Professional Documents

Culture Documents

Activity 7.3 Tolerances: © 2012 Project Lead The Way, Inc. IED Activity 7.3 Tolerances - Page 1

Activity 7.3 Tolerances: © 2012 Project Lead The Way, Inc. IED Activity 7.3 Tolerances - Page 1

Uploaded by

CaBreon WiseCopyright:

Available Formats

You might also like

- Activity 2.1.1 Tolerate This!: Additional PracticeDocument4 pagesActivity 2.1.1 Tolerate This!: Additional PracticeOmkaar Sampigeadi0% (1)

- Draft Usance LC by Acceptance 60 Days 752 MPEDocument3 pagesDraft Usance LC by Acceptance 60 Days 752 MPEAdhitya Achmad100% (3)

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- 7.3.a TolerancesDocument5 pages7.3.a TolerancesKeegan SneadNo ratings yet

- CH 8 Palepu JW C PDFDocument14 pagesCH 8 Palepu JW C PDFcherry wineNo ratings yet

- Activity 7.3 Tolerances Part 2Document3 pagesActivity 7.3 Tolerances Part 2fenn shibuNo ratings yet

- 7 3 Atolerances Modified1Document4 pages7 3 Atolerances Modified1api-3319987910% (1)

- 7 3 Atolerances Modified1 1Document4 pages7 3 Atolerances Modified1 1api-339017928No ratings yet

- Ied 211 Tolerate This Additional Practice Answer KeyDocument5 pagesIed 211 Tolerate This Additional Practice Answer Key836616477No ratings yet

- GD T ExamplesDocument10 pagesGD T ExamplesJuan Posada GNo ratings yet

- Geometric Dimensioning 1Document36 pagesGeometric Dimensioning 1mohanNo ratings yet

- 2 - Tolerances&Fits (Wk2,3)Document8 pages2 - Tolerances&Fits (Wk2,3)franciseton115No ratings yet

- Chapter 12 Working DrawingDocument63 pagesChapter 12 Working DrawingBit RecordsNo ratings yet

- 1-Tolerances and FitsDocument45 pages1-Tolerances and FitsTt OwnsqqNo ratings yet

- M.S Ramaiah School of Advanced Studies: Postgraduate Engineering and Management Programme (PEMP)Document5 pagesM.S Ramaiah School of Advanced Studies: Postgraduate Engineering and Management Programme (PEMP)jibharatNo ratings yet

- Linear TolerancesDocument7 pagesLinear Tolerancesbrpnaidu2157No ratings yet

- Manufacturing TolerancesDocument13 pagesManufacturing TolerancesHarsh100% (1)

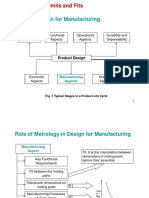

- Fundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, IndianDocument35 pagesFundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, Indianyair Enrique Romero OspinoNo ratings yet

- 20-7 S D S B: Eismic Esign of Lab RidgesDocument12 pages20-7 S D S B: Eismic Esign of Lab RidgesAngga Fajar SetiawanNo ratings yet

- AssemblyDocument50 pagesAssemblyhemanthogadeNo ratings yet

- FINAL Test Engineering - Design - 80 Points in Total-Which Count For 40% of Your Grade!Document14 pagesFINAL Test Engineering - Design - 80 Points in Total-Which Count For 40% of Your Grade!B NinhNo ratings yet

- Module 2Document14 pagesModule 2Reginald VelanoNo ratings yet

- Working Drawing-AssembledDocument78 pagesWorking Drawing-Assembledflorence mwakyusaNo ratings yet

- 20201019-Advanced Computer Aided ModellingDocument38 pages20201019-Advanced Computer Aided ModellingNaveena mNo ratings yet

- Chapter 8 Detail Drawing: Understanding & CreatingDocument80 pagesChapter 8 Detail Drawing: Understanding & CreatingMohsin JavedNo ratings yet

- 3.4.A LinearDimensionsDocument10 pages3.4.A LinearDimensionsitsmedd1No ratings yet

- True/False: Modern Steel Construction's Monthly Steel Buildings. Where Appropriate, OtherDocument2 pagesTrue/False: Modern Steel Construction's Monthly Steel Buildings. Where Appropriate, Otherfarru foruNo ratings yet

- 1 2 10 P Gliderdesign1Document6 pages1 2 10 P Gliderdesign1api-325609547No ratings yet

