Professional Documents

Culture Documents

IIITM - Operations Management

IIITM - Operations Management

Uploaded by

Ishan KakkarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IIITM - Operations Management

IIITM - Operations Management

Uploaded by

Ishan KakkarCopyright:

Available Formats

Operations Management Concepts

&

their Application

(Operations Management)

By

Ishan Kakkar

(2019MBA-13)

April 13, 2020

2

Operations Management

Table of Contents

S No. Title Page No.

1. Concept of Lean 3

2. Concept of 5S 5

3. Concept of Kaizen 7

4. Concept of JIT 9

5. Concept of Waiting Line Management System 11

6. References 13

April 13, 2020

2

April 13, 2020

2

Operations Management

Concept of Lean

Organisation: Bank of Baroda (Sub-Process: Loan Processing)

Sector: Banking & Finance

Basic Process: A customer applying for a loan submits documents at the branch, basis his/her

requirements (amount-wise) relevant approvals are taken from 5 different

authorities in the entire process starting from branch manager, cluster manager

and going all the way up to general manager or deputy general manager. After

receiving the documents either in branch or online the documents are handed

over to the regional loan processing centre where the credit department performs

all types of verifications and checks are done and the loan is sanctioned.

Problem Statement: 1. Too many approvals even for a small amount, thus increasing the

overhead and turn-around-time (TAT).

2. Some branch employees found unaware of all key inputs & requirements

from the customer.

3. Documents requirement mismatch between branch and credit department

leading to reproaching the customer for additional documents or missed

out mandatory documents.

4. Erroneous mistakes resulting tremendous amount of rework.

5. Duplication of information in multiple reports by various departments.

6. ‘Blame & Shame’ culture when deviations & delays are reported.

7. Silo operation of stakeholder department leading to departmental

conflicts and rivalries instead of customer satisfaction.

Concept: Lean operations are best business practices that minimize time of task,

inventories on hand, supplies, and work-related instructions and steps in order to

create desirable products and/or services that satisfy or exceed customer’s

expectations and producers’ profitability goals.

Lean Solution: 1. Do the right work:

Instead of doing things simply because ‘they were always done that way’,

there is more focus on activities that create legitimate value and all tasks

are tailored to reduce unnecessary steps.

The bank reduced the number of approvals required for a loan by

increasing the limit for the 1st tier (increasing the limit from 25 lac to 50

lacs for initial approval) and maintaining the total number of approval

levels to three or below.

2. Do the work right:

Employees are well trained and have easy access to vital information.

Bank’s customer facing staff should have easy access to key inputs,

documentation and procedures required to carry out their activities

efficiently and in a standardized manner across all touch points. For this

the bank setup an intranet-based knowledge hub where all vital

information is available in the system.

3. Know the Customer:

Employees have a clear understanding of what their internal customers

want and only deliver what is required, when it is required.

The bank introduced a standard system-based checklist where branches

ensure all mandatory documents and required information is sent in the

exact manner required by the credit evaluation team..

April 13, 2020

3

April 13, 2020

2

Operations Management

4. Flow:

Tasks are aligned in the best possible sequence and value flows without,

rework, back flow or duplication. When the right information is sent,

there is no rework, resulting in smooth process flow.

The bank implemented system-based validation & controls (‘mistake

proofing’) to prevent staff from erroneously missing mandatory

documents.

5. Full Visibility to Work Status:

Dashboards are used to provide visibility to the status of work and who is

doing what and by when it should be delivered.

The bank implemented a centrally accessible dashboard that can be used

to view the status of all files (loans) reducing possible duplication of

information in multiple reports created by different stakeholder

departments.

6. Spirit of Teamwork and Respect:

No ‘blame and shame’ culture. Problems are blamed on processes and

systems and not people. Leaders support and empower staff to

continuously improve their areas of work.

