Professional Documents

Culture Documents

Technical Note Standards For Plaster Finish

Technical Note Standards For Plaster Finish

Uploaded by

kimberly solisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Note Standards For Plaster Finish

Technical Note Standards For Plaster Finish

Uploaded by

kimberly solisCopyright:

Available Formats

completely smooth and true surface finish.

Painting will tend to reveal any

inherent surface irregularities. These minor imperfections will be

highlighted when gloss or semi-gloss paints are used, particularly where the

plasterwork is subjected to intense of shallow lighting.

Therefore, these types of paints and lighting require additional measures to

be taken. Otherwise the consequential minor irregularities will have to be

accepted.’

Standards for plaster finish In addition to flatness of a plastered surface there is also a standard of

smooth finish is defined in BS EN 13914-2 and these are described as Levels

1 to 4:

Comments on installation of plastering need reference points from which to

measure judgments: Where there are no specifications on the project for the drylining and

plastering, BS EN 13914-2 recommends that if the level of smoothness is

BS EN 13914-2:2005 Design, preparation and application of external not specified Level 1 should be assumed.

rendering and internal plastering. Design considerations and essential

principles for internal plastering. This Code of practice provides guidance on

the flatness of plaster finish, application, design and inspection of plaster

systems.

Other standards that should be used when considering standards for a

plaster skim finish:

Where there is glancing illumination, additional measures will be required

• BS EN 13964-2014 is the recently published current definitive and this should be specified.

standard for the manufacture and installation of suspended

systems. The natural glancing light, such as from full height windows, should be

• BS 8212 1995 Code of practice for Drylining and Partitioning known by a main contractor/designer and therefore consideration to this

using Gypsum Plasterboard and BS 8000 Part 8 1994 should be made and included in a specification. It is known that the general

Workmanship on building sites - Code of practice for level of illumination will have a critical effect on the appearance of the

plasterboard partitions & linings & BS 5234-1 1992 Partitions finished plaster surface and therefore the temporary lighting conditions on

(including matching linings)- Part 1 Code of practice for design site during application of the plaster should simulate the same or higher

and installation, are the current definitive standards for the lighting conditions produced by the final permanent installation.

installation of drylining systems.

The angle of illumination will also accentuate minor imperfections and the

The flatness of the plastered finish will depend on the accuracy to which the direction of the supplementary lighting should also be adjustable.

background has been constructed and the thickness of the plaster specified.

Thinner applications of plaster such as 2mm skim coats will only overcome BS EN 13914-2 states that contract documentation should specify if the final

minor irregularities or small deviations from the line of the background. In lighting of any surface is to fall at glancing angles. The main

general, no tolerance can be laid down for a skim coat plaster since this will contractor/designer would be fully aware of any onerous natural lighting.

closely follow the contour of the background. It is imperative that the The BS goes on to state that in situations under glancing light this would

accuracy and tolerances of the background to the plastered surfaces is consist of working under special conditions.

given special attention.

When inspecting the quality of the finished plaster, BS EN 13914 -2 advises

Where there are no specific enhanced tolerances are specified; it would be that works should be inspected for acceptance from positions normally

standard practice to use the tolerances stated for the drylining and ceiling used in adjacent areas. This is normally from an entrance doorway and from

specification and in BS 8212 and BS EN 13964 as the standard to be the centre of a room in a domestic house and from about 2m away from the

achieved for the skim. e.g. This would allow the finished face of a partition surface in larger areas.

to be installed within a BS 8212 deviation band of 10mm (+/- 5mm).

Decorator’s preparatory work Surfaces should be cleaned of all dirt, dust,

It is essential that the contractor establishes a benchmark for the quality of plaster splashes and other foreign matter. Minor defects such as pinholes,

finish which can be referred to throughout the contract. paper scuffs and damage should be made good and all stopping and filling

carried out. Where movement has disturbed the original stopping

In Chapter 1.2 the NHBC standards ‘A consistent approach to finishes’ it treatment of screws and nails, additional preparatory work should be

states that wall and ceiling finishes shall have an appropriate appearance carried out in accordance with the recommendations of BS 6150. The need

and surfaces should be reasonably uniform, although there may be minor for this additional preparatory work may not become evident until after the

textural differences around lights and other fittings. It goes on to state that application of the first coat of decoration.

jointing tapes should be fully covered and not obtrusive in the finished wall

or ceiling surface. Under the section ‘Other surfaces and finishes’ the NHBC Where surfaces are re-painted locally after any snagging, this can result in

refer to inspecting works from 2m and not be shinning artificial light onto patterns in the paint finish. Re painting the entire surface after snagging can

the surface. Wall lights and up lights should also be switched off. potentially eliminate this and provide a more consistent finish.