- Geometrical Dimensioning and TolerenceDocument61 pagesGeometrical Dimensioning and TolerenceAd Man GeTigNo ratings yet

- Module 03 - Tolerances and AllowancesDocument9 pagesModule 03 - Tolerances and AllowancesNeil Joshua LerinNo ratings yet

- 7.2.A SectionViewsDocument7 pages7.2.A SectionViewsKhemari EllisNo ratings yet

- Chapter 28Document17 pagesChapter 28Ghazala FarooqNo ratings yet

- prEN1993 1 8 06Document16 pagesprEN1993 1 8 06José CarlosNo ratings yet

- 4 Working DrawingDocument70 pages4 Working DrawingMohdRosmainiNo ratings yet

- PT - Lesson 13. Limits, Fits and ToleranceDocument9 pagesPT - Lesson 13. Limits, Fits and ToleranceAkash SinghNo ratings yet

- Steel Beam - Web OpenningDocument17 pagesSteel Beam - Web OpenningMadhurimaMitraNo ratings yet

- Cadcam - Rme701Document2 pagesCadcam - Rme701Pandit Animesh TripathiNo ratings yet

- Masjien Ontwerp 244: TekeningeDocument12 pagesMasjien Ontwerp 244: TekeningeIlghe van der MerweNo ratings yet

- Sleeve Bearing ClearanceDocument3 pagesSleeve Bearing ClearanceRian Jamaludin PogramNo ratings yet

- GD&T Shaft Clamp BracketDocument4 pagesGD&T Shaft Clamp Bracketmadhusudhan.bhumireddi0% (1)

- Design For Manufacturing ExamplesDocument13 pagesDesign For Manufacturing ExamplesVikash Singh100% (1)

- CEE 542 - Advanced Topics in Steel Design: Homework #4 Spring 2015 1 To 3 Person Assignment Due Date: Thursday March 12Document1 pageCEE 542 - Advanced Topics in Steel Design: Homework #4 Spring 2015 1 To 3 Person Assignment Due Date: Thursday March 12AbdiDamantaNo ratings yet

- Chapter 3 Coventional FastnersDocument37 pagesChapter 3 Coventional FastnersAtalelew ZeruNo ratings yet

- Fictiv GuidetoTightTolerances SmallDocument34 pagesFictiv GuidetoTightTolerances Smallmax mullNo ratings yet

- GD&T, Mechanical TolerancingDocument12 pagesGD&T, Mechanical TolerancingsandeshbhavsarNo ratings yet

- LEEA Correspondence Courses: Assignment 5.3 Total MarkDocument4 pagesLEEA Correspondence Courses: Assignment 5.3 Total MarkYAKUBU A. AROGENo ratings yet

- Model Answer Winter 2017Document22 pagesModel Answer Winter 2017jitesh mahadik100% (1)

- Limits Fits & ToleranceDocument30 pagesLimits Fits & ToleranceSrikanth SrikeeNo ratings yet

- Steel Structures-Lecture 4 PDFDocument15 pagesSteel Structures-Lecture 4 PDFAli FarooqNo ratings yet

- Limits Fits and TolerancesDocument42 pagesLimits Fits and Tolerances544 vishwavijay PatilNo ratings yet

- Limits Fits Tolerance Control SystemDocument19 pagesLimits Fits Tolerance Control SystemUjjwal kecNo ratings yet

- Detailing Corner 2008-2009Document26 pagesDetailing Corner 2008-2009Arden PoncioNo ratings yet

- CENG 5503 Chapter 2Document13 pagesCENG 5503 Chapter 2Getachew MekuriawNo ratings yet

- 2.1 Terms of Sizes: Unit 1 Limit and FitsDocument20 pages2.1 Terms of Sizes: Unit 1 Limit and FitsRamu VasaNo ratings yet

- Cable Trench DesignDocument74 pagesCable Trench DesignJANMESHNo ratings yet

- UEMX3333 Structural AnalysisDocument107 pagesUEMX3333 Structural AnalysisZin-E ShioNo ratings yet

- Computer Numerical Control: Standards For CADDocument14 pagesComputer Numerical Control: Standards For CADibraheemNo ratings yet

- ED7111Document117 pagesED7111palaniappan_pandianNo ratings yet

- List of The Technical QuestionDocument3 pagesList of The Technical QuestionMitul patelNo ratings yet

