Professional Documents

Culture Documents

Chapter 3 - Design of Springs: Sr. No. Questions

Chapter 3 - Design of Springs: Sr. No. Questions

Uploaded by

darshit dadhaniyaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 3 - Design of Springs: Sr. No. Questions

Chapter 3 - Design of Springs: Sr. No. Questions

Uploaded by

darshit dadhaniyaCopyright:

Available Formats

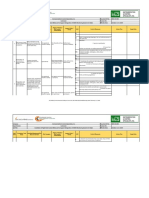

GTU Paper Analysis

Chapter 3 – Design of Springs

May – 16

May – 17

May – 18

May – 19

Nov – 16

Nov – 17

Nov – 18

Dec – 15

Sr.

Questions

No.

Theory

1. Explain buckling of spring in detail. 04

2. What is nipping in a leaf spring? Discuss its role. 04 04 04 04

3. Explain surge phenomenon in spring. 04 03 01 03

4. When a helical compression spring is subjected to an axial compressive load, 01 01

the stress induced in the wire is

(a) tensile stress (b) compressive stress (c) torsional shear stress (d) bending

stress

5. In leaf springs, the longest leaf is known as 01

(a) lower leaf (b) master leaf (c) upper leaf (d) none of these

6. What is shot peening? 03

7. Define Spring Rate. 01

8. Which type of spring is mostly used in Gramophone? 01

9. What is the function of a spring? In which type of springs the behavior is non- 03

linear?

10. Explain the following terms of the spring: 04

(1) Free Length (2) Spring Rate (3) Spring Index (4) Solid Height.

11. The extension springs are in considerably less use than the compression springs, 03

why?

12. What is helical torsion spring? How does it differ from helical compression 07

spring?

Design of Machine Elements (2151907)

Department of Mechanical Engineering

Darshan Institute of Engineering & Technology

GTU Paper Analysis

13. Classify and explain springs according to their shapes with neat sketches. 03

14. Prove that equal strength nested springs having the same solid length and 04

deflection would have the same spring index.

15. Why is factor of safety in spring preferred near to unity? 03

16. Explain the stresses induced in compression and tension spring. 04

17. Explain the Belleville spring and its applications. 03

18. Explain the design steps of semi elliptical laminated multi leaf spring. 04

19. Explain leaf spring with neat sketch. 03

20. Explain springs in series and parallel connections with sketch. 04

21. Explain the merits and demerits of Non-circular cross section wire used in spring 04

22. Explain concentric spring and its applications. 03

Examples

1. Design a helical compression spring from the following data: 07

Minimum load = 100 N, Maximum load = 225.6 N,

Compression of spring = 10 mm, Permissible shear stress for spring material =

440 MPa,

Spring end – square and ground ends,

Modulus of rigidity for spring material = 0.80 x 105 MPa.

2. A semi-elliptic leaf spring consists of two extra full length leaves and eight 07

graduated length leaves, including the master leaf. The center to center distance

between the two eyes of the spring is 1 m. The maximum force acting on the

spring is 10 kN and the width of the leaf is 50 mm. The spring is initially

preloaded in such a way that when the load is maximum, the stresses induced in

all the leaves are equal to 350 N/mm2. The modulus of elasticity of the leaf

material is 2.07 x 105 N/mm2.

Determine: (i) The thickness of leaves. (ii) The deflection of the spring at

maximum load.

3. A helical compression spring made of oil tempered carbon steel is subjected to 07

Design of Machine Elements (2151907)

Department of Mechanical Engineering

Darshan Institute of Engineering & Technology

GTU Paper Analysis

a fluctuating load from 400 N to 1000 N. The spring index is 6 and the design

factor of safety is 1.25. If the yield stress in shear is 770 MPa and endurance

stress in shear is 350 MPa, Find: 1. Size of the spring wire, 2. Diameters of the

spring, 3. Number of turns of the spring, and 4. Free length of the spring. The

compression of the spring at the maximum load is 30 mm. For spring material,

the modulus of rigidity is 80 KN/mm2. Spring ends are square and ground.

4. A semi-elliptical laminated vehicle spring to carry a load of 6000 N is to consist 07

of seven leaves 65 mm wide, two of the leaves extending the full length of the

spring. The spring is to be 1.1 m in length and attached to the axle by two U-bolts

80 mm apart. The bolts hold the central portion of the spring so rigidly that they

may be considered equivalent to a band having a width equal to the distance

between the bolts. Assume a design stress for spring material as 350 N/mm2.

