Professional Documents

Culture Documents

Feature Article Additive Impact Part 2 - How Additive Manufacturing Could Disrupt Your Market

Feature Article Additive Impact Part 2 - How Additive Manufacturing Could Disrupt Your Market

Uploaded by

Nalla ThambiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Feature Article Additive Impact Part 2 - How Additive Manufacturing Could Disrupt Your Market

Feature Article Additive Impact Part 2 - How Additive Manufacturing Could Disrupt Your Market

Uploaded by

Nalla ThambiCopyright:

Available Formats

Renishaw plc T

+44 (0)1453 524524

New Mills, Wotton-under-Edge, F +44 (0)1453 524901

Gloucestershire, GL12 8JR E uk@renishaw.com

United Kingdom www.renishaw.com

Additive impact part #2 - how additive manufacturing

could disrupt your market

Metal 3D printing has the potential to shake up the way that we design and make products, creating opportunities for valuable

innovations and whole new business models. In this second feature article of two, I am exploring the nature of the changes that

additive manufacturing (AM) could bring to product markets, and the steps that companies can take to lead this disruption.

In the first post Additive impact part #1, I introduced a staircase model of AM adoption, and explained how the production and

lifetime benefits of AM increase as you move up through the levels. These benefits build up as you employ more and more of the

unique characteristics of AM.

Having explored the first two steps of the staircase in part #1. In this feature article, I will detal the two upper steps.

New product designs that:

1. Deliver lifetime benefits in use

2. Provide mass customisation

Complex parts that simplify assembly

& enhance reliability

Re-production parts, that avoid

complex manufacturing

Low volume parts made direct from

CAD

Level 2 - Part consolidation Feature rich components

This is the first step where we start to change the design Details can be designed in and built directly, rather than

requiring additional process steps

of our product to take advantage of AM’s ability to make

complex shapes. In this instance, we are looking to simplify

our product by combining collections of parts into a single,

integral build. There are three AM capabilities in play at this

level:

a. Feature-rich components

AM enables detailed features to be designed and built into Manifold with complex pipework and struts

components in a single operation, rather than requiring

additional process steps. We take complexity out of the Production benefits

process and put it into the part.

£ Lower tooling costs

Consolidating these multiple steps into a single additive £ Shorter processing time

operation reaps many production cost benefits including;

£ Shorter lead time

reduced tooling costs, shorter overall processing time,

£ Simpler assembly

shorter lead time, and replacement of complex assembly

processes with a single, automated build. £ Automation

3

2 £

1 X

0

© 2019-2020 Renishaw plc. All rights reserved. Page 1 of 7

Feature article: Additive impact part #2 - how additive manufacturing

could disrupt your market

b. Removal of joints c. Mechanisms

Joints find their way into product designs to enable complex It is possible to produce interlinked mechanisms in a single

shapes to be produced that cannot be formed in a single AM build, that then require no further assembly. The results

conventional manufacturing operation. Joints mean mating can be neat, functional and highly attractive.

features, fixings, connectors, gaskets and seals. They add

to the part count, the weight, the processing time and the

assembly time of a product. They also create points of

Mechanisms

potential weakness and mismatch between parts that have

Multi-component mechanisms built together in an

been separately manufactured, resulting in potential failure inter-linked state

modes and performance shortfalls. Joints are best avoided!

AM enables complex shapes - e.g. the twisting waveguide

shown below - to be made in a single operation. This can

lead both to cost savings in assembly and to a range of

lifetime benefits in use.

