosophy of A Protective Relaying System 1Document6 pagesIntroduction and Philosophy of A Protective Relaying System 1J Naveen KumarNo ratings yet

- Electricity Training Association. - Institution of Electrical Engineers-Power System Protection (Vol 2 - Systems and Methods) - Institution of Electrical Engineers (1995) PDFDocument331 pagesElectricity Training Association. - Institution of Electrical Engineers-Power System Protection (Vol 2 - Systems and Methods) - Institution of Electrical Engineers (1995) PDFMiguel CbNo ratings yet

- 10 18 IndiceDocument9 pages10 18 IndicebryanNo ratings yet

- 6 Table of ContentsDocument4 pages6 Table of ContentsCho Lin MaungNo ratings yet

- 04.02.008.002-11204 Compact 100 Touch Serv Man-Intermed - 01-08-12Document167 pages04.02.008.002-11204 Compact 100 Touch Serv Man-Intermed - 01-08-12Юрий ЧередничокNo ratings yet

- Modern Power Transformer Practice2Document3 pagesModern Power Transformer Practice2amulya sNo ratings yet

- Power Electronics Devices Circuits and I PDFDocument1,017 pagesPower Electronics Devices Circuits and I PDFama001100% (1)

- High-Speed Digital System DesignDocument14 pagesHigh-Speed Digital System DesignaylonsNo ratings yet

- Fundamentals of ELectrical Enginneering 1Document5 pagesFundamentals of ELectrical Enginneering 1Natali MonizNo ratings yet

- IEE On-Site GuideDocument179 pagesIEE On-Site GuideMahmud Sied100% (5)

- Manual Distribution Network Operation ManualDocument113 pagesManual Distribution Network Operation ManualJorge Cáceres0% (1)

- Second Edition: An Introduction ToDocument16 pagesSecond Edition: An Introduction ToanujNo ratings yet

- Chapter No Description Page No: 1. 1-4 2. Transformer Basic Theory 5-28Document3 pagesChapter No Description Page No: 1. 1-4 2. Transformer Basic Theory 5-28kniight23No ratings yet

- Electrical Model of Thermal Power PlantDocument81 pagesElectrical Model of Thermal Power PlantMahesh KumbharNo ratings yet

- Concepts Engineering: ApplicationsDocument11 pagesConcepts Engineering: ApplicationsGS AryaNo ratings yet

- EEE 1101 - NewDocument165 pagesEEE 1101 - Newদেবব্রত সেনNo ratings yet

- Selection of Switchyard EquipmentDocument64 pagesSelection of Switchyard EquipmentkrcdewanewNo ratings yet

- I Cellular Mobile CommunicationDocument110 pagesI Cellular Mobile Communicationavinash00000No ratings yet

- Applied Industrial Electricity 1591728448Document460 pagesApplied Industrial Electricity 1591728448Ervis GegaNo ratings yet

- Basics of Circuit Breakers RockwellDocument102 pagesBasics of Circuit Breakers RockwellThanh KieuNo ratings yet

- Electrical Craft Principles Volume 2 5th Edition PDFDocument429 pagesElectrical Craft Principles Volume 2 5th Edition PDFRafael olivaresNo ratings yet

- S.No Content Chapter I Magnetic Circuits and Magnetic MaterialDocument141 pagesS.No Content Chapter I Magnetic Circuits and Magnetic MaterialROHIT SINGHNo ratings yet

- Electrical Machines and Drives An Introduction To Principles and CharacteristicsDocument267 pagesElectrical Machines and Drives An Introduction To Principles and CharacteristicsJules Nikko Dela Cruz67% (3)

- NXPLUS C 24 SpecificationDocument21 pagesNXPLUS C 24 SpecificationRoni Pardamean SijabatNo ratings yet

- Physics 1Document6 pagesPhysics 1joekeery86020100% (1)

- High Voltage Direct Current Transmission: 2nd EditionDocument296 pagesHigh Voltage Direct Current Transmission: 2nd EditionYagnesh ParmarNo ratings yet