- Dimensioning Tolerances ProcessesDocument12 pagesDimensioning Tolerances ProcessespatrikcncNo ratings yet

- Autodesk Inventor 2019 For Beginners - Part 1 (Part Modeling)From EverandAutodesk Inventor 2019 For Beginners - Part 1 (Part Modeling)No ratings yet

- The First Meat Sector IPO CASEDocument3 pagesThe First Meat Sector IPO CASEabiraNo ratings yet

- Unnumbered 2022 174 Submission of ELECTION BIR FORM NO. 2316Document4 pagesUnnumbered 2022 174 Submission of ELECTION BIR FORM NO. 2316Albino GalgoNo ratings yet

- Dorks Target Netflix BY (@global™ - ™cracking )Document778 pagesDorks Target Netflix BY (@global™ - ™cracking )abdessamadzaher05No ratings yet

- FINANCIAL DERIVATIVES Unit - 1Document18 pagesFINANCIAL DERIVATIVES Unit - 1Neehasultana ShaikNo ratings yet

- Marine Policy: Steven W. Purcell, David H. Williamson, Poasi NgaluafeDocument8 pagesMarine Policy: Steven W. Purcell, David H. Williamson, Poasi NgaluafeCésar LevioNo ratings yet

- For Each Period, Calculate The Ratio of Each COQ Category To RevenuesDocument2 pagesFor Each Period, Calculate The Ratio of Each COQ Category To RevenuesElliot RichardNo ratings yet

- The Importance of Business EthicsDocument2 pagesThe Importance of Business EthicsKent AguilarNo ratings yet

- Frankart Global Xero Degrees Brand DeckDocument25 pagesFrankart Global Xero Degrees Brand DeckPradyut TiwariNo ratings yet

- Be17280324 17840043 FiDocument2 pagesBe17280324 17840043 FiJay WalkerNo ratings yet

- Analysis of Financial Statements Solved MCQs (Set-2)Document6 pagesAnalysis of Financial Statements Solved MCQs (Set-2)VenkataRamana IkkurthiNo ratings yet

- Corporate Securities Law Class Presentation 2 Topic-Hate Crimes Manvesh Vats Meaning of Corporate CrimesDocument6 pagesCorporate Securities Law Class Presentation 2 Topic-Hate Crimes Manvesh Vats Meaning of Corporate CrimesManvesh VatsNo ratings yet

- WWW Canadavisa Com Canadian Temporary Work Visa HTMLDocument6 pagesWWW Canadavisa Com Canadian Temporary Work Visa HTMLEric HazzardNo ratings yet

- BCIF - Ver9 With DPA and Bill Delivery Agreement - 02022022Document1 pageBCIF - Ver9 With DPA and Bill Delivery Agreement - 02022022Tegnap NehjNo ratings yet

- Qmethods & Manscie Prelim Transportation (Vam)Document13 pagesQmethods & Manscie Prelim Transportation (Vam)Dylan GutierrezNo ratings yet

- Banking & Economy PDF - January 2020 by AffairsCloud PDFDocument141 pagesBanking & Economy PDF - January 2020 by AffairsCloud PDFAjith DivakaranNo ratings yet

- Billing System Thesis DocumentationDocument6 pagesBilling System Thesis Documentationafkngwetd100% (2)

- SAP Certified Application Associate - SAP S - 4HANA Asset Management - Full - ERPPrep19Document34 pagesSAP Certified Application Associate - SAP S - 4HANA Asset Management - Full - ERPPrep19Budigi RajaekharNo ratings yet

- Sample Assignment - Strategic MarketingDocument9 pagesSample Assignment - Strategic MarketingPrimera700100% (1)

- DS - TW9515 - GB - 726 - Poço de Proteção RoscadoDocument3 pagesDS - TW9515 - GB - 726 - Poço de Proteção RoscadoThomasFrenchNo ratings yet

- Level 1 Business Process Id Level 1 Process Code L2 Process CodeDocument27 pagesLevel 1 Business Process Id Level 1 Process Code L2 Process CodeDebojyoti Chakraborty (IN)No ratings yet

- Instant Download Managerial Accounting Canadian 9th Edition Garrison Solutions Manual PDF Full ChapterDocument7 pagesInstant Download Managerial Accounting Canadian 9th Edition Garrison Solutions Manual PDF Full ChapterMarcusAndersonsftg100% (10)

- Dibrugarh AirportDocument30 pagesDibrugarh AirportRafikul RahemanNo ratings yet