Interlocking titanium

Removal of joints ‘heartvalve’ necklace

Combining an assembly of parts into a single component,

removing interfaces, bonds, gaskets and clamps

Production benefits

£ Simpler assembly

£ Automation

Lifetime benefits

One-piece microwave guide for space application

£ Faster product launch

£ Product attraction

Production benefits

£ Simpler assembly

3

Lifetime benefits 2 £

£ Less weight 1 X

£ Faster product launch

0

£ Product reliability

£ Increased performance

3

2 £

1 X

0

© 2019-2020 Renishaw plc. All rights reserved. Page 2 of 7

Feature article: Additive impact part #2 - how additive manufacturing

could disrupt your market

Level 3 - DfAM optimised

So now we’ve reached the top step, where the most b. Topological optimisation

advanced capabilities are deployed. We are employing Another technique for light-weighting is topological

Design for AM (DfAM) principles to take full advantage optimisation. The principle here is to define the interfaces that

of the freedom available to us. Here, everything is open the component has with the rest of the mechanism and the

to optimisation, resulting in some radical and customised loads that it has to carry. Then we look at the stresses in the

solutions. There are quite a few capabilities to think about material that these loads induce and remove material that is

here: under the least strain. This leaves the most efficient way for

a. Hollow / porous structures the material to transmit the specified loads.

Many parts are produced conventionally with solid structures, The example below is a bracket in a space application, where

even though a hollow structure is often as strong, simply weight really is at a premium. The conventional bracket

because it is too difficult or expensive to access the material evolves into a hollow freeform shape - we call it the ‘fingers of

in the middle. AM enables hollow structures to be readily fate’ - reducing mass by a third. The lead time to design and

produced in a single operation, with the added bonus of produce a radical new design can also be surprisingly short.

reduced material use and shorter build times. Lattices can

also be used to lighten components, often by as much as

50%, whilst retaining stiffness.

Hollow / porous structures Topological optimisation

Replace solid structures with shelled or lattice-filled designs Part shape optimised to transmit loads with unstressed

material removed

Solid valve body Lattice-filled design Conventional bracket Optimised design

50% mass reduction 34% mass reduction, 10 week design & build

Production benefits Production benefits

£ Less wasted materials £ Less wasted materials

£ Shorter processing time £ Lower tooling costs

Lifetime benefits Lifetime benefits

£ Less weight £ Less weight

£ Faster product launch

3 £

2 3 £

1 X 2

0 1 X

0

© 2019-2020 Renishaw plc. All rights reserved. Page 3 of 7

Feature article: Additive impact part #2 - how additive manufacturing

could disrupt your market

c. Improved aesthetics d. Increased surface area

AM gives us the freedom to design unusual, organic forms, Load-bearing interfaces often require a large surface area to

which can be used in creative ways to design attractive ensure good adhesion. This is particularly true in orthopaedic

products, such as jewellery. implants, where clinicians want to promote integration between

the metal implant and the neighbouring bone, to build a strong

bond and to prevent ‘stress shielding’ and subsequent surgical

revision. This is currently an area of intense research, with

investigations into osseointegration with regular and irregular

lattices designs.

Another application that benefits from large and carefully

designed interface surfaces is bonding of metal and composite

parts.

Improved aesthetics Increased surface area

Freedom to produce unusual and graceful shapes Complex and textured surfaces enabling different interfaces

with other system or anatomical elements

Load bearing orthopaedic implant

lattices designed to encourage bone

regrowth

Random

lattice

femoral cup

exterior (in

partnership

with Imperial

College,

Aorta necklace London)

Production benefits Production benefits

£ Simpler assembly £ Less wasted materials

Lifetime benefits Lifetime benefits

£ Better adaption £ Increased performance

£ Product attraction £ Better adaption

3 £ 3 £

2 2

1 X 1 X

0 0

© 2019-2020 Renishaw plc. All rights reserved. Page 4 of 7

Feature article: Additive impact part #2 - how additive manufacturing

could disrupt your market

e. Increased heat transfer f. High strength alloys

Heat exchangers are a great application for AM. To maximise The difficulty of machining some alloys can prevent their

heat transfer between one fluid and another, a heat exchanger practical use, even though they may exhibit highly desirable

ideally comprises a network of complex micro-channels with thermal and mechanical properties. AM is essentially a

thin primary walls, and complex secondary surfaces. The welding process, and so, provided the alloy can be ‘atomised’

unique capability of AM to produce detailed internal and into a powder, it may be possible to process such challenging

external features cost-effectively means that more efficient materials using laser techniques. Exotic alloys are generally

heat exchangers are possible, enabling either lighter weight, expensive, so minimising waste through near-net-shape

or higher performance, or both. This is of obvious interest for processing is also helpful.

motorsport, road vehicle design and green energy applications.