The bank brought in an approach shift on dealing with problems, if there

are delays in receiving approvals, the process is reviewed to identify and

address key bottlenecks and SLAs are implemented and monitored to

ensure adherence to set targets.

7. Assigned ownership for each job:

Every process has an owner who is responsible and accountable and has

authority to ensure successful timely implementation.

The bank implemented the concept of process owner rather than

department heads whereby all relevant departments worked for the

process rather than their own departments ensuring adherence to highest

customer standards.

8. Continuous Improvement:

Improvement is considered to be a continuous process.

The bank has mandated weekly process meets to identify key stress

points.

Conclusion: Thus, by using the concepts of lean the PSU bank (Bank of Baroda) was able to

streamline their operations & increase their operational efficiency.

April 13, 2020

4

April 13, 2020

2

Operations Management

Concept of 5S

Organization: Container Corporation of India Ltd. (CONCOR) (Sub-Process: Inland Container

Depot (Dry Port), Whitefield, Bengaluru)

Sector: Logistics (Cargo Carrier, Terminal Operator, Warehouse Operator)

Basic Process: An initiative by the Indian Railways, to containerise cargo transport in India a

subsidiary to develop & handle Inland Container Depots (ICD) called CONCOR

was established with the objective of handling intermodal freight container. The

first ISO Container was moved by railways in 1981 at Bengaluru ICD. Their

process includes warehousing, connection with other hubs as well as cargo

management.

Problem Statement: 1. Sub-par warehousing process whereby arrangement of containers &

container tracking was inefficient.

2. Erroneous vendor/customer management whereby documentation &

verification problems were persistent.

3. Lack of visibility within the processes due to absence of detailed Standard

operating Procedures (SOPs) and minimal co-relation with other

processes.

4. Cost Management issues whereby the approach to calculate container and

warehouse charges were obsolete.

5. Disruptive unity of command since information flow was abrupt & there

were coordination issues between management & employees.

6. Improper job role definition.

Concept: A technique that originated from Japan, for organizing spaces so work can be

performed efficiently, effectively, and safely. This system focuses on putting

everything where it belongs and keeping the workplace clean, which makes it

easier for people to do their jobs without wasting time or risking injury.

Sort (Seri)

Set in Order (Seiton)

Shine (Seiso)

Standardize (Seiketsu)

Sustain (Shitsukue)

5S Solution: 1. Sort (Seri)

Identified the core in-depth breakdown of process which are required

(Gate Operations, Container Tracking, Weighment, Seal Cutting,

Examination, Survey, etc).

2. Set in order (Seiton)

Step by step ordering of the interrelated process (Gate In, Examination,

Weighment In, Offloading /Loading, Weighment Out, Gate Out, etc).

3. Shine (Seiso)

Shine in this case stand of maintenance of machine or equipment (Cargo

loading /offloading cranes, fork lifts etc).

4. Standardize(Seiketsu)

Creating standard operating procedures to conduct the particular task

(Process documents, Process flow diagrams, User Manuals).

April 13, 2020

5

April 13, 2020

2

Operations Management

5. Sustain (Shitsuke)

To sustain in this competitive market is one of the challenges that

CONCOR took very seriously, for this reason they opted to get the

customized ERP solution that helps them to maintain their position in the

market and capture as much as possible through effective system-based

inventory management, tracking etc.

Conclusion: The 5S implementation helped them attain the following:

Proper warehousing and container or cargo management.

Broader visibility of the scope.

Transparency between the processes.

Establishment of unity of command (Common decision making).

Proper vendor/customer management.

Right set of people at right place.

April 13, 2020

6

April 13, 2020

2

Operations Management

Concept of Kaizen

Organization: Honda Motor Company Ltd.

Sector Automotive

Basic Process: The process here implies the assembly line manufacturing process employed by

Honda to manufacture various models of their cars.

