Professional Documents

Culture Documents

Combination Air Eliminator-Strainer: OVAL Corporation

Combination Air Eliminator-Strainer: OVAL Corporation

Uploaded by

Chuong DongOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Combination Air Eliminator-Strainer: OVAL Corporation

Combination Air Eliminator-Strainer: OVAL Corporation

Uploaded by

Chuong DongCopyright:

Available Formats

COMBINATION GENERAL SPECIFICATION

AIR ELIMINATOR-STRAINER

03 1 GS.No.GCCOO6-4-E

MODEL AE 04 2G

J 01 1

05 2

■ GENERAL

This device is an air release valve combined with a

strainer in a single housing and is intended to eliminate air

entrained in the liluid while preventing foreign solids from

getting into the meter, which could present a serious

problem.

By installing this device immediately upstream of the

meter, of as close to the inlet as possible, accurate and

precise flow measurements can be made.

■ GENERAL SPECIFICATIONS

The fact is that the greater the capacity of an air eliminator,

the greater the air eliminating capability. It is important

that the correct size and type are chosen.

Factors to be taken into consideration in the selection are

(1) application, (2) type of liquid, (3) flow rate, viscosity,

specific gravity, and (4) pressure:

1. Application

Elimination of small quantities of air introduced temporar-

ily during transfer between storage tanks, pumping to

lorries, process control, etc.

2. Liquid to be applied.

* Low viscosity products-gasoline, JP4, kerosene, water,

alcohol, etc. (below 2 mPa•S and having least tendency

to foam)

* High viscosity products-crude oil, light oil, heavy oil,

caustic soda, etc. (products having a tendency to

foam or products above 2 mPa•S) 7. Material:

3. Max. operating pressure: 0.97MPa Body-steel sheet (SS400) or stn. steel (SUS316)

4. Test pressure: 1.46MPa Vent valve-Float; stn. steel (SUS304, SUS316)

5. Max. operating temperature: 110˚C Body; stn. steel (SCS13A)

6. Flange rating: JIS 10K FF (STD.), JIS 10K RF Valve Seat; Teflon

ANSI 150 RF Net -stn. steel (SUS304 60mesh)

Models and Capacity

Max. Flowrate m3 /h Max. Venting Capacity Acceptable Max. Vent Valve Vent valve

Inlet & Outlet

Model Low Viscosity High Viscosity at Critical Vent Valve Sp. Gr. Operating Pressure type

Bore mm

Liquid Liquid Pressure m3 /n Range g /mL MPa

AE 2 G 0111

25. 40. 50 15 10 9 0.7~1.1 0.97 WS-III

AE 2 J 0121

■ OPERATING PRINCIPLE AND CONSTRUCTION

Elimination

Construction Operating Principle

/ Venting

(Air eliminator/strainer combination type)

Vent Rc1/2

Included air in the liquid is separated and collected in

Vent Valve

upper part of the strainer, and when it will reach the given

Gravity type/Self-venting

volume the liquid level is lowered.

Float Following the liquid level, float is lowered, release

valve is opened by linked float, and collected air is

Inlet exhausted out of the strainer.

Outlet

Strainer Net

OVAL Corporation http://www.oval.co.jp

Head Office: Tokyo; Tel. 81-3-3360-5121. Fax 81-3-3365-8605

Beijing Office: Tel., Fax. 86-10-6525-3601. Tel. 86-10-6513-3516

Overseas Branch Offices: Seoul, Singapore, Taipei. 1

■ PRESSURE DROP ■ DIMENSIONS

50

420

150mm2/s

40 1mm2/s

30 60

Pres. Drop

Bore 25mm

20

10 Bore 40mm Rc1/2 Vent Port

P Bore 50mm 300

kPa

0 5 10 15

Flowrate Q m3/h

247

216.3

■ MODEL CODE NUMBER Flow IN

567

120

OUT

AE 03 2 G 01 1 1

200

90

Operating pres.

