Professional Documents

Culture Documents

SWP-Electric Arc and MIG & TIG Welding

SWP-Electric Arc and MIG & TIG Welding

Uploaded by

LeslieOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWP-Electric Arc and MIG & TIG Welding

SWP-Electric Arc and MIG & TIG Welding

Uploaded by

LeslieCopyright:

Available Formats

SWP No.

72(W)

SAFE WORKING PROCEDURE

Page: 1 of 1

Electric Arc and MIG/TIG Welding Date: April 2004

Personal Protective

Key Hazards Risks

Equipment

1. Contact with hot metal 1. Burns 1. Welding Masks

2. Ignition of 2. Fire 2. Gauntlets

gases/workpiece/clothes 3. Electric Shock 3. Face mask or air fed

3. Faulty equipment causing 4. Eye Damage helmet

electric shock 5. Fume Inhalation 4. Fire retardant overalls

4. Toxic fumes produced by or specialist welding

welding process PPE

5. Safety footwear

DO DO NOT

x Ensure any welding operations are carried x Weld if you don’t know what you are

out by trained, competent welders whether doing !

using gas, arc or MIG equipment x Carry out any welding work unless

x Check equipment before use-specifically competent and trained to do so

electric cables, plugs and any compressed x Carry out any welding work where

gas equipment there is a risk of igniting gases/liquids-

x Ensure adequate ventilation and/or use purge all containers before starting

fume extraction equipment work

x Ensure other operatives in vicinity are x Use equipment that is not properly

protected from arc welding ‘flash’ inspected and fit for purpose

x Ensure workpiece is properly earthed in any x Carry out any work on materials of

electric welding processes unknown specification-clean

x Ensure suitable fire extinguisher equipment workpiece of coatings before welding

is on hand x Carry out any welding work in

x Check workpiece for coatings liable to confined spaces without specific

produce fumes when welded assessment of fumes/fire risk

x Protect any vulnerable areas when welding x Carry outany welding work without

(e.g. fuel tanks, inflammable materials) adequate means of fire control

x Select the correct wire/rod for the type of x Carry out structural welding unless

welding being planned and ensure the you are properly qualified (i.e. ‘coded’)

equipment has adequate capacity for the

task Specific Training Requirements

x Use special equipment to prevent damage x Technical training in welding

to sensitive equipment (e.g. vehicle battery techniques (trade qualification)

‘spike’) x Manual handling training

nd

x Consider using 2 person to check x Recognition of COSHH assessments

possibility of fire starting in unseen areas x Industrial gases-safety training

which are inflammable when carrying

welding work

References

You might also like

- Child 20protection 20policy BB 2012Document27 pagesChild 20protection 20policy BB 2012imaan0% (1)

- Welding SOP 29 Feb 12 1Document6 pagesWelding SOP 29 Feb 12 1Trương Định100% (1)

- Hot Work Safety Training (1122)Document15 pagesHot Work Safety Training (1122)Rosano D. Manamtam100% (1)

- Manual 13-026Document10 pagesManual 13-026lipNo ratings yet

- Title: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBDocument1 pageTitle: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBBharat Patil100% (1)

- Welding & Hotwork Safety-JackieDocument43 pagesWelding & Hotwork Safety-JackieNinia GannabanNo ratings yet

- Welding & Hotwork Safety-JackieDocument43 pagesWelding & Hotwork Safety-JackieSalve Ignacio100% (1)

- Mig Welding Work JSA HSE ProfessionalsDocument2 pagesMig Welding Work JSA HSE ProfessionalsNoval Febri100% (1)

- JOB: Welding A Broken Bottle Lifter of A Maheu MachineDocument4 pagesJOB: Welding A Broken Bottle Lifter of A Maheu MachinemunatsiNo ratings yet

- MIG Series: Operator ManualDocument18 pagesMIG Series: Operator ManualAn VinhNo ratings yet

- Jasic MIG 200 Synergic MIG Welding Inverter Operation ManualDocument18 pagesJasic MIG 200 Synergic MIG Welding Inverter Operation ManualFogarasiIstvánNo ratings yet

- Tig 200 Ac/Dc Analogseries: Operator ManualDocument18 pagesTig 200 Ac/Dc Analogseries: Operator ManualAlejandro CKNo ratings yet

