Professional Documents

Culture Documents

3

3

Uploaded by

Venkatesha Hebbar0 ratings0% found this document useful (0 votes)

25 views4 pages2222

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document2222

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

25 views4 pages3

3

Uploaded by

Venkatesha Hebbar2222

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

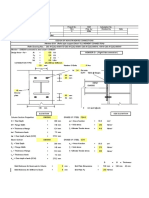

1. 300 m3 Settling Tank x 6Nos.

2. 500m3 Settling Tank x 2nos.

3. 430 m3 Settling Tank x 6Nos.

ITEM DESCRIPTION UNITS REQUIRED OFFERED

1. GENERAL DATA

As per

PE19EF006QA-

RFQ_Site_Fabricat

1.1 Site Conditions - ed_Storage_ To be inspected

Tanks_Package-1

(Requisition No-

GT19101900)

1.2 Number of tanks - 6/2/6 6/2/6

1.3 Interior / Exterior - Exterior Exterior

1.4 KKS numbers - Not mentioned ------

1.5 Type - Site tank Site Tank

Outdoor built at

1.6 Installation - Outdoor

site

PRODUCED PRODUCED

1.7 Service - WATER WATER

2. DESIGN DATA

PRODUCED PRODUCED

2.1 Fluid

WATER WATER

2.2 Net Working Capacity m³ 300 / 500 / 430 ~300 / 500 / 430

350 / 575 / 510 ~350 / ~575 /

2.3 Maximum Capacity

(TBC) ~510

Steel

2.4 mm TBC

structure

NA(Internal NA(Internal

2.5 Shell mm

Corrosion Coating) Coating)

Allowances Roof & NA(Internal NA(Internal

2.6 mm

Structure Coating) Coating)

Bottom NA(Internal NA(Internal

2.7 mm

Plate Coating) Coating)

2.8 Roof kN/m² To be Specified To be Specified

2.9 Live Loads Platforms kN/m² To be Specified To be Specified

2.10 Stairs kN/m² To be Specified To be Specified

2.11 Design Tank API 650 API 650

2.12 Standard Vents API 2000 API 2000

2.13 Material

Pressure

2.14 barg Atmospheric Atmospheric

Min amb: 7 °C, Min amb 7 Deg

Temperature

2.15 °C design 60 °C C, Design 60 Deg

C

2.16 Dynamic Viscosity P 0.46 – 1.3 0.46 – 1.3

2.17 Internal Diameter m 6.5 / 8.0 / 7.5 6.5 / 8.0 / 7.5

9000 / 9000 / 9000 / 9000 / 9000

2.18 Height (Straight) mm

9000

To be confirmed To be confirmed

2.19 Height (total) mm

after Design Cal. after Design Cal.