- Demographics, Psychographics & Lifestyle SegmentationDocument28 pagesDemographics, Psychographics & Lifestyle SegmentationMard GeerNo ratings yet

- GENBUL - Next Generation Registration ProcessDocument2 pagesGENBUL - Next Generation Registration ProcessGailNo ratings yet

- CONTRACT TO SELL - CondominiumDocument6 pagesCONTRACT TO SELL - CondominiumJoshua AmancioNo ratings yet

- Sheela Foam LTD.: Issue Type: DebtDocument15 pagesSheela Foam LTD.: Issue Type: DebtIshaan DuaNo ratings yet

- Attachment 119-Environmental Aspects and ImpactDocument8 pagesAttachment 119-Environmental Aspects and Impactum erNo ratings yet

- Jsa HadeedDocument8 pagesJsa Hadeedproj.engr9No ratings yet

Activity 7.3 Tolerances: © 2012 Project Lead The Way, Inc. IED Activity 7.3 Tolerances - Page 1

Activity 7.3 Tolerances: © 2012 Project Lead The Way, Inc. IED Activity 7.3 Tolerances - Page 1

Uploaded by

CaBreon WiseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Activity 7.3 Tolerances: © 2012 Project Lead The Way, Inc. IED Activity 7.3 Tolerances - Page 1

Activity 7.3 Tolerances: © 2012 Project Lead The Way, Inc. IED Activity 7.3 Tolerances - Page 1

Uploaded by

CaBreon WiseCopyright:

Available Formats

Activity 7.

3 Tolerances Part 2

E

F

1. Consider the adjustable rocker arm represented in the drawing above. An axle is to pass through the

smallest hole (labeled “D”). The manufacturer is considering buying bar stock for the axle that is

manufactured according to the drawing below using the same general tolerances as those specified on

the Rocker Arm Drawing. Answer the following questions and SHOW YOUR WORK.

ROD LENGTH ROD DIAMETER

a. What is the tolerance (upper limit – lower limit) for the diameter of the rod?

b. What is the tolerance for the rod length? (Hint: Use the General Tolerance table in the

drawing.)

© 2012 Project Lead The Way, Inc.

IED Activity 7.3 Tolerances – Page 1

c. Is the fit between the rod and the hole (“D”) a clearance fit, interference fit, or transition fit?

Explain your answer.

d. What is the allowance (smallest hole – largest rod diameter) between the rod and the hole

(“D”)?

e. If the design of the assembled machine requires that the rod is sized such that the actual

clearance between the rod and the hole is never greater than 0.005 inches, will the current rod

design meet the requirement? Explain.

f. The machine specification requires that the rod is no longer than 3.025 inches and no shorter

than 2.955 in.

Let L represent the actual length of the rod. Write the length constraint as a compound

inequality. (compound inequality: lower limit ≤ L ≤ upper limit)

Will the stock rods always meet the length constraint? Explain.

g. If the stock rods do not always meet the machine specifications for rod length, how can the

manufacturer alter the rod part drawing such that the rod length will always conform to the

specifications?

2. Design a rod that will have an interference fit so that the allowance (the maximum interference) is

0.010 with the center hole in the Rocker Arm (labled “F”) and the tolerance on the rod diameter is .002.

Sketch a section view of your rod design below. Be sure to specify the tolerance in the diameter

dimension of your design.

© 2012 Project Lead The Way, Inc.

IED Activity 7.3 Tolerances – Page 2

Conclusion

1. Why do engineers place tolerances on dimensions?

3. What are the three types of tolerances that appear on dimensioned drawings?

4. What is the difference between a general and a specific tolerance, and how can you tell the

difference on a drawing?

© 2012 Project Lead The Way, Inc.

IED Activity 7.3 Tolerances – Page 3

You might also like

- Activity 2.1.1 Tolerate This!: Additional PracticeDocument4 pagesActivity 2.1.1 Tolerate This!: Additional PracticeOmkaar Sampigeadi0% (1)

- Draft Usance LC by Acceptance 60 Days 752 MPEDocument3 pagesDraft Usance LC by Acceptance 60 Days 752 MPEAdhitya Achmad100% (3)

- Manual of Engineering Drawing: British and International StandardsFrom EverandManual of Engineering Drawing: British and International StandardsRating: 3.5 out of 5 stars3.5/5 (4)

