Professional Documents

Culture Documents

Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Elect

Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Elect

Uploaded by

karthi51289Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Elect

Saudi Aramco Test Report: MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 Elect

Uploaded by

karthi51289Copyright:

Available Formats

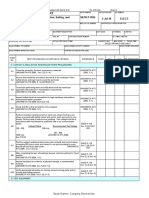

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.

00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED TEST DATE & TIME ACTUAL TEST DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

TEST PROCEDURE ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

A. PROCEDURE FOR TEST PREPARATION

Individual performing the test shall be qualified and capable of conducting

SAES-P-116

A1 the tests in a safe manner and with the complete knowledge of the

Sec. 3.2

hazards involved. (NETA ATS, 2009 Sec.5.1)

A safety lead person shall be identified prior to the commencement of SAES-P-116

A2

work. (NETA ATS, 2009 Sec.5.1.1.2) Sec. 3.2

A safety briefing shall be conducted prior to the commencement of work. SAES-P-116

A3

(NETA ATS, 2009 Sec. 5.1.1.2) Sec. 3.2

Secure and isolate the area where the test is to be conducted.Place a

SAES-P-116

A4 safety fence and sign board around the perimeter. (NETA

Sec. 3.2

ATS, 2009 Sec.5.1)

SAES-P-116

A5 Thoroughly clean the cable bus before starting the test.

Sec. 3.2

All ends under test shall be guarded from accidental contact as well as SAES-P-104

A6

separation from all ends or elements not being subject to test. Sec.13.2d

Ground the cables which are not under test. SAES-P-116

A7

(NETA ATS, 2009 Sec.7.2.2.3) Sec. 3.2

Prior to high potential test, perform a shield continuity test by ohm meter SAES-P-116

A8

method. (NETA ATS, 2009 Sec. 7.4) Sec. 3.2

Perform insulation resistance between each conductor and each

SAES-P-116

A9 conductor and the shield using a megger tester. The test voltage should

Sec. 3.2

be 5000 volts. (NETA ATS, 2009 Sec.7.3.2.2.)

After installation and before cablebus is placed in regular service, medium

16-SAMSS-520

A10 voltage power cables shall be 5 kV megger tested and then shall be DC

Sec. 9.3.2

high-potential tested at voltages specified in 15-SAMSS-502.

Insulating material for supporting and clamping cables and connections

shall be tested in accordance with section 7.8 of ANSI/IEEE C37.23 - 16-SAMSS-520

A11

1987. If requested, proof of successful testing shall be provided to the Sec. 9.4

BUYER as certified test results.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

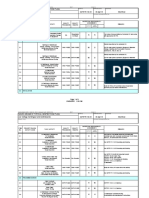

Insulation resistance

Bus Phases Applied Voltage Pass Fail Remarks

(Mega-ohms)

Phase 1 to Ground

Phase 2 to Ground

Phase 3 to Ground

Phase 1 to Phase 2

Phase 2 to Phase 3

Phase 3 to Phase 1

Notes:

1-Hi-pot test shall not be proceeded unless the insulation resistance test above is found to be satisfactory.

2-Leakage current test shall be by high potential dc step voltage method.

3-Test voltages shall not exceed 80 percent of cable manufacturer's factory test value or the maximum test voltage in the table below.

Insulation 80% Test 65% Test Rated Insulation 80% Test 65% Test

Rated Voltage

thickness Voltage Voltage Voltage thickness Voltage Voltage

5 kV 115 mils 36 kV DC 29 kV DC 6/10 kV 3.4 mm 36 kV DC 29 kV DC

15 kV 220 mils 64 kV DC 52 kV DC 12/20 kV 5.5 mm 64 kV DC 52 kV DC

35 kV 345 mils 100 kV DC 81 kV DC

Notes:

80% and 65% refer to the percentages of the factory test voltages specified in AEIC CS5 and CS6. AEIC CS5 and CS6

1

permit testing at 65% test voltage at any time during the period of the guarantee.