Problem Statement: Honda at first started with a fixed-factory type of factory associated with the

idealized (American) style of mass production. But due to constant upgrade of

their models along with introduction of new models as well as the need for rapid

model changeover in tandem with customer demands.

Other problems/limitations included:

Dedicated machinery for a single model

Major investment cost for new model (factory changes imminent)

Longer shutdown period (Due to factory changes)

Tedious and tough redeployment of human resources

Capacity balancing across plants is difficult (difficult to shift production

in a geographic region)

Concept of Kaizen: Kaizen stands for continuous improvement. Honda adapted this Kaizen concept

into an indigenously developed manufacturing system known as the Flexi-

Factory Manufacturing System.

Kaizen Solution: A flexi-factory (improved) is a factory capable of changing the product it makes,

with relative ease, at low cost and great rapidity: whether changing production

volumes, changing models or changing the nature of the products made

metamorphosizing the fixed factory & facilitating rapid model changeover as

well as mixed model production. Basically, a flexi factory is a modular factory

that can be retooled on the go to manufacture a different product (In Honda’s

case a car model) by changing the machine parts without any drastic changes.

A Kaizen based flexi-factory allowed Honda to:

1. Switch from making one model to starting with an entirely different

model.

2. Minimally (Zero Shutdown factory) to incorporate new model.

3. Loose minimal production while retooling the factory.

4. Made it possible to batch produce the model.

5. Eliminated the need for redeployment of human resources, since a

change in factory hardware allowed same employees to continue

manufacturing without disruption or requirements for any additional skill

development training.

6. Adapt to product change over a long term.

7. Balance of Models required to maintain market flexibility.

8. Operated as a network to balance their capacities. (Ex. Shifting

production in a region)

Even the flexi model had its limitations & to address the customers’ demands of

additional customization Honda once again adapted to incorporate a new method

of manufacturing called Agile Manufacturing (3d Printing manufacturing). Agile

manufacturing as the ability to successfully market low-cost, high-quality

products with short lead times (and in varying volumes) that provide enhanced

customer value through customization

April 13, 2020

7

April 13, 2020

2

Operations Management

Agility refers to the ability to respond quickly to customer needs and market

changes while still controlling costs and quality.

Enriching the customer

Cooperating to enhance competitiveness

Organizing to master change and uncertainty.

Leveraging the impact of people and information

Conclusion: The kaizen based improved flexi factory and then further augmentation through

agile manufacturing allowed Honda to:

Small to big: flexible, optimization of designs.

Rapid tooling with additive manufacturing cuts the steps, cuts the time.

Fast customization via 3d printing.

Validation and advanced measurement on demand.

Real world functional testing: Discovering what works

April 13, 2020

8

April 13, 2020

2

Operations Management

Concept of JIT

Organization: Dell Technologies Inc.

Sector: Original Equipment Manufacturer (PC)

Basic Process (Pre- Dell receives various PC components from a varied range of manufacturers,

JIT): assemble them into their designed platforms and sell it through distributors &

retailers to end-users (consumers)

Problem Statement: This traditional manufacturing process led to the following problems for dell &

limited Dell’s revenue:

Addition of time & cost due to distributors & retailers.

Inability to offer customized solutions (hardware).

Difficulty in keeping up with rapidly changing technology.

Huge inventory turn-over time.

Unreliable Cash Conversion Cycle

Inaccurate demand forecasts.

Component depreciation due to high inventory.

Concept of JIT: Just in Time Manufacturing (JIT) refers to a system of manufacturing in which

products are not built until the product is ordered and paid for. It is a methodology

aimed primarily at reducing times within the production system as well as

response times from suppliers and to customers. Its origin and development was

mainly in Japan, largely in the 1960s and 1970s and particularly at Toyota.

JIT Solution: Dell was one of the first companies in the OEM business to adopt JIT & direct

sales approach in order to provide better customized and cost-effective offerings

to its customers.

1. Dell changed its approach of manufacturing equipment on a predefined

platform to that of an order to build platform.