- 7.3.a TolerancesDocument5 pages7.3.a TolerancesKeegan SneadNo ratings yet

- CH 8 Palepu JW C PDFDocument14 pagesCH 8 Palepu JW C PDFcherry wineNo ratings yet

- Activity 7.3 Tolerances Part 2Document3 pagesActivity 7.3 Tolerances Part 2fenn shibuNo ratings yet

- 7 3 Atolerances Modified1Document4 pages7 3 Atolerances Modified1api-3319987910% (1)

- 7 3 Atolerances Modified1 1Document4 pages7 3 Atolerances Modified1 1api-339017928No ratings yet

- Ied 211 Tolerate This Additional Practice Answer KeyDocument5 pagesIed 211 Tolerate This Additional Practice Answer Key836616477No ratings yet

- GD T ExamplesDocument10 pagesGD T ExamplesJuan Posada GNo ratings yet

- Geometric Dimensioning 1Document36 pagesGeometric Dimensioning 1mohanNo ratings yet

- 2 - Tolerances&Fits (Wk2,3)Document8 pages2 - Tolerances&Fits (Wk2,3)franciseton115No ratings yet

- Chapter 12 Working DrawingDocument63 pagesChapter 12 Working DrawingBit RecordsNo ratings yet

- 1-Tolerances and FitsDocument45 pages1-Tolerances and FitsTt OwnsqqNo ratings yet

- M.S Ramaiah School of Advanced Studies: Postgraduate Engineering and Management Programme (PEMP)Document5 pagesM.S Ramaiah School of Advanced Studies: Postgraduate Engineering and Management Programme (PEMP)jibharatNo ratings yet

- Linear TolerancesDocument7 pagesLinear Tolerancesbrpnaidu2157No ratings yet

- Manufacturing TolerancesDocument13 pagesManufacturing TolerancesHarsh100% (1)

- Fundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, IndianDocument35 pagesFundamentals of Limits and Fits: Notes Prepared by Dr. Suhas S. Joshi, Department of Mechanical Engineering, Indianyair Enrique Romero OspinoNo ratings yet

- 20-7 S D S B: Eismic Esign of Lab RidgesDocument12 pages20-7 S D S B: Eismic Esign of Lab RidgesAngga Fajar SetiawanNo ratings yet

- AssemblyDocument50 pagesAssemblyhemanthogadeNo ratings yet

- FINAL Test Engineering - Design - 80 Points in Total-Which Count For 40% of Your Grade!Document14 pagesFINAL Test Engineering - Design - 80 Points in Total-Which Count For 40% of Your Grade!B NinhNo ratings yet

- Module 2Document14 pagesModule 2Reginald VelanoNo ratings yet

- Working Drawing-AssembledDocument78 pagesWorking Drawing-Assembledflorence mwakyusaNo ratings yet

- 20201019-Advanced Computer Aided ModellingDocument38 pages20201019-Advanced Computer Aided ModellingNaveena mNo ratings yet

- Chapter 8 Detail Drawing: Understanding & CreatingDocument80 pagesChapter 8 Detail Drawing: Understanding & CreatingMohsin JavedNo ratings yet

- 3.4.A LinearDimensionsDocument10 pages3.4.A LinearDimensionsitsmedd1No ratings yet

- True/False: Modern Steel Construction's Monthly Steel Buildings. Where Appropriate, OtherDocument2 pagesTrue/False: Modern Steel Construction's Monthly Steel Buildings. Where Appropriate, Otherfarru foruNo ratings yet

- 1 2 10 P Gliderdesign1Document6 pages1 2 10 P Gliderdesign1api-325609547No ratings yet

- Geometrical Dimensioning and TolerenceDocument61 pagesGeometrical Dimensioning and TolerenceAd Man GeTigNo ratings yet

- Module 03 - Tolerances and AllowancesDocument9 pagesModule 03 - Tolerances and AllowancesNeil Joshua LerinNo ratings yet

- 7.2.A SectionViewsDocument7 pages7.2.A SectionViewsKhemari EllisNo ratings yet

- Chapter 28Document17 pagesChapter 28Ghazala FarooqNo ratings yet

- prEN1993 1 8 06Document16 pagesprEN1993 1 8 06José CarlosNo ratings yet

- 4 Working DrawingDocument70 pages4 Working DrawingMohdRosmainiNo ratings yet

- PT - Lesson 13. Limits, Fits and ToleranceDocument9 pagesPT - Lesson 13. Limits, Fits and ToleranceAkash SinghNo ratings yet