AEIC CS5 and CS6, and ANSI/IEEE Standard 400 do not differentiate cables based upon insulation thickness and,

2

consequently, list differing test voltages.

Insure the maximum test voltage does not exceed the voltage limits for potheads and terminators specified in IEEE Std. 48

(IEEE Standard Test Procedures and Requirements for High Voltage AC cable Terminations) or for molded rubber

3

terminations specified in IEEE std.386 ( IEEE Standard for Separable Insulated Connector Systems for Power Distribution

Systems Above 600V), or manufacturer's published data.

In accordance to SAES-P-104, Section 13.2 (e), if separable connectors (elbows) conforming to ANSI/IEEE std. 386 are

used, the high potential test on medium voltage cables may, at the request of the cable Proponent, be performed after

4

installation of the elbows. For new 15 kV cable, when tested with elbows, the test voltage is reduced from 64 kV to 53 kV; for

35 kV cable it remains unchanged at 100 kV DC ( the ICEA cable test value).

B. HIGH POTENTIAL TESTING PROCEDURE

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

Terminations shall be adequately corona-suppressed by guard ring, field

reduction sphere, or other suitable methods as necessary. Precaution

should be taken to insure that the maximum test voltage does not exceed SAES-P-116

B1

the limits for termination specified in IEEE Standard 48 or manufacturer's Sec. 3.2

specifications.

(NETA ATS, 2009 Sec. 7.4)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

The D.C. high voltage shall be applied in a minimum of four steps ( each

of an order of the rated ac rms voltage of the cable) of one (1) minute

SAES-P-116

B2 duration each except for the final test voltage which shall be maintained

Sec. 3.2

for fifteen (15) minutes.

(NETA ATS, 2009 Sec. 7.4)

Raise the voltage slowly between steps. SAES-P-116

B3

(NETA ATS, 2009 Sec. 7.4) Sec. 3.2

At the end of each step, allow the charging currents to decay, and time the

SAES-P-116

B4 interval of decay.

Sec. 3.2

(NETA ATS, 2009 Sec. 7.4)

Read the leakage current and plot a curve of leakage currents versus test

voltage on graph paper as the test progresses. Read the leakage current SAES-P-116

B5

at the same time interval for each voltage step. Sec. 3.2

(NETA ATS, 2009 Sec. 7.4)

Stop the test if leakage currents increase excessively or a "knee" appears

in the curve before maximum test voltage is reached.

A. For new cable, repair or replace the cable and repeat the test.

SAES-P-116

B6 B. For

Sec. 3.2

existing cable interconnected to new cable, notify the proponent of the

cable and the PMT for further instruction.

(NETA ATS, 2009 Sec. 7.4)

Upon reaching maximum test voltage, hold the voltage for 15 minutes.

Read the leakage current at 60 seconds intervals and plot a curve of

leakage current versus time on the same graph paper as the step voltage

SAES-P-116

B7 curve. Stop the test if leakage current starts to rise, or decrease and again

Sec. 3.2

starts to rise. the leakage current should decrease and stabilize for good

cable.

(NETA ATS, 2009 Sec. 7.4)

C. TEST EQUIPMENT AND MATERIALS CRITERIA

Schedule Q

C1 The test equipment calibration cycle shall not exceed six (6) months.

Att. IV, Sec. 7.1

S. No Equipment Name Brand Serial Number Calibration Date Remarks

D. TEST RESULTS

PHASE PHASE 1 TO GND PHASE 2 TO GND PHASE 3 TO GND

LEAKAGE CURRENT MICRO AMPS MICRO AMPS MICRO AMPS

Step 1 kV

Step 2 kV

Step 3 kV

Step 4 kV

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

15 SEC

30 SEC

45 SEC

1 MIN

2 MIN

3 MIN

4 MIN

5 MIN

6 MIN

7 MIN

8 MIN

9 MIN

10 MIN

11 MIN

12MIN

13 MIN

14 MIN

15 MIN

GENERAL DATA

TEMP. DEG. F/C

% REL. HUM.

