Professional Documents

Culture Documents

Pt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)

Pt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)

Uploaded by

Solikhul HarisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)

Pt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)

Uploaded by

Solikhul HarisCopyright:

Available Formats

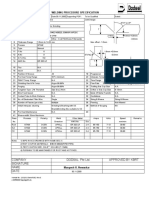

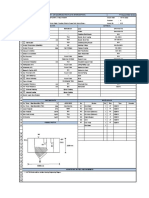

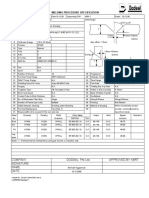

Project Title :

Job No : WELDING BOOK DOC. NO :

Client : PERTAMINA HULU MAHAKAM PROCESS PIPING (DUPLEX) SHEET :

Main Contractor : PT. BUKAKA TEKNIK UTAMA REVISION :0

Sub-Contractor : ASME IX:2019 & ASME B31.3 :2018 DATE : April 16. 2020

WPS PQR ACTUAL MATERIAL TO BE WELDED WELDING CONSUMABLE

No. PWHT REMARK

PREHEAT OD RANGE THK.

No. PROCESS NO POSITION MATERIAL CV TEST HARDNESS TEST GROUPING GRADE JOINT TYPE AWS. CLASS BRAND

TEMP. (inch) (mm)

SA 790 UNS S31803 Dia. 8" Thk 12.7 mm All Duplex SS SINGLE V, ER 2594

Ambient 36 J ALL ESAB / LINCOLN

1 WPS / ASME / 001 GTAW + SMAW PQR / ASME / 001 6G UPHILL TO 290 Hv10 P No. 10H 12.7 Up to 25.4 SINGLE BEVEL, + N/A Main

30oC -46 OC UNS S31803 DIAMETER OR SIMILAR

SA 790 UNS S31803 Dia. 8" Thk 12.7 mm & FILLET WELD E 2209-15

SA 790 UNS S31803 Dia. 8" Thk 12.7 mm All Duplex SS SINGLE V, ER 2594

Ambient 36 J ALL ESAB / LINCOLN Full Thickness

2 WPS / ASME / 002 GTAW + SMAW PQR / ASME / 002 6G UPHILL TO 290 Hv10 P No. 10H 12.7 Up to 25.4 SINGLE BEVEL, + N/A

30oC -46 OC UNS S31803 DIAMETER OR SIMILAR Repair

SA 790 UNS S31803 Dia. 8" Thk 12.7 mm & FILLET WELD E 2209-15

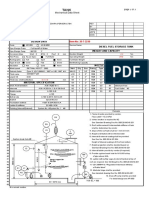

PQR & MECH. TEST SUMMARY

Project Title : FOR

Job No : PROCESS PIPING (DUPLEX) DOC. NO :

Client : PERTAMINA HULU MAHAKAM SHEET :

Main Contractor : PT. BUKAKA TEKNIK UTAMA REVISION :0

Sub-Contractor : ASME IX:2019 & ASME B31.3 :2018 DATE : April 16. 2020

JOINT PWPS No. PQR NUMBER OF MECH. TEST

No. DETAIL (S) NEW REV. PQR No QTY Of Transv. Root Bend

PROCESS & FILLER METAL POSITION MATERIAL PWHT NDT MECHANICAL TEST Side Bend CV Mid Macro Hardness (Point) Ferrit Content Metallographic Pitting Corrosion

Coupon Tensile Face Bend

- TENSILE

PIPE SA 790 UNS S31803 - BENDING 2 ea. n/a SB : 4 ea WM : 3 ea 1 ea. Near OD : 15 ea WM : 3 ea WM : 3 ea 24 hours

60°

0 - CHARPY o

1 PWPS / ASME / 001 PQR/ ASME / CP001 ROOT : 6G UP HILL Dia. 8" Thk 12.7 mm - VISUAL FL : 3 ea Near ID : 15 ea HAZ : 6 ea (L+R) HAZ : 6 ea (L+R) at 20 C

0 - 2 mm

GTAW ER 2594 Dia. 2.4 mm TO 2 N/A - PT - MACRO FL+2 : 3 ea (6-8) BM : 6 ea (L+R) BM : 6 ea (L+R) weight loss

HOT , FILL AND CAP : PIPE SA 790 UNS S31803 - RT/UT - HARDNESS HV10 FL+5 : 3 ea o'clock 4.0 g/m2