Always 1 (Max. 0.97 MPa)

Operating Type & Vent Valve Material

l: Self-Venting: All stainless steel(SUS304)

Applicable to body material "G" Rc1 Drain Plug Unit in mm

2: Self-Venting: All stainless steel (SUS316)

Applicable to body material "J"

Model Capacity Always 01

Body Material: Inner

G: Carbon steel plate (SS400) Model Bore mm Mass kg Capacity L

J: Stainless steel (SUS316)

Type A E 0 3 2 G 1

J 0 1 21 25 42 15.5

2: Air- Eliminator / Strainer Combination Type

Bore mm (inch) A E 0 4 2 G 1

J 0 1 21 40 44 15.5

03: 25(1)

04: 40 (1 1/2) A E 0 5 2 J 0 1 1

G

21 50 48 15.5

05: 50 (2)

Air Eliminator

■ TYPICAL PIPING LAYOUT

V3 Bypass

Vent Line

Union Joint Space

Vent Tank Riser Head

Flowmeter

Direction of Flow

V1

V2

Combination A/S

To maintain the stated performance of your air eliminator the atmosphere, small quantities of petroleum prod-

throughout its service life, observe the following instruc- ucts or vaporized products contained in the discharged

tions: gas are hazardous. From a safety viewpoint, installing

1. Sequence of component installation-Install, from the a vent tank to collect the entrained products is sug-

inlet side, the air eliminator, strainer, and flowmeter, gested. (available upon request).

in this order. 5. Provide as long a straight pipe section as circum-

2. The basic unit must be installed vertically. stances permit ahead of the air eliminator. Avoid tur-

3. Air pressure inside the air eliminator must be higher bulence causing objects in the stream, e.g., partially

than the atmospheric pressure to effect venting. open valves. Gate valves are recommended.

To fill the flowmeter piping system with liquid, pro- 6. Control throughput with a valve V2 on the discharge

vide a riser pipe downstream of the meter. side of the flowmeter.

A riser head is not necessary in a case where a storage 7. When handling fluids which must be heated to pre-

tank is installed downstream of the meter and its tank vent solidification, throttle the flow through valve V2

head acts on the air eliminator. to maintain the temperature in the air eliminator

4. Vent tank installation-In the case the vent is open to above the melting point of the fluid.

The specification as of Feb., 2001 is stated in this GS Sheet. Specifications and design are subject to change without notice.

Sales Representative:

You might also like

- Technical Manual Premier 11222013Document86 pagesTechnical Manual Premier 11222013ChristieBrownNo ratings yet

- Operation Instructions For Duplex-Body Flow Meter SkidDocument21 pagesOperation Instructions For Duplex-Body Flow Meter SkidGeorge GuoNo ratings yet

- RCH +D + +F+¡ (+ ) PDFDocument38 pagesRCH +D + +F+¡ (+ ) PDFSyamil DzulfidaNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Asme Pvho-1Document14 pagesAsme Pvho-1luisarrien100% (1)

- BP Macondo Estimate 1Document99 pagesBP Macondo Estimate 1Simone Sebastian100% (1)

- Drilling Formulas Calculation Sheet Version 1.6Document252 pagesDrilling Formulas Calculation Sheet Version 1.6sharafudheen_s100% (2)

- Centrifugal Pumps: Process Calculation / Data SheetDocument3 pagesCentrifugal Pumps: Process Calculation / Data SheetMurali MuthuNo ratings yet

- Air Eliminator: Low Pressure ServiceDocument6 pagesAir Eliminator: Low Pressure Servicemr,jengNo ratings yet

- OVAL Corporation: Comblnatlon Alr Ellmlnator-StralnerDocument4 pagesOVAL Corporation: Comblnatlon Alr Ellmlnator-StralnerChuong DongNo ratings yet

- 28 - Ficha Tecnica ElectrovalvulaDocument12 pages28 - Ficha Tecnica ElectrovalvulaStephany Rueda YnocheaNo ratings yet