Not mentioned To be confirmed

2.20 Shell mm

after Design Cal

Not mentioned To be confirmed

2.21 Thickness Roof mm

after Design Cal

Not mentioned To be confirmed

2.22 Base mm

after Design Cal

2.23 Roof type - Fixed Roof (Cone) Fixed Roof (Cone)

Not mentioned To be confirmed

2.24 Roof radius mm

after Design Cal

Siphon Drain (D) Yes

2.25 Draw-Off sump

mentioned

2.26 X-rays inspection Not mentioned TBD

2.27 Penetrating liquids inspection Not mentioned TBD

2.28 Foundation type Not mentioned Client Scope

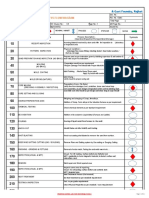

3. TECHNICAL FEATURE

3.1 Pumping rates

322.0 / 513.0 /

3.1.1 Pumping rate IN m³/h Excluded

438.0

3.1.2 Pumping Rate OUT m³/h 81.0 / 81.0 / 81.0

3.1.3 Maximum velocity IN m/s Not mentioned

3.1.4 Maximum velocity OUT m/s Not mentioned

3.2 Joints

3.2.1 Bottom Plates Joint Type - Not mentioned TBD

3.3 Anchor Bolts

3.3.1 Material Not mentioned Excluded

3.3.2 Quantity Not mentioned Excluded

DN /

3.3.3 Size Not mentioned Excluded

Length

3.4 Firefighting Ring

3.4.1 Yes / NO - NO NO

3.4.2 Qty / Ring C.L Diam - / mm Not applicable

3.4.3 Nominal diam / Sch Not applicable

3.4.4 Type of Sparge Nozzles Not applicable

3.4.5 Number of Sparge Nozzles Not applicable

4. AUXILIARY EQUIPMENT

Yes - See Data Sheet

Tag Nos. 12-13-14-

T-4XX1A/B

Fittings, Nozzles and

4.1 Tag No. 31-T- Yes

Fittings 4XX1A/B

Tag Nos. 22-23-24-T-

4XX1A/B

4.1.1 Inside pipes to the bottom Yes - See Data Sheet Yes

for any filling line Tag Nos. 12-13-14-

T-4XX1A/B

Tag No. 31-T-

4XX1A/B

Tag Nos. 22-23-24-

T-4XX1A/B

Yes - See Data Sheet

Tag Nos. 12-13-14-

T-4XX1A/B

4.2 Vents Tag No. 31-T-

4XX1A/B

Tag Nos. 22-23-24-T-

4XX1A/B

Yes - See Data Sheet

Tag Nos. 12-13-14-

T-4XX1A/B

4.3 Manhole (with davit) Tag No. 31-T-

4XX1A/B

Tag Nos. 22-23-24-

T-4XX1A/B

To be confirmed

4.4 Design Plates Not mentioned

after Design Cal.

4.5 Cathodic Protection Not Required Excluded

Lugs, brackets for earth

4.6 connection (earth net by Yes Yes

others)

Overpressure / Vacuum

4.7 Not mentioned Not considered

valve

mmH2

4.7.1 Max Over pressure Not mentioned To be considered

O

4.7.2 Max Depression Not mentioned To be considered

5 SCOPE

5.1 Mechanical Scope

Nozzles of equipment or

terminal points of pipes at

5.1.1 Not mentioned Excluded

the limit of the skid in the

case of packaged systems

Platforms, stairs, ladders

5.1.2 Ladder Ladder is included

and other steel structures

Piping supports at tank

5.1.3 Not mentioned TBD

shell

As per PE19EF006QA-

RFQ_Site_Fabricated_Sto

5.1.4 Painting rage_ Tanks_Package-1 Not in Scope

(Requisition No-

GT19101900)

5.2 Electrical scope

3 lugs every 120º and the

5.2.1 possibility to install - Not in Scope Not in Scope

arrestors

5.3 Services scope

5.3.1 Project management Not in Scope Not in Scope

5.3.2 Engineering Yes Yes

5.3.3 Quality assurance Not in Scope Not in Scope

5.3.4 Factory/shop tests Not in Scope Not in Scope

5.3.5 Packing Not in Scope Not in Scope

5.3.6 Guarantees

Legalization of

5.3.7 project/installation with Not in Scope Not in Scope

local authority

5.4 Site services/works scope

5.4.1 Erection supervision Not in Scope Not in Scope

Commissioning and start-

5.4.2 Not in Scope Not in Scope

up supervision

5.4.3 Complete erection works Not in Scope Not in Scope

Complete commissioning

5.4.4 Not in Scope Not in Scope

and start-up works

5.4.5 Site tests Not in Scope Not in Scope

Training for operation

5.4.6 Not in Scope Not in Scope

staff

5.5 Spare parts/consumables/special tool scope

Special tools required for

5.5.1 operation and maintenance Not in Scope Not in Scope

of the equipment supplied

Spare parts for 2 years of

5.5.2 Not in Scope Not in Scope

operation

First filling of

5.5.3 Not in Scope Not in Scope

lubricants/chemicals

6 Guarantees

Maximum Velocity –

6.1 Not in Scope Not in Scope

In/Out

6.2 No Leakage through Joints Not in Scope Not in Scope

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- A Requiem To Mother EarthDocument5 pagesA Requiem To Mother EarthSandra SabuNo ratings yet

- Moment Connection Beam Column Is Bs Section For Is800Document27 pagesMoment Connection Beam Column Is Bs Section For Is800Ramesh SelvarajNo ratings yet

- STANDARD 20' or 20' GP or 20' DVDocument2 pagesSTANDARD 20' or 20' GP or 20' DVVenkatesha HebbarNo ratings yet

- Kleiberit PUR 501 - FISPQDocument8 pagesKleiberit PUR 501 - FISPQYuri SouzaNo ratings yet

- Leg Support Calculation PDFDocument2 pagesLeg Support Calculation PDFSanjay MoreNo ratings yet

- CyclophosphamideDocument7 pagesCyclophosphamideFrances Ramos33% (3)

- MC Case PDFDocument20 pagesMC Case PDFShivani KarkeraNo ratings yet

- Scanned by CamscannerDocument25 pagesScanned by CamscannerVenkatesha HebbarNo ratings yet

- Air Pollution Control Equipments: (Design, Manufacture & Commissioning)Document11 pagesAir Pollution Control Equipments: (Design, Manufacture & Commissioning)Venkatesha HebbarNo ratings yet

- Beam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesDocument13 pagesBeam Splice Design: 1 Input Data: 1.1 Section and Section PropertiesVenkatesha Hebbar100% (1)