2. Whereby customers had the freedom to choose various internal

components of a system as per their needs.

3. Dell eliminated distributors & retailers and started selling directly through

its website (direct sales model)

4. Order was placed for components of their systems when customers placed

and order on their website.

5. For high-tech components like processors & software Dell relies on big

players like intel & Microsoft respectively.

6. While for low-tech components they rely on multiple vendors who

compete on price & availability.

7. Turn-over-time reduced since systems are made in a configure & order

fashion thus eliminating the need to store input components thus also

reducing the cost of inventory storage.

8. Another problem of depreciation of components was eliminated since low

inventory meant quick switch to new improved feature rich components

thus reducing further overhead for Dell.

9. Customer satisfaction also peaked due to offering of a customized price-

effective solution by Dell.

April 13, 2020

9

April 13, 2020

2

Operations Management

Conclusion: The application of JIT & direct sales approach enabled Dell to:

1. Maintain a negative cash conversion cycle (customer paid before

manufacturing).

2. This meant dell had an interest free financing method whereby they were

paid before they had to pay suppliers & service providers.

3. They had humongous reduction of costs on their inventory.

4. They had the flexibility to switch over to newer components quickly.

5. Due to Dell’s configure to order approach they are able to forecast more

accurately as compared to their competitors.

6. Direct sales enabled manifold increase in their revenues.

April 13, 2020

10

April 13, 2020

2

Operations Management

Concept of Waiting-Line-Management (Queue Management)

Organization: Vodafone UK

Sector: Telecom (Service)

Basic Process: Customers of Vodafone UK visit its stores to attain various services such as bill

payments etc., purchase new connection or handsets, resolve some queries and

some other service-related tasks. Also, Vodafone employees try cross-selling

products while customers visit their stores.

Problem Statement: Vodafone UK faced the following problems while entertaining the customers

visiting their stores:

Overall low customer satisfaction levels.

Stagnant sales of new connections and low upgrades of existing

connections.

Disruptively high utilization of other support channels like call centres

etc.

High cost of sale at stores leading to low profit margins.

Lower productivity & transactions

Higher support costs

Inefficient resource deployment.

While performing a root cause analysis the Vodafone UK management found

that one of the primary causes was a lack of Waiting-line control at the store

level and other causes included non-automation of commodity purchase

transactions.

Concept of Waiting- A queue management system or a waiting-line management system is used to

line management: control queues. Queues of people form in various situations and locations in a

queue area. The process of queue formation and propagation is defined as

queuing theory. Queueing theory is the mathematical study of waiting lines, or

queues. A queueing model is constructed so that queue lengths and waiting time

can be predicted. Queueing theory is generally considered a branch of operations

research because the results are often used when making business decisions

about the resources needed to provide a service.

Waiting-line As Fujitsu already had a long-standing relationship with Vodafone it was a

Management System natural partner to develop its new technology requirements. Fujitsu’s deployment

Solution: and ongoing management of Q-MATIC, the world leading solution for queue

management was just the solution Vodafone needed. Utilising touch-screen

technology, Q-MATIC leads the customer through a set of questions to identify

their in-store requirements. They are then given a ticket and allocated to a

service queue, so that an appropriate Vodafone sales advisor or a service

representative can serve them accordingly. A client terminal application allows

store employees to call their next customer, add notes next to each enquiry or

move it to another service desk, and can also be used to access customer queuing

status and monitor store throughput.

The in-store services from Fujitsu are enabling Vodafone to:

Improve the customer experience – Customers now have more time to

browse the store and choose how to purchase, so everyone benefits from

faster and more efficient service, in a more relaxed atmosphere. This has

led to a considerable uplift in customer satisfaction.

April 13, 2020

11

April 13, 2020

2

Operations Management

Increase performance – Optimised stores outperform other stores.

Average new connection volumes have increased with average upgrade

volumes also increasing.