BS EN 13914-2 goes on to state that ‘Whatever the plastering system and FIS offers an independent advisory service which reports on site issues

finish and however skilled and conscientious the operative, plastering is a including plaster finishes https://www.thefis.org/membership-

craft and it should be appreciated that it is not possible to achieve a hub/memberbenefits/fis-advisory-service/

Technical note Standards for plaster finish

Page 1 of 1

You might also like

- Ce Este Arta Proiect La EnglezăDocument16 pagesCe Este Arta Proiect La EnglezăSAMURAYNo ratings yet

- Ga 214 96Document4 pagesGa 214 96ptc2win4cahNo ratings yet

- f906 PDFDocument3 pagesf906 PDFαlιf GamersNo ratings yet

- ConRepair 04 JurcemNonshirk GP Ed01Document2 pagesConRepair 04 JurcemNonshirk GP Ed01Tuntun Tat0% (1)

- VOC Test Results of ABC Zemcoat SkimcoatDocument1 pageVOC Test Results of ABC Zemcoat SkimcoatRejoice SamboNo ratings yet

- Cs-Trident Hilton, GurugramDocument21 pagesCs-Trident Hilton, GurugramAsif Ahmed0% (1)

- The Analysis of Form, Symbol, and Sign: ConclusionDocument7 pagesThe Analysis of Form, Symbol, and Sign: Conclusionjuanp sazaNo ratings yet

- Roof Maintenance and InspectionDocument5 pagesRoof Maintenance and InspectionLawrence AsabaNo ratings yet

- Flooring ReportDocument4 pagesFlooring Reportn.k.indiaNo ratings yet

- Natsteel - Reinforcement BarsDocument12 pagesNatsteel - Reinforcement BarsJianhua WuNo ratings yet

- Brick ConquasDocument17 pagesBrick ConquasIs EastNo ratings yet

- Bathroom 3Document4 pagesBathroom 3mohdshahrircheabdulNo ratings yet

- PCG MS Wall Painting 30122022Document23 pagesPCG MS Wall Painting 30122022Muhammad Danang WijayaNo ratings yet

- Masterflex 700 GGDocument3 pagesMasterflex 700 GGHaresh BhavnaniNo ratings yet

- C672C672M 12 Scaling Resistance of Concrete Surfaces Exposed ToDocument3 pagesC672C672M 12 Scaling Resistance of Concrete Surfaces Exposed ToJamman Shahid ShiblyNo ratings yet

- Op-3-65. Checklist For Jack-In-Pile Supervision: Work Instructions For EngineersDocument4 pagesOp-3-65. Checklist For Jack-In-Pile Supervision: Work Instructions For Engineersjinwook75No ratings yet

- Altro WarrantyDocument5 pagesAltro WarrantyWorkmanCoNo ratings yet

- Sika Tiling System - Porcelain TilesDocument2 pagesSika Tiling System - Porcelain TilesElyse Kymberly Teoh100% (1)

- WHITE BOOK Full PublicationDocument573 pagesWHITE BOOK Full Publicationramonyk_003558No ratings yet

- Hebel MC v09.11Document12 pagesHebel MC v09.11subhaschandraNo ratings yet

- EIFSDocument55 pagesEIFSYazmin AvilaNo ratings yet

- 9 Painting WorksDocument5 pages9 Painting WorksNorazmiMohdNorNo ratings yet

- NCR RepairDocument4 pagesNCR RepairPanruti S SathiyavendhanNo ratings yet

- Uniform Building By-Laws 1984Document7 pagesUniform Building By-Laws 1984oioian0% (4)

- Method Statement Tile TrimDocument10 pagesMethod Statement Tile Trimfarooq ali khan100% (1)

- USG Boral FireStop - FA - 041217 - PH PDFDocument4 pagesUSG Boral FireStop - FA - 041217 - PH PDFridwanmdNo ratings yet

- Alwitra EVALASTIC Installation Manual 04 2016Document100 pagesAlwitra EVALASTIC Installation Manual 04 2016Dalia FathyNo ratings yet

- Concrete Masonry - Site Practice and Workmanship GuideDocument28 pagesConcrete Masonry - Site Practice and Workmanship GuideRey Eduard Q. UmelNo ratings yet

- Installation Guide DriLyner RF PDFDocument16 pagesInstallation Guide DriLyner RF PDFPandu WijayaNo ratings yet

- PCI - Precast Prestressed Concrete Parking StructuresDocument40 pagesPCI - Precast Prestressed Concrete Parking Structuresnap_carinoNo ratings yet

- Masterseal 620 TdsDocument3 pagesMasterseal 620 TdsNadeem Khan SelaniNo ratings yet

