Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

334 viewsSoap Case Study

Soap Case Study

Uploaded by

Dinesh KilladaThis document provides information about Lifebuoy soap, including its manufacturing process. Lifebuoy soap is manufactured by Hindustan Unilever in Haridwar, India. Haridwar was chosen as the location due to availability of energy, water, raw materials, and cheap land and labor. The plant uses a product layout, where machines are arranged sequentially based on the production process. Soap is manufactured through a flow production method, where raw materials continuously move through production stages to produce standardized bars of soap efficiently at large scale.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Detergent Manufacturing Business PlanDocument3 pagesDetergent Manufacturing Business Planjamal sanadNo ratings yet

- TDS Koralone HP 150Document8 pagesTDS Koralone HP 150Quoc ThanhNo ratings yet

- The Perfumer's - An Index To The Aromatic Artists PDFDocument26 pagesThe Perfumer's - An Index To The Aromatic Artists PDFFaisel Khan100% (4)

- Marketing Research For Harpic FlushmaticDocument8 pagesMarketing Research For Harpic Flushmaticnidhs85No ratings yet

- DettolDocument8 pagesDettolMohammed SohailNo ratings yet

- Concept 02Document36 pagesConcept 02Fikri EfendiNo ratings yet

- Habib Cooking Oil ReviewDocument1 pageHabib Cooking Oil Reviewali_abbas144No ratings yet

- Rural Indebtedness in India-1Document8 pagesRural Indebtedness in India-1HASHMI SUTARIYANo ratings yet

- 3operations at LuxDocument13 pages3operations at LuxchrisNo ratings yet

- Project Report On Latex Gloves Manufacturing UnitDocument7 pagesProject Report On Latex Gloves Manufacturing UnitEIRI Board of Consultants and PublishersNo ratings yet

- The Bogey BeastDocument5 pagesThe Bogey BeastBrayan ChiribogaNo ratings yet

- Malta Soap Operations ManagementDocument15 pagesMalta Soap Operations Managementسعد كاظمNo ratings yet

- Handmade Soap Project ReportDocument17 pagesHandmade Soap Project ReportfsdcvdfzbNo ratings yet

- SIP OdonilDocument7 pagesSIP OdonilDiksha LathNo ratings yet

- MB0036 - Strategic Management and Business PolicyDocument297 pagesMB0036 - Strategic Management and Business Policysuahik100% (2)

- Consumer Preference Towards Lifeboy HulDocument84 pagesConsumer Preference Towards Lifeboy HulshobhitNo ratings yet

- Muhammad Umair LatifDocument2 pagesMuhammad Umair LatifCH Umair MerryNo ratings yet

- Schedule III of Companies Act 2013 in Excel Format-2Document48 pagesSchedule III of Companies Act 2013 in Excel Format-2divya shindeNo ratings yet

- DettolDocument10 pagesDettolTwinkle AgarwalNo ratings yet

- Om Evolution of Operations ManagementDocument7 pagesOm Evolution of Operations ManagementBrein Symon DialaNo ratings yet

- Blackbook 2021-2022Document63 pagesBlackbook 2021-2022rajNo ratings yet

- The Comprehensive Analysis of Mcdowells No1Document46 pagesThe Comprehensive Analysis of Mcdowells No1Pradipta Mukherjee100% (1)

- Tide Surt ExcelDocument75 pagesTide Surt ExcelDeep Tiwari100% (1)

- MBA Semester 1 Assignments With AnswerDocument8 pagesMBA Semester 1 Assignments With AnswerRajesh SinghNo ratings yet

- Dettol ProjectDocument25 pagesDettol ProjectPramod PradhanNo ratings yet

- Marketing in Indian EconomyDocument15 pagesMarketing in Indian Economyshivakumar NNo ratings yet

- Ground and Processed Spices and Cereals Project ReportDocument5 pagesGround and Processed Spices and Cereals Project ReportGirish DaryananiNo ratings yet

- Case Study DownsizingDocument13 pagesCase Study DownsizingManisha GuptaNo ratings yet

- Fikir Pure Natural Spring WaterDocument2 pagesFikir Pure Natural Spring WaterbirukNo ratings yet

- Business Environment and McCain Foods CompanyDocument19 pagesBusiness Environment and McCain Foods CompanyEmmanuel Kiiza100% (5)