Minimise business disruption – Systems availability is enhanced, with a

substantial reduction in support calls and improvement in first time fixes,

increasing sales opportunities.

Maximise profit margins – Self-service significantly reduces the cost of

sale especially amongst core pre-pay customers.

Enhancement of productivity – Automation of commodity purchases

enables faster transaction times and frees up resources to help other

customers. The number of customers leaving stores without seeing an

advisor is also declining.

Reduce support costs – Tailoring services and removing duplicate effort

and resources has cut costs, while increasing the overall level of support

Optimise resource deployment – Increased management information,

such as customer numbers, waiting times and sales conversion figures, is

helping to track and measure the customer experience in-store and enable

staffing rosters to be prepared to reflect store and customer requirements.

Conclusion: The Q-MATIC offering by Fujitsu for Vodafone UK stores has completely

transformed the store operations of Vodafone thus leading to higher customer

satisfaction, sales & revenue.

April 13, 2020

12

April 13, 2020

2

Operations Management

References

1. Operations Management- William J. Stevenson 11th ed

2. Operations & Supply Chain Management- F. Robert Jacobs & Richard B. Chase 15th ed

3. Operations Management- Nigel Slack, Stuart Chambers & Robert Johnston 6th ed

4. How did Vodafone increase customer satisfaction? - Fujitsu Case Study

5. Honda's global flexi-factory network – Andrew Marr

6. Impact of just‐in‐time inventory systems on OEM suppliers – John Kros, S. Scott Nadler

7. Just-In-Time Inventory Management Strategy: An overview of Just-in-Time Inventory Management –

David Broyles, Jennifer Beims, James Franko & Michelle Bergmen

April 13, 2020

13

You might also like

- Clinical Applications of Digital Dental TechnologyDocument397 pagesClinical Applications of Digital Dental TechnologyTheo_96100% (1)

- Ebook Form and Force 2019 PDFDocument2,922 pagesEbook Form and Force 2019 PDFAndrea BarcelosNo ratings yet

- ch29 of Mikell P Groover: Principles of Modern Manufacturing, 5th EditionDocument2 pagesch29 of Mikell P Groover: Principles of Modern Manufacturing, 5th EditionLizzsel FranchesNo ratings yet

- Bank Management System V.BDocument73 pagesBank Management System V.B1990 rahul55% (31)

- Analysis of Credit Appraisal System at Bank of India: A Project Report OnDocument88 pagesAnalysis of Credit Appraisal System at Bank of India: A Project Report OnVelankani100% (1)

- Digital Locker Updated Report1Document43 pagesDigital Locker Updated Report1Monu Kumar Modi0% (1)

- Using Slic3r With The XYZprinting DaVinci 1.0Document6 pagesUsing Slic3r With The XYZprinting DaVinci 1.0anonymoose47150% (2)

- CADCAM PortfolioDocument5 pagesCADCAM PortfolioGuhan MNo ratings yet

- Semi FinalDocument25 pagesSemi FinalKirgestNo ratings yet

- Saurabh Final FinalDocument85 pagesSaurabh Final FinalMonu SinghNo ratings yet

- BA Training BRD RajDocument28 pagesBA Training BRD RajSathish CNo ratings yet

- Chapter One: 1.1 A Brief Introduction of The BankDocument10 pagesChapter One: 1.1 A Brief Introduction of The BankAnuj KarkiNo ratings yet

- Knowledge Management ProcessDocument7 pagesKnowledge Management Processketan156No ratings yet

- Mohammed Ashraf: ObjectiveDocument3 pagesMohammed Ashraf: ObjectiveAshraf KhamisaNo ratings yet

- HDFC BankDocument3 pagesHDFC Bankvictorious xtremeNo ratings yet

- © The Institute of Chartered Accountants of IndiaDocument154 pages© The Institute of Chartered Accountants of IndiaJattu TatiNo ratings yet