3 - 4mm SMAW E 2209-15 Dia. 3.2 mm Dia. 8" Thk 12.7 mm - PMI - FERRITE CONTENT (Near OD, ID, Mid)) (Near OD, ID, Mid))

- METALLOGRAPHIC

- PITTING CORROSION Total = 2 ea Total = 4 ea Total = 15 ea Total = 1 ea Total = 30 ea Total = 15 Total = 15 Total = 1 ea

MAIN WPS Acceptance 620 Mpa n/a 3 mm max 36 J, min. no defect 290 HV10 Ferrite content : Intermetallic Phase no pitting

o

Criteria : --> minimum discontinue at -46 C maximum 30% - 60% max. 0.05%

- TENSILE

PIPE SA 790 UNS S31803 - BENDING 2 ea. n/a SB : 4 ea WM : 3 ea 1 ea. Near OD : 15 ea WM : 3 ea WM : 3 ea 24 hours

60°

2 PWPS / ASME / 001 0 PQR/ ASME / CP001 ROOT : 6G UP HILL Dia. 8" Thk 12.7 mm - VISUAL - CHARPY FL : 3 ea Near ID : 15 ea HAZ : 6 ea (L+R) HAZ : 6 ea (L+R) at 20oC

0 - 2 mm

GTAW ER 2594 Dia. 2.4 mm TO 2 N/A - PT - MACRO FL+2 : 3 ea (6-8) BM : 6 ea (L+R) BM : 6 ea (L+R) weight loss

HOT , FILL AND CAP : PIPE SA 790 UNS S31803 - RT/UT - HARDNESS HV10 FL+5 : 3 ea o'clock 4.0 g/m2

3 - 4mm SMAW E 2209-15 Dia. 3.2 mm Dia. 8" Thk 12.7 mm - PMI - FERRITE CONTENT (Near OD, ID, Mid)) (Near OD, ID, Mid))

- METALLOGRAPHIC

TROUGH THICKNESS REPAIR - PITTING CORROSION Total = 2 ea Total = 4 ea Total = 15 ea Total = 1 ea Total = 30 ea Total = 15 Total = 15 Total = 1 ea

WPS Acceptance 620 Mpa n/a 3 mm max 36 J, min. no defect 290 HV10 Ferrite content : Intermetallic Phase no pitting

o

Criteria : --> minimum discontinue at -46 C maximum 30% - 60% max. 0.05%

You might also like

- Qualifikasi Material ASME IX LTCS A333, A350, A420Document3 pagesQualifikasi Material ASME IX LTCS A333, A350, A420Solikhul Haris0% (1)

- Positive Material Identification (Pmi) - PresentationDocument9 pagesPositive Material Identification (Pmi) - PresentationSolikhul HarisNo ratings yet

- Parametros Corte y Grabado LaserDocument1 pageParametros Corte y Grabado LaserMangan uruguay100% (1)

- Fwir Drain LineDocument2 pagesFwir Drain LineMuhamad Hifni SyahbanaNo ratings yet

- PWPS Skid & Piping Nitrogen Vaporizer PackageDocument6 pagesPWPS Skid & Piping Nitrogen Vaporizer PackageAlvin ZulkarnainNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ds-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Document2 pagesDs-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Panisa BanimaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Fwir Wellhead Instrume Bleed LineDocument2 pagesFwir Wellhead Instrume Bleed LineMuhamad Hifni SyahbanaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Wps 22Document2 pagesWps 22Avishek GuptaNo ratings yet

- Mds ScrubberDocument1 pageMds ScrubberYosses Sang NahkodaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Diaphragm ValveDocument2 pagesDiaphragm ValveHardik ShahNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Fwir Branch LineDocument10 pagesFwir Branch LineMuhamad Hifni SyahbanaNo ratings yet

- Stack Gas Specification: Project Name Client Location GeneralDocument6 pagesStack Gas Specification: Project Name Client Location Generalbudi utomo0% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Material List TIP.255-277 GI BauBau 2021.08.18Document1 pageMaterial List TIP.255-277 GI BauBau 2021.08.18Asheptya KurniawanNo ratings yet

- R1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1Document15 pagesR1-Ff-Bhadra Dam-30mt Hoist - Under Sluice Gate - r1ajwalNo ratings yet

- ER89-187-2 CL 9002 VacDocument1 pageER89-187-2 CL 9002 VacGabriel VejarNo ratings yet

- 4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Document11 pages4103 TOYO20 92DJ 1300 011 - Rev 1 - Sht001Dinesh SunderNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS 19Document15 pagesWPS 19Avishek Gupta100% (1)