- This Study Resource Was: Surf Excel Marketing Mix (4Ps) StrategyDocument9 pagesThis Study Resource Was: Surf Excel Marketing Mix (4Ps) StrategyIshu GunasekaraNo ratings yet

- Case Study Asian PaintsDocument20 pagesCase Study Asian PaintsRajan Girdhar100% (1)

- Project Report ShampooDocument2 pagesProject Report Shampoovineetaggarwal50% (2)

- Cust Satisfaction ArielDocument32 pagesCust Satisfaction ArielShams SNo ratings yet

- A Mini Project On SapmDocument28 pagesA Mini Project On SapmPraveen KumarNo ratings yet

- Test Bank For Corporate Finance 2nd Canadian Edition BerkDocument14 pagesTest Bank For Corporate Finance 2nd Canadian Edition BerkmessiphatwtpwNo ratings yet

- Afroze ReportDocument23 pagesAfroze ReportWaleed KhalidNo ratings yet

- RM Fairness CreamDocument25 pagesRM Fairness CreamDharadahhirajlalsh100% (5)

- Surf Excel Workshop (Product Overview)Document27 pagesSurf Excel Workshop (Product Overview)Roger DsouzaNo ratings yet

- Product Strategy of LuxDocument28 pagesProduct Strategy of LuxMadhumeeta BaukNo ratings yet

- Export Processing Zone PDFDocument2 pagesExport Processing Zone PDFStacyNo ratings yet

- Dishwasing AtbpDocument14 pagesDishwasing AtbpLeigh LynNo ratings yet

- Dabur Company Market Over Wive PPT at Bec Bagalkot MbaDocument65 pagesDabur Company Market Over Wive PPT at Bec Bagalkot MbaBabasab Patil (Karrisatte)No ratings yet

- Indian Detergent WarsDocument21 pagesIndian Detergent WarsBilal HussainNo ratings yet

- Industrial Visit Report of PadgilwarDocument23 pagesIndustrial Visit Report of PadgilwarDIPAK VINAYAK SHIRBHATE100% (3)

- Fabindia Retail Case Study: Group Project - Retail MarketingDocument9 pagesFabindia Retail Case Study: Group Project - Retail MarketingLakshmi SrinivasanNo ratings yet

- Management Accounting Notes: Nature of Management Accounting Characteristics of Management AccountingDocument7 pagesManagement Accounting Notes: Nature of Management Accounting Characteristics of Management AccountingRobin FernandoNo ratings yet

- Importance of Entrepreneurship Development ProgrammeDocument3 pagesImportance of Entrepreneurship Development ProgrammekunkumabalaNo ratings yet

- Business Economics Notes Unit 1Document16 pagesBusiness Economics Notes Unit 1Ayush PandeyNo ratings yet

- Good KnightDocument12 pagesGood Knightkarishma_sehgalNo ratings yet

- SM ProjectDocument38 pagesSM ProjectNooral AlfaNo ratings yet

- Ruchi SoyaDocument52 pagesRuchi Soyakhaledawarsi0% (2)

- Presentation On Vim BarDocument12 pagesPresentation On Vim BarSourav MondalNo ratings yet

- Agrochemical Industry: Importance of AgrochemicalsDocument8 pagesAgrochemical Industry: Importance of AgrochemicalsKommineni Krishna Prasad100% (1)

- HUL-DOVE ReportDocument28 pagesHUL-DOVE ReportMrinal ChoudhuryNo ratings yet

- Os PCBLDocument7 pagesOs PCBLJibin KuriakoNo ratings yet

- Sandip Voltas ReportDocument43 pagesSandip Voltas ReportsandipNo ratings yet

- Value Chain Management Capability A Complete Guide - 2020 EditionFrom EverandValue Chain Management Capability A Complete Guide - 2020 EditionNo ratings yet

- Soap Manufacturing ProcessDocument4 pagesSoap Manufacturing ProcessNayan Gautam100% (2)

- Business PlanDocument14 pagesBusiness Plannida zehraNo ratings yet

- Final ReportDocument64 pagesFinal ReportHanan BiyaNo ratings yet

- Group 13Document43 pagesGroup 13RichaBhartiyaNo ratings yet

- Report 1Document4 pagesReport 1Menahil Sheikh100% (1)

- Course Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDocument21 pagesCourse Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDinesh Killada50% (2)

- pm2 Course HandoutDocument3 pagespm2 Course HandoutDinesh KilladaNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument13 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDinesh KilladaNo ratings yet

