Professional Documents

Culture Documents

Wps Aws d1.1 NEW

Wps Aws d1.1 NEW

Uploaded by

Ikhy TohepalyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wps Aws d1.1 NEW

Wps Aws d1.1 NEW

Uploaded by

Ikhy TohepalyCopyright:

Available Formats

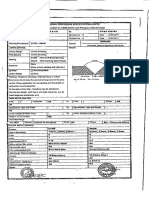

WELDING PROCEDURE SPECIFICATION (WPS)

Company nameMECHANICAL

: ENGINEERING Identification #MPS-PQR-2

Welding process

GMAW-S/CO2

: revision 0 Date : 16/04/2020 By MUH. MAS'UD T.

Supporting PQRMPS-WPS-2

No. Authorizet by Date : 19/04/2020

Type - Manual Semiautomatic

JOINT DESIGN USED Mechanized Automatic

Type Butt

: Tee Corner Lap Edge

Singel : Double Weld : POSITION

Backing

Yes: No Position of Groove : 3G Fillet : NA

Backing Material NA Vertical Progression Up

: Down

Root Opening : 1,5 mm

Root Face Dimencion : 1,5 mm Electrical Characteristics

Groove Angle : Radius ( J-U ) : NA Transfer Mode (GMAW) Short-Chircuiting

Back Gouging : Yes No Method NA Globular Spray

Current : AC DCEP DCEN PULSED

BASE METALS Other

Material Spec. IS 2062 Tungsten Electrode (GTAW)

Type of Grade GRADE B Size : NA

Thickness : GROOVE 10 mm Fillet NA Type: NA

Diameter(Pipe) NA

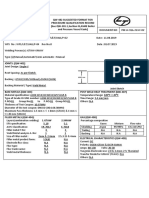

TECHNIQUE

FILLER METALS Stringer or Weave Bead : WEAVE

AWS Specification AWS A5.18 Multi-Pass or Single Pass (per side) MULTIPLE

AWS Clacification ER 70 S-6 Number of Electrodes ONE

Electrode Spacing Longitudinal NA

SHIELDING Lateral NA

Flux NA Gas CO2 Angle 15˚

Composition 100% Contact Tube to work Distance 20 mm

Electrode-Flux (Class) NA Peening NA

Flow Rate 17 L/MIN Interpass Cleaning : WIRE BRUSHING

Gas Cup Size 20 mm

POST WELD HEAT TREATMENT

PREHEAT Temp. NA

Preheat Temp. Min. NA Time NA

Interpass Temp. Min. NA Max. NA

WELDING PROCEDURE

Pass or Filler Metals Current Travel Speed

Weld Process Type & Amps or Wire Volts (IPM) Joint Details

Class Diam. Polarity Feed Speed

Larer (s)

1 GMAW ER 70 S-6 1-2 mm DCEP 116-120 A 18-19 6-7

2 GMAW ER 70 S-6 1-2 mm DCEP 128-132 A 21-22 6-7

3 GMAW ER 70 S-6 1-2 mm DCEP 128-132 A 21-22 6-7

Checked by : V. D. Wass, ST,MT. Approved by : Ir. W. M. E. Wattimena, MS.Eng

You might also like

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFThe Welding Inspections CommunityNo ratings yet

- Wps Is 2062 GR B Butt-OkDocument2 pagesWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- 3500c Auxiliary Engine SchematicDocument2 pages3500c Auxiliary Engine Schematicmohammad hazbehzadNo ratings yet

- Welding Procedure Specification: ST NDDocument1 pageWelding Procedure Specification: ST NDMaung SleeperNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Welding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionDocument2 pagesWelding Procedure Specification (PWPS) - 5fpipe To Plate: Joint Design Used PositionTrudie0% (1)

- WPS 316 L PDFDocument4 pagesWPS 316 L PDFIrinaNo ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- PQR - PipeDocument3 pagesPQR - PipeAdvanced Quality Centre AQC100% (1)