INSUL THICK

CABLE TEST VOLTAGE

E. CONCLUSIONS

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

A satisfactory test is the exponential decrease of current with time with a

SAES-P-116

E1 fixed dc voltage applied.

Sec. 3.2

(NETA ATS, 2009 Sec. 7.4)

Step voltage slope should be reasonably linear. SAES-P-116

E2

(NETA ATS, 2009 Sec. 7.4) Sec. 3.2

Absorption slope should be flat or negative. In no case should slope

SAES-P-116

E3 exhibit positive characteristic.

Sec. 3.2

(NETA ATS, 2009 Sec. 7.4)

Test results are acceptable and in accordance with Saudi Aramco Schedule Q

E4

Engineering Standards and contractual requirements. Sec. 1.3

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU -3- July-2018 - REV. 2018.04.00 (Standards Cutoff -April 30, 2018) Rev. 2018.04.00 30-Apr-18

SATR NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO TEST REPORT

MV Cablebus High-Potential Withstand Testing SATR-P-3235 3-Jul-18 ELECT-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

TEST RESULTS ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-TEST DATE

No.

REMARKS:

REFERENCE DOCUMENTS:

1. Schedule G -- Material, Tools and Equipment (Pro Forma MP-IK-LS Contract), Contract Specific

2. Schedule Q -- Quality Requirements (Pro Forma Contract), Contract Specific

3. 16-SAMSS-520 -- Cablebus, 4 June 2014

4. NETA ATS -- Acceptance Testing Specifications for Electrical Equipment and Systems, 2009

5. SAES-P-104 -- Wiring Methods and Materials, 01 January 2018

6. SAES-P-116 -- Switchgear and Control Equipment,8 August 2017

7. Saudi Aramco Form 7823 (5/91)

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material, or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol, or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Technician Performing Test* PMT Representative

Test Performed Successfully and Results are Acceptable: T&I Witnessed QC Record Reviewed Work Verified

Name, Title, Department,

Name, Initials and Date:

Company, Initials and Date:

QC Inspector PID Representative

Witnessed Test Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Implementation of Test and Analysis of Results Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

You might also like

- QAQC Electrical Inspection: A Beginner's GuideFrom EverandQAQC Electrical Inspection: A Beginner's GuideRating: 4 out of 5 stars4/5 (1)

- 14-SAMSS-534 Oh TransformerDocument8 pages14-SAMSS-534 Oh TransformerHatemS.MashaGbehNo ratings yet

- Saudi Aramco Test ReportDocument6 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SAP 8000 Registry For Contractor/Sub-Contractor QC PersonnelDocument2 pagesSAP 8000 Registry For Contractor/Sub-Contractor QC PersonnelMudabbir HussainNo ratings yet

- Saudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 ElectDocument7 pagesSaudi Aramco Test Report: LV Panelboard - Pre-Energized and Functional Testing SATR-P-3825 3-Jul-18 Electkarthi51289No ratings yet

- Saes T 494Document9 pagesSaes T 494Ahamedulla KhanNo ratings yet

- Saudi Aramco Test Report: High Voltage Power Cable, Termination Torque Testing SATR-P-3213 3-Jul-18 ElectDocument5 pagesSaudi Aramco Test Report: High Voltage Power Cable, Termination Torque Testing SATR-P-3213 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116Document5 pagesSaudi Aramco Test Report: 3-Jul-18 Elect-DC Switchboard / CB'S, Pre-Commissioning & Functional Testing SATR-P-3116karthi51289No ratings yet