Determine: 1. Thickness of leaves 2. Deflection of spring 3. Diameter of eye 4.

Length of leaves. Take E = 210 KN/mm2, Bearing pressure = 8 N/mm2.

5. The valve of an aircraft engine is operated by a cluster of two concentric 07

springs made of same material. The maximum load on the spring is 6500 N. The

permissible shear stress for the spring material is 625 N/mm2. Assuming spring

index for both springs as 6 and the deflection under the load should not exceed

30 mm. Calculate the main dimensions of the springs. G = 8 ×104 N/mm2. Use

standard coil clearance.

6. A semi-elliptical spring has ten leaves in all, with the two full length leaves 07 07

extending 625 mm. It is 62.5 mm wide and is made of strips 6 mm thick. The

leaves are pre-stressed so as to equalize stresses in all leaves.

7. Design a helical compression spring for a maximum load of 1000 N for a 07

deflection of 25 mm using the value of spring index as 5. The maximum

permissible stress for spring wire is 420 N/mm2, and modulus of rigidity is 84

KN/ mm2.

8. Design a leaf spring for following specification: Total load = 14 tonnes, Numbers 07

of springs supporting the load = 4, Maximum number of leaves = 10, Span of the

spring = 1000 mm, Permissible deflection = 80 mm, Take Young Modulus = 0.2 x

106 N/mm2, Allowable stress in spring material = 600 N/mm2

Design of Machine Elements (2151907)

Department of Mechanical Engineering

Darshan Institute of Engineering & Technology

GTU Paper Analysis

9. Design a close coiled helical compression spring for a service load ranging 07

from 2250 N to 2750 N. The axial deflection of the spring for the load range is 6

mm. Assume a spring index of 5. The permissible shear stress intensity is 420

N/mm2 and modulus of rigidity, G = 84 kN/mm2.

10. A semi-elliptic leaf spring used for automobile suspension consists of three 07

extra full-length leaves and 15 graduated-length leaves, including the master leaf.

The centre-to-centre distance between two eyes of the spring is 1 m. The

maximum force that can act on the spring is 75 kN. For each leaf, the ratio of

width to thickness is 9:1. The modulus of elasticity of the leaf material is 207000

N/mm2. The leaves are pre-stressed in such a way that when the force is

maximum, the stresses induced in all leaves are same and equal to 450 N/mm2.

Determine (i) the width and thickness of the leaves; (ii) the initial nip.

11. A wagon weighing 1530 Kg mass and moving with a speed of 3 km/hr is to be 07

brought to rest by means of a buffer made of two closed helical springs of

circular section, on each end of wagon. The spring stiffness is 30 kN/mm and

spring index is 6. Maximum permissible shear stress is not to exceed 600

N/mm2. Find the diameter of wire and number of coils in each spring. Take for

spring material G = 8.4 x 104 N/mm2. Check the design for buckling.

12. A laminated spring of an automobile is to carry a load of 5 kN. The spring is 07

made 1000 mm between the supports. Design the spring. Number of leaves to be

taken as 8 with two of them of full length. Distance between U-bolts may be

taken as 60 mm.

13. A spring having outer diameter of coil as 72 mm, deflects for 50 mm at the 07

maximum load of 700 N. Calculate the wire diameter and number of turns for the

spring if the shear stress is 300 MPa and modulus of rigidity 84 KN/mm2. Take

spring index of 8.

14. Design a helical compression spring with plain ends made out of bronze for 07

operating load range of 100 N to 150 N. The deflection of the spring is 6 mm and

spring index = 9. The allowable shear stress for spring is 300 MPa and modulus

of rigidity is 80 KN/mm2. Determine (1) Diameter of spring wire (2) Mean coil

diameter (3) Total number of turns (4) Stiffness of spring

15. Calculate the dimensions of a helical spring for a spring loaded Ramsbottom 07

safety valve from the following data: Valve diameter = 65 mm, Maximum

Design of Machine Elements (2151907)

Department of Mechanical Engineering

Darshan Institute of Engineering & Technology

GTU Paper Analysis

pressure when the valve blows off freely = 0.73

N/mm2 Valve lift when pressure

rise from 0.7 to 0.73 N/mm2 = 3.2 mm Maximum permissible stress = 500

N/mm2 Spring Index = 6 Modulus of rigidity = 0.85x105 N/mm2.