Conformal cooling, mentioned in feature article part #1 in

the context of mould tool design, can also be applied to

components that require cooling during their use. Intricate

channels that follow the component surface enable heat to be

efficiently carried away from the component core.

Increased heat transfer High strength alloys

Intricate fluid micro-channels and complex external Fully dense and high strength alloys, those that are not

surfaces, enabling greater heat flow per unit volume used now due to poor machinability

Compact aluminium heat exchanger for a race car Process exotic / expensive alloys with no waste

Production benefits Production benefits

£ Less wasted materials £ Lower tooling costs

£ Lower tooling costs

£ Simpler assembly Lifetime benefits

£ Product reliability

Lifetime benefits £ Increased performance

£ Increased performance

3 £

2

3 £

1 X

2

0

1 X

0

© 2019-2020 Renishaw plc. All rights reserved. Page 5 of 7

Feature article: Additive impact part #2 - how additive manufacturing

could disrupt your market

g. Architectured materials h. Build the bill of materials

AM’s ability produce fine lattices opens up the possibility to Because AM requires no tooling, you can combine different

make metal ‘foams’ with carefully tailored properties. Such elements of a product together in a single build. This means

micro-structured materials could be designed to include that you can make all the major components of a product

anisotropic properties - e.g. different stiffness and thermal in one go, so that they can then be post-processed and

conductivity in different planes. This is a bit like topological assembled together. This makes for easier scheduling,

optimisation, but on a microscopic scale. Standard and reduced stocking, and offers the option to combine this with

bespoke architectured materials open up new possibilities for localised production and mass customisation for superior

lightweight, high performance products. The examples below service.

are provided by Betatype.

Anisotropic properties Build the Bill of Materials

Metal ‘foams’ exhibiting different stiffness and thermal Produce a suite of parts to construct a product in a single

conductivity in different planes build

‘Architectured’ materials

with bespoke mechanical

properties

Image courtesy of Betatype Bike frame kit on a build plate (l) and assembled (r)

Production benefits Production benefits

£ N/A £ Shorter lead time

£ Simpler assembly

Lifetime benefits

£ Product attraction Lifetime benefits

£ Increased performance £ Reduced stocking

£ Better adaption

3 £

3 £ 2

2 1 X

1 X 0

0

© 2019-2020 Renishaw plc. All rights reserved. Page 6 of 7

Feature article: Additive impact part #2 - how additive manufacturing

could disrupt your market

i. Mass customisation Summary - part #2

Provided that you have a CAD model for the part you’re trying So we’ve completed our journey to the top of the staircase,

to make, it makes very little difference in terms of cost and employing more and more AM capabilities along the way. Of

build time if that part is exactly the same as others that have course, it’s not essential to use all of these in your AM product

gone before, or if it is slightly different. The lack of tooling - just pick those that will create the greatest value for your

required for AM means that customised part production can customers, and save you the most in bringing your innovative

be very cost-effective. A great example of this is Renishaw’s new product to market.

dental implants business - we make hundreds of unique

I hope that this framework is useful to help you to analyse

restorations every day, based on designs sent to us by different

how AM could impact on your market, and to think about the

dental laboratories. These are consolidated into a single build

approach that you could take to lead the change in your sector.

to keep costs low.

Mass customisation relies on an effective upstream process

chain: accurate measurement of the situation in which the Next steps

part will be deployed, user-friendly CAD design of the custom

product, and software to convert the CAD model into a Visit www.renishaw.com/amguide for more educational

producible AM build. resources and to access downloadable versions of feature

articles and white papers by Renishaw authors.