- Saudi Aramco Test ReportDocument3 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument7 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: SATR-P-3117 3-Jul-18 Elect-DC Panelboards / CB'S, Pre-Commissioning & Functional TestingDocument6 pagesSaudi Aramco Test Report: SATR-P-3117 3-Jul-18 Elect-DC Panelboards / CB'S, Pre-Commissioning & Functional Testingkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 ElectDocument6 pagesSaudi Aramco Test Report: LV Cablebus Continuity and Insulation Resistance Testing SATR-P-3238 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Satr-P-3210 Rev 7 FinalDocument11 pagesSatr-P-3210 Rev 7 FinalzhangNo ratings yet

- Saudi Aramco Test ReportDocument11 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- SATR-P-3825 LV Panelboard - Pre-Energized TestingDocument4 pagesSATR-P-3825 LV Panelboard - Pre-Energized TestingheikelNo ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test ReportDocument10 pagesSaudi Aramco Test Reportkarthi51289100% (1)

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SATIP-P-111-01 Rev 7 FinalDocument12 pagesSATIP-P-111-01 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Saes P 121Document18 pagesSaes P 121wastazoheb_700349353No ratings yet

- Saudi Aramco Test ReportDocument5 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- Saudi Aramco Test Report: Medium Voltage Power Cable, Termination Torque Testing SATR-P-3209 3-Jul-18 ElectDocument4 pagesSaudi Aramco Test Report: Medium Voltage Power Cable, Termination Torque Testing SATR-P-3209 3-Jul-18 Electkarthi51289No ratings yet

- 15 Samss 503Document17 pages15 Samss 503YOUSUF KHANNo ratings yet

- SATIP-P-116-03 Rev 7 FinalDocument4 pagesSATIP-P-116-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- CPP-NA2-PM-PLN-0027 Procedure For Cable and Conduit Seal InstallationDocument9 pagesCPP-NA2-PM-PLN-0027 Procedure For Cable and Conduit Seal InstallationAdil IjazNo ratings yet

- Saes P 114Document23 pagesSaes P 114HatemS.MashaGbehNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument TransformersDocument4 pagesSaudi Aramco Pre-Commissioning Form: Instrument TransformersJithuRaj0% (1)

- CL-NG-6460-002-056 Checklist For Protection Relays General Mechanical Checks - Visual Inspection Rev00Document3 pagesCL-NG-6460-002-056 Checklist For Protection Relays General Mechanical Checks - Visual Inspection Rev00VAJIRAVEL NAGALINGAMNo ratings yet

- Method Statment Power Quality MeasurmentDocument2 pagesMethod Statment Power Quality Measurmentm.bakrNo ratings yet

- Standard SDocument7 pagesStandard SMohan Kumar67% (3)

- SAIC-P-3007 Rev 7 FinalDocument20 pagesSAIC-P-3007 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- SATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFDocument2 pagesSATIP-P-104-05 Rev 8 Final Above Grade Conduits PDFSabheeh AliNo ratings yet

- SATIP-P-113-01 Rev 8 Final Induction Motor PDFDocument3 pagesSATIP-P-113-01 Rev 8 Final Induction Motor PDFSabheeh AliNo ratings yet

- SAIC-P-3701 Rev 0Document3 pagesSAIC-P-3701 Rev 0mkalidas2006No ratings yet

- Ongoing / Upcoming Activities at Manifa CHF Project: HSE HSEDocument12 pagesOngoing / Upcoming Activities at Manifa CHF Project: HSE HSERahil TasawarNo ratings yet

- Lightning Protection System Installation Works Inspection ChecklistDocument1 pageLightning Protection System Installation Works Inspection ChecklistReda HamedNo ratings yet

- SATIP-P-104-02 Rev 7 FinalDocument3 pagesSATIP-P-104-02 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument and Control CablesDocument2 pagesSaudi Aramco Pre-Commissioning Form: Instrument and Control Cableszahid1078No ratings yet

- KP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationDocument1 pageKP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationUtku Can KılıçNo ratings yet

