Professional Documents

Culture Documents

BI645092-01-ENtbo Mangueras PDF

BI645092-01-ENtbo Mangueras PDF

Uploaded by

Jaime Miloz Masle JaksicCopyright:

Available Formats

You might also like

- SAE J517 Hydraulic Hose RatingsDocument6 pagesSAE J517 Hydraulic Hose RatingsR L100% (2)

- Rock Breaker Operation ManualDocument58 pagesRock Breaker Operation ManualNiten Gupta75% (4)

- Coflexip HosesDocument58 pagesCoflexip HosesAnis Kacem67% (3)

- Rtaa SB 20Document5 pagesRtaa SB 20kulilin1100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Dunlop Hoses and Fittings CatalogDocument242 pagesDunlop Hoses and Fittings CatalogBrandon Troc50% (4)

- Hydraulic Cylinder Tie Rod Design: Replaces: 02.13Document68 pagesHydraulic Cylinder Tie Rod Design: Replaces: 02.13Juan Diego Garcia EsquenNo ratings yet

- TD ManualDocument31 pagesTD Manualramlalmittal100% (1)

- COUPP - 60 Hydraulic Hose Failure AnalysisDocument26 pagesCOUPP - 60 Hydraulic Hose Failure AnalysisRomulus Situ MorankNo ratings yet

- Đầu Ống Thủy LựcDocument16 pagesĐầu Ống Thủy LựcNguyen Le Thanh VuNo ratings yet

- Models: CDU CDX 2cdu 2Cdx: Instruction and Operation ManualDocument19 pagesModels: CDU CDX 2cdu 2Cdx: Instruction and Operation ManualHoàng Điệp NguyễnNo ratings yet

- Book FracpumpDocument7 pagesBook FracpumpMehdi MortezapourNo ratings yet

- Hose & Fittings Technical HandbookDocument60 pagesHose & Fittings Technical HandbookLeobardo IslasNo ratings yet

- 10 HydrocycloneBasics 6180305 01Document50 pages10 HydrocycloneBasics 6180305 01Mohamed Bouchareb100% (2)

- Dynamic Seal in The Fertilizer Industry 11-09Document9 pagesDynamic Seal in The Fertilizer Industry 11-09Souvik Singha RoyNo ratings yet

- Hose Technic DataDocument28 pagesHose Technic Dataerol_ay98No ratings yet

- BT Series Owners Manual - CombinedDocument142 pagesBT Series Owners Manual - Combinedalejandro777_eNo ratings yet

- Goulds 3196: Process Pump With Patented Intelligent MonitoringDocument20 pagesGoulds 3196: Process Pump With Patented Intelligent MonitoringDesmond Prince OmorogiuwaNo ratings yet

- Swivel Joint 229-244Document16 pagesSwivel Joint 229-244Gregory StewartNo ratings yet

- WireTough CNG Cylinder Owners ManualDocument19 pagesWireTough CNG Cylinder Owners Manual김범용No ratings yet

- Severe Service Ball Valves For High Pressure Slurry PipelinesDocument7 pagesSevere Service Ball Valves For High Pressure Slurry PipelinesCesar YalanNo ratings yet

- C-14 Selection and Limitation of Piping ComponentsDocument14 pagesC-14 Selection and Limitation of Piping Componentscristhian100% (1)

- Mechanical Seals Often Fail As A Consequence of Prior Bearing DistressDocument4 pagesMechanical Seals Often Fail As A Consequence of Prior Bearing DistressMagical RiyaNo ratings yet

- Attachment 1 - Bk12dhz PumpsDocument14 pagesAttachment 1 - Bk12dhz PumpsluisalonsonucetteranNo ratings yet

- Propping CylDocument2 pagesPropping CyljulioferoNo ratings yet

- Rotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceDocument36 pagesRotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceSaurav DasNo ratings yet

- Appendix 3 FinalDocument96 pagesAppendix 3 FinalMehedi IslamNo ratings yet

- GR KPL&KWMDocument12 pagesGR KPL&KWMHeri SulasionoNo ratings yet

- Instructions For The Use of Long Length and Spliced Hoses: HandlingDocument6 pagesInstructions For The Use of Long Length and Spliced Hoses: HandlingRhdh kldmkNo ratings yet