- Load Input File: CHKD VRH Appd VRH Date 13-SEPT-2019Document31 pagesLoad Input File: CHKD VRH Appd VRH Date 13-SEPT-2019Venkatesha HebbarNo ratings yet

- (Logistics Team) PDO Oilfield Transport & Interior Based Vehicle SpecificationsDocument22 pages(Logistics Team) PDO Oilfield Transport & Interior Based Vehicle SpecificationsVenkatesha HebbarNo ratings yet

- Air BlastersDocument3 pagesAir BlastersVenkatesha HebbarNo ratings yet

- XssDocument16 pagesXssVenkatesha HebbarNo ratings yet

- Crane Rail Fixing StandardsDocument5 pagesCrane Rail Fixing StandardsVenkatesha HebbarNo ratings yet

- Specification and Tender Schedule For Various Types of Repair of ConcreteDocument58 pagesSpecification and Tender Schedule For Various Types of Repair of ConcreteVenkatesha HebbarNo ratings yet

- Water Proofing StandardsDocument33 pagesWater Proofing StandardsVenkatesha Hebbar100% (2)

- Excel Anchor Bolt CalculatorDocument2 pagesExcel Anchor Bolt Calculatorラディチャ ドハルマワングサNo ratings yet

- Methods of Water ProofingDocument5 pagesMethods of Water ProofingVenkatesha HebbarNo ratings yet

- Geometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALDocument67 pagesGeometry - Olympiad Material BY DR SHYAM SUNDAR AGRAWALdrssagrawalNo ratings yet

- Data Transformation by Andy FieldDocument1 pageData Transformation by Andy FieldGon MartNo ratings yet

- English3 Q2 Mod2 TensesOfTheVerb V3Document33 pagesEnglish3 Q2 Mod2 TensesOfTheVerb V3Johanna Zandra MariaNo ratings yet

- Inbound 7104382368239826711Document51 pagesInbound 7104382368239826711katNo ratings yet

- Abb Reg615 Ansi Appl 859072 EndDocument124 pagesAbb Reg615 Ansi Appl 859072 EndjppreciadomNo ratings yet

- 02 Flyer Beverly LR enDocument2 pages02 Flyer Beverly LR enluisgabrielbuca2246No ratings yet

- LTE TDD - Network - Export - 2018 - 07 - 04Document3,760 pagesLTE TDD - Network - Export - 2018 - 07 - 04saadNo ratings yet

- Manual Epson L555Document92 pagesManual Epson L555Asesorias Académicas En CaliNo ratings yet

- UVU Jungle Marathon 2012 BookDocument41 pagesUVU Jungle Marathon 2012 BookGerhard FlatzNo ratings yet

- BSD-GL-HAL-HMS-100 - (Terms & Definitions)Document42 pagesBSD-GL-HAL-HMS-100 - (Terms & Definitions)Eduard GadzhievNo ratings yet

- Peniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Document3 pagesPeniel Integrated Christian Academy of Rizal, Inc. Science Weblinks GRADE 4 S.Y. 2020-2021Jhocen Grace GanironNo ratings yet

- 1 Kawasaki FSDocument16 pages1 Kawasaki FSmatgoffNo ratings yet

- Process SequenceDocument2 pagesProcess SequenceUmesh SakhareliyaNo ratings yet

- Grammar 04 18Document5 pagesGrammar 04 18zsuzsi_harangoz2218No ratings yet

- Koch - Control ChartsDocument40 pagesKoch - Control ChartsAkash MarathakamNo ratings yet

- Minireview: C-Reactive ProteinDocument4 pagesMinireview: C-Reactive ProteinFernando Amblódegui GarcíaNo ratings yet

- HDR10+ System Whitepaper: September 4, 2019 HDR10+ Technologies, LLCDocument14 pagesHDR10+ System Whitepaper: September 4, 2019 HDR10+ Technologies, LLCDragomir ConstantinNo ratings yet

- KDIGO CKD MBD Quick Reference Guide June 2022Document11 pagesKDIGO CKD MBD Quick Reference Guide June 2022Esy LNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)

- MCQ - AcousticsDocument16 pagesMCQ - AcousticsRomeo Espenida0% (1)

- Synchronous Generators: Instructional ObjectivesDocument18 pagesSynchronous Generators: Instructional Objectivessanthosh2009No ratings yet

- Cobra XRS9690Document45 pagesCobra XRS9690marwan71No ratings yet

- Biology Investigatory Project: Malaria: Its Effects and CausesDocument17 pagesBiology Investigatory Project: Malaria: Its Effects and CausesRishi KeshavNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- Bored Piles - Bilfinger Spezialtiefbau GMBHDocument4 pagesBored Piles - Bilfinger Spezialtiefbau GMBHOga MeoNo ratings yet