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- WPQ-1083 3G PDFDocument2 pagesWPQ-1083 3G PDFduendex360100% (1)

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Welder I.D CardDocument2 pagesWelder I.D Cardvhung TranNo ratings yet

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pages163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonNo ratings yet

- Welding Procedure Specification For GTAW & GMAWDocument4 pagesWelding Procedure Specification For GTAW & GMAWanh thoNo ratings yet

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmDocument3 pagesVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi Jerbi100% (1)

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Wps 1010 IfrDocument28 pagesWps 1010 IfrSyed Mahmud Habibur RahmanNo ratings yet

- WPS & PQR (E Co Cr-E)Document3 pagesWPS & PQR (E Co Cr-E)HossamSAshourNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Document2 pages(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- Aws 001Document1 pageAws 001akshay sarfareNo ratings yet

- WPS Reg Rev.0Document3 pagesWPS Reg Rev.0Ed FangNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- Aws D1.1 - WPS - Smaw-Fcaw PDFDocument1 pageAws D1.1 - WPS - Smaw-Fcaw PDFBernathTurnipNo ratings yet

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Document2 pagesWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Dobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingDocument3 pagesDobhi Durgapur Haldia Pipeline Project (Part - A) : Welding Procedure Specification For Station PipingBiswajit DeyNo ratings yet

- Wps & Pqr-013 (Ss Gtaw-Smaw TGS)Document17 pagesWps & Pqr-013 (Ss Gtaw-Smaw TGS)Atuk SafizNo ratings yet

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- WPQR2Document3 pagesWPQR2Thanasis KyrgiazoglouNo ratings yet

- WPS ListDocument2 pagesWPS ListAdeel OmerNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Electrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedureDocument2 pagesElectrode Brad Qualification Procedure As Per ASME Section II Part C Along With NPCIL ProcedurePrashant Puri100% (2)

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Document1 pageWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Red DN80 50 50936Document1 pageRed DN80 50 50936slimane AIT-IDIRNo ratings yet

- ASME P NumbersDocument1 pageASME P NumbersFahri Risfa ZulfiNo ratings yet

- PQR Saw ProcessDocument1 pagePQR Saw ProcessARUL ARON JOSENo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Procedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Document2 pagesProcedure Qualification Record (PQR) : Annex N AWS D1.1/D1.1M:2010Menad SalahNo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Afcons Infrastructure Limited: Procedure Qualification Record (PQR)Document21 pagesAfcons Infrastructure Limited: Procedure Qualification Record (PQR)GaapchuNo ratings yet

- WPS - 600 MW ChampaDocument7 pagesWPS - 600 MW ChampaAmjad PathanNo ratings yet

- PQR 3G Fcaw SF71Document3 pagesPQR 3G Fcaw SF71long phamNo ratings yet

- Is.1893 Codebook PDFDocument25 pagesIs.1893 Codebook PDFArbaz HussainNo ratings yet

- Steel Raw Material PDFDocument3 pagesSteel Raw Material PDFRudiantoNo ratings yet

- Molecular Diffusion in GasesDocument28 pagesMolecular Diffusion in GasesDharyl Flores100% (1)

- Conceptual Design of A Natural Fibre-Reinforced Composite Automotive Anti-Roll Bar Using A Hybrid ApproachDocument18 pagesConceptual Design of A Natural Fibre-Reinforced Composite Automotive Anti-Roll Bar Using A Hybrid ApproachPrawal JainNo ratings yet

- Practice Questions (Closed) : Asme Section Viii, Div. IDocument30 pagesPractice Questions (Closed) : Asme Section Viii, Div. Ikorichi100% (2)

- Meivalvole SerieCD ENG 20150212Document4 pagesMeivalvole SerieCD ENG 20150212Marine CaptainNo ratings yet