Design of Machine Elements (2151907)

Department of Mechanical Engineering

Darshan Institute of Engineering & Technology

You might also like

- Solenoid Actuators: Theory and Computational MethodsFrom EverandSolenoid Actuators: Theory and Computational MethodsRating: 3 out of 5 stars3/5 (1)

- The Open University of Sri Lanka: DMX4306 - Design of Machine Elements Assignment # 2Document6 pagesThe Open University of Sri Lanka: DMX4306 - Design of Machine Elements Assignment # 2Dilshan0% (1)

- Acsr ConductorsDocument10 pagesAcsr ConductorsPhani KumarNo ratings yet

- MD GTU Study Material GTU-Paper-Analysis ALL 18092019084700AM PDFDocument20 pagesMD GTU Study Material GTU-Paper-Analysis ALL 18092019084700AM PDFD VNo ratings yet

- DME - New Paper Analysis 4 - Belt and Chain DriveDocument5 pagesDME - New Paper Analysis 4 - Belt and Chain Drivedarshit dadhaniyaNo ratings yet

- Chapter 5 - Pressure Vessels: Sr. No. QuestionsDocument5 pagesChapter 5 - Pressure Vessels: Sr. No. Questionsdarshit dadhaniyaNo ratings yet

- Lab Report 2Document12 pagesLab Report 2Adnan ArshadNo ratings yet

- Unit - Iv Design of Energy Storing Elements: Prepared by R. Sendil KumarDocument61 pagesUnit - Iv Design of Energy Storing Elements: Prepared by R. Sendil KumarTalha AbbasiNo ratings yet

- Unit 5 DMMDocument23 pagesUnit 5 DMMAkhila MNo ratings yet

- 2 Marks Question On Springs & BearingsDocument9 pages2 Marks Question On Springs & BearingsAman BansalNo ratings yet

- Chapter 2 - Design Against Fluctuating Loads: Sr. No. QuestionsDocument4 pagesChapter 2 - Design Against Fluctuating Loads: Sr. No. Questionsdarshit dadhaniyaNo ratings yet

- Definition For SpringDocument18 pagesDefinition For SpringamanpurushothNo ratings yet

- Sanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsDocument35 pagesSanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsChaitanya YengeNo ratings yet

- Som QBDocument6 pagesSom QB123rtyNo ratings yet

- Tutorial - 3 Design of SpringsDocument1 pageTutorial - 3 Design of SpringsRyan FloresNo ratings yet

- Leaf SpringsDocument33 pagesLeaf SpringsBharath PolNo ratings yet

- Technical Drawing SS3Document36 pagesTechnical Drawing SS3Moyo DaviesNo ratings yet

- Spring Design E-BookDocument10 pagesSpring Design E-BookDomingo Argumedo Gómez100% (1)

- TRD B 1201Document15 pagesTRD B 1201Prihastya WishnutamaNo ratings yet

- DME Question Bank - 3171917Document4 pagesDME Question Bank - 3171917fgyjnsv786No ratings yet

- Spring - DmeDocument42 pagesSpring - DmeSumitNo ratings yet

- Tutorial Sheet - 1 On Design of Spring': Department of Mechanical EngineeringDocument2 pagesTutorial Sheet - 1 On Design of Spring': Department of Mechanical EngineeringSrimanthula SrikanthNo ratings yet

- SpringsDocument51 pagesSpringsInnocent J MathonsiNo ratings yet

- TOM GTU Study Material GTU-Paper-Analysis All-Units 05102019072605AMDocument23 pagesTOM GTU Study Material GTU-Paper-Analysis All-Units 05102019072605AMSanat PatelNo ratings yet

- Screw Thread CuttingDocument41 pagesScrew Thread CuttingRocio Mtz100% (2)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- EMD Question Bank II 2Document4 pagesEMD Question Bank II 2Soham MisalNo ratings yet

- Mos QBDocument4 pagesMos QBJaishree ChauhanNo ratings yet

- Lecture 18Document21 pagesLecture 18fkaram1965No ratings yet

- 64217Document28 pages64217amdevaNo ratings yet

- To Study and Design A Helical Spring.Document6 pagesTo Study and Design A Helical Spring.Kartik BadalNo ratings yet

- ME374 - Module 4 (Updated)Document36 pagesME374 - Module 4 (Updated)VinNo ratings yet