- Design Guideline For Hydraulic Fluid CleanlinessDocument24 pagesDesign Guideline For Hydraulic Fluid CleanlinessCarlosNo ratings yet

- Hidrolik SilindirlerDocument20 pagesHidrolik SilindirlerEnver AtamanNo ratings yet

- SB 7-1-108Document6 pagesSB 7-1-108jussmeeeNo ratings yet

- TEC - TA05NALDEA #125869 v1 MT 2721 0 312 02 7507 - ConstruccionDocument110 pagesTEC - TA05NALDEA #125869 v1 MT 2721 0 312 02 7507 - ConstruccionandinoNo ratings yet

- Liquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Document70 pagesLiquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Achmadda FebiyonoNo ratings yet

- Veljan Hydraulic CatlogueDocument20 pagesVeljan Hydraulic CatlogueRaji SuriNo ratings yet

- Tapflo CT BrochureDocument8 pagesTapflo CT BrochureСања БанковићNo ratings yet

- Strainer GuideDocument26 pagesStrainer Guidemudrijasm100% (1)

- Rickmeier 34Document12 pagesRickmeier 34carlosNo ratings yet

- Catalogo de Industria Minera PoberajDocument48 pagesCatalogo de Industria Minera PoberajWillintonPoloNo ratings yet

- 3196 I FRAME Bulletin ReadersDocument19 pages3196 I FRAME Bulletin ReadersPedro SanchezNo ratings yet

- High Pressure Carbon DioxideDocument6 pagesHigh Pressure Carbon Dioxideleunamsayan100% (1)

- PumpsDocument19 pagesPumpsIon_Riswan100% (1)

- 741 VLB BrochureDocument4 pages741 VLB BrochureMohammad Ali ZamanNo ratings yet

- Catálogo e Los Cilindros Neumaticos PARKERDocument124 pagesCatálogo e Los Cilindros Neumaticos PARKERmaurozuriNo ratings yet

- Life Cycle Costs WastewaterDocument6 pagesLife Cycle Costs WastewaterRicardo BarrosNo ratings yet

- Coiled Tubing Systems From Evolution Oil ToolsDocument73 pagesCoiled Tubing Systems From Evolution Oil ToolsEvolution Oil Tools100% (2)

- Api C23 1CW-FL E1Document19 pagesApi C23 1CW-FL E1kevin_lim90No ratings yet

- Specification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02Document9 pagesSpecification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02GopalMahantaNo ratings yet

- 3196 I FRAME BulletinDocument19 pages3196 I FRAME BulletinLuis CuaxiloNo ratings yet

- An Engineers CasebookDocument87 pagesAn Engineers CasebookParesh AdhwaryuNo ratings yet

- HDPH436vikingheavypump (German)Document17 pagesHDPH436vikingheavypump (German)Hector_Cornejo_5673No ratings yet

- G Series Industrial and Chemical Owners ManualDocument20 pagesG Series Industrial and Chemical Owners ManualbayuNo ratings yet

- Shell Tellus S2 M 68 (en-GB) TDSDocument3 pagesShell Tellus S2 M 68 (en-GB) TDSJasmine TsoNo ratings yet

- Instalasi POMPADocument106 pagesInstalasi POMPAMeliaGrinaNo ratings yet

- Hermatic LRVP CatalogueDocument12 pagesHermatic LRVP CatalogueSunil BawaneNo ratings yet

- Hose TestingDocument7 pagesHose Testingaan_pkppk100% (1)

- APH CPAC Brochure PDFDocument28 pagesAPH CPAC Brochure PDFdavelegg2No ratings yet

- Greenlee Dobladora de TubosDocument16 pagesGreenlee Dobladora de TuboswilfredoNo ratings yet

- Cat Hüdrovoolikud Ja Liitmikud (ENG)Document8 pagesCat Hüdrovoolikud Ja Liitmikud (ENG)angeloborNo ratings yet