- Cad Cam HandoutDocument2 pagesCad Cam HandoutDinesh KilladaNo ratings yet

- Book On CastingDocument10 pagesBook On CastingDinesh KilladaNo ratings yet

- Small 19Document86 pagesSmall 19Dinesh KilladaNo ratings yet

- PHYSICAL SCIENCE 4th QUARTER EXAMINATION REVIEWERDocument8 pagesPHYSICAL SCIENCE 4th QUARTER EXAMINATION REVIEWERsiwestitohahahaNo ratings yet

- HelloDocument19 pagesHelloSaroj JiNo ratings yet

- Data Dead Stock 2020-2022 Update 23 Mei (Raw Material)Document22 pagesData Dead Stock 2020-2022 Update 23 Mei (Raw Material)Sandi SaputraNo ratings yet

- Nitoprime 25 TDS PDFDocument2 pagesNitoprime 25 TDS PDFgalih mahardikaNo ratings yet

- Drilling Mitsubishi CatalogueDocument187 pagesDrilling Mitsubishi CatalogueAmanTiwaryNo ratings yet

- Volatile of Malaysian Fruits: ComponentsDocument6 pagesVolatile of Malaysian Fruits: ComponentsРусланNo ratings yet

- TDS (Slate Finish Matt)Document3 pagesTDS (Slate Finish Matt)Nippon Paint PakistanNo ratings yet

- Periodic - Properties - Part 2 - by - AKansha - Karnwal - 1702453072953Document68 pagesPeriodic - Properties - Part 2 - by - AKansha - Karnwal - 1702453072953Saktipratik MishraNo ratings yet

- KLINGER Quantum - A - E - HomeDocument10 pagesKLINGER Quantum - A - E - HomeOctavio fnNo ratings yet

- Worksheet For Respiration Low AnswersDocument2 pagesWorksheet For Respiration Low AnswersIcs 2022No ratings yet

- Memorandum On Hair Dye Chemical Sensitisation: Scientific Committee On Consumer Safety SccsDocument18 pagesMemorandum On Hair Dye Chemical Sensitisation: Scientific Committee On Consumer Safety SccsAdi PurnomoNo ratings yet

- Transferrin 1 PDFDocument72 pagesTransferrin 1 PDFMONIRUZZAMAN MONIRNo ratings yet

- Sum Academy 2 ChemDocument5 pagesSum Academy 2 ChemRAO UMAIRNo ratings yet

- Grade Twelve Biology Model QuestionsDocument9 pagesGrade Twelve Biology Model Questionsmmree yyttNo ratings yet

- Partoza - JB, Concept Article - Endomembranesystem - DocxDocument4 pagesPartoza - JB, Concept Article - Endomembranesystem - DocxJenny PartozaNo ratings yet

- M Pharm Pharmaceutics Thesis PDFDocument8 pagesM Pharm Pharmaceutics Thesis PDFafknjdsta100% (2)

- Small Volume Parenterals by MVRR2Document37 pagesSmall Volume Parenterals by MVRR2mvrr9100% (3)

- Softening CalculationsDocument12 pagesSoftening Calculationsprannoy0% (1)

- Metal Release From Stainless Steel in Biological Environments: A ReviewDocument18 pagesMetal Release From Stainless Steel in Biological Environments: A ReviewTiên TrầnNo ratings yet

- InhibitionDocument17 pagesInhibitionLong Nhật PhanNo ratings yet

- FROSIO - Flash QuesDocument4 pagesFROSIO - Flash QuesAnte BosancicNo ratings yet

- Class Ix Biology Assignment 6 The Fundamental Unit of LifeDocument4 pagesClass Ix Biology Assignment 6 The Fundamental Unit of LifeMadhusudan BanerjeeNo ratings yet

- Belgian Standard ISO 660 - 2020 EN ISO 660 - 2020 NBN EN ISO 660 - 2020Document10 pagesBelgian Standard ISO 660 - 2020 EN ISO 660 - 2020 NBN EN ISO 660 - 2020AJ ManurungNo ratings yet

- Table Ac-1 Permissible Exposure Limits For Chemical ContaminantsDocument26 pagesTable Ac-1 Permissible Exposure Limits For Chemical ContaminantsMilena FierroNo ratings yet

- Aspen 3 Design of PFR EdtDocument8 pagesAspen 3 Design of PFR EdtethanNo ratings yet

- HDFO-30 Technial BookDocument20 pagesHDFO-30 Technial BookMao SequeirosNo ratings yet

Soap Case Study

Soap Case Study

Uploaded by

Dinesh Killada0 ratings0% found this document useful (0 votes)

334 views4 pagesThis document provides information about Lifebuoy soap, including its manufacturing process. Lifebuoy soap is manufactured by Hindustan Unilever in Haridwar, India. Haridwar was chosen as the location due to availability of energy, water, raw materials, and cheap land and labor. The plant uses a product layout, where machines are arranged sequentially based on the production process. Soap is manufactured through a flow production method, where raw materials continuously move through production stages to produce standardized bars of soap efficiently at large scale.