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Fwir Equalizing Line LineDocument1 pageFwir Equalizing Line LineMuhamad Hifni SyahbanaNo ratings yet

- Wps 11Document2 pagesWps 11Avishek GuptaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Document55 pagesG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHNo ratings yet

- Hav HKN 219001 Gas Me DS 0017Document5 pagesHav HKN 219001 Gas Me DS 0017bkm dizaynNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Data Sheet: Cpi (Corrugated Plate Interceptor)Document1 pageData Sheet: Cpi (Corrugated Plate Interceptor)wahyu hidayatNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Equipment Data Sheet: Type: Doc No: Mds-Pv-01Document3 pagesEquipment Data Sheet: Type: Doc No: Mds-Pv-01Waqas WaqasNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Rev.2 Calculation Tag# HAA10AA201Document4 pagesRev.2 Calculation Tag# HAA10AA201psaayoNo ratings yet

- Revised Weld Map (23!07!2015)Document15 pagesRevised Weld Map (23!07!2015)Midhun K Chandrabose100% (1)

- Ins PT005Document1 pageIns PT005faisal hajjNo ratings yet

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- Data Sheet Válvula de Seguridad y AlivioDocument4 pagesData Sheet Válvula de Seguridad y Aliviorenzo condeNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WaruExperienceList UpdateDocument15 pagesWaruExperienceList UpdateHANIF AKBARNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Wps 18Document2 pagesWps 18Avishek GuptaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Bectel ASME Process Cal R2Document21 pagesBectel ASME Process Cal R2Sivakumar SelvarajNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- J33388i-Editable Datasheet Spare List and ItpDocument7 pagesJ33388i-Editable Datasheet Spare List and ItptoonaughtyNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- KRO2-WM01-S-0702 - Specific Equipment Dimensional Drawings Rev.6Document55 pagesKRO2-WM01-S-0702 - Specific Equipment Dimensional Drawings Rev.6ABAID ULLAHNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Summary PWPS TMG 11april 2018Document1 pageSummary PWPS TMG 11april 2018Solikhul HarisNo ratings yet

- Pages From AWS D1.1-D1.1M-2015 - Structural Welding Code-SteelDocument1 pagePages From AWS D1.1-D1.1M-2015 - Structural Welding Code-SteelSolikhul HarisNo ratings yet

- PT ACU Environmental and Spillage Rev 0Document5 pagesPT ACU Environmental and Spillage Rev 0Solikhul HarisNo ratings yet

- PT ACU Contingency Planning Rev 0Document4 pagesPT ACU Contingency Planning Rev 0Solikhul HarisNo ratings yet

- Report of Positive Material Identification (PMI)Document16 pagesReport of Positive Material Identification (PMI)Solikhul HarisNo ratings yet

- Akumulasi Welding & NDT PipingDocument4 pagesAkumulasi Welding & NDT PipingSolikhul HarisNo ratings yet

- Iso 744-2020 PDFDocument12 pagesIso 744-2020 PDFSolikhul HarisNo ratings yet

- Sio 5763-1989 PDFDocument10 pagesSio 5763-1989 PDFSolikhul HarisNo ratings yet

- Certificate of Compliance For Radioactive Material Packages USA 9296 B (U) - 96 Rev. 11Document4 pagesCertificate of Compliance For Radioactive Material Packages USA 9296 B (U) - 96 Rev. 11Solikhul HarisNo ratings yet

- QW-403 6Document1 pageQW-403 6Solikhul HarisNo ratings yet

- Pages From AWS D1.1-D1.1M-2015 - Structural Welding Code-Steel Table 9.10Document2 pagesPages From AWS D1.1-D1.1M-2015 - Structural Welding Code-Steel Table 9.10Solikhul HarisNo ratings yet

- Kobe LB-52U Technical PropertiesDocument1 pageKobe LB-52U Technical PropertiesIlyas HabibiNo ratings yet

- Document Title: Standard Specification: Duplex Induction Bends COPI Doc No.: ID-G-BU-KK0-STS-GN-00-0008Document15 pagesDocument Title: Standard Specification: Duplex Induction Bends COPI Doc No.: ID-G-BU-KK0-STS-GN-00-0008Solikhul HarisNo ratings yet

- Posc : Mill Test Cedificate Sertifikat Pengujian PabrikDocument5 pagesPosc : Mill Test Cedificate Sertifikat Pengujian PabrikSolikhul HarisNo ratings yet