- SpringDocument30 pagesSpringlin_meckylogiNo ratings yet

- CH 23Document65 pagesCH 23gowrisankarNo ratings yet

- Strength of Materials - Department of Mechanical Engineering PDFDocument7 pagesStrength of Materials - Department of Mechanical Engineering PDFM.Thirunavukkarasu100% (2)

- Spring DesignDocument10 pagesSpring DesignimpetuskolNo ratings yet

- Design of Springs: DR Andrei Lozzi Design IIA, MECH3460Document12 pagesDesign of Springs: DR Andrei Lozzi Design IIA, MECH3460KTMONo ratings yet

- Vehicle Frame & SuspensionDocument68 pagesVehicle Frame & SuspensionHema KumarNo ratings yet

- Screw Thread Cutt Book-N° 32 PDFDocument41 pagesScrew Thread Cutt Book-N° 32 PDFDamian100% (1)

- Name: Deepak Bhanushali EN ROLL: 160050119504 CLASS: ME-3 (A)Document24 pagesName: Deepak Bhanushali EN ROLL: 160050119504 CLASS: ME-3 (A)ABHISHEK CHOUDHARINo ratings yet

- GB SpringDocument69 pagesGB Springshivkumar1587100% (1)

- CE8395 QB - by WWW - Easyengineering.net 1Document18 pagesCE8395 QB - by WWW - Easyengineering.net 1sureshkumarNo ratings yet

- MCE16 SpringsDocument13 pagesMCE16 Springsedradjray88No ratings yet

- Design of Helical and Leaf SpringsDocument92 pagesDesign of Helical and Leaf Springs208W1A1027Sec-A LINGAMANENI KOWSHIKNo ratings yet

- Design of Leaf Springs PDFDocument8 pagesDesign of Leaf Springs PDFGerry Villamor Lindayao Jr.No ratings yet

- DME4THDocument17 pagesDME4THManivannanNo ratings yet

- Lecture 08 SpringsDocument30 pagesLecture 08 SpringsAreeba MujtabaNo ratings yet

- SpringDocument21 pagesSpringa.f .alrawiNo ratings yet

- Strength of Materials PDFDocument8 pagesStrength of Materials PDFkalirajgurusamyNo ratings yet

- ME-603 SpringsDocument15 pagesME-603 Springskanaktanu54No ratings yet

- ME374P1C2 - Exercise 5 - GuditoDocument49 pagesME374P1C2 - Exercise 5 - GuditoDessa GuditoNo ratings yet

- Thread EngagementDocument15 pagesThread Engagementsumeetsaini88No ratings yet

- Design of Springs (Course-Notes)Document112 pagesDesign of Springs (Course-Notes)mOchONo ratings yet

- Som QB PDFDocument32 pagesSom QB PDFvasanthmech092664No ratings yet

- DME Unit 5 Springs PDFDocument51 pagesDME Unit 5 Springs PDFsachinroy8638No ratings yet

- EGR 236 Lab 10 Helical Spring TestDocument3 pagesEGR 236 Lab 10 Helical Spring TestBahah Tyty100% (2)

- Strength of Materials Important 2-Mark QuestionsDocument4 pagesStrength of Materials Important 2-Mark QuestionsSai KrishnaNo ratings yet

- Unit I Q&A StudentDocument4 pagesUnit I Q&A StudentG. Somasekhar SomuNo ratings yet

- Three-Dimensional Link Theory and Invariants of Plane Curve Singularities. (AM-110), Volume 110From EverandThree-Dimensional Link Theory and Invariants of Plane Curve Singularities. (AM-110), Volume 110No ratings yet

- 1800 Mechanical Movements, Devices and AppliancesFrom Everand1800 Mechanical Movements, Devices and AppliancesRating: 4 out of 5 stars4/5 (7)

- DME - New Paper Analysis 4 - Belt and Chain DriveDocument5 pagesDME - New Paper Analysis 4 - Belt and Chain Drivedarshit dadhaniyaNo ratings yet

- Chapter 5 - Pressure Vessels: Sr. No. QuestionsDocument5 pagesChapter 5 - Pressure Vessels: Sr. No. Questionsdarshit dadhaniyaNo ratings yet

- Chapter 2 - Design Against Fluctuating Loads: Sr. No. QuestionsDocument4 pagesChapter 2 - Design Against Fluctuating Loads: Sr. No. Questionsdarshit dadhaniyaNo ratings yet

- Introduction To Operation ResearchDocument8 pagesIntroduction To Operation Researchdarshit dadhaniyaNo ratings yet