- New Age Banking and Auditing - It's Different: The Banking Sector Has Moved FromDocument4 pagesNew Age Banking and Auditing - It's Different: The Banking Sector Has Moved FromKarthik RajNo ratings yet

- Pengelolaan Keuangan Berbasis Web PT. Mutualplus Global Resources Cabang PontianakDocument10 pagesPengelolaan Keuangan Berbasis Web PT. Mutualplus Global Resources Cabang PontianakRizky IkaNo ratings yet

- Requirements Gathering GuidelinesDocument5 pagesRequirements Gathering GuidelinesBalasubrahmanyam100% (1)

- Bank Management SystemDocument26 pagesBank Management SystemsyedNo ratings yet

- Loan Syndication System - ICICI - Business Requirement DocumentDocument15 pagesLoan Syndication System - ICICI - Business Requirement DocumentLalatenduNo ratings yet

- Banking Operational BiDocument20 pagesBanking Operational Bisharas77No ratings yet

- Bank Management System V BDocument72 pagesBank Management System V BGokila GokilaNo ratings yet

- Management Information System: Prepared byDocument10 pagesManagement Information System: Prepared bysonalNo ratings yet

- Tree Chapter Loan SaxanDocument34 pagesTree Chapter Loan SaxanMohamed Ahmed AbdiNo ratings yet

- Asset Management - Executive - CopyDocument2 pagesAsset Management - Executive - Copysuman.roy23-25No ratings yet

- Asset Management - ExecutiveDocument2 pagesAsset Management - Executivesuman.roy23-25No ratings yet

- Receivables & PayableDocument122 pagesReceivables & Payablemanoj phadtareNo ratings yet

- Online Based Appraisal System For KCI Management ConsultantsDocument7 pagesOnline Based Appraisal System For KCI Management Consultantsrobbymalcolm18No ratings yet

- Discovery Phase DocumentDocument10 pagesDiscovery Phase DocumentVinod RaoNo ratings yet

- Final English DPR PraposalDocument24 pagesFinal English DPR PraposalAnand KumarNo ratings yet

- Organization Process of Premier Bank LimitedDocument11 pagesOrganization Process of Premier Bank Limitedsayemauvi7567No ratings yet

- BN 92 Internal Audit and IT Based MIS SystemDocument2 pagesBN 92 Internal Audit and IT Based MIS SystemAddisuNo ratings yet

- ISS OrientationDocument4 pagesISS OrientationMohammad Arifur RahmanNo ratings yet

- Business Intelligence in Banking IndustryDocument11 pagesBusiness Intelligence in Banking IndustryKrishna Bhaskar100% (1)

- Final Report Loan RecoveryDocument35 pagesFinal Report Loan RecoveryPriyadharsshini100% (1)

- Receivable Management With Ref To Sbi PDFDocument46 pagesReceivable Management With Ref To Sbi PDFSampada GovekarNo ratings yet

- 01 - Initial PagesDocument12 pages01 - Initial PagesPrabhakar TripathiNo ratings yet

- MBI Simplify Digitize Workshop ProcessDocument54 pagesMBI Simplify Digitize Workshop ProcessVictor HoNo ratings yet

- Group Ii - December 2022Document74 pagesGroup Ii - December 2022ANISH KAFLENo ratings yet

- KccaDocument8 pagesKccaHasahya BrianNo ratings yet

- Certificate: "Banking Operations Implementation"Document67 pagesCertificate: "Banking Operations Implementation"Mridul AgarwalNo ratings yet

- Yatin Suhas Gokhale: Email Id: Contact: (M) +91 9619719090Document4 pagesYatin Suhas Gokhale: Email Id: Contact: (M) +91 9619719090Yatin GokhaleNo ratings yet

- Suhaimi Chan Project Management Capstone Handwriting Conversion - VerificationDocument22 pagesSuhaimi Chan Project Management Capstone Handwriting Conversion - VerificationbbbeatxNo ratings yet