- Week No 1Document2 pagesWeek No 1laxman ramNo ratings yet

- Plasma Cut Series: Operator ManualDocument20 pagesPlasma Cut Series: Operator ManualprisilliawongNo ratings yet

- Common 1 General Safety Precaution in WeldingDocument49 pagesCommon 1 General Safety Precaution in WeldingEgghead YTCNo ratings yet

- Welder PPT2 Safetyprecautionsin Shielding Metal ArcweldingDocument13 pagesWelder PPT2 Safetyprecautionsin Shielding Metal ArcweldingmagyanojenoelNo ratings yet

- Lesson Plan: Welding SafetyDocument1 pageLesson Plan: Welding Safetysriram 1814No ratings yet

- Welding Safety31650 PDFDocument21 pagesWelding Safety31650 PDFFikri RahimNo ratings yet

- Workshop WeldingDocument10 pagesWorkshop WeldingakhilNo ratings yet

- Sop Welder TigDocument2 pagesSop Welder TigShahid Raza100% (1)

- Niranjanaaradhya 1Document16 pagesNiranjanaaradhya 1Akash NNo ratings yet

- MigweldingprocedureDocument1 pageMigweldingprocedureTapas PalNo ratings yet

- HSE Docs Welding Safety Procedure 1698468959Document34 pagesHSE Docs Welding Safety Procedure 1698468959r2mgt28ssvNo ratings yet

- Jasic 315P ACDC Pulse Multiwave TIG Inverter Welder Operator ManualDocument24 pagesJasic 315P ACDC Pulse Multiwave TIG Inverter Welder Operator ManualMilomir KojicNo ratings yet

- Safety Training: Hot WorksDocument66 pagesSafety Training: Hot WorksMuneeb Ur Rehman100% (2)

- Sheet Metal Welding CodeDocument4 pagesSheet Metal Welding CodeJuan Carlos Fernandez LoveraNo ratings yet

- Cutting / Welding & Hot Work: Master Builders of IowaDocument38 pagesCutting / Welding & Hot Work: Master Builders of IowaDee DeeNo ratings yet

- Welding Works JSA HSE ProfessionalsDocument1 pageWelding Works JSA HSE ProfessionalsViron BaxhiaNo ratings yet

- Nebosh Igc-2 Important Questions and Answers: Element 6Document6 pagesNebosh Igc-2 Important Questions and Answers: Element 6Wafula RobertNo ratings yet

- Robotic Interfase Digipulse ESABDocument28 pagesRobotic Interfase Digipulse ESABJohan ZraghozNo ratings yet

- CBLM COMMON SMAW - PPE & ToolsDocument17 pagesCBLM COMMON SMAW - PPE & ToolsESTRELLA PALERNo ratings yet

- MP II lab manual Experiment 1Document5 pagesMP II lab manual Experiment 1Uttakantha DixitNo ratings yet

- Hot Works: Job Safety AnalysisDocument8 pagesHot Works: Job Safety AnalysisUğur BilenNo ratings yet

- Hot Work Safety TrainingDocument36 pagesHot Work Safety Trainingarnold arayataNo ratings yet

- TIG 200 Pulse AC/DC Mini Digital (JT-200DS)Document32 pagesTIG 200 Pulse AC/DC Mini Digital (JT-200DS)bobisaNo ratings yet

- Training Presentation Hot WorkDocument39 pagesTraining Presentation Hot Workathul subashNo ratings yet

- 1 HotworkDocument1 page1 Hotworkchariot1729No ratings yet

- Spot WeldersDocument2 pagesSpot WeldersJohanNo ratings yet

- Workshop Safety Basics: MENG 339 Fundamentals of Manufacturing ProcessesDocument3 pagesWorkshop Safety Basics: MENG 339 Fundamentals of Manufacturing ProcessesseifelsaieNo ratings yet

- NEW CL - JLA Steel Hand Tool - SWPDocument3 pagesNEW CL - JLA Steel Hand Tool - SWPAbdul Rafiq100% (1)

- Arc WeldingDocument2 pagesArc WeldingYoga PradiptaNo ratings yet

- Im 445Document20 pagesIm 445miguelNo ratings yet

- Hobart Handler 140 Manual 15165Document48 pagesHobart Handler 140 Manual 15165hovno2002No ratings yet