Original Description:

Original Title

Soap case study.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information about Lifebuoy soap, including its manufacturing process. Lifebuoy soap is manufactured by Hindustan Unilever in Haridwar, India. Haridwar was chosen as the location due to availability of energy, water, raw materials, and cheap land and labor. The plant uses a product layout, where machines are arranged sequentially based on the production process. Soap is manufactured through a flow production method, where raw materials continuously move through production stages to produce standardized bars of soap efficiently at large scale.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

334 views4 pagesSoap Case Study

Soap Case Study

Uploaded by

Dinesh KilladaThis document provides information about Lifebuoy soap, including its manufacturing process. Lifebuoy soap is manufactured by Hindustan Unilever in Haridwar, India. Haridwar was chosen as the location due to availability of energy, water, raw materials, and cheap land and labor. The plant uses a product layout, where machines are arranged sequentially based on the production process. Soap is manufactured through a flow production method, where raw materials continuously move through production stages to produce standardized bars of soap efficiently at large scale.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 4

SOAP

About the product: Soap is a salt of fatty acids used in a variety of

cleansing products. In a household, soaps are surfactants usually

used for washing, bathing. When used for cleaning, soap separates

particles from the article being cleaned. When we wash our hands,

soap, lathered with a little water, kills microorganisms by

disorganizing their membrane lipid bilayer and denaturing their

proteins. It also emulsifies oils, enabling them to be carried away by

running water.

Soap is created by mixing fats and oils with a base, as opposed to

detergent which is created by combining chemical compounds in a

mixer.

The following case study will be conducted by taking Lifebuoy soap

as an example.

Company Profile: Lifebuoy is a product of Unilever and

manufactured and marketed in India by Hindustan Unilever, the

Indian subsidiary of Unilever. Hindustan Unilever Limited is a market

leader in Indian consumer products with presence in over 20

categories of consumer products which includes soaps, shampoos,

teas and detergents etc. It has its headquarter in Mumbai with

manufacturing plants located all around India depending upon the

facility requirements of the product.

Facility location: The manufacturing plant of Lifebuoy is located in

Haridwar, Uttarakhand. Following are the reasons behind the

location of Lifebuoy’s manufacturing plant in Haridwar:

1 Availability of Energy: The energy needs of the plant are fulfilled by

energy generated by Tehri Hydro Development Corporation which is

situated only 100 kms away from Haridwar.

2 Availability of water: Plenty of water is available due to close

proximity to the river Ganges, its tributaries and distributaries.

3 Availability of raw materials: Major raw material of soap

manufacturing is palm oil and there are plenty of palm oil refining

units situated in and around Haridwar.

4 Cost of land is cheap and ample amount of land is available for

future expansion.

5 Cheap labour is easily available

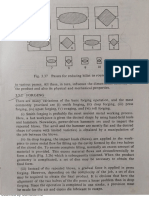

Plant Layout:

Product layout is the preferred plant layout for soap manufacturing.

It is also known as line (type) layout. It implies that various

operations on raw materials are performed in a sequence and the

machines are placed along the product flow line, i.e., machines are

arranged in the sequence in which the raw materials will be

operated upon. This type of layout is preferred for continuous

production, i.e. involving a continuous flow of raw material

processing towards the finished product stage.

Reasons behind the selection of this layout are:

(1) Less space requirements for the same volume of production.

(2) Automatic material handling, lesser material handling

movements, time and costs.

(3) Less in-process inventory.

(4) Product completes in lesser time.

(5) Better co-ordination and simple production planning and

control.

(6) Smooth and continuous work flow.

(7) Less skilled workers may serve the purpose.

