Professional Documents

Culture Documents

A. Lecoanet, D. G. Ivey, H. Henein Department of Chemical & Materials Engineering, University of Alberta, Edmonton, AB, Canada

A. Lecoanet, D. G. Ivey, H. Henein Department of Chemical & Materials Engineering, University of Alberta, Edmonton, AB, Canada

Uploaded by

claralisieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A. Lecoanet, D. G. Ivey, H. Henein Department of Chemical & Materials Engineering, University of Alberta, Edmonton, AB, Canada

A. Lecoanet, D. G. Ivey, H. Henein Department of Chemical & Materials Engineering, University of Alberta, Edmonton, AB, Canada

Uploaded by

claralisieCopyright:

Available Formats

Simulation of Temperature Profile During Welding with

COMSOL Multiphysics® Using Rosenthal’s Approach

A. Lecoanet, D. G. Ivey, H. Henein

Department of Chemical & Materials Engineering, University of Alberta, Edmonton, AB, Canada

Introduction

The goal is to find a quick and efficient way to simulate the thermal profile during welding. An approach close to Rosenthal’s one [1] is utilized. After validation of the first results the

possibility to go beyond the scope of Rosenthal’s results is investigated.

The main equation is the heat transfer equation:

The highlighted term does not exist in the equations

Computational Methods

𝜕𝑇 provided by the heat transfer in solids COMSOL module.

𝛻 𝑘𝛻𝑇 + 𝑄 = 𝜌𝐶𝑝 (1) So the weak form of the first order term in this module has

𝜕𝑡 No volumetric been tuned:

sources; k

and Cp are -ht.rho*ht.Cp*(ht.ux*Tx+ht.uy*Ty+ht.uz*Tz)*test(T)

2

𝜌𝐶𝑝 𝜕𝑇

𝛻 𝑇= (2) constants

𝑘 𝜕𝑡

Change of

coordinate -ht.rho*ht.Cp* (ht.ux*Tx+v*Tx+ht.uy*Ty+ht.uz*Tz)*test(T)

system: X=x-vt 𝜌𝐶𝑝 𝜕𝑇 𝜕𝑇

𝛻2𝑇 = −𝑣 (3)

𝑘 𝜕𝑡 𝜕𝑋 Steady-state A convective heat flux is applied on all boundaries Figure 1: Geometry used in this

assumed in this except where the source is applied. The source is study.

coordinate system applied as an entering flux.

𝑣𝜌𝐶𝑝 𝜕𝑇 The geometry used is shown in Figure 1.

𝛻2𝑇 + = 0 (4)

𝑘 𝜕𝑋

RESULTS

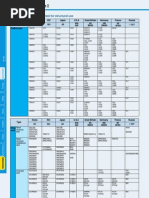

Point source Hemispherical source

Rosenthal reproduction

Figure 2a: Thermal profile. Figure 2b: Absolute relative Figure 3a: Thermal profile. Figure 3b: Absolute relative

Point source. difference with Rosenthal with a Source applied on a hemisphere. difference with Rosenthal.

reduced color scale. Source applied on a hemisphere.

Maximum observed Improvements due to the

Hemisphere radius hemispherical source:

The features occurring because of point source: absolute relative

(m) • The results are closer to Rosenthal

• Results close to Rosenthal’s results for most of the domain error

(Figure 3a)

• Temperature below the initial one (Figure 2a) 1x10-2 78.86%

• No temperature below the initial one

• Large discrepancies with Rosenthal close to the source 1x10-3 14.5%

1x10-4 11.17% (Figure 3a) (Figure 3b)

(Figure 2b)

• Easier post processing

1x10-5 25.86%

Table 1: Maximum absolute relative Also the relevance of the use of a

error observed for several hemisphere hemispherical source depends on its

radii. radius. Table 1 shows the evolution of

the error when the radius of the

hemisphere is changed.

Variation of k and Cp with temperature Two sources

Beyond Rosenthal

Figure 4a: Thermal profile. Figure 4b: Absolute relative Figure 5a: Thermal profile. Two Figure 5b: Absolute relative

Source applied on a hemisphere. difference with Rosenthal for k sources applied on a hemisphere. difference with the analytical

k and Cp are functions of and Cp functions of the k and Cp kept constant. model. Two sources applied on a

temperature. temperature. Same color scale hemisphere. k and Cp are kept

as Figure 3b. constant.