- NotesDocument8 pagesNotesniczNo ratings yet

- Study of Online Services Offered by BanksDocument34 pagesStudy of Online Services Offered by Bankssarvesh dhatrakNo ratings yet

- DMS BRD V1.0 Final PDFDocument18 pagesDMS BRD V1.0 Final PDFSUNDAR RAJANNo ratings yet

- 275-File Utama Naskah-1354-2-10-20210428Document10 pages275-File Utama Naskah-1354-2-10-20210428285Dila Eri AstiniNo ratings yet

- Ameya LakheDocument3 pagesAmeya Lakheameya lakheNo ratings yet

- Ashish Mishra BaDocument3 pagesAshish Mishra BaAwanish TiwariNo ratings yet

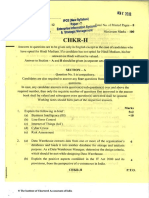

- Question No. 1 Is Compulsory. Answer Any Three Questions From The RestDocument14 pagesQuestion No. 1 Is Compulsory. Answer Any Three Questions From The RestGAURAV KHERANo ratings yet

- Lending Case StudyDocument7 pagesLending Case Studyanon_821676994No ratings yet

- DBMS ProjectDocument28 pagesDBMS ProjectNidhi HiranNo ratings yet

- Faisal Khan: IAM Business AnalystDocument3 pagesFaisal Khan: IAM Business AnalystAshwani kumarNo ratings yet

- S4H-BPD-FICO-Bank AccountingDocument22 pagesS4H-BPD-FICO-Bank AccountingPradeep Reddy FICONo ratings yet

- Facilities and Equipment Management System SLIDocument10 pagesFacilities and Equipment Management System SLINguyễn Đăng Anh TúNo ratings yet

- JD - DM InspectionDocument3 pagesJD - DM InspectionSubrat NandaNo ratings yet

- Suresh Gyan Vihar University: Department of Ceit SynopsisDocument8 pagesSuresh Gyan Vihar University: Department of Ceit SynopsisAbodh KumarNo ratings yet

- JD - Consumer Staff Finance Product Management (2021)Document3 pagesJD - Consumer Staff Finance Product Management (2021)arqumcNo ratings yet

- CMS Report 1Document101 pagesCMS Report 1Kamal PurohitNo ratings yet

- DIT 104 ICT Business Analysis AD Oct 21 PDFDocument8 pagesDIT 104 ICT Business Analysis AD Oct 21 PDFlahirudeshan.officialNo ratings yet

- Internal Audit ReportsDocument8 pagesInternal Audit ReportsRazaq RamadanNo ratings yet

- Intelligent Document Processing (IDP): A Comprehensive Guide to Streamlining Document ManagementFrom EverandIntelligent Document Processing (IDP): A Comprehensive Guide to Streamlining Document ManagementNo ratings yet

- Incident Management Process Guide For Information TechnologyFrom EverandIncident Management Process Guide For Information TechnologyNo ratings yet

- Honda Flexi Factory PDFDocument18 pagesHonda Flexi Factory PDFIshan KakkarNo ratings yet

- Amar Jyoti Trust - Marketing PlanDocument13 pagesAmar Jyoti Trust - Marketing PlanIshan KakkarNo ratings yet

- Assignment 3: Submitted ToDocument7 pagesAssignment 3: Submitted ToIshan KakkarNo ratings yet

- DM S2 Formulation ProblemsDocument3 pagesDM S2 Formulation ProblemsIshan KakkarNo ratings yet

- Assignment 1: (Decision Support System & Expert System)Document10 pagesAssignment 1: (Decision Support System & Expert System)Ishan KakkarNo ratings yet

- Year Geico Dividend Per Share in $ Total Dividend To Berkshire Hathaway in $ MillionDocument8 pagesYear Geico Dividend Per Share in $ Total Dividend To Berkshire Hathaway in $ MillionIshan KakkarNo ratings yet