Production Method:

Flow production is the preferred production method for soap

manufacturing. It involves continuous movement of items through

each stage of production, often along a conveyor belt or assembly

line. Individual jobs are done in sequence. Also known as mass or line

production, the process involves the manufacturing of a large

volume of identical, standardised products. Flow production is highly

capital-intensive and has high set-up costs, leading to high capacity

utilisation. Employees are normally semi-skilled and the process is

suited to both mechanisation and automation.

Flow production allows for economy of scale and division of labour.

Specialised staff tends to work on a single task.

You might also like

- Detergent Manufacturing Business PlanDocument3 pagesDetergent Manufacturing Business Planjamal sanadNo ratings yet

- TDS Koralone HP 150Document8 pagesTDS Koralone HP 150Quoc ThanhNo ratings yet

- The Perfumer's - An Index To The Aromatic Artists PDFDocument26 pagesThe Perfumer's - An Index To The Aromatic Artists PDFFaisel Khan100% (4)

- Marketing Research For Harpic FlushmaticDocument8 pagesMarketing Research For Harpic Flushmaticnidhs85No ratings yet

- DettolDocument8 pagesDettolMohammed SohailNo ratings yet

- Concept 02Document36 pagesConcept 02Fikri EfendiNo ratings yet

- Habib Cooking Oil ReviewDocument1 pageHabib Cooking Oil Reviewali_abbas144No ratings yet

- Rural Indebtedness in India-1Document8 pagesRural Indebtedness in India-1HASHMI SUTARIYANo ratings yet

- 3operations at LuxDocument13 pages3operations at LuxchrisNo ratings yet

- Project Report On Latex Gloves Manufacturing UnitDocument7 pagesProject Report On Latex Gloves Manufacturing UnitEIRI Board of Consultants and PublishersNo ratings yet

- The Bogey BeastDocument5 pagesThe Bogey BeastBrayan ChiribogaNo ratings yet

- Malta Soap Operations ManagementDocument15 pagesMalta Soap Operations Managementسعد كاظمNo ratings yet

- Handmade Soap Project ReportDocument17 pagesHandmade Soap Project ReportfsdcvdfzbNo ratings yet

- SIP OdonilDocument7 pagesSIP OdonilDiksha LathNo ratings yet

- MB0036 - Strategic Management and Business PolicyDocument297 pagesMB0036 - Strategic Management and Business Policysuahik100% (2)

- Consumer Preference Towards Lifeboy HulDocument84 pagesConsumer Preference Towards Lifeboy HulshobhitNo ratings yet

- Muhammad Umair LatifDocument2 pagesMuhammad Umair LatifCH Umair MerryNo ratings yet

- Schedule III of Companies Act 2013 in Excel Format-2Document48 pagesSchedule III of Companies Act 2013 in Excel Format-2divya shindeNo ratings yet

- DettolDocument10 pagesDettolTwinkle AgarwalNo ratings yet

- Om Evolution of Operations ManagementDocument7 pagesOm Evolution of Operations ManagementBrein Symon DialaNo ratings yet

- Blackbook 2021-2022Document63 pagesBlackbook 2021-2022rajNo ratings yet

- The Comprehensive Analysis of Mcdowells No1Document46 pagesThe Comprehensive Analysis of Mcdowells No1Pradipta Mukherjee100% (1)

- Tide Surt ExcelDocument75 pagesTide Surt ExcelDeep Tiwari100% (1)

- MBA Semester 1 Assignments With AnswerDocument8 pagesMBA Semester 1 Assignments With AnswerRajesh SinghNo ratings yet

- Dettol ProjectDocument25 pagesDettol ProjectPramod PradhanNo ratings yet

- Marketing in Indian EconomyDocument15 pagesMarketing in Indian Economyshivakumar NNo ratings yet

- Ground and Processed Spices and Cereals Project ReportDocument5 pagesGround and Processed Spices and Cereals Project ReportGirish DaryananiNo ratings yet

- Case Study DownsizingDocument13 pagesCase Study DownsizingManisha GuptaNo ratings yet

- Fikir Pure Natural Spring WaterDocument2 pagesFikir Pure Natural Spring WaterbirukNo ratings yet

- Business Environment and McCain Foods CompanyDocument19 pagesBusiness Environment and McCain Foods CompanyEmmanuel Kiiza100% (5)

- This Study Resource Was: Surf Excel Marketing Mix (4Ps) StrategyDocument9 pagesThis Study Resource Was: Surf Excel Marketing Mix (4Ps) StrategyIshu GunasekaraNo ratings yet