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- BI644913-01-EN Frenos Tralasdo PDFDocument5 pagesBI644913-01-EN Frenos Tralasdo PDFJaime Miloz Masle JaksicNo ratings yet

- BI645092-01-ENtbo Mangueras PDFDocument4 pagesBI645092-01-ENtbo Mangueras PDFJaime Miloz Masle JaksicNo ratings yet

- Bi644917-00-En (Mangueras Artic) PDFDocument66 pagesBi644917-00-En (Mangueras Artic) PDFJaime Miloz Masle JaksicNo ratings yet

- BI644913-01-EN Frenos Tralasdo PDFDocument5 pagesBI644913-01-EN Frenos Tralasdo PDFJaime Miloz Masle JaksicNo ratings yet

- 6060 SuperestructutaDocument19 pages6060 SuperestructutaJaime Miloz Masle JaksicNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- Physical BarrierDocument18 pagesPhysical BarrierPratik TiwariNo ratings yet

- Spec Schedule40 Pipe Galvanized PDFDocument2 pagesSpec Schedule40 Pipe Galvanized PDFSahil SharmaNo ratings yet

- Railways NotesDocument57 pagesRailways NotesUllas S LokeshNo ratings yet

- Final Fantasy Xiii Playmania GuiaspdfDocument32 pagesFinal Fantasy Xiii Playmania Guiaspdftest223No ratings yet

- Circular - NEPI Schedule For HHP Products On 04 05.2016Document3 pagesCircular - NEPI Schedule For HHP Products On 04 05.2016Anil KumarNo ratings yet

- Varanasi BrickDocument73 pagesVaranasi Brickrajesh laddhaNo ratings yet

- Aprilia Scarabeo 250 USA-CNDDocument160 pagesAprilia Scarabeo 250 USA-CNDlynhaven1No ratings yet

- Kevin ResumeDocument2 pagesKevin ResumekfriendNo ratings yet

- Brake Rotor Material SelectionDocument2 pagesBrake Rotor Material SelectionAbhishek KulkarniNo ratings yet

- 11 Manual Chiller YCADocument64 pages11 Manual Chiller YCAinvestigador_1977No ratings yet

- Mil STD 331 AmendDocument286 pagesMil STD 331 AmendGiridhar Rao SanaNo ratings yet

- Class D Tutorial 606Document51 pagesClass D Tutorial 606luizcpimenta100% (1)

- Aerodynamic CarsDocument18 pagesAerodynamic CarsArunava Ray100% (1)

- Pile Foundation Notes DesignDocument24 pagesPile Foundation Notes DesignSnow YoshimaNo ratings yet

- Amarillo Endurance-OM-09.2022Document8 pagesAmarillo Endurance-OM-09.2022Anonymous CMS3dL1TNo ratings yet

- Engine Oil 15W 40 PDFDocument2 pagesEngine Oil 15W 40 PDFAngela Jackson100% (1)

- Thermo Hydro and Thermo Hydro Mechanical Wood Processing DICK SANDBERGDocument26 pagesThermo Hydro and Thermo Hydro Mechanical Wood Processing DICK SANDBERGAlmir AkvicNo ratings yet

- EcoStruxure Plant - 2018 - Ebrochure PDFDocument8 pagesEcoStruxure Plant - 2018 - Ebrochure PDFskmailNo ratings yet

- Ch07 Website Design and Development 100 Questions To Ask Before Building A Website 1Document46 pagesCh07 Website Design and Development 100 Questions To Ask Before Building A Website 1dgalvis_1No ratings yet

- How To Configure IPSec VPNs 2.1Document15 pagesHow To Configure IPSec VPNs 2.1Monica VanceNo ratings yet

- Scope of WorkDocument10 pagesScope of WorkRenato KaindoyNo ratings yet

- A307 PDFDocument5 pagesA307 PDFxaviereduardoNo ratings yet

- Secondary Beam ExampleDocument5 pagesSecondary Beam ExampleAboalmaail AlaminNo ratings yet

- Valvula de Acc Manual - E150Document4 pagesValvula de Acc Manual - E150DANIZACHNo ratings yet