- Chapter 1 - Introduction: Sr. No. QuestionsDocument2 pagesChapter 1 - Introduction: Sr. No. Questionsdarshit dadhaniyaNo ratings yet

- Electrical and Starting System: 237-4294 WIRING GP-ENGINEDocument108 pagesElectrical and Starting System: 237-4294 WIRING GP-ENGINEKen HaniNo ratings yet

- JSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Document11 pagesJSEA-ICS-002-Installation of Rigid Steel Conduit (RSC)Jayson EscamillanNo ratings yet

- Softronic HCMS Brochure (Recruitment Edition)Document10 pagesSoftronic HCMS Brochure (Recruitment Edition)Asif MaqboolNo ratings yet

- Loading Instruction A340-600Document2 pagesLoading Instruction A340-600rustedangel1976No ratings yet

- Example Uses of The Linux Command UnzipDocument3 pagesExample Uses of The Linux Command UnzipBalakrishna AlluNo ratings yet

- Chapter 7 - Timber DesignDocument97 pagesChapter 7 - Timber DesignIqbarMaliki100% (2)

- 2012 Accessories & Equipment Power Lumbar Support - TLDocument4 pages2012 Accessories & Equipment Power Lumbar Support - TLsoftallNo ratings yet

- Advanced Technical SEO A Complete GuideDocument385 pagesAdvanced Technical SEO A Complete GuideSebastian Estrada ValenciaNo ratings yet

- 2019 BPR RJ1230 Anx3 SeleccionadosNoPriorizados PDFDocument2 pages2019 BPR RJ1230 Anx3 SeleccionadosNoPriorizados PDFSaul Omar Fernandez RojasNo ratings yet

- Gymnasium DesignDocument3 pagesGymnasium DesignjimmyboyjrNo ratings yet

- Dry Transformers - Schneider Electric - Trihal - 15 or 20kV-400VDocument9 pagesDry Transformers - Schneider Electric - Trihal - 15 or 20kV-400VVăn Đạt Nguyễn VănNo ratings yet

- MainBridge - Design ReportDocument18 pagesMainBridge - Design ReportWan100% (1)

- Notes 1Document68 pagesNotes 1Vo SantosNo ratings yet

- Hardering OracleDocument40 pagesHardering OracleFabian Alejandro Molina SosaNo ratings yet

- P22-1 (50HZ)Document2 pagesP22-1 (50HZ)Daniel StanNo ratings yet

- Job Title: Software Development & Support Reports To: Senior Manager Location: Toronto, ONDocument1 pageJob Title: Software Development & Support Reports To: Senior Manager Location: Toronto, ONThomas RosickyNo ratings yet

- Iconos SapDocument17 pagesIconos SapRodrigo VargasNo ratings yet

- OM 002 Belt Conveyor Idler Instruct 6E74091AB9993Document9 pagesOM 002 Belt Conveyor Idler Instruct 6E74091AB9993gopi_ggg20016099No ratings yet

- Lorry Report Month of August 2015Document22 pagesLorry Report Month of August 2015PrasantaKumarMallikaNo ratings yet

- HORDY Design ExampleDocument6 pagesHORDY Design Examplebrian1mugadzaNo ratings yet

- 2016CompositeList Web 104Document1 page2016CompositeList Web 104AnuranjanNo ratings yet

- Hyundai Hd-78 (Ремонт Китайского Редуктора Harbin)Document28 pagesHyundai Hd-78 (Ремонт Китайского Редуктора Harbin)Bigfair HD78100% (2)

- Class #29 Short Circuit Analysis 5-4-04Document19 pagesClass #29 Short Circuit Analysis 5-4-04AlexNo ratings yet

- FPL Brochure (2019!06!14 Final)Document2 pagesFPL Brochure (2019!06!14 Final)Sofia ForeroNo ratings yet

- BEIJER - StartUp Ix (09 - 2014)Document362 pagesBEIJER - StartUp Ix (09 - 2014)Jorge_Andril_5370No ratings yet

- E&I Inspection Engineer, 5years - MumbaiDocument3 pagesE&I Inspection Engineer, 5years - MumbaiAbhishek IngaleNo ratings yet

- Electrical Double Layer in Biological MembranesDocument6 pagesElectrical Double Layer in Biological MembranesJuan LopezNo ratings yet

- Thermal Expansion Loop - ML Loops ALLDocument6 pagesThermal Expansion Loop - ML Loops ALLPamela De Melo-LangfordNo ratings yet