- Case Study Asian PaintsDocument20 pagesCase Study Asian PaintsRajan Girdhar100% (1)

- Project Report ShampooDocument2 pagesProject Report Shampoovineetaggarwal50% (2)

- Cust Satisfaction ArielDocument32 pagesCust Satisfaction ArielShams SNo ratings yet

- A Mini Project On SapmDocument28 pagesA Mini Project On SapmPraveen KumarNo ratings yet

- Test Bank For Corporate Finance 2nd Canadian Edition BerkDocument14 pagesTest Bank For Corporate Finance 2nd Canadian Edition BerkmessiphatwtpwNo ratings yet

- Afroze ReportDocument23 pagesAfroze ReportWaleed KhalidNo ratings yet

- RM Fairness CreamDocument25 pagesRM Fairness CreamDharadahhirajlalsh100% (5)

- Surf Excel Workshop (Product Overview)Document27 pagesSurf Excel Workshop (Product Overview)Roger DsouzaNo ratings yet

- Product Strategy of LuxDocument28 pagesProduct Strategy of LuxMadhumeeta BaukNo ratings yet

- Export Processing Zone PDFDocument2 pagesExport Processing Zone PDFStacyNo ratings yet

- Dishwasing AtbpDocument14 pagesDishwasing AtbpLeigh LynNo ratings yet

- Dabur Company Market Over Wive PPT at Bec Bagalkot MbaDocument65 pagesDabur Company Market Over Wive PPT at Bec Bagalkot MbaBabasab Patil (Karrisatte)No ratings yet

- Indian Detergent WarsDocument21 pagesIndian Detergent WarsBilal HussainNo ratings yet

- Industrial Visit Report of PadgilwarDocument23 pagesIndustrial Visit Report of PadgilwarDIPAK VINAYAK SHIRBHATE100% (3)

- Fabindia Retail Case Study: Group Project - Retail MarketingDocument9 pagesFabindia Retail Case Study: Group Project - Retail MarketingLakshmi SrinivasanNo ratings yet

- Management Accounting Notes: Nature of Management Accounting Characteristics of Management AccountingDocument7 pagesManagement Accounting Notes: Nature of Management Accounting Characteristics of Management AccountingRobin FernandoNo ratings yet

- Importance of Entrepreneurship Development ProgrammeDocument3 pagesImportance of Entrepreneurship Development ProgrammekunkumabalaNo ratings yet

- Business Economics Notes Unit 1Document16 pagesBusiness Economics Notes Unit 1Ayush PandeyNo ratings yet

- Good KnightDocument12 pagesGood Knightkarishma_sehgalNo ratings yet

- SM ProjectDocument38 pagesSM ProjectNooral AlfaNo ratings yet

- Ruchi SoyaDocument52 pagesRuchi Soyakhaledawarsi0% (2)

- Presentation On Vim BarDocument12 pagesPresentation On Vim BarSourav MondalNo ratings yet

- Agrochemical Industry: Importance of AgrochemicalsDocument8 pagesAgrochemical Industry: Importance of AgrochemicalsKommineni Krishna Prasad100% (1)

- HUL-DOVE ReportDocument28 pagesHUL-DOVE ReportMrinal ChoudhuryNo ratings yet

- Os PCBLDocument7 pagesOs PCBLJibin KuriakoNo ratings yet

- Sandip Voltas ReportDocument43 pagesSandip Voltas ReportsandipNo ratings yet

- Value Chain Management Capability A Complete Guide - 2020 EditionFrom EverandValue Chain Management Capability A Complete Guide - 2020 EditionNo ratings yet

- Soap Manufacturing ProcessDocument4 pagesSoap Manufacturing ProcessNayan Gautam100% (2)

- Business PlanDocument14 pagesBusiness Plannida zehraNo ratings yet

- Final ReportDocument64 pagesFinal ReportHanan BiyaNo ratings yet

- Group 13Document43 pagesGroup 13RichaBhartiyaNo ratings yet

- Report 1Document4 pagesReport 1Menahil Sheikh100% (1)

- Course Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDocument21 pagesCourse Title: Metal Forming (Pr-603) Lecture Note: Instructor In-Charge: Dr. Raj BallavDinesh Killada50% (2)

- pm2 Course HandoutDocument3 pagespm2 Course HandoutDinesh KilladaNo ratings yet

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument13 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDinesh KilladaNo ratings yet