- CH 4Document28 pagesCH 4Suraj ShahNo ratings yet

- Blue Swimming Crab Shell Waste Reinforced Cement PavementsDocument8 pagesBlue Swimming Crab Shell Waste Reinforced Cement PavementsFelipe De Oca0% (1)

- SLC 500Document2 pagesSLC 500Rodney PimentaNo ratings yet

- Nrel Phase ViDocument310 pagesNrel Phase Viarash_7444No ratings yet

- Mobile RepairingDocument4 pagesMobile RepairingNishant Sharma100% (2)

- 1TB01005-005C17 - Hah-Xx-Xx-Sdw-Me-10005-C1-Dwg-Equipment Positioning - General Plan (B)Document2 pages1TB01005-005C17 - Hah-Xx-Xx-Sdw-Me-10005-C1-Dwg-Equipment Positioning - General Plan (B)MAZHAR ALINo ratings yet

BI645092-01-ENtbo Mangueras PDF

BI645092-01-ENtbo Mangueras PDF

Uploaded by

Jaime Miloz Masle JaksicOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BI645092-01-ENtbo Mangueras PDF

BI645092-01-ENtbo Mangueras PDF

Uploaded by

Jaime Miloz Masle JaksicCopyright:

Available Formats

BI645092-01

24. Aug. 2015

Service Magazine

New Options for Preventative/ Proactive Maintenance for

Hydraulic Hose Assemblies on Hydraulic Mining Shovels

6015 DHB15001 - up

6015 FS DHF15001 - up

6018 DHT18001 - up

6018 FS DHD18001 - up

6030 DHL30001 - up

6030 FS DHG30001 - up

6040 DHJ40001 - up

6040 FS DHX40001 - up

6050 DHM50001 - up

6050 FS DH250001 - up

6060 DHN60001 - up

6060 FS DH360001 - up

DHS90001- up

6090 FS

DM690015 - up

Attention: Follow appropriate safety procedures and use personal

protective equipment as required.

Corresponding local safety regulation must always be observed.

The purpose of this Service Magazine is to provide operational information for hydraulic hoses

and recommended change out intervals for hydraulic hoses on HMS machines.

The first section provides information how to handle and store hydraulic hoses. In the second

section recommendations on how to minimize unplanned downtimes and achieve the lowest

cost of ownership are made.

Caterpillar: Confidential Green

©2015 Caterpillar Cat, Caterpillar, their respective logos, “Caterpillar Yellow” and the Power edge trade dress, as well as corporate

Caterpillar Global Mining HMS GmbH, Karl Funke Str. 36, D-44149 Dortmund, Germany DF

2015-069-SM-BI645092-01 Guidelines for Servicing Hydraulic Hoses.docx Page 1 of 4

BI645092-01

1. Operational information

1.1 General

Hydraulic lines and hoses must never be repaired.

Using hose assemblies close to the limit ranges of permitted use shortens the service

life (e.g. environmental influences as cold weather or high temperatures, frequent

working cycles, extremely high impulse frequencies).

Service life should always be referred to operating hours (e.g. multi shift operation or

24hours operation collects more hours/ year).

HMS usage in excess of manufactures recommended practices should be avoided to

achieve maximum life of hydraulic hoses.

Recommended change-out of hose, particularly for hoses in critical areas, is related to

working hours / load and is provided later in this Magazine.

1.2 Storage

Even if hydraulic hose assemblies are stored and used properly, they undergo a natural

aging process. For that reason their service life is limited.

According to ISO 8331 bulk hose in general has a shelf life of up to 7 years from the

date of manufacture with an extension of 3 years, as long as the hose is stored in

accordance with ISO 2230.

The overall service life of a hose assembly must not exceed 6 years, including a storage

period of not more than 2 years. Therefore built date/ hose assembly date shall be

traceable, e.g. imprint on ferrule, hose tag.

Hose assemblies must always be stored straight either flat on shelving or hanging from

racking. Assemblies left coiled can affect the natural lay of the hose assembly therefore

affect angle settings for angled fittings. All hose assemblies must remain capped to

prevent contamination.