- Automatic Air Release Valve For Low PressureDocument2 pagesAutomatic Air Release Valve For Low PressuresijilNo ratings yet

- PRO Combination Air Valve For High Flow: DescriptionDocument4 pagesPRO Combination Air Valve For High Flow: DescriptionVanderson LimaNo ratings yet

- Trident Flow Controls - CatloughDocument2 pagesTrident Flow Controls - Catloughrupeshp1989No ratings yet

- Combination Air Valve For Wastewater: DescriptionDocument4 pagesCombination Air Valve For Wastewater: Descriptionhanumantha raoNo ratings yet

- CVS 1000L Electro-Pneumatic Linear Positioner: Product ManualDocument12 pagesCVS 1000L Electro-Pneumatic Linear Positioner: Product Manualmhidayat108No ratings yet

- Combination Air Valve For Wastewater: DescriptionDocument4 pagesCombination Air Valve For Wastewater: DescriptionVanderson LimaNo ratings yet

- Av010agr SPC 13Document2 pagesAv010agr SPC 13floresguevara987No ratings yet

- Intercooler (260 Engine)Document5 pagesIntercooler (260 Engine)Steven AmadorNo ratings yet

- AI236986444669en 001203Document17 pagesAI236986444669en 001203Gojek OkNo ratings yet

- Gas Filter Separators 4Document8 pagesGas Filter Separators 4Anonymous bHh1L1No ratings yet

- LPHX Serie 4500 SIHIDocument11 pagesLPHX Serie 4500 SIHIJorge FernandezNo ratings yet

- Sihi lphx45000Document12 pagesSihi lphx45000jarivillasNo ratings yet

- RNP Actuator Metso NewDocument11 pagesRNP Actuator Metso NewOGPE-AMC1No ratings yet

- Compressed Air Quality - RENNERDocument16 pagesCompressed Air Quality - RENNERAbrahamNdewingo100% (1)

- Mechanical Vacuum SystemsDocument17 pagesMechanical Vacuum Systemsصلاح الواديNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 743Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 743Francisco Mones RuizNo ratings yet

- Iiche Online Internship - 2020 Petroleum Refinery Engineering - Batch 1 Assignment 1 - White Paper 1Document3 pagesIiche Online Internship - 2020 Petroleum Refinery Engineering - Batch 1 Assignment 1 - White Paper 1Shivam Kumar RaiNo ratings yet

- D-050 D-050-C D-052: Combination Air ValveDocument6 pagesD-050 D-050-C D-052: Combination Air Valve7erick7No ratings yet

- Cedaspe Buchholz RelayDocument22 pagesCedaspe Buchholz RelayRichard Sy100% (2)

- 2way/2 - Part IDocument2 pages2way/2 - Part IYidel FloresNo ratings yet

- Instruction Manual: Portable Oil Purifier (Coalescer Type)Document4 pagesInstruction Manual: Portable Oil Purifier (Coalescer Type)truongtxNo ratings yet

- Related Products: Auto Drain Valve: PrecautionsDocument10 pagesRelated Products: Auto Drain Valve: Precautionsteknik otomotifNo ratings yet

- Series: Oil Sampling ValveDocument2 pagesSeries: Oil Sampling Valvemarran almarranyNo ratings yet

- TZ TZ Dryer 22135834Document8 pagesTZ TZ Dryer 22135834Емил ГавриловNo ratings yet

- Prepared By: Harish C Divya M Kartikagouda K Soumya R Poornima S Shweta L Sahana WDocument28 pagesPrepared By: Harish C Divya M Kartikagouda K Soumya R Poornima S Shweta L Sahana WHarish ChauhanNo ratings yet

- Ace CatalogueDocument8 pagesAce Catalogueosmanyildirim85No ratings yet

- Basic Pneumatic TrainingDocument68 pagesBasic Pneumatic TrainingquynhthomNo ratings yet