As a first approximation to take into account the variation of k and Cp with temperature, The difference between the numerical model and the superposition of two Rosenthal’s

Equation 4 is used, but k and Cp are considered as functions of temperature. solutions is bounded by 18%. Therefore the idea of superposing two Rosenthal’s solutions

Large discrepancies are observed compared with Rosenthal, which means that the seems valid. This still needs to be compared with experimental data.

variations in k and Cp with temperature have a significant effect on the thermal profile.

The data used come from the work of Nart and Celik [2].

Conclusions Acknowledgements

• It is possible to reproduce Rosenthal’s results accurately with COMSOL The authors are grateful to the Natural Sciences and Engineering Research Council

• Applying the source on the surface of a hemisphere is the best way to do so (NSERC) of Canada and to the following companies for providing research funding:

• Variations of k and Cp with temperature have a significant effect on the thermal profile Evraz Inc. NA, TansCanada Pipelines Ltd., Enbridge Pipelines Inc., UT quality Inc.

• A numerical and analytical way to simulate two sources welding have been proposed and Alliance Pipeline Ltd. Valuable discussions with Dr. J. Mmbaga are also

acknowledged.

References:

1. Rosenthal D., The theory of moving sources of heat and its application to metal treatments, Trans A.S.M.E., 68, 849-866 (1946)

2. Nart, E. and Celik, Y., A practical approach for simulating submerged arc welding process using FE method, Journal Of Constructional Steel Research, 84, 62-71(2013)

Excerpt from the Proceedings of the 2014 COMSOL Conference in Boston

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Modeling Rubber and Viscoelasticity With AbaqusDocument408 pagesModeling Rubber and Viscoelasticity With Abaqusrnizioł100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- NACA Airfoil Optimization: Created in COMSOL Multiphysics 5.3aDocument5 pagesNACA Airfoil Optimization: Created in COMSOL Multiphysics 5.3aclaralisieNo ratings yet

- Control HNC MANUAL DE PROGRAMACIONDocument144 pagesControl HNC MANUAL DE PROGRAMACIONSaul Fernando Cujaban AceroNo ratings yet

- Geometry of Packaging ProjectDocument10 pagesGeometry of Packaging ProjectSkye Jaba0% (1)

- Unit Weight of AggregatesDocument5 pagesUnit Weight of AggregatesMayolites50% (4)

- Circular Motion LabDocument4 pagesCircular Motion LabJasdeepSinghNo ratings yet

- Devolatilization Characteristics of Large Particles of Tyre Rubber Under Combustion Conditions PDFDocument11 pagesDevolatilization Characteristics of Large Particles of Tyre Rubber Under Combustion Conditions PDFclaralisieNo ratings yet

- How To Do Structural and Thermal Analysis of Disc Brake Rotor Using Ansys Software - GrabCAD TutorialsDocument1 pageHow To Do Structural and Thermal Analysis of Disc Brake Rotor Using Ansys Software - GrabCAD TutorialsclaralisieNo ratings yet

- Experimental Flow Field Characteristics of OFA For Large-Angle Counter Flow of Fuel-Rich Jet Combustion TechnologyDocument9 pagesExperimental Flow Field Characteristics of OFA For Large-Angle Counter Flow of Fuel-Rich Jet Combustion TechnologyclaralisieNo ratings yet

- H SO Catalysis: Perspective & Opportunities For Reducing SO EmissionsDocument16 pagesH SO Catalysis: Perspective & Opportunities For Reducing SO EmissionsclaralisieNo ratings yet

- Study of A Full Scale Oxy-Fuel Cement Rotary Kiln PDFDocument10 pagesStudy of A Full Scale Oxy-Fuel Cement Rotary Kiln PDFclaralisieNo ratings yet

- Review of Aeroelasticity For Wind Turbine Current Status, Research Focus and Future PerspectivesDocument16 pagesReview of Aeroelasticity For Wind Turbine Current Status, Research Focus and Future PerspectivesclaralisieNo ratings yet

- Adaptive Robust Control of A Class of Non Affine Variable Spee 2016 ISA TranDocument9 pagesAdaptive Robust Control of A Class of Non Affine Variable Spee 2016 ISA TranclaralisieNo ratings yet

- A Cost and Performance Comparison of LRTM and VI For The Manu 2011 RenewableDocument6 pagesA Cost and Performance Comparison of LRTM and VI For The Manu 2011 RenewableclaralisieNo ratings yet

- Advanced Control Algorithms For Reduction of Wind Turbine 2015 Renewable enDocument14 pagesAdvanced Control Algorithms For Reduction of Wind Turbine 2015 Renewable enclaralisieNo ratings yet