1.3 Inspection/ Preventative Maintenance

Caterpillar continues to recommend Preventative Maintenance, with hoses being

inspected for signs of leaks, abrasion wear, cracked rubber, twisting, contact/ rubbing

and loss of flexibility on a regular frequency. Hoses exhibiting these characteristics

should be removed and replaced as soon as possible to prevent unplanned downtime

and loss of productivity.

It is recommended that all hose assemblies are checked daily but at very least weekly

for external visible damage. Any damaged assembly should be replaced immediately.

1.4 Indications for Replacement

Hose assemblies must be replaced if any of the following points are found during an

inspection:

- Damage on the external layer into the internal layer (chaffing, cuts, rips).

- Brittleness on the outer layer (crack formation of the hose material).

- Changes in shape, which differ from the natural shape of the hose, when under

pressure or not, or in bends or curves, such as separation of layers, blister or bubble

formation.

Caterpillar: Confidential Green

Caterpillar Global Mining HMS GmbH, Karl Funke Str. 36, D-44149 Dortmund, Germany

2015-069-SM-BI645092-01 Guidelines for Servicing Hydraulic Hoses.docx Page 2 of 4

BI645092-01

- Leaks

- Non observance of installation requirements/ incorrect installation.

- Damage or deformation of hose fittings, which might reduce the strength of the fitting or

connection.

- Corrosion on fittings, which might reduce the function or strength of the fitting.

Special Instruction BI644931 provides assembly and installation details for Code 61 and

Code 62 hydraulic hoses and further replacement recommendation for CAT dealer built

hose assemblies.

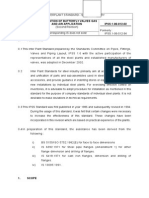

2. Recommended change intervals

The advantages to setting up such change-out intervals is to minimize unplanned

downtimes and achieve the lowest cost of ownership. The given intervals reflect the best

mix between achievable life and maximum component utilization.

Where possible the change-out intervals should be aligned with the recommended

service intervals for major components. Hydraulic Hose recommendations have been

developed to be integrated, if possible, with existing service intervals to reduce

unplanned machine downtime due to failure.

These change out recommendations should be adjusted for site specific reasons and

performance history.

Service intervals for hydraulic hoses listed below can now be utilized:

Clam Cylinder Hoses: 5,000 hours

Boom Cylinder Hoses: 10,000 hours

Stick Cylinder Hoses: 8,000 hours

Bucket Cylinder Hoses: 8,000 hours

Travel and Slew Hoses: 10,000 hours

Pilot Hoses: 20,000 hours

Oil Cooler & Return Hoses: 15,000 hours

Main Pump Hoses: 10,000 hours

Other high pressure hoses 10,000 hours

on superstructure

Caterpillar: Confidential Green

Caterpillar Global Mining HMS GmbH, Karl Funke Str. 36, D-44149 Dortmund, Germany

2015-069-SM-BI645092-01 Guidelines for Servicing Hydraulic Hoses.docx Page 3 of 4

BI645092-01

Illustration 1: Recommended Service Intervals for Hydraulic Hoses

on Hydraulic Mining Shovels

Caterpillar: Confidential Green

Caterpillar Global Mining HMS GmbH, Karl Funke Str. 36, D-44149 Dortmund, Germany

2015-069-SM-BI645092-01 Guidelines for Servicing Hydraulic Hoses.docx Page 4 of 4

You might also like

- SAE J517 Hydraulic Hose RatingsDocument6 pagesSAE J517 Hydraulic Hose RatingsR L100% (2)

- Rock Breaker Operation ManualDocument58 pagesRock Breaker Operation ManualNiten Gupta75% (4)

- Coflexip HosesDocument58 pagesCoflexip HosesAnis Kacem67% (3)

- Rtaa SB 20Document5 pagesRtaa SB 20kulilin1100% (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Dunlop Hoses and Fittings CatalogDocument242 pagesDunlop Hoses and Fittings CatalogBrandon Troc50% (4)

- Hydraulic Cylinder Tie Rod Design: Replaces: 02.13Document68 pagesHydraulic Cylinder Tie Rod Design: Replaces: 02.13Juan Diego Garcia EsquenNo ratings yet