- D070Q Agr CatDocument4 pagesD070Q Agr CatRuben ManuelNo ratings yet

- Surface Facilities 2 STDocument155 pagesSurface Facilities 2 STI Made Wahyu WiratmajaNo ratings yet

- CE BasicDocument28 pagesCE Basicpapbtm btm100% (1)

- 2 Continental Hydraulics Directional Control Valves PDFDocument11 pages2 Continental Hydraulics Directional Control Valves PDFDaniel VillarroelNo ratings yet

- Energy-Saving Free Float Steam Trap: FeaturesDocument2 pagesEnergy-Saving Free Float Steam Trap: FeaturesSebastian AcevedoNo ratings yet

- PU LPH 80540 80553 Esite GBDocument7 pagesPU LPH 80540 80553 Esite GBAl-Alamiya TradeNo ratings yet

- En5922 6 - Db16621e 10Document2 pagesEn5922 6 - Db16621e 10markoNo ratings yet

- Regulator Iom EnglishDocument32 pagesRegulator Iom EnglishShaoranNo ratings yet

- DanfossDocument10 pagesDanfossconstantin balanNo ratings yet

- CKEB Full en Metric LetterDocument2 pagesCKEB Full en Metric LetterRafalNo ratings yet

- E) DSF1000 AlDocument5 pagesE) DSF1000 AlAgeng A. PooNo ratings yet

- AI236986444669 enDocument17 pagesAI236986444669 enAli GameelNo ratings yet

- 2DRE Technical CatalogueDocument20 pages2DRE Technical CatalogueLuis CaballeroNo ratings yet

- Accumulator Charging Valve: Spool Type, Direct-Acting UNF Cartridge - 350 BarDocument5 pagesAccumulator Charging Valve: Spool Type, Direct-Acting UNF Cartridge - 350 BarWandi Roma AriyantoNo ratings yet

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- 1.5DRE - Technical CatalogueDocument16 pages1.5DRE - Technical CatalogueBsaltda GestionNo ratings yet

- 2DRE - Technical CatalogueDocument20 pages2DRE - Technical CatalogueBsaltda GestionNo ratings yet

- DMBF Full en Metric LetterDocument4 pagesDMBF Full en Metric LetterRonaldNo ratings yet

- 13 - SRK S-PlatformDocument46 pages13 - SRK S-PlatformLassané KINDONo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting: Type 744Document4 pages3/2-Way Solenoid Valve, Direct-Acting: Type 744Francisco Mones RuizNo ratings yet

- Buchholz Relays EB Series: The Most Popular Buchholz Relay For Oil-Immersed Power TransformersDocument20 pagesBuchholz Relays EB Series: The Most Popular Buchholz Relay For Oil-Immersed Power TransformersbharathNo ratings yet

- Be106-01 NDVDocument6 pagesBe106-01 NDVcodoik_050No ratings yet

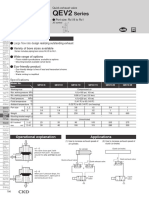

- QEV2 Series Specifications・How to Order・Dimensions (0.2MB)Document4 pagesQEV2 Series Specifications・How to Order・Dimensions (0.2MB)renanta_adiyasNo ratings yet

- Katalog SIHI Liquid Ring Vacuum PumpsDocument12 pagesKatalog SIHI Liquid Ring Vacuum PumpsTrisna RamadhanNo ratings yet

- IM en 8 260 110 F68V F68YDocument2 pagesIM en 8 260 110 F68V F68Y2m8vzmsz5qNo ratings yet

- Deno Start Air Compressor Manual L2-28Document70 pagesDeno Start Air Compressor Manual L2-28Дмитрий КовтунNo ratings yet

- How To Check The Calibration of Cooling Fan Airflows: PyroprocessingDocument2 pagesHow To Check The Calibration of Cooling Fan Airflows: Pyroprocessingrupesh soniNo ratings yet