- Inspection and Test Plan (Quality - Plan) : Product Type: Medium Voltage - Manufacturer: P.T. Siemens IndonesiaDocument6 pagesInspection and Test Plan (Quality - Plan) : Product Type: Medium Voltage - Manufacturer: P.T. Siemens IndonesiavinodNo ratings yet

- 14 Samss 531Document23 pages14 Samss 531HatemS.MashaGbehNo ratings yet

- MOS-MV Cable Installation, Testing, Splicing & TerminationDocument9 pagesMOS-MV Cable Installation, Testing, Splicing & Termination01095902062ahmedNo ratings yet

- Satip P 121 01 Rev 7 MPDocument7 pagesSatip P 121 01 Rev 7 MPmohamedqcNo ratings yet

- MCC Items '242009'Document188 pagesMCC Items '242009'rabso2005No ratings yet

- Inspection & Test Plan: LFC-AUHMM-E-MST-00001 Inspection & Testing - LV PanelsDocument1 pageInspection & Test Plan: LFC-AUHMM-E-MST-00001 Inspection & Testing - LV PanelsejohnNo ratings yet

- Motor InstallationDocument4 pagesMotor InstallationAj100% (1)

- Job Safety Analysis - Precast Manhole Installtion.Document5 pagesJob Safety Analysis - Precast Manhole Installtion.salauddin0mohammedNo ratings yet

- CABLE Sheath Test - 3 15.10.17Document1 pageCABLE Sheath Test - 3 15.10.17Khalid AwanNo ratings yet

- TCS P 105 00 R0Document222 pagesTCS P 105 00 R0yassir zyadahNo ratings yet

- DS-15-TMSS-07, Rev. 01 - RTV SILICON RUBBER INSULATOR COATINGDocument4 pagesDS-15-TMSS-07, Rev. 01 - RTV SILICON RUBBER INSULATOR COATINGHARINo ratings yet

- IndexDocument9 pagesIndexTori SmallNo ratings yet

- Saudi Aramco Test Report: Cable Tray, NEMA VE 1 Static Load Testing SATR-P-3301 3-Jul-18 ElectDocument4 pagesSaudi Aramco Test Report: Cable Tray, NEMA VE 1 Static Load Testing SATR-P-3301 3-Jul-18 Electkarthi51289No ratings yet

- WI-NG-6460-114 Pole Discrepancy Panel Scheme Check and Function TestDocument9 pagesWI-NG-6460-114 Pole Discrepancy Panel Scheme Check and Function Testessam khalilNo ratings yet

- 21 - Low Voltages Electl. Power Conductors and CablesDocument6 pages21 - Low Voltages Electl. Power Conductors and CablesWalid MarhabaNo ratings yet

- WI-NG-6460-002-063 Work Instruction For Trip-Circuit Supervision Rev00Document7 pagesWI-NG-6460-002-063 Work Instruction For Trip-Circuit Supervision Rev00Mohamed NasrNo ratings yet

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289No ratings yet

- TWAD - Hdpe Certificate - 75231 Sudhakar 90mmDocument2 pagesTWAD - Hdpe Certificate - 75231 Sudhakar 90mmkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18Document5 pagesSaudi Aramco Inspection Checklist: Inspection of Filling & Pressurization (Hydro Test) SAIC-A-2013 3-Jul-18karthi51289No ratings yet

- Saudi Aramco Inspection Checklist Visual Inspection at Test PressureDocument8 pagesSaudi Aramco Inspection Checklist Visual Inspection at Test Pressurekarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- Digital Sound Projector: Owner'S ManualDocument106 pagesDigital Sound Projector: Owner'S ManualFrancisco Simón FuertesNo ratings yet

- Low-Cost, Green-Mode PWM Controller For Flyback Converters: Features DescriptionDocument13 pagesLow-Cost, Green-Mode PWM Controller For Flyback Converters: Features DescriptionzoasqgzuNo ratings yet