- NDT Steel CastingsDocument17 pagesNDT Steel CastingsWoodrow FoxNo ratings yet

- Hercules Structural Systems Pvt. LTDDocument5 pagesHercules Structural Systems Pvt. LTDNeeraj SinghNo ratings yet

- Mud Hands: Earth Architects, BangaloreDocument43 pagesMud Hands: Earth Architects, BangaloreNamitha PraveenNo ratings yet

- En 196 (Summary)Document6 pagesEn 196 (Summary)Ja Phe TiNo ratings yet

- Northparkes TFPM CP 07122020Document20 pagesNorthparkes TFPM CP 07122020EDUARDO ROBLES VENEGASNo ratings yet

- SMApaperDocument15 pagesSMApaperDipNo ratings yet

- Lecture 22 PDFDocument6 pagesLecture 22 PDFBhavesh Dilip ChanchlaniNo ratings yet

- Temperature Enthalpy (HG) KJ/KG Enthalpy (HF) KJ/KGDocument104 pagesTemperature Enthalpy (HG) KJ/KG Enthalpy (HF) KJ/KGUzair BukhariNo ratings yet

- Basf Masterbrace 4500 TdsDocument2 pagesBasf Masterbrace 4500 TdsShivanan SinghNo ratings yet

- The Growth Kinetics of Tio Nanoparticles From Titanium (Iv) Alkoxide at High Water/ Titanium RatioDocument5 pagesThe Growth Kinetics of Tio Nanoparticles From Titanium (Iv) Alkoxide at High Water/ Titanium RatioVarisa RahmawatiNo ratings yet

- SkinnySelectKevlar 4841Document1 pageSkinnySelectKevlar 4841Carlos Manuel Leonardo Vargas NavaNo ratings yet

- List of Material: Saudi Arabian Oil CompanyDocument1 pageList of Material: Saudi Arabian Oil CompanyRanielNo ratings yet

- Брошюра На Girbau LS-332 (Англ.)Document6 pagesБрошюра На Girbau LS-332 (Англ.)Altay ZeynalovNo ratings yet

- Composite ImpactDocument32 pagesComposite Impacteugeniovn2012No ratings yet

- Construction Method for Underground Water Tank - معدلDocument21 pagesConstruction Method for Underground Water Tank - معدلM.ZEKEBANo ratings yet

- Epoxy SLV MapeiDocument4 pagesEpoxy SLV MapeiAvinash PrajapatiNo ratings yet

- Solubility - WikipediaDocument14 pagesSolubility - Wikipediatsvmpm1765No ratings yet

- TVL Tools and Equipment NeededDocument1 pageTVL Tools and Equipment NeededKATHERINE IBANEZNo ratings yet

- Engineering Chemistry Refractories and NanomaterialsDocument14 pagesEngineering Chemistry Refractories and NanomaterialsSiddharth Singh100% (1)

- Product Catalogue EN PDFDocument104 pagesProduct Catalogue EN PDFAPEX SONNo ratings yet

- En 10025-2 ExtractDocument1 pageEn 10025-2 Extractpalani.djpNo ratings yet

- Shell and Tube Heat Exchanger - WikipediaDocument5 pagesShell and Tube Heat Exchanger - Wikipediabinok19No ratings yet

- Composites: EN 2561 Tensile Properties Parallel To The Fibre Direction of Unidirectional Carbon Fibre-Reinforced PlasticsDocument2 pagesComposites: EN 2561 Tensile Properties Parallel To The Fibre Direction of Unidirectional Carbon Fibre-Reinforced PlasticsDavid SimangunsongNo ratings yet

- Modeling of Corona+koui+Transmission SystemsDocument12 pagesModeling of Corona+koui+Transmission SystemsDadi AzizNo ratings yet

- Sika Injection 304 PDS PDFDocument4 pagesSika Injection 304 PDS PDFslantsyhimNo ratings yet

- Strength of Materials: Prepared By: Engr. Jeric P. SarteDocument30 pagesStrength of Materials: Prepared By: Engr. Jeric P. SarteGiacomo EllieNo ratings yet

- IS516 Part2 Sec3 2022Document16 pagesIS516 Part2 Sec3 2022Manoj Kumar Singh100% (1)

- Alia AMF600 Sanitary FlowmeterDocument3 pagesAlia AMF600 Sanitary FlowmeterRexCrazyMindNo ratings yet

- Cellulose Fibers, RegeneratedDocument39 pagesCellulose Fibers, Regeneratedyemresimsek100% (1)