- Steel Beam - Web OpenningDocument17 pagesSteel Beam - Web OpenningMadhurimaMitraNo ratings yet

- Cadcam - Rme701Document2 pagesCadcam - Rme701Pandit Animesh TripathiNo ratings yet

- Masjien Ontwerp 244: TekeningeDocument12 pagesMasjien Ontwerp 244: TekeningeIlghe van der MerweNo ratings yet

- Sleeve Bearing ClearanceDocument3 pagesSleeve Bearing ClearanceRian Jamaludin PogramNo ratings yet

- GD&T Shaft Clamp BracketDocument4 pagesGD&T Shaft Clamp Bracketmadhusudhan.bhumireddi0% (1)

- Design For Manufacturing ExamplesDocument13 pagesDesign For Manufacturing ExamplesVikash Singh100% (1)

- CEE 542 - Advanced Topics in Steel Design: Homework #4 Spring 2015 1 To 3 Person Assignment Due Date: Thursday March 12Document1 pageCEE 542 - Advanced Topics in Steel Design: Homework #4 Spring 2015 1 To 3 Person Assignment Due Date: Thursday March 12AbdiDamantaNo ratings yet

- Chapter 3 Coventional FastnersDocument37 pagesChapter 3 Coventional FastnersAtalelew ZeruNo ratings yet

- Fictiv GuidetoTightTolerances SmallDocument34 pagesFictiv GuidetoTightTolerances Smallmax mullNo ratings yet

- GD&T, Mechanical TolerancingDocument12 pagesGD&T, Mechanical TolerancingsandeshbhavsarNo ratings yet

- LEEA Correspondence Courses: Assignment 5.3 Total MarkDocument4 pagesLEEA Correspondence Courses: Assignment 5.3 Total MarkYAKUBU A. AROGENo ratings yet

- Model Answer Winter 2017Document22 pagesModel Answer Winter 2017jitesh mahadik100% (1)

- Limits Fits & ToleranceDocument30 pagesLimits Fits & ToleranceSrikanth SrikeeNo ratings yet

- Steel Structures-Lecture 4 PDFDocument15 pagesSteel Structures-Lecture 4 PDFAli FarooqNo ratings yet

- Limits Fits and TolerancesDocument42 pagesLimits Fits and Tolerances544 vishwavijay PatilNo ratings yet

- Limits Fits Tolerance Control SystemDocument19 pagesLimits Fits Tolerance Control SystemUjjwal kecNo ratings yet

- Detailing Corner 2008-2009Document26 pagesDetailing Corner 2008-2009Arden PoncioNo ratings yet

- CENG 5503 Chapter 2Document13 pagesCENG 5503 Chapter 2Getachew MekuriawNo ratings yet

- 2.1 Terms of Sizes: Unit 1 Limit and FitsDocument20 pages2.1 Terms of Sizes: Unit 1 Limit and FitsRamu VasaNo ratings yet

- Cable Trench DesignDocument74 pagesCable Trench DesignJANMESHNo ratings yet

- UEMX3333 Structural AnalysisDocument107 pagesUEMX3333 Structural AnalysisZin-E ShioNo ratings yet

- Computer Numerical Control: Standards For CADDocument14 pagesComputer Numerical Control: Standards For CADibraheemNo ratings yet

- ED7111Document117 pagesED7111palaniappan_pandianNo ratings yet

- List of The Technical QuestionDocument3 pagesList of The Technical QuestionMitul patelNo ratings yet

- Dimensioning Tolerances ProcessesDocument12 pagesDimensioning Tolerances ProcessespatrikcncNo ratings yet

- Autodesk Inventor 2019 For Beginners - Part 1 (Part Modeling)From EverandAutodesk Inventor 2019 For Beginners - Part 1 (Part Modeling)No ratings yet

- The First Meat Sector IPO CASEDocument3 pagesThe First Meat Sector IPO CASEabiraNo ratings yet

- Unnumbered 2022 174 Submission of ELECTION BIR FORM NO. 2316Document4 pagesUnnumbered 2022 174 Submission of ELECTION BIR FORM NO. 2316Albino GalgoNo ratings yet

- Dorks Target Netflix BY (@global™ - ™cracking )Document778 pagesDorks Target Netflix BY (@global™ - ™cracking )abdessamadzaher05No ratings yet