- Standing Seam Installation-23-11-21Document35 pagesStanding Seam Installation-23-11-21Gokulnath TgNo ratings yet

- Construction Method Statement For ApplicDocument5 pagesConstruction Method Statement For ApplicKhasan MustofaNo ratings yet

- Hebel Floor PlusDocument12 pagesHebel Floor PlusAbu100% (1)

- Cop On Access For External Maintenance 2021Document34 pagesCop On Access For External Maintenance 2021Ck ManNo ratings yet

- White Book C04 S11 Partitions Non Loadbearing Timber StudDocument17 pagesWhite Book C04 S11 Partitions Non Loadbearing Timber StudPavaloaie Marian ConstantinNo ratings yet

- GRCA Specification PDFDocument15 pagesGRCA Specification PDFrencydNo ratings yet

- Plaster Accessories - CatnicDocument52 pagesPlaster Accessories - CatnicRaed HaloubNo ratings yet

- Celotex BBA - Cavity WallsDocument12 pagesCelotex BBA - Cavity Wallsfaber1972No ratings yet

- Bca BE Permit FormDocument4 pagesBca BE Permit Formapsapsaps1988No ratings yet

- Work Method StatementDocument2 pagesWork Method StatementSetyawanNo ratings yet

- SDI - 130 - Standard Steel Doors and FramesDocument4 pagesSDI - 130 - Standard Steel Doors and FramesIsang BertingNo ratings yet

- Roller Shurter Door Maintenance 2021Document28 pagesRoller Shurter Door Maintenance 2021Abiodun IloriNo ratings yet

- 8.1 Fis em RebarDocument51 pages8.1 Fis em RebarJeyasingh GopalakrishnanNo ratings yet

- Pentens - Green Carpark SystemDocument20 pagesPentens - Green Carpark SystemJun QuanNo ratings yet

- TG20-13 Design Guide Draft BDocument198 pagesTG20-13 Design Guide Draft BimadNo ratings yet

- Temporary Works RegisterDocument2 pagesTemporary Works Registerrachel banfieldNo ratings yet

- Speed Deck 508: Metal Roof & Wall Cladding SystemDocument6 pagesSpeed Deck 508: Metal Roof & Wall Cladding SystemMuraleedharanNo ratings yet

- Qcs 2010 Section 5 Part 8 Transportation and Placing of ConcreteDocument7 pagesQcs 2010 Section 5 Part 8 Transportation and Placing of Concretebryanpastor106No ratings yet

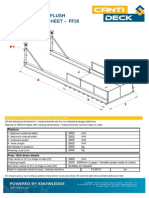

- FF35 CantiDeck Data SheetDocument1 pageFF35 CantiDeck Data SheetAndreas AntonopoulosNo ratings yet

- Autoclaved Aerated Concrete Blocks (Acc Blocks)Document3 pagesAutoclaved Aerated Concrete Blocks (Acc Blocks)Omar DaghistaniNo ratings yet

- Sika Tilling SystemsDocument32 pagesSika Tilling SystemsEduardo Rojas100% (1)

- Manual of Metal Roofing Sheet Roll Forming MachineDocument8 pagesManual of Metal Roofing Sheet Roll Forming Machinenovo orderNo ratings yet

- Guide To The Specification & Application of Screeds: The Resin Flooring AssociationDocument16 pagesGuide To The Specification & Application of Screeds: The Resin Flooring Associationmoizm53100% (1)

- MCT Sem 4 PanellingDocument22 pagesMCT Sem 4 PanellingKhushi ChauhanNo ratings yet

- 2395 1 PaintingDocument14 pages2395 1 Paintingmrraee4729No ratings yet

- IS2395 (Part1) :1994Document14 pagesIS2395 (Part1) :1994giriNo ratings yet

- Acceptable TolerancesDocument5 pagesAcceptable TolerancesAsmita DharkarNo ratings yet

- Ga 214 07Document4 pagesGa 214 07bender2000No ratings yet

- Eurogypsum Finshing Uk02Document12 pagesEurogypsum Finshing Uk02Chan Yong HongNo ratings yet

- Repair of Damages in Zinc LayersDocument4 pagesRepair of Damages in Zinc LayersBobNo ratings yet

- Levels of Finish2Document4 pagesLevels of Finish2John David SernatNo ratings yet

- Wall Level of FinishDocument4 pagesWall Level of FinishjavyusfNo ratings yet

- Sikawall®-181 Skimcoat: Product Data SheetDocument2 pagesSikawall®-181 Skimcoat: Product Data Sheetkimberly solisNo ratings yet