- TD ManualDocument31 pagesTD Manualramlalmittal100% (1)

- COUPP - 60 Hydraulic Hose Failure AnalysisDocument26 pagesCOUPP - 60 Hydraulic Hose Failure AnalysisRomulus Situ MorankNo ratings yet

- Đầu Ống Thủy LựcDocument16 pagesĐầu Ống Thủy LựcNguyen Le Thanh VuNo ratings yet

- Models: CDU CDX 2cdu 2Cdx: Instruction and Operation ManualDocument19 pagesModels: CDU CDX 2cdu 2Cdx: Instruction and Operation ManualHoàng Điệp NguyễnNo ratings yet

- Book FracpumpDocument7 pagesBook FracpumpMehdi MortezapourNo ratings yet

- Hose & Fittings Technical HandbookDocument60 pagesHose & Fittings Technical HandbookLeobardo IslasNo ratings yet

- 10 HydrocycloneBasics 6180305 01Document50 pages10 HydrocycloneBasics 6180305 01Mohamed Bouchareb100% (2)

- Dynamic Seal in The Fertilizer Industry 11-09Document9 pagesDynamic Seal in The Fertilizer Industry 11-09Souvik Singha RoyNo ratings yet

- Hose Technic DataDocument28 pagesHose Technic Dataerol_ay98No ratings yet

- BT Series Owners Manual - CombinedDocument142 pagesBT Series Owners Manual - Combinedalejandro777_eNo ratings yet

- Goulds 3196: Process Pump With Patented Intelligent MonitoringDocument20 pagesGoulds 3196: Process Pump With Patented Intelligent MonitoringDesmond Prince OmorogiuwaNo ratings yet

- Swivel Joint 229-244Document16 pagesSwivel Joint 229-244Gregory StewartNo ratings yet

- WireTough CNG Cylinder Owners ManualDocument19 pagesWireTough CNG Cylinder Owners Manual김범용No ratings yet

- Severe Service Ball Valves For High Pressure Slurry PipelinesDocument7 pagesSevere Service Ball Valves For High Pressure Slurry PipelinesCesar YalanNo ratings yet

- C-14 Selection and Limitation of Piping ComponentsDocument14 pagesC-14 Selection and Limitation of Piping Componentscristhian100% (1)

- Mechanical Seals Often Fail As A Consequence of Prior Bearing DistressDocument4 pagesMechanical Seals Often Fail As A Consequence of Prior Bearing DistressMagical RiyaNo ratings yet

- Attachment 1 - Bk12dhz PumpsDocument14 pagesAttachment 1 - Bk12dhz PumpsluisalonsonucetteranNo ratings yet

- Propping CylDocument2 pagesPropping CyljulioferoNo ratings yet

- Rotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceDocument36 pagesRotary Unions Swivel Joints: Manufactured in The UK With Over 70 Years ExperienceSaurav DasNo ratings yet

- Appendix 3 FinalDocument96 pagesAppendix 3 FinalMehedi IslamNo ratings yet

- GR KPL&KWMDocument12 pagesGR KPL&KWMHeri SulasionoNo ratings yet

- Instructions For The Use of Long Length and Spliced Hoses: HandlingDocument6 pagesInstructions For The Use of Long Length and Spliced Hoses: HandlingRhdh kldmkNo ratings yet

- Design Guideline For Hydraulic Fluid CleanlinessDocument24 pagesDesign Guideline For Hydraulic Fluid CleanlinessCarlosNo ratings yet

- Hidrolik SilindirlerDocument20 pagesHidrolik SilindirlerEnver AtamanNo ratings yet

- SB 7-1-108Document6 pagesSB 7-1-108jussmeeeNo ratings yet

- TEC - TA05NALDEA #125869 v1 MT 2721 0 312 02 7507 - ConstruccionDocument110 pagesTEC - TA05NALDEA #125869 v1 MT 2721 0 312 02 7507 - ConstruccionandinoNo ratings yet

- Liquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Document70 pagesLiquid Cylinder Manual Cryo-DuraCyl (Contoh Tabung)Achmadda FebiyonoNo ratings yet