- Effect of Ethanol-Gasoline Blends On Engine Performance PDFDocument7 pagesEffect of Ethanol-Gasoline Blends On Engine Performance PDFclaralisieNo ratings yet

- A Boundary Integral Equation Over The Thin Ro 2016 Engineering Analysis WithDocument7 pagesA Boundary Integral Equation Over The Thin Ro 2016 Engineering Analysis WithclaralisieNo ratings yet

- A CFD Analysis of The Operating Conditions of A Multitube PD Membrane Prification H2Document1 pageA CFD Analysis of The Operating Conditions of A Multitube PD Membrane Prification H2claralisieNo ratings yet

- Energy Policy: Jing Geng, Yonglong Lu, Tieyu Wang, John P. Giesy, Chunli ChenDocument11 pagesEnergy Policy: Jing Geng, Yonglong Lu, Tieyu Wang, John P. Giesy, Chunli ChenclaralisieNo ratings yet

- Lube Oil Consumption Simulation Validation and Parametric InvestigationDocument11 pagesLube Oil Consumption Simulation Validation and Parametric InvestigationclaralisieNo ratings yet

- Modelagem em CFDDocument7 pagesModelagem em CFDclaralisieNo ratings yet

- FHSC1014 Mechanics 201701 L 1Document52 pagesFHSC1014 Mechanics 201701 L 1Sky ChinNo ratings yet

- M-412-066 T4000 Users Manual English Rev ADocument18 pagesM-412-066 T4000 Users Manual English Rev Ajimbo1978100% (1)

- Brochure Speedmaster XL 75 en PDFDocument26 pagesBrochure Speedmaster XL 75 en PDFFarid Mawardi100% (1)

- FEACrack TutorialDocument14 pagesFEACrack Tutorialknulp74No ratings yet

- Prelim Exam Draw 213 Alther A. DabonDocument3 pagesPrelim Exam Draw 213 Alther A. DabonAlther DabonNo ratings yet

- Choke E Series MasterFloDocument14 pagesChoke E Series MasterFloianherzogNo ratings yet

- The Water Permeability of Concrete and Its Relationship With StrengthDocument9 pagesThe Water Permeability of Concrete and Its Relationship With StrengthReny AkmaliaNo ratings yet

- Modul Kawalan KebisinganDocument66 pagesModul Kawalan KebisinganHafiz Sabri100% (1)

- Physics Test - Form 4 Work, Energy, Power, Machines, EfficiencyDocument2 pagesPhysics Test - Form 4 Work, Energy, Power, Machines, EfficiencysuzembartonNo ratings yet

- (Astm D790 03Document14 pages(Astm D790 03Eduardo SNNo ratings yet

- LevinDocument6 pagesLevinRavikumaar RayalaNo ratings yet

- Einstein's DreamDocument8 pagesEinstein's DreamEarleen Del Rosario0% (1)

- MHD StudySheetDocument12 pagesMHD StudySheetAndrew GuarendiNo ratings yet

- Darwin - The Next Million Years (How To Kill Off Excess Population) (1953)Document201 pagesDarwin - The Next Million Years (How To Kill Off Excess Population) (1953)uncleretro92% (13)

- Ceramic Matrix CompositeDocument10 pagesCeramic Matrix CompositeMohammed KhalidNo ratings yet

- Ag12062 Mro PG Uk WebDocument78 pagesAg12062 Mro PG Uk WebsanjeevNo ratings yet

- Industrial Visit 3Document3 pagesIndustrial Visit 3rutvikNo ratings yet

- Installation, Wiring, Operation Manual: C E R T I F I E DDocument38 pagesInstallation, Wiring, Operation Manual: C E R T I F I E DkmpoulosNo ratings yet

- Comparación B73.1 Vs ISO 5199Document2 pagesComparación B73.1 Vs ISO 5199AlvialvarezNo ratings yet

- Theoretical and Experimental Contactless Eddy Current Braking SystemDocument3 pagesTheoretical and Experimental Contactless Eddy Current Braking SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 1 Aircraft Navigation PDFDocument3 pages1 Aircraft Navigation PDFMuizzuddin Rosli0% (1)

- Multiple Steady StateDocument29 pagesMultiple Steady StateSerly AnggrainiNo ratings yet

- Trashrack DesignDocument12 pagesTrashrack DesignAnonymous b9DIaPTq6BNo ratings yet

- Technical BookDocument37 pagesTechnical BookDariusNeculcia100% (2)

- Catálogo ElectrodosDocument110 pagesCatálogo ElectrodosCamilo González VargasNo ratings yet