- 71 Arc Welding - JOB PROCEDUREDocument3 pages71 Arc Welding - JOB PROCEDUREAdilMunirNo ratings yet

- DEMOLITION SAFETY Print PDFDocument16 pagesDEMOLITION SAFETY Print PDFTed Alden Magno ZamoraNo ratings yet

- 71 Arc Welding - Job Procedure - 2Document3 pages71 Arc Welding - Job Procedure - 2Angga EHSKOINNo ratings yet

- HW-26, HW-26R, & HW-26F Tig Welding Torches: Instruction ManualDocument12 pagesHW-26, HW-26R, & HW-26F Tig Welding Torches: Instruction Manualmaverick kitaroNo ratings yet

- Standard Operating Procedure Welding machine-MIG: PedestalDocument2 pagesStandard Operating Procedure Welding machine-MIG: PedestalKranthi Kumar ReddyNo ratings yet

- Job Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Document7 pagesJob Safety Analysis: Step 1: Job Safety Hazard & PPE Checklist: (General Hazards Associated With The Job)Ranadheer Reddy KanthalaNo ratings yet

- Hot Work JSA - SAFETYMGMTSTUDY PDFDocument1 pageHot Work JSA - SAFETYMGMTSTUDY PDFMohammed AlshehhiNo ratings yet

- Arc Ja140Document19 pagesArc Ja140Александр ПанкратовNo ratings yet

- 28 HotworkDocument5 pages28 HotworkMohammed MinhajNo ratings yet

- Handy Plasma 125: Plasma Arc Cutting Package - P/N 37884 115V 60HzDocument24 pagesHandy Plasma 125: Plasma Arc Cutting Package - P/N 37884 115V 60Hzbouriahi hassaneNo ratings yet

- Water Injection AreaDocument5 pagesWater Injection Areasudeesh kumarNo ratings yet

- SWP Welding 20SWMBDocument2 pagesSWP Welding 20SWMBvincecook0202No ratings yet

- Title: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBDocument1 pageTitle: Safe Work Procedure Template: No. DET ESWB-05-2-2 Authorised By: Manager ESWBKhaled ElsayedNo ratings yet

- WeldingDocument17 pagesWeldingMr. MushahidNo ratings yet

- Safe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety AnalysisDocument2 pagesSafe Work Procedure: Required Personal Protective Equipment General Notes: Job Safety Analysisrazed86No ratings yet

- Popular Topics: Help GuideDocument212 pagesPopular Topics: Help GuideLeslieNo ratings yet

- Washer Dryer: Register YourDocument60 pagesWasher Dryer: Register YourLeslieNo ratings yet

- Nokia X30 5G: User GuideDocument43 pagesNokia X30 5G: User GuideLeslieNo ratings yet

- School Request Excuse Letter TemplateDocument1 pageSchool Request Excuse Letter TemplateLeslieNo ratings yet

- School Official Excuse Letter TemplateDocument1 pageSchool Official Excuse Letter TemplateLeslieNo ratings yet

- School Absence Excuse Letter TemplateDocument1 pageSchool Absence Excuse Letter TemplateLeslieNo ratings yet

- Personal Report Rajiv Patil: Focus StylesDocument3 pagesPersonal Report Rajiv Patil: Focus Stylesrajivpatil11No ratings yet

- Water and Slurry Bulkheads in Underground Coal Mines: Design, Monitoring and Safety ConcernsDocument7 pagesWater and Slurry Bulkheads in Underground Coal Mines: Design, Monitoring and Safety ConcernsDinesh dhakarNo ratings yet

- Writing Results in A Research PaperDocument6 pagesWriting Results in A Research Paperafedpmqgr100% (1)

- Plain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryDocument4 pagesPlain Concrete Footing Design Based On ACI 318-14: Input Data Design SummaryShadin Asari ArabaniNo ratings yet

- IBM Power Systems Cloud Security Guide: Protect IT Infrastructure in All LayersDocument220 pagesIBM Power Systems Cloud Security Guide: Protect IT Infrastructure in All Layersbenmagha9904No ratings yet

- UPS KAISE 600-800va - Hoja de DatosDocument2 pagesUPS KAISE 600-800va - Hoja de DatosGermanYPNo ratings yet