- Veljan Hydraulic CatlogueDocument20 pagesVeljan Hydraulic CatlogueRaji SuriNo ratings yet

- Tapflo CT BrochureDocument8 pagesTapflo CT BrochureСања БанковићNo ratings yet

- Strainer GuideDocument26 pagesStrainer Guidemudrijasm100% (1)

- Rickmeier 34Document12 pagesRickmeier 34carlosNo ratings yet

- Catalogo de Industria Minera PoberajDocument48 pagesCatalogo de Industria Minera PoberajWillintonPoloNo ratings yet

- 3196 I FRAME Bulletin ReadersDocument19 pages3196 I FRAME Bulletin ReadersPedro SanchezNo ratings yet

- High Pressure Carbon DioxideDocument6 pagesHigh Pressure Carbon Dioxideleunamsayan100% (1)

- PumpsDocument19 pagesPumpsIon_Riswan100% (1)

- 741 VLB BrochureDocument4 pages741 VLB BrochureMohammad Ali ZamanNo ratings yet

- Catálogo e Los Cilindros Neumaticos PARKERDocument124 pagesCatálogo e Los Cilindros Neumaticos PARKERmaurozuriNo ratings yet

- Life Cycle Costs WastewaterDocument6 pagesLife Cycle Costs WastewaterRicardo BarrosNo ratings yet

- Coiled Tubing Systems From Evolution Oil ToolsDocument73 pagesCoiled Tubing Systems From Evolution Oil ToolsEvolution Oil Tools100% (2)

- Api C23 1CW-FL E1Document19 pagesApi C23 1CW-FL E1kevin_lim90No ratings yet

- Specification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02Document9 pagesSpecification of Butterfly Valves Gas and Air Application IPSS:1-06-012-02GopalMahantaNo ratings yet

- 3196 I FRAME BulletinDocument19 pages3196 I FRAME BulletinLuis CuaxiloNo ratings yet

- An Engineers CasebookDocument87 pagesAn Engineers CasebookParesh AdhwaryuNo ratings yet

- HDPH436vikingheavypump (German)Document17 pagesHDPH436vikingheavypump (German)Hector_Cornejo_5673No ratings yet

- G Series Industrial and Chemical Owners ManualDocument20 pagesG Series Industrial and Chemical Owners ManualbayuNo ratings yet

- Shell Tellus S2 M 68 (en-GB) TDSDocument3 pagesShell Tellus S2 M 68 (en-GB) TDSJasmine TsoNo ratings yet

- Instalasi POMPADocument106 pagesInstalasi POMPAMeliaGrinaNo ratings yet

- Hermatic LRVP CatalogueDocument12 pagesHermatic LRVP CatalogueSunil BawaneNo ratings yet

- Hose TestingDocument7 pagesHose Testingaan_pkppk100% (1)

- APH CPAC Brochure PDFDocument28 pagesAPH CPAC Brochure PDFdavelegg2No ratings yet

- Greenlee Dobladora de TubosDocument16 pagesGreenlee Dobladora de TuboswilfredoNo ratings yet

- Cat Hüdrovoolikud Ja Liitmikud (ENG)Document8 pagesCat Hüdrovoolikud Ja Liitmikud (ENG)angeloborNo ratings yet

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- BI644913-01-EN Frenos Tralasdo PDFDocument5 pagesBI644913-01-EN Frenos Tralasdo PDFJaime Miloz Masle JaksicNo ratings yet

- BI645092-01-ENtbo Mangueras PDFDocument4 pagesBI645092-01-ENtbo Mangueras PDFJaime Miloz Masle JaksicNo ratings yet

- Bi644917-00-En (Mangueras Artic) PDFDocument66 pagesBi644917-00-En (Mangueras Artic) PDFJaime Miloz Masle JaksicNo ratings yet

- BI644913-01-EN Frenos Tralasdo PDFDocument5 pagesBI644913-01-EN Frenos Tralasdo PDFJaime Miloz Masle JaksicNo ratings yet

- 6060 SuperestructutaDocument19 pages6060 SuperestructutaJaime Miloz Masle JaksicNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- Physical BarrierDocument18 pagesPhysical BarrierPratik TiwariNo ratings yet