The benefit to the user of customised parts is better adaptation

to its context, which can lead to easier fitting, better outcomes,

and a higher value service. When combined with other AM

capabilities, customised production opens up opportunities to

About the author

disrupt mass produced business models. Marc Saunders, Director of AM Applications

Marc Saunders has over 25 years’ experience in high tech

manufacturing. In previous positions at Renishaw, he played

Mass customisation

a key role in developing the company award-winning RAMTIC

Matching of product design to its context in use, creating

automated machining platform, and has also delivered turnkey

optimised forms and interfaces

metrology solutions to customers in the aerospace sector.

Marc manages Renishaw’s global network of Additive

Manufacturing Solutions Centres, enabling customers who

are considering deploying AM as a production process to gain

hands-on experience with the technology before committing to

a new facility.

100s of

Custom dental custom

frameworks frameworks

designed to fit a in a single www.renishaw.com/additive

scanned model of AM build

a patient’s mouth

Production benefits

£ Lower tooling costs

Lifetime benefits

£ Product reliability

£ Increased performance

3 £

2

1 X

0

© 2019-2020 Renishaw plc. All rights reserved. Page 7 of 7

You might also like

- Tnswan Telephone Directory: Pre - AmbleDocument88 pagesTnswan Telephone Directory: Pre - AmbleNalla ThambiNo ratings yet

- Atomic and Ionic ArrangementsDocument50 pagesAtomic and Ionic ArrangementsUğurörengülNo ratings yet

- Jose Antonio Moreno - Danobat ScoopDocument6 pagesJose Antonio Moreno - Danobat ScoopÂrbaoui MedNo ratings yet

- Catalogo Sinumerik 808Document96 pagesCatalogo Sinumerik 808Macchi_RJNo ratings yet

- Design For: Who Casts The Biggest Shadow ?Document6 pagesDesign For: Who Casts The Biggest Shadow ?ROHIT VERMANo ratings yet

- EN - Epiroc Parts and Services Portfolio - 04032024 - LRDocument54 pagesEN - Epiroc Parts and Services Portfolio - 04032024 - LRNathalee MontañezNo ratings yet

- Hobart WW Service-Manual ROI-18-01 en UK 1218-0122Document40 pagesHobart WW Service-Manual ROI-18-01 en UK 1218-0122jacquesgelderblomNo ratings yet

- Precast IFCDocument42 pagesPrecast IFCar_raghvendra4151No ratings yet

- SERED111220Document2 pagesSERED111220raul sanchezNo ratings yet

- YuMi Presentacion PDFDocument47 pagesYuMi Presentacion PDFLily ParadaNo ratings yet

- ABB-412-WPO Higher Efficiency in OperationsDocument16 pagesABB-412-WPO Higher Efficiency in OperationsSergio Alexander Fonseca CorredorNo ratings yet

- Paper56251 254Document4 pagesPaper56251 254jvanandhNo ratings yet

- Unit 2Document71 pagesUnit 2Aditya GuptaNo ratings yet

- NC81 1 2020Document96 pagesNC81 1 2020Henrique SantosNo ratings yet

- PDF - Selection and Application Guide MeteringDocument112 pagesPDF - Selection and Application Guide MeteringjosepitbulNo ratings yet

- Robotics Digital ServicesDocument32 pagesRobotics Digital Servicesalextran3252No ratings yet

- Aras Managing Context Using Digital TwinDocument9 pagesAras Managing Context Using Digital TwinRaul ReynosoNo ratings yet

- Lean Management in Apparel ManufacturingDocument7 pagesLean Management in Apparel Manufacturingabineshm1310No ratings yet

- Preventive Maintenance Service Concept For SPACOM Product FamilyDocument27 pagesPreventive Maintenance Service Concept For SPACOM Product FamilyMiguel MarquesNo ratings yet