- TM H628 V1.00 RA Amps Operation ManualDocument24 pagesTM H628 V1.00 RA Amps Operation ManualJErryNo ratings yet

- Electrochemistry Exercises - SolutionsDocument19 pagesElectrochemistry Exercises - SolutionsHữu ĐứcNo ratings yet

- 4010-9825 24V Distribution Block Installation InstructionsDocument2 pages4010-9825 24V Distribution Block Installation InstructionsRobel MTNo ratings yet

- THAT 4301 DatasheetDocument12 pagesTHAT 4301 DatasheetSaverioCorNo ratings yet

- DS-KD8003-IME1 Video Intercom Module Door Station: Key FeatureDocument4 pagesDS-KD8003-IME1 Video Intercom Module Door Station: Key FeatureYakerWalidNo ratings yet

- TPItL10 ARDETEM EN PDFDocument37 pagesTPItL10 ARDETEM EN PDFJose Yamid Jojoa GomezNo ratings yet

- 03 13003 enDocument4 pages03 13003 enImam MunandarNo ratings yet

- NBA Final MPMC Lab ManualDocument93 pagesNBA Final MPMC Lab ManualValetiNo ratings yet

- Class 4 ComputerDocument3 pagesClass 4 ComputerumeshNo ratings yet

- Driverless TrainDocument57 pagesDriverless TrainRoshan MNo ratings yet

- Infineon TC23xAC - DS DataSheet v01 - 00 ENDocument238 pagesInfineon TC23xAC - DS DataSheet v01 - 00 ENSajid EFINo ratings yet

- Project On Maglev Train Class 12Document30 pagesProject On Maglev Train Class 12vishwhaajeaayNo ratings yet

- CM303Document34 pagesCM303api-3849444No ratings yet

- EC501 - 1 - Intro - History (Compatibility Mode)Document20 pagesEC501 - 1 - Intro - History (Compatibility Mode)Naishadh BhavsarNo ratings yet

- LIT1011 DelconRelaysDocument4 pagesLIT1011 DelconRelaysalltheloveintheworldNo ratings yet

- HL19T CH MT5380P1 V2Document61 pagesHL19T CH MT5380P1 V2Jazziel DomínguezNo ratings yet

- 77 PubDocument6 pages77 PubMojtaba JabbariNo ratings yet

- DSP Project ReportDocument14 pagesDSP Project ReportMuhammad RashidNo ratings yet

- Insulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeDocument17 pagesInsulated Gate Bipolar Transistor With Ultrafast Soft Recovery DiodeOlavo FelterNo ratings yet

- ME451: Control Systems Course RoadmapDocument6 pagesME451: Control Systems Course RoadmapVu NghiaNo ratings yet

- PowerFlex Remote I-O Adapter 20 COMM-RDocument122 pagesPowerFlex Remote I-O Adapter 20 COMM-RMario Duarte100% (1)

- Lec # 04 Substation Bus SchemesDocument12 pagesLec # 04 Substation Bus SchemesAwesh KumarNo ratings yet

- Contents:: Checking Uwe Viper 2000 Axial 100Document9 pagesContents:: Checking Uwe Viper 2000 Axial 100xx100% (1)

- Overloadable Distribution Transformers For Flexible Loading in Future Distribution NetworksDocument5 pagesOverloadable Distribution Transformers For Flexible Loading in Future Distribution NetworksGokhan KalkanNo ratings yet

- Towing 4CBTDocument75 pagesTowing 4CBTAemy100% (1)

- Hkts 210 Sub/Hkts 200 Sub: SubwooferDocument6 pagesHkts 210 Sub/Hkts 200 Sub: SubwooferDan PopNo ratings yet

- XR Calculation LearnersDocument4 pagesXR Calculation LearnersDaniel ThomasNo ratings yet

- Pepprl Fuchs Barrier Switch AmpDocument4 pagesPepprl Fuchs Barrier Switch AmpShabeer CVNo ratings yet