- FFM1-Ch 2.1. Inventory ManagementDocument37 pagesFFM1-Ch 2.1. Inventory ManagementQuỳnhNo ratings yet

- Handout - 20475 - AU 2016 Class Handout - Revit and Dynamo For Landscape ArchitectureDocument58 pagesHandout - 20475 - AU 2016 Class Handout - Revit and Dynamo For Landscape ArchitectureKelvinatorNo ratings yet

- Meeting Minutes of 17th Departmental MeetingDocument3 pagesMeeting Minutes of 17th Departmental Meetingmyousafzai67No ratings yet

- The Square and NTH Roots of Square Matrices: Taran Lynn 2014Document15 pagesThe Square and NTH Roots of Square Matrices: Taran Lynn 2014arvind lakshmi ranjanNo ratings yet

- The PTB Simulation Report: User: Chandran Geetha Pramoth Chandran User Email: 200512299@student - Georgianc.on - CaDocument9 pagesThe PTB Simulation Report: User: Chandran Geetha Pramoth Chandran User Email: 200512299@student - Georgianc.on - CaPramodh ChandranNo ratings yet

- Chapter 1 Transaction Management and Concurrency Control Lec 1 andDocument68 pagesChapter 1 Transaction Management and Concurrency Control Lec 1 andFiromsa DineNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetFahad NaveedNo ratings yet

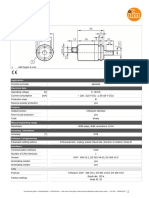

- Multiturn Solid Shaft Encoder: 1 M4 Depth 6 MMDocument2 pagesMultiturn Solid Shaft Encoder: 1 M4 Depth 6 MMSoha EzzaldenNo ratings yet

- Visto-Resume 26710306Document1 pageVisto-Resume 26710306api-350663722No ratings yet

- Relationship Between Nurse Case Manager's Communication Skills and Patient Satisfaction at Hospital in JakartaDocument6 pagesRelationship Between Nurse Case Manager's Communication Skills and Patient Satisfaction at Hospital in Jakartakritis ardiansyahNo ratings yet

- Phenomena of Double RefractionDocument5 pagesPhenomena of Double RefractionMahendra PandaNo ratings yet

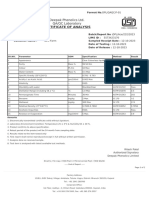

- Acetone - Deepak PhenolicsDocument1 pageAcetone - Deepak PhenolicsPraful YadavNo ratings yet

- Environmental Conservation in Bhutan: Organization and PolicyDocument21 pagesEnvironmental Conservation in Bhutan: Organization and PolicyApriele Rose Gaudicos HermogenesNo ratings yet

- 3 - Module 2 Masonry WorksDocument20 pages3 - Module 2 Masonry WorksallankatenguddoNo ratings yet

- Advance Data StructuresDocument184 pagesAdvance Data StructureskamsiNo ratings yet

- Lab Assignment 11313Document2 pagesLab Assignment 11313abhaybaranwalNo ratings yet

- Gustav A. Wetter - The Ambivalence of The Marxist Concept of Ideology, Studies in East European Thought, 1969 PDFDocument7 pagesGustav A. Wetter - The Ambivalence of The Marxist Concept of Ideology, Studies in East European Thought, 1969 PDFMihaela GeorgescuNo ratings yet

- Aditya Vikram Verma - CVDocument2 pagesAditya Vikram Verma - CVAdityaVikramVermaNo ratings yet

- Why The Giant Sleeps So Deeply - Political Consequences of Individual-Level Latino DemographicsDocument23 pagesWhy The Giant Sleeps So Deeply - Political Consequences of Individual-Level Latino DemographicsTyler SmithNo ratings yet

- Design Guides For Bridges Vulnerable To Coastal StormsDocument27 pagesDesign Guides For Bridges Vulnerable To Coastal StormsjeovanNo ratings yet

- Devops MCQ PDFDocument6 pagesDevops MCQ PDFSaad Mohamed SaadNo ratings yet

- 865-RUGC Manuscript-2653-1-10-20200306Document4 pages865-RUGC Manuscript-2653-1-10-20200306Bal Deep SharmaNo ratings yet