- MM323 Assignment 2 Report Format - NewDocument21 pagesMM323 Assignment 2 Report Format - NewKelemedi DreuNo ratings yet

- Dfam Strategy - Create Design Space' For Maximum Am ImpactDocument3 pagesDfam Strategy - Create Design Space' For Maximum Am Impactmilad afshariNo ratings yet

- Bosch Lean Manufacturing Guidebook-1Document16 pagesBosch Lean Manufacturing Guidebook-1minal potavatreNo ratings yet

- 3DSystems Ebook Parts Consolidation - EbookDocument14 pages3DSystems Ebook Parts Consolidation - EbookThebe HanyaneNo ratings yet

- UR Application Fact Sheet Assembly ITDocument2 pagesUR Application Fact Sheet Assembly ITGrazianoNo ratings yet

- DX360LC-7M EN LowDocument17 pagesDX360LC-7M EN LowGruppo ZECCANo ratings yet

- Briq - Catalouge 100Document2 pagesBriq - Catalouge 100Amit TiwariNo ratings yet

- CEPS Burnishing of Steering WormsDocument2 pagesCEPS Burnishing of Steering Wormsanon_517822417No ratings yet

- Additive Adoption A - Z - ADAPTABILITYDocument20 pagesAdditive Adoption A - Z - ADAPTABILITYDesainCADNo ratings yet

- Alloy Wheel H-2000-3805-01 MC PDFDocument6 pagesAlloy Wheel H-2000-3805-01 MC PDFAliya RaheelNo ratings yet

- BAM GB Automotive Engineering OverviewDocument15 pagesBAM GB Automotive Engineering OverviewMu FaddaNo ratings yet

- Design For Manufacturing and AssemblyDocument10 pagesDesign For Manufacturing and AssemblyMohammed Abdul RahmanNo ratings yet

- Cat Wheeled Excavator m318 Manual OriginalDocument12 pagesCat Wheeled Excavator m318 Manual OriginalNil AcuñaNo ratings yet

- GT and CAPPDocument20 pagesGT and CAPPBizuayehu TadesseNo ratings yet

- Common Voss Assembly Station With Poka-YokeDocument7 pagesCommon Voss Assembly Station With Poka-YokeAnuj Kumar ShrivastavaNo ratings yet

- Engineering Showcase 2017: Motion ControlDocument76 pagesEngineering Showcase 2017: Motion ControlCristian SNo ratings yet

- DFM DFA Student Edition7Document77 pagesDFM DFA Student Edition7manNo ratings yet

- C07 Instr PPT Mowen4CeDocument83 pagesC07 Instr PPT Mowen4Cepiker.trance.0uNo ratings yet

- MA Plus 20191013 GBDocument30 pagesMA Plus 20191013 GBИлхомбек ИбрагимовNo ratings yet

- Lean ManufacturingDocument27 pagesLean ManufacturingPuttnala Prakash rajNo ratings yet

- 18may pp2 MsDocument16 pages18may pp2 MsZhang YuchiNo ratings yet

- Building The Business Case:: Identifying Criteria To Measure ROI For Additive ManufacturingDocument11 pagesBuilding The Business Case:: Identifying Criteria To Measure ROI For Additive ManufacturingRushabh ZambadNo ratings yet

- Cacfd-1508 Mains Approach-Answer e 2021Document22 pagesCacfd-1508 Mains Approach-Answer e 2021Nikhil Reddy AndruNo ratings yet

- Unlocking Value Digital Twin With Ansys Twin Builder InfographicDocument1 pageUnlocking Value Digital Twin With Ansys Twin Builder InfographicJohn GreenNo ratings yet

- Flexitol en 0590Document28 pagesFlexitol en 0590WANKEL25No ratings yet

- Micro-Hybrid Operational AmplifiersDocument14 pagesMicro-Hybrid Operational AmplifiersLannoyNo ratings yet