- Application Guidelines Medium Voltage E01 1HC PDFDocument86 pagesApplication Guidelines Medium Voltage E01 1HC PDFAnonymous kdFzbQ4jfNo ratings yet

- Wave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsFrom EverandWave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsNo ratings yet

- Microwave Devices, Circuits and Subsystems for Communications EngineeringFrom EverandMicrowave Devices, Circuits and Subsystems for Communications EngineeringRating: 4 out of 5 stars4/5 (1)

- IGARD IEEE 1584 Based Arc Flash Calculator REV2 05dec2009Document9 pagesIGARD IEEE 1584 Based Arc Flash Calculator REV2 05dec2009Satheesh Kumar NatarajanNo ratings yet

- Check With Athi For Interpretation of The SameDocument3 pagesCheck With Athi For Interpretation of The SameSatheesh Kumar NatarajanNo ratings yet

- Cable Connected Secondary SwitchgearDocument17 pagesCable Connected Secondary SwitchgearSatheesh Kumar NatarajanNo ratings yet

- Distribution Switchgear: Stan StewartDocument2 pagesDistribution Switchgear: Stan StewartSatheesh Kumar NatarajanNo ratings yet

- PDF PCC LP No 2 DTD 15march 2016Document9 pagesPDF PCC LP No 2 DTD 15march 2016Satheesh Kumar NatarajanNo ratings yet

- References: & Power Journal, February 1979Document1 pageReferences: & Power Journal, February 1979Satheesh Kumar NatarajanNo ratings yet

- High-Voltage Fuse-LinksDocument11 pagesHigh-Voltage Fuse-LinksSatheesh Kumar NatarajanNo ratings yet

- Index Terms LinksDocument15 pagesIndex Terms LinksSatheesh Kumar NatarajanNo ratings yet

- The FutureDocument5 pagesThe FutureSatheesh Kumar NatarajanNo ratings yet

- Fault Level CalculationsDocument11 pagesFault Level CalculationsSatheesh Kumar NatarajanNo ratings yet

- GXT MT 6 - 10 - 20 KvaDocument4 pagesGXT MT 6 - 10 - 20 KvaSatheesh Kumar NatarajanNo ratings yet

- Techniques For Estimation of Hot Spot Temperatures in TransformersDocument4 pagesTechniques For Estimation of Hot Spot Temperatures in TransformersSatheesh Kumar NatarajanNo ratings yet

- Battery Size Calculator (22.8.12)Document3 pagesBattery Size Calculator (22.8.12)Satheesh Kumar NatarajanNo ratings yet

- Assignment DGADocument5 pagesAssignment DGASatheesh Kumar NatarajanNo ratings yet

- School of Electrical, Electronics and Computer EngineeringDocument7 pagesSchool of Electrical, Electronics and Computer EngineeringSatheesh Kumar NatarajanNo ratings yet

- D.G Size Calculation (22.8.12)Document1 pageD.G Size Calculation (22.8.12)Satheesh Kumar Natarajan100% (1)

- L&T MLCP East Block HVAC Heat Load SUMMARYDocument3 pagesL&T MLCP East Block HVAC Heat Load SUMMARYSatheesh Kumar NatarajanNo ratings yet

- Bus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)Document6 pagesBus Bar Voltage Drop Calculation: Bus Bar No SR - No Location Sub Panel No Power Line Length (MT) Line Current (Amp)Satheesh Kumar NatarajanNo ratings yet

- Time Allowed - 2 Hours: (Turn OverDocument3 pagesTime Allowed - 2 Hours: (Turn OverSatheesh Kumar NatarajanNo ratings yet

- LMS - Design PhilosophyDocument2 pagesLMS - Design PhilosophySatheesh Kumar NatarajanNo ratings yet

- Fault Level CalculationsDocument18 pagesFault Level CalculationsSatheesh Kumar NatarajanNo ratings yet

- Final Load SheetDocument25 pagesFinal Load SheetSatheesh Kumar NatarajanNo ratings yet