- Spec Schedule40 Pipe Galvanized PDFDocument2 pagesSpec Schedule40 Pipe Galvanized PDFSahil SharmaNo ratings yet

- Railways NotesDocument57 pagesRailways NotesUllas S LokeshNo ratings yet

- Final Fantasy Xiii Playmania GuiaspdfDocument32 pagesFinal Fantasy Xiii Playmania Guiaspdftest223No ratings yet

- Circular - NEPI Schedule For HHP Products On 04 05.2016Document3 pagesCircular - NEPI Schedule For HHP Products On 04 05.2016Anil KumarNo ratings yet

- Varanasi BrickDocument73 pagesVaranasi Brickrajesh laddhaNo ratings yet

- Aprilia Scarabeo 250 USA-CNDDocument160 pagesAprilia Scarabeo 250 USA-CNDlynhaven1No ratings yet

- Kevin ResumeDocument2 pagesKevin ResumekfriendNo ratings yet

- Brake Rotor Material SelectionDocument2 pagesBrake Rotor Material SelectionAbhishek KulkarniNo ratings yet

- 11 Manual Chiller YCADocument64 pages11 Manual Chiller YCAinvestigador_1977No ratings yet

- Mil STD 331 AmendDocument286 pagesMil STD 331 AmendGiridhar Rao SanaNo ratings yet

- Class D Tutorial 606Document51 pagesClass D Tutorial 606luizcpimenta100% (1)

- Aerodynamic CarsDocument18 pagesAerodynamic CarsArunava Ray100% (1)

- Pile Foundation Notes DesignDocument24 pagesPile Foundation Notes DesignSnow YoshimaNo ratings yet

- Amarillo Endurance-OM-09.2022Document8 pagesAmarillo Endurance-OM-09.2022Anonymous CMS3dL1TNo ratings yet

- Engine Oil 15W 40 PDFDocument2 pagesEngine Oil 15W 40 PDFAngela Jackson100% (1)

- Thermo Hydro and Thermo Hydro Mechanical Wood Processing DICK SANDBERGDocument26 pagesThermo Hydro and Thermo Hydro Mechanical Wood Processing DICK SANDBERGAlmir AkvicNo ratings yet

- EcoStruxure Plant - 2018 - Ebrochure PDFDocument8 pagesEcoStruxure Plant - 2018 - Ebrochure PDFskmailNo ratings yet

- Ch07 Website Design and Development 100 Questions To Ask Before Building A Website 1Document46 pagesCh07 Website Design and Development 100 Questions To Ask Before Building A Website 1dgalvis_1No ratings yet

- How To Configure IPSec VPNs 2.1Document15 pagesHow To Configure IPSec VPNs 2.1Monica VanceNo ratings yet

- Scope of WorkDocument10 pagesScope of WorkRenato KaindoyNo ratings yet

- A307 PDFDocument5 pagesA307 PDFxaviereduardoNo ratings yet

- Secondary Beam ExampleDocument5 pagesSecondary Beam ExampleAboalmaail AlaminNo ratings yet

- Valvula de Acc Manual - E150Document4 pagesValvula de Acc Manual - E150DANIZACHNo ratings yet

- CH 4Document28 pagesCH 4Suraj ShahNo ratings yet

- Blue Swimming Crab Shell Waste Reinforced Cement PavementsDocument8 pagesBlue Swimming Crab Shell Waste Reinforced Cement PavementsFelipe De Oca0% (1)

- SLC 500Document2 pagesSLC 500Rodney PimentaNo ratings yet

- Nrel Phase ViDocument310 pagesNrel Phase Viarash_7444No ratings yet

- Mobile RepairingDocument4 pagesMobile RepairingNishant Sharma100% (2)

- 1TB01005-005C17 - Hah-Xx-Xx-Sdw-Me-10005-C1-Dwg-Equipment Positioning - General Plan (B)Document2 pages1TB01005-005C17 - Hah-Xx-Xx-Sdw-Me-10005-C1-Dwg-Equipment Positioning - General Plan (B)MAZHAR ALINo ratings yet