- 1 OMC2015 ISA YOKOGAWA Optimization Vs PerformanceDocument43 pages1 OMC2015 ISA YOKOGAWA Optimization Vs PerformanceWalid AissaNo ratings yet

- Industrial EngDocument9 pagesIndustrial EngSunday JohnNo ratings yet

- Maquina de Inyeccion de PlasticoDocument39 pagesMaquina de Inyeccion de PlasticoCedro del himalayaNo ratings yet

- A Review of Assembly Line Changes For Lean Manufacturing: Awasare Anant Dattatray, M.V.KavadeDocument5 pagesA Review of Assembly Line Changes For Lean Manufacturing: Awasare Anant Dattatray, M.V.KavadeAeyrul KhairulNo ratings yet

- Rapid FitDocument6 pagesRapid FitDoanh NguyenNo ratings yet

- Energy Measuring Unit PDFDocument48 pagesEnergy Measuring Unit PDFhuynh ngoc hoi HuynhNo ratings yet

- Analyst Meet October 2019Document46 pagesAnalyst Meet October 2019Gaurav ShuklaNo ratings yet

- Operation ManagementDocument6 pagesOperation ManagementWinter NaiNo ratings yet

- Additive Manufacturing - Question Bank With Answers - May 2023Document13 pagesAdditive Manufacturing - Question Bank With Answers - May 2023Surya100% (2)

- Eleven Benefits of AutomationDocument9 pagesEleven Benefits of Automationshahdad sayedNo ratings yet

- Increasing Efficiency: Case Study of Ready Made Garments in BangladeshDocument16 pagesIncreasing Efficiency: Case Study of Ready Made Garments in BangladeshDr. Nazrul IslamNo ratings yet

- StackPack 300 TechsheetDocument2 pagesStackPack 300 TechsheetmanishNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- The Kotak Mahindra Group An Overview: #DiscoverkliDocument6 pagesThe Kotak Mahindra Group An Overview: #DiscoverkliNalla ThambiNo ratings yet

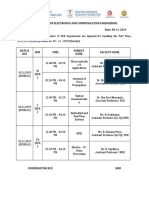

- Department of Electronics and Communication Engineering Venue: Kilpauk Date: 08-11-2019Document1 pageDepartment of Electronics and Communication Engineering Venue: Kilpauk Date: 08-11-2019Nalla ThambiNo ratings yet

- Key Pointers For The RDM Role - TIEDDocument3 pagesKey Pointers For The RDM Role - TIEDNalla Thambi100% (1)

- Fabpro 1000 For Dental ApplicationsDocument1 pageFabpro 1000 For Dental ApplicationsNalla ThambiNo ratings yet

- Em Taking Care of Business Brochure enDocument30 pagesEm Taking Care of Business Brochure enNalla ThambiNo ratings yet

- The Power of Additive ManufacturingDocument4 pagesThe Power of Additive ManufacturingNalla ThambiNo ratings yet

- AIIRF Advertisement-26july19Document4 pagesAIIRF Advertisement-26july19Nalla ThambiNo ratings yet

- Agro and Food Processing Sector ProfileDocument14 pagesAgro and Food Processing Sector ProfileNalla ThambiNo ratings yet

- Rating Rationale: Facility Amount ( CR) Tenure RatingDocument4 pagesRating Rationale: Facility Amount ( CR) Tenure RatingNalla ThambiNo ratings yet

- Fabpro 1000 Entry-Level Industrial 3D PrinterDocument2 pagesFabpro 1000 Entry-Level Industrial 3D PrinterNalla ThambiNo ratings yet

- Schools Selected For ATL Round 2: S. NO. Atl Code School Name District StateDocument4 pagesSchools Selected For ATL Round 2: S. NO. Atl Code School Name District StateNalla ThambiNo ratings yet