- Creating The Guiding CoalitionDocument36 pagesCreating The Guiding CoalitionIshan KakkarNo ratings yet

- Diversity in OrganizationsDocument15 pagesDiversity in OrganizationsIshan KakkarNo ratings yet

- Emerging Technology For Engineering KMC202Document1 pageEmerging Technology For Engineering KMC202YashNo ratings yet

- MKT318m GlossaryDocument13 pagesMKT318m GlossaryPhan Dinh Tri (K17 HCM)No ratings yet

- Wa001Document6 pagesWa001Mandeep HaldarNo ratings yet

- Polygon Rendering MethodDocument11 pagesPolygon Rendering MethodRijas Rasheed0% (2)

- TMC - Metal 3D Printing HubDocument11 pagesTMC - Metal 3D Printing HubTHE METAL COMPANYNo ratings yet

- Recent Developments in High Temperature Heat Exchangers: A ReviewDocument15 pagesRecent Developments in High Temperature Heat Exchangers: A Reviewnantha kumarNo ratings yet

- Delta Bot Perfect DIY 3D PrinterDocument14 pagesDelta Bot Perfect DIY 3D PrinterPankaj ChaudhariNo ratings yet

- MIL9Document56 pagesMIL9Karen RoyoNo ratings yet

- MECH Lab ManualDocument64 pagesMECH Lab ManualDiksha PadiyarNo ratings yet

- Cocoon Create ModelMaker (HE170703) Aldi 3D Printer ManualDocument38 pagesCocoon Create ModelMaker (HE170703) Aldi 3D Printer ManualTristanNo ratings yet

- Additive ManufacturingDocument20 pagesAdditive Manufacturingjoeborderline100% (1)

- Set By: Prof. T.H. Lee, Prof. Kevin Kuang and Prof. K.G. NeohDocument4 pagesSet By: Prof. T.H. Lee, Prof. Kevin Kuang and Prof. K.G. NeohCl SkyeNo ratings yet

- Group 5 - Project ProposalDocument23 pagesGroup 5 - Project ProposalkajiNo ratings yet

- Bego USA TriniQ PDFDocument5 pagesBego USA TriniQ PDFELIEZER REYESNo ratings yet

- 3d Printing For MilitaryDocument16 pages3d Printing For MilitaryMehul KothariNo ratings yet

- Effects of FDM-3D Printing Parameters On MechanicaDocument14 pagesEffects of FDM-3D Printing Parameters On Mechanicaghariharan95No ratings yet

- 3D Printed Auxetic Lattice StructuresDocument18 pages3D Printed Auxetic Lattice StructuresrohanNo ratings yet

- Radiology in EndodonticsDocument107 pagesRadiology in EndodonticsMohamed kamelNo ratings yet

- On AutocadDocument17 pagesOn AutocadNarendra PatelNo ratings yet

- Unit3 AMDocument18 pagesUnit3 AMSaikiran AitipamulaNo ratings yet

- Cole Paullin: Publications and PatentsDocument2 pagesCole Paullin: Publications and PatentsCole PaullinNo ratings yet

- DATA SHEET Gas Atomized Powder For Additive ManufacturingDocument1 pageDATA SHEET Gas Atomized Powder For Additive ManufacturingdaffaNo ratings yet

- HackSpace Magazine - Issue 57Document116 pagesHackSpace Magazine - Issue 57Luiz AlmeidaNo ratings yet

- Amara Vikas Original Work Product Proposal and Calendar 4a 3 22 17Document5 pagesAmara Vikas Original Work Product Proposal and Calendar 4a 3 22 17api-352257233No ratings yet

- 4-Taxonomy of Design Strategies For A Circular Design ToolDocument5 pages4-Taxonomy of Design Strategies For A Circular Design ToolAslı KAYANo ratings yet