- FINANCIAL DERIVATIVES Unit - 1Document18 pagesFINANCIAL DERIVATIVES Unit - 1Neehasultana ShaikNo ratings yet

- Marine Policy: Steven W. Purcell, David H. Williamson, Poasi NgaluafeDocument8 pagesMarine Policy: Steven W. Purcell, David H. Williamson, Poasi NgaluafeCésar LevioNo ratings yet

- For Each Period, Calculate The Ratio of Each COQ Category To RevenuesDocument2 pagesFor Each Period, Calculate The Ratio of Each COQ Category To RevenuesElliot RichardNo ratings yet

- The Importance of Business EthicsDocument2 pagesThe Importance of Business EthicsKent AguilarNo ratings yet

- Frankart Global Xero Degrees Brand DeckDocument25 pagesFrankart Global Xero Degrees Brand DeckPradyut TiwariNo ratings yet

- Be17280324 17840043 FiDocument2 pagesBe17280324 17840043 FiJay WalkerNo ratings yet

- Analysis of Financial Statements Solved MCQs (Set-2)Document6 pagesAnalysis of Financial Statements Solved MCQs (Set-2)VenkataRamana IkkurthiNo ratings yet

- Corporate Securities Law Class Presentation 2 Topic-Hate Crimes Manvesh Vats Meaning of Corporate CrimesDocument6 pagesCorporate Securities Law Class Presentation 2 Topic-Hate Crimes Manvesh Vats Meaning of Corporate CrimesManvesh VatsNo ratings yet

- WWW Canadavisa Com Canadian Temporary Work Visa HTMLDocument6 pagesWWW Canadavisa Com Canadian Temporary Work Visa HTMLEric HazzardNo ratings yet

- BCIF - Ver9 With DPA and Bill Delivery Agreement - 02022022Document1 pageBCIF - Ver9 With DPA and Bill Delivery Agreement - 02022022Tegnap NehjNo ratings yet

- Qmethods & Manscie Prelim Transportation (Vam)Document13 pagesQmethods & Manscie Prelim Transportation (Vam)Dylan GutierrezNo ratings yet

- Banking & Economy PDF - January 2020 by AffairsCloud PDFDocument141 pagesBanking & Economy PDF - January 2020 by AffairsCloud PDFAjith DivakaranNo ratings yet

- Billing System Thesis DocumentationDocument6 pagesBilling System Thesis Documentationafkngwetd100% (2)

- SAP Certified Application Associate - SAP S - 4HANA Asset Management - Full - ERPPrep19Document34 pagesSAP Certified Application Associate - SAP S - 4HANA Asset Management - Full - ERPPrep19Budigi RajaekharNo ratings yet

- Sample Assignment - Strategic MarketingDocument9 pagesSample Assignment - Strategic MarketingPrimera700100% (1)

- DS - TW9515 - GB - 726 - Poço de Proteção RoscadoDocument3 pagesDS - TW9515 - GB - 726 - Poço de Proteção RoscadoThomasFrenchNo ratings yet

- Level 1 Business Process Id Level 1 Process Code L2 Process CodeDocument27 pagesLevel 1 Business Process Id Level 1 Process Code L2 Process CodeDebojyoti Chakraborty (IN)No ratings yet

- Instant Download Managerial Accounting Canadian 9th Edition Garrison Solutions Manual PDF Full ChapterDocument7 pagesInstant Download Managerial Accounting Canadian 9th Edition Garrison Solutions Manual PDF Full ChapterMarcusAndersonsftg100% (10)

- Dibrugarh AirportDocument30 pagesDibrugarh AirportRafikul RahemanNo ratings yet

- Demographics, Psychographics & Lifestyle SegmentationDocument28 pagesDemographics, Psychographics & Lifestyle SegmentationMard GeerNo ratings yet

- GENBUL - Next Generation Registration ProcessDocument2 pagesGENBUL - Next Generation Registration ProcessGailNo ratings yet

- CONTRACT TO SELL - CondominiumDocument6 pagesCONTRACT TO SELL - CondominiumJoshua AmancioNo ratings yet

- Sheela Foam LTD.: Issue Type: DebtDocument15 pagesSheela Foam LTD.: Issue Type: DebtIshaan DuaNo ratings yet

- Attachment 119-Environmental Aspects and ImpactDocument8 pagesAttachment 119-Environmental Aspects and Impactum erNo ratings yet

- Jsa HadeedDocument8 pagesJsa Hadeedproj.engr9No ratings yet