- Direct Metal Solutions: Precision Production Metal Printing With The DMP Printer Series, 3dxpert Laserform® MaterialsDocument6 pagesDirect Metal Solutions: Precision Production Metal Printing With The DMP Printer Series, 3dxpert Laserform® MaterialsNalla ThambiNo ratings yet

- XRD Ebook PDFDocument54 pagesXRD Ebook PDFSunny SharmaNo ratings yet

- EE130 hw1Document1 pageEE130 hw1Thomas SmithNo ratings yet

- Solid State Physics Chapter 1Document9 pagesSolid State Physics Chapter 1Sergio NuñezNo ratings yet

- Crystal Structure PDFDocument51 pagesCrystal Structure PDFKUSHAGRA MANIKNo ratings yet

- SheetDocument108 pagesSheetPinkyNo ratings yet

- Powder XRD Technique and Its Applications in Science and TechnologyDocument5 pagesPowder XRD Technique and Its Applications in Science and Technologyomeger07No ratings yet

- Crit BondsDocument125 pagesCrit Bondsdidodad248No ratings yet

- Vesta ManualDocument156 pagesVesta ManualJessiel GueribaNo ratings yet

- Basics of CrystallographyDocument60 pagesBasics of Crystallographylmanna454No ratings yet

- Students Guide To SHELXTLDocument16 pagesStudents Guide To SHELXTLJubin KumarNo ratings yet

- PhysicsDocument2 pagesPhysicsapi-236544093No ratings yet

- Propylene PolymersDocument72 pagesPropylene PolymersThùy LinhNo ratings yet

- AK Das-Vol-2Document634 pagesAK Das-Vol-2Shreetama Bhattacharya100% (1)

- J Jcrysgro 2003 12 035Document15 pagesJ Jcrysgro 2003 12 035Magui Ros MonNo ratings yet

- States of Matter: Advanced Secondary 1Document29 pagesStates of Matter: Advanced Secondary 1David JonesNo ratings yet

- Literature Review IridatesDocument8 pagesLiterature Review IridatesGaby ChristofsonNo ratings yet

- TEMDocument37 pagesTEMathaNo ratings yet

- 03 Symmetry of CrystalsDocument21 pages03 Symmetry of CrystalsArtav SaurabhNo ratings yet

- Materials Science in Semiconductor ProcessingDocument8 pagesMaterials Science in Semiconductor ProcessingjacoboNo ratings yet

- Emerging Research Landscape of AltermagnetismDocument25 pagesEmerging Research Landscape of AltermagnetismAybüke GülkayaNo ratings yet

- Material Science Important Questions For AMIE Section-ADocument8 pagesMaterial Science Important Questions For AMIE Section-AThota Sai Swaroop67% (3)

- The Purdue Visualization of Rotations Test: The Chemical Educator October 1997Document18 pagesThe Purdue Visualization of Rotations Test: The Chemical Educator October 1997matsalNo ratings yet

- Drug Discovery Strategies and Methods 2004 - Makriyannis & BiegelDocument338 pagesDrug Discovery Strategies and Methods 2004 - Makriyannis & Biegeljoshigauta100% (1)

- Hexagonal Reciprocal LatticeDocument3 pagesHexagonal Reciprocal LatticeAmlan DasNo ratings yet

- Order Parameters, Broken Symmetry, and Topology: PACS Numbers: KeywordsDocument10 pagesOrder Parameters, Broken Symmetry, and Topology: PACS Numbers: KeywordsgoogleNo ratings yet

- X-Ray Diffraction PrinciplesDocument123 pagesX-Ray Diffraction Principlesatswalla100% (1)

- 422 Chem Part2Document202 pages422 Chem Part2Yui YamamotoNo ratings yet

- I & II Sem Marine C SDocument23 pagesI & II Sem Marine C SGaacksonNo ratings yet

- Structure Factors and Systematical AbsencesDocument15 pagesStructure Factors and Systematical AbsencesAhmed EssamNo ratings yet