- Assignment Brief and GuidanceDocument5 pagesAssignment Brief and GuidanceKhanur AysahNo ratings yet

- Dryer Pressure Rating: Technical White Paper SeriesDocument10 pagesDryer Pressure Rating: Technical White Paper SeriesnitantharaniNo ratings yet

- Momentum Equation and Its Applications: Dr. Khalil Mahmoud ALASTALDocument42 pagesMomentum Equation and Its Applications: Dr. Khalil Mahmoud ALASTALManicks VelanNo ratings yet

- Engineering Handbook Spray NozzlesDocument40 pagesEngineering Handbook Spray NozzlesWalter Rigamonti100% (2)

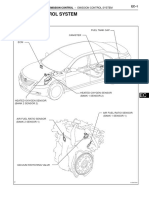

- Emission Control System: Parts LocationDocument23 pagesEmission Control System: Parts LocationNassar Al-EssawiNo ratings yet

- Activity 4Document4 pagesActivity 4Misael Camposano100% (1)

- Boiler AnalysisDocument11 pagesBoiler Analysisnageswara raoNo ratings yet

- Design Support Software: Charge and Discharge To/from Tank Calculation SoftwareDocument1 pageDesign Support Software: Charge and Discharge To/from Tank Calculation SoftwaremooninjaNo ratings yet

- Water PropertiesDocument4 pagesWater Propertiesaw_aeNo ratings yet

- Black Oil DefinitionsDocument21 pagesBlack Oil Definitionsmanish.7417No ratings yet

- Cortec, VpCI-371 Application GuideDocument2 pagesCortec, VpCI-371 Application Guidemonserrat PereaNo ratings yet

- Igcse Physics RevisionDocument44 pagesIgcse Physics Revisionlozzzzz88% (17)

- Irrigation Engineering and Hydraulic Structure Santosh Kumar GargDocument165 pagesIrrigation Engineering and Hydraulic Structure Santosh Kumar GargAnand RatnaNo ratings yet

- Unsw Mechanical Thesis DatabaseDocument8 pagesUnsw Mechanical Thesis Databaserobynchampagnemanchester100% (2)

- A796 Practice For Structural Design of Corrugated Steel Pipe, Pipe-Arches, and Arches For Storm and Sanitary ....Document20 pagesA796 Practice For Structural Design of Corrugated Steel Pipe, Pipe-Arches, and Arches For Storm and Sanitary ....Franco Saenz SolisNo ratings yet

- Fluid Machines and HYdraulic MachinesDocument106 pagesFluid Machines and HYdraulic Machinesvamsi krishnaNo ratings yet

- 2008 02 An Investigation Into The Impact of Changing From K0 and K1 Values To API IP Standard Values Stewart Kelton Engineering LTD PDFDocument11 pages2008 02 An Investigation Into The Impact of Changing From K0 and K1 Values To API IP Standard Values Stewart Kelton Engineering LTD PDFAmilkar Kindelan GonzalezNo ratings yet

- Pressure MeasurementDocument37 pagesPressure MeasurementSaumya GoelNo ratings yet

- Presion de Vapor Del ClorometanoDocument2 pagesPresion de Vapor Del ClorometanoSandra MilenaNo ratings yet

- Surface Tension PDFDocument17 pagesSurface Tension PDFsandeep08051988No ratings yet

- 7-1. Maintenance StandardDocument36 pages7-1. Maintenance StandardYamilaNo ratings yet

- 2006.02 Motor Toyota EVAP-Non-Intrusive SystemDocument3 pages2006.02 Motor Toyota EVAP-Non-Intrusive SystemMNo ratings yet

- Variation of Pressure With Depth in A Fluid - Advance Engineering Mathematics ReviewDocument2 pagesVariation of Pressure With Depth in A Fluid - Advance Engineering Mathematics ReviewimrancenakkNo ratings yet

- FMDS0128Document103 pagesFMDS0128Suneesh PNo ratings yet