- Physics For Scientists and Engineers A Strategic Approach With Modern Physics 4th Edition Knight Test Bank 1Document36 pagesPhysics For Scientists and Engineers A Strategic Approach With Modern Physics 4th Edition Knight Test Bank 1kimberlysheltonoagfzwcndy100% (34)

- Ed1801 - Inst & MFG - DWG - of - Sea - Chest - Cover - (Er & Aux - R)Document11 pagesEd1801 - Inst & MFG - DWG - of - Sea - Chest - Cover - (Er & Aux - R)luisNo ratings yet

- Mechanics of Materials - IiDocument43 pagesMechanics of Materials - IiSaAhRaNo ratings yet

- Manual de Fundicion - StandardsDocument1 pageManual de Fundicion - StandardsFederico MoranNo ratings yet

- Power Drive: Gesellschaft Fuer Wissenschaftlichen Apparatebau Gesellschaft Fuer Wissenschaftlichen ApparatebauDocument2 pagesPower Drive: Gesellschaft Fuer Wissenschaftlichen Apparatebau Gesellschaft Fuer Wissenschaftlichen ApparatebauGomez, Francisco (AJR)No ratings yet

- Appendix A. Type HB To SV Conversion ChartsDocument1 pageAppendix A. Type HB To SV Conversion ChartsKiran K CNo ratings yet

- General Overview of WartsilaDocument34 pagesGeneral Overview of WartsilaantonNo ratings yet

- Fuel Oil System Testing & Commissioning Method of Statement - WebDocument5 pagesFuel Oil System Testing & Commissioning Method of Statement - Webvin ssNo ratings yet

- Turow Power PlantDocument14 pagesTurow Power Plantdobrilog100% (1)

- Answer All Questions. (40 Marks) : Sekolah Sri Utama Kuala Lumpur Penilaian Akhir Tahun 2015 Science Form 2Document12 pagesAnswer All Questions. (40 Marks) : Sekolah Sri Utama Kuala Lumpur Penilaian Akhir Tahun 2015 Science Form 2Zainurain Zainal AbidinNo ratings yet

- Variable Speed Unit VARIMOT DF16: Sew-Eurodrive, IncDocument2 pagesVariable Speed Unit VARIMOT DF16: Sew-Eurodrive, Inccarlos aguileraNo ratings yet

- C5101 ADocument2 pagesC5101 AKALILNo ratings yet

- MECHANICS Kinematics: Chapter 2 - Motion Along A Straight LineDocument11 pagesMECHANICS Kinematics: Chapter 2 - Motion Along A Straight LineDan AltmanNo ratings yet

- GT-POWER Engine Simulation Software: HighlightsDocument2 pagesGT-POWER Engine Simulation Software: HighlightsIrfan ShaikhNo ratings yet

- Defender - Accessory Fitting InstructionsDocument312 pagesDefender - Accessory Fitting InstructionsMiguel Seral PérezNo ratings yet

- DHLDocument20 pagesDHLMohammad Faraz AkhterNo ratings yet

- MAINA Universal ShaftsDocument56 pagesMAINA Universal ShaftsAlvaro Patricio Etcheverry TroncosoNo ratings yet

- Pressure Vessel BrochureDocument19 pagesPressure Vessel BrochureNikhil VermaNo ratings yet

- RT ProcedureDocument43 pagesRT ProcedureJeganeswaranNo ratings yet

- Experiment 2. Vapor Pressure.Document4 pagesExperiment 2. Vapor Pressure.Esmeralda A OcampoNo ratings yet

- 4082 ArticleText 20334 1 10 20210105Document15 pages4082 ArticleText 20334 1 10 20210105AxBDNo ratings yet

- Class 0 Air: Parker Zander Oil Free Air System. Innovative Engineering and TechnologyDocument4 pagesClass 0 Air: Parker Zander Oil Free Air System. Innovative Engineering and Technologyramirez759No ratings yet