- Astm C151 (2002)Document2 pagesAstm C151 (2002)kimberly solisNo ratings yet

- Astm C109 (2005)Document5 pagesAstm C109 (2005)kimberly solisNo ratings yet

- Skills Matrix - Quality Assurance: NomineeDocument1 pageSkills Matrix - Quality Assurance: Nomineekimberly solisNo ratings yet

- Guidelines For Acceptance Sampling 052217 Rev. 0 PDFDocument10 pagesGuidelines For Acceptance Sampling 052217 Rev. 0 PDFkimberly solisNo ratings yet

- C 807 - 03, Qzgwny0wmwDocument3 pagesC 807 - 03, Qzgwny0wmwbasse123No ratings yet

- En 7410Document6 pagesEn 7410kimberly solis100% (1)

- 2019 Mir DC Seminar SchedDocument8 pages2019 Mir DC Seminar Schedkimberly solisNo ratings yet

- ReferencesDocument1 pageReferenceskimberly solisNo ratings yet

- The Generic CityDocument1 pageThe Generic CityKhalil BINo ratings yet

- Engineering Drawing by N.D BhattDocument738 pagesEngineering Drawing by N.D BhattJagadish90% (48)

- Visual Arts FAT Grade 5Document10 pagesVisual Arts FAT Grade 5Jerome FankomoNo ratings yet

- Rfi Check-List For Door ShuttersDocument1 pageRfi Check-List For Door ShuttersOmkar AdurkarNo ratings yet

- Arts Week 1Document3 pagesArts Week 1MIRANDA ANGELICANo ratings yet

- Art App PrelimsDocument8 pagesArt App PrelimsmkyxxNo ratings yet

- Introduction To Technical DrawingDocument41 pagesIntroduction To Technical Drawingnormanjames966No ratings yet

- 7 Lessons of Painting For ArchitectureDocument8 pages7 Lessons of Painting For ArchitectureviagensinterditasNo ratings yet

- Basic Technical Drawing: Grade 12Document109 pagesBasic Technical Drawing: Grade 12Gumball 8No ratings yet

- Image ArtifactsDocument33 pagesImage ArtifactsRichelle BrozoNo ratings yet

- Film Techniques ResourceDocument6 pagesFilm Techniques ResourceHelal YassineNo ratings yet

- National Museum of Fine ArtsDocument10 pagesNational Museum of Fine ArtsKrista Joy PetalioNo ratings yet

- Week 1-Techniques and Performance Practices Applied To Contemporary ArtDocument26 pagesWeek 1-Techniques and Performance Practices Applied To Contemporary ArtSharmine Ashley B. MarquezNo ratings yet

- Present Simple and ContinuousDocument3 pagesPresent Simple and ContinuousGabesz SzőcsNo ratings yet

- The Statue of Liberty Test PDFDocument2 pagesThe Statue of Liberty Test PDFTheint Thazin MaungNo ratings yet

- Softcopy 261 EN Robot Head Helmet With AntenneDocument17 pagesSoftcopy 261 EN Robot Head Helmet With AntenneMuchlas AkbarNo ratings yet

- HammerFlower GuideDocument2 pagesHammerFlower GuideCarmela VazquezNo ratings yet

- Book Review: "Van Gogh in Auvers: His Last Days" by Wouter Van Der Veen and Peter Knapp - Published by The Monacelli PressDocument3 pagesBook Review: "Van Gogh in Auvers: His Last Days" by Wouter Van Der Veen and Peter Knapp - Published by The Monacelli PressBill GuskyNo ratings yet

- Oscar Wilde - The Picture of Dorian Gray (Book 3) (EnglishOnlineClub - Com)Document71 pagesOscar Wilde - The Picture of Dorian Gray (Book 3) (EnglishOnlineClub - Com)omaima bourkhissiNo ratings yet

- Tle 6 Q3 PTDocument5 pagesTle 6 Q3 PTJUDYLAND YUNo ratings yet

- New Units Rates DerivationDocument29 pagesNew Units Rates DerivationJohn Henry OcampoNo ratings yet

- Historical BuildingsDocument25 pagesHistorical Buildingsaaron kangNo ratings yet

- Nationals Artist in PaintingDocument42 pagesNationals Artist in PaintingRachel EdquidNo ratings yet

- Celebrations - CarnivalDocument4 pagesCelebrations - CarnivalPio DorcoNo ratings yet

- Local Architecture: Why Study of Local Heritage Is ImportantDocument12 pagesLocal Architecture: Why Study of Local Heritage Is ImportantAK YadavNo ratings yet

- Module1 LeDocument43 pagesModule1 LePAOLO AGORILLANo ratings yet

- Art Coursework ExamplesDocument8 pagesArt Coursework Examplesmhzkehajd100% (2)