- Atys & Sircover: Transfer Switch Equipment For Your Power AvailabilityDocument20 pagesAtys & Sircover: Transfer Switch Equipment For Your Power AvailabilityMesseňger HệŢhốngNo ratings yet

- Arc CC cdq2 - en PDFDocument5 pagesArc CC cdq2 - en PDFShashidhar C NNo ratings yet

- UPS Clearances: Size Unit A3 MM Scale NTSDocument8 pagesUPS Clearances: Size Unit A3 MM Scale NTSFarshad MahmoudiNo ratings yet

- BOQ of Screen House For Saplings For KathmanduDocument1 pageBOQ of Screen House For Saplings For Kathmanduavs kfleNo ratings yet

- Stafford 301kiln ControllerDocument4 pagesStafford 301kiln ControllerJamie HerschelNo ratings yet

- 43ff-TGard Part Number Book - DigitalDocument21 pages43ff-TGard Part Number Book - DigitalAlan David Rojo HernandezNo ratings yet

- Questions & Answers On Synchronous MotorsDocument28 pagesQuestions & Answers On Synchronous Motorskibrom atsbha100% (1)

- IACO Komponenty 2014Document448 pagesIACO Komponenty 2014Gesiel SoaresNo ratings yet

- A4989 Demo Board SchematicDocument6 pagesA4989 Demo Board SchematicmontolinNo ratings yet

- POP POS DisplaysDocument18 pagesPOP POS DisplaysMarilyn AriasNo ratings yet

- MM FCU 4F Wiring Diagram v1.0Document1 pageMM FCU 4F Wiring Diagram v1.0alexNo ratings yet

- WEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTDocument2 pagesWEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTLuanNo ratings yet

- Schema Electrica Passatb5 ComfortDocument16 pagesSchema Electrica Passatb5 ComfortAnda PleseaNo ratings yet

- 10.0 IS 1127 (1970) Recommendations For Diamensions and Workmanship of Natural Building Stones For Masonary WorkDocument11 pages10.0 IS 1127 (1970) Recommendations For Diamensions and Workmanship of Natural Building Stones For Masonary WorkShabbir LokhandwalaNo ratings yet

- 54-K Model Town-Final SUBMISSIONDocument1 page54-K Model Town-Final SUBMISSIONSohail AshrafNo ratings yet

- Mil STD 1913 - CHG - Notice 1Document2 pagesMil STD 1913 - CHG - Notice 1Red BeardNo ratings yet

- Elevator Lighting Controls PDFDocument1 pageElevator Lighting Controls PDFTai Nguyen DucNo ratings yet

- QOCircuit Breakers 2005Document5 pagesQOCircuit Breakers 2005Sanjeev KumarNo ratings yet

- MDB Specs PDFDocument9 pagesMDB Specs PDFAbdElrahman AhmedNo ratings yet

- Hi-Line Hippo ConnectorsDocument6 pagesHi-Line Hippo ConnectorsTonyNo ratings yet

- Snubber Circuit Workshop-DikompresiDocument22 pagesSnubber Circuit Workshop-DikompresiNafila WidyaNo ratings yet

- DC Inverter Forming PDFDocument2 pagesDC Inverter Forming PDFFrancisco TorresNo ratings yet

- List of ComponentsDocument2 pagesList of ComponentsRainwin TamayoNo ratings yet

- Incubadoras Manual Operacion Dni-Series-300Document4 pagesIncubadoras Manual Operacion Dni-Series-300déborah_rosalesNo ratings yet

- Pioneer SA-410 Service ManualDocument6 pagesPioneer SA-410 Service ManualSofei Adrian FlorinNo ratings yet

- Inst RocaW12 533145Document4 pagesInst RocaW12 533145Nes Choque SolizNo ratings yet

- DSU MaintenanceDocument26 pagesDSU MaintenancedamirNo ratings yet

- Clicker ChamberlainDocument2 pagesClicker ChamberlainFrancisco HerreraNo ratings yet