- Cad Cam HandoutDocument2 pagesCad Cam HandoutDinesh KilladaNo ratings yet

- Book On CastingDocument10 pagesBook On CastingDinesh KilladaNo ratings yet

- Small 19Document86 pagesSmall 19Dinesh KilladaNo ratings yet

- PHYSICAL SCIENCE 4th QUARTER EXAMINATION REVIEWERDocument8 pagesPHYSICAL SCIENCE 4th QUARTER EXAMINATION REVIEWERsiwestitohahahaNo ratings yet

- HelloDocument19 pagesHelloSaroj JiNo ratings yet

- Data Dead Stock 2020-2022 Update 23 Mei (Raw Material)Document22 pagesData Dead Stock 2020-2022 Update 23 Mei (Raw Material)Sandi SaputraNo ratings yet

- Nitoprime 25 TDS PDFDocument2 pagesNitoprime 25 TDS PDFgalih mahardikaNo ratings yet

- Drilling Mitsubishi CatalogueDocument187 pagesDrilling Mitsubishi CatalogueAmanTiwaryNo ratings yet

- Volatile of Malaysian Fruits: ComponentsDocument6 pagesVolatile of Malaysian Fruits: ComponentsРусланNo ratings yet

- TDS (Slate Finish Matt)Document3 pagesTDS (Slate Finish Matt)Nippon Paint PakistanNo ratings yet

- Periodic - Properties - Part 2 - by - AKansha - Karnwal - 1702453072953Document68 pagesPeriodic - Properties - Part 2 - by - AKansha - Karnwal - 1702453072953Saktipratik MishraNo ratings yet

- KLINGER Quantum - A - E - HomeDocument10 pagesKLINGER Quantum - A - E - HomeOctavio fnNo ratings yet

- Worksheet For Respiration Low AnswersDocument2 pagesWorksheet For Respiration Low AnswersIcs 2022No ratings yet

- Memorandum On Hair Dye Chemical Sensitisation: Scientific Committee On Consumer Safety SccsDocument18 pagesMemorandum On Hair Dye Chemical Sensitisation: Scientific Committee On Consumer Safety SccsAdi PurnomoNo ratings yet

- Transferrin 1 PDFDocument72 pagesTransferrin 1 PDFMONIRUZZAMAN MONIRNo ratings yet

- Sum Academy 2 ChemDocument5 pagesSum Academy 2 ChemRAO UMAIRNo ratings yet

- Grade Twelve Biology Model QuestionsDocument9 pagesGrade Twelve Biology Model Questionsmmree yyttNo ratings yet

- Partoza - JB, Concept Article - Endomembranesystem - DocxDocument4 pagesPartoza - JB, Concept Article - Endomembranesystem - DocxJenny PartozaNo ratings yet

- M Pharm Pharmaceutics Thesis PDFDocument8 pagesM Pharm Pharmaceutics Thesis PDFafknjdsta100% (2)

- Small Volume Parenterals by MVRR2Document37 pagesSmall Volume Parenterals by MVRR2mvrr9100% (3)

- Softening CalculationsDocument12 pagesSoftening Calculationsprannoy0% (1)

- Metal Release From Stainless Steel in Biological Environments: A ReviewDocument18 pagesMetal Release From Stainless Steel in Biological Environments: A ReviewTiên TrầnNo ratings yet

- InhibitionDocument17 pagesInhibitionLong Nhật PhanNo ratings yet

- FROSIO - Flash QuesDocument4 pagesFROSIO - Flash QuesAnte BosancicNo ratings yet

- Class Ix Biology Assignment 6 The Fundamental Unit of LifeDocument4 pagesClass Ix Biology Assignment 6 The Fundamental Unit of LifeMadhusudan BanerjeeNo ratings yet

- Belgian Standard ISO 660 - 2020 EN ISO 660 - 2020 NBN EN ISO 660 - 2020Document10 pagesBelgian Standard ISO 660 - 2020 EN ISO 660 - 2020 NBN EN ISO 660 - 2020AJ ManurungNo ratings yet

- Table Ac-1 Permissible Exposure Limits For Chemical ContaminantsDocument26 pagesTable Ac-1 Permissible Exposure Limits For Chemical ContaminantsMilena FierroNo ratings yet

- Aspen 3 Design of PFR EdtDocument8 pagesAspen 3 Design of PFR EdtethanNo ratings yet

- HDFO-30 Technial BookDocument20 pagesHDFO-30 Technial BookMao SequeirosNo ratings yet