Professional Documents

Culture Documents

Definition and Test Procedures For Ammonium Nitrate

Definition and Test Procedures For Ammonium Nitrate

Uploaded by

Robert Roberts0 ratings0% found this document useful (0 votes)

77 views18 pagesWork

Original Title

definition-and-test-procedures-for-ammonium-nitrate

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWork

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

77 views18 pagesDefinition and Test Procedures For Ammonium Nitrate

Definition and Test Procedures For Ammonium Nitrate

Uploaded by

Robert RobertsWork

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 18

DEFINITION AND TEST PROCEDURES

FoR

AMMONIUM NITRATE FERTILIZER

‘The Fartiier institute

1015 Tah Steet. Nn,

Washington. 0.6. 20036

August, 1986

DEFINITION AND TEST PROCEDURES FOR AMMONIUM NITRATE FERTILIZER

‘This aookiet sts forth the definition and test procecures tor

ammonium nitrate feriizer orginally cevelogee By the Agricultural

Nitrogen ingttute, & forerunner organization of The Fertilizer In

tute [TFI). “This booklet does not pertain to blasting apents OF

‘tier ammonium ritrates Previous. revisons. of this Booklet Dy

‘TEV are deta May 7, 1971, and lanuary 16, 1973,

In Mey of 1984, TF convened 2 Task Force of industry anc

government ‘earetentatves, experts on the physical and chemical

Eharacterates of ammonium nitrate fertiiet, 10 review this pub-

leation ana to make any necessary changes a6 they deemed proper.

Besec on that "eve andthe technical expertise and experience

fof the Task Force members, TF! published this "vised edition deted

‘August, 1386,

‘TEE and its members, Jointly and separately, are rot responsible

for nor shall they nave ony "ability of any Kind whatsoever for any

low or Gamage resulting ‘rom the use of the Definition and Test

Procedu'er for Ammonium Niv‘ste Ferizers or fo" the violation of

fey Ter, tate” mural reguson with whieh they ayo

ineentionally eontliet.

[AMMONIUM NITRATE PUBLICATION REVIEW TASK FORCE

Wiliam Bone

Marion Browe

WS Chang

Dexter Colemas

James Gormanion

Frank Jonnson

BH Marlow

George Martinez

nn Mason

Jon Mesnuity

‘PO! Nickerson

1.8. Paterson

Charen Suite

Paul Thereault

Harold Tae

Jones Tolar

May 1984

company

Air Proguets & Cremicals

Mlstisiop! Chemical Cor.

Buresu of Sxpigsves/AAR

WR: Grace & Company

U.S. Cone cura

Teoneenee Valey Authority

Keiser Agricultural Chemical

‘Company

Wycon Chemical Company

Bureau of Exaiosvew AAA

US Const Guaea

USS Age Chemicals

Hawkeye Crem! Company

UPS" Sesr, of Transportation

‘tes Power Company

Ghevron Creriea) Company

‘air Praguets & Cnernens,

iny/Sexte

Pensacola, FL

Yazoo City. MS

Eiuon, No

Wilmington, NC

Warmington, DC

Muscle Snoais, AL

Sevannan, GA

Cheyene, WY

Ecizon,

Wasniaton, OC

‘Atanta, CA

Glinton, 1A

Warmington, OC

‘opin, MO

Ricnmond, CA

Pensacola, FL

INTRODUCTION

It is fet that the following combination of sefintion and test

procedures precludes the possbility. of classying as Ammonium

Nitra Feriger any ammonium itates wnich contain witficient

Crgenies of other oxiagble materia! to present any azard in trans

potution of rage. the cefntion sone would not be adequate

Fort would the test procedures alone be suequate to arcomoish this

Che “However, the requirement. that a Materia) pas both the Ce

finition ard te cents should accomplish the desired end. The com

‘ination of definition and fesse many times more severe than the

Currently sed definition ond fest requirements.

The texte specified are in no way to de confused with oF t0 be

used to ‘eblace the indurtry standard est for distinguishing between

xplosies and blotting agents. The tests gwven herein are designed

2Paeting thowe mateals which ae propery considered to be Am

‘onism Nirate Fertil ze.

‘The latest revision of this booklet is referenced in the U.S. Oe

penmont of Transporation’ "Hazardous “Materiais Regulations”

[Goce ot Sedera) Regulations, Tite 49, 173.182) as the everia that

‘host be net belore a material ean be sipped under the description

Tenmeniun strate ferieer, containing ne mare than O.2% carbon

uN2067"

INDEX

SECTION 1.0 DEFINITION coe seed

SECTION 20 DETONATION RESISTANCE TEST

Preparation of Sample fr Tesing

Priming

Deronation

Inverpratarich af esis,

ANALYTICAL METHODS.

Nitrogen «

Feterence

Reagents.

Procecure

Chicuiaton

SECTION

oon

Reference

Priseiple

Reagents

Apparatus

Praceaure

Cestation

Elemental Metals

Reference

Prneipie

Apperatus

Reagents

Procedure

Caicsiaton

Experimental Results

2S ESSSSES

Elemental Sulfur. Methox 1

Reference

Reagents

Procedure

Chlesiaton

Sulfur Methos 2

Retoren

Apparatus

Rewge

Procesure

Gatestation

Suvovee CeELL BEBBBERE BEBLEEL BeAnY

INDEX (Continued)

Cchiorees.

Reterenes

Reagents

Procecure

Cateutaton ©.

SECTION BURNING TEST.

Introduction

Eouipment

Evawvation of Result

Notes

pease & wenee

§

SECTION 1.0 DEFINITION

‘Ammonium Nitrate Fertilizer is cefined as solid ammonium nitrate containing a minimum

‘of 33.0% nitrogen, having a minimum pH of 4.0 in 2 10% aqueous s ution, 0.20% maximum

‘arbon, 0.010% maximum element! sifur, 0.180% maximum ehioride as CL of particulates

tlemental metals sufeent to releage £60 rl, maximum, of Rysrogen from 80.0 gram sample

Ene which wil sans the Setonation resistance tax Section 2.0 ang the burning tet Section

4.

SECTION 2.0 DETONATION RESISTANCE TEST

2.1 _Preparition of Semple for Testing

[A representative sample of the material to be tested shall be used to fla two foot

Section [minimum length) of Schedule 40, three ine (Iron Pipe Sze Black ran

\eloed pipe, closed at one end with carsbosrd or equwalent closure. The met

Sha be compacted by dropping the filiea pie, one ume, closed end down, from a

Felgnt of sx inches onto aboars. It necessary, agditions| sample shal be added to

bring the level of materiel 9 one inch below the ip oF the Pipe

22° Priming

{A Pentolite pellet weighing 4.7 grams is use forthe primer inthis text. The

Pentalte used 's 50% ?-€ T.N. ana 60% TNT. ‘The pellet eax inch i lenath, one

‘natin im diameter, wish a onetourth inch hale inthe top center one-fourth ch

deep. One No. 6 blasting cap ie tapeg into the Pentalite pellet. The pales buried

inthe test materia, with the tom of the pellet ane.nen deep. Note: In order to

andarize the tert, a material sll be tested st TOO,

23° Detonation

The primed pipe shal be placed ina vertical position behing 2 suitable barricase (to

proteer personne! from possible shvaprell. After sersonnel have taken cover, the

primar shall be tired. Caution This ter shall be run only by gualified personnel

Angin elites designed for sxplonve test ng.

24 Interpretation of Results

[Any material which pases the tes will ot propagate throush she two-toot section

oF pipe and wil leave ome undamaged pipe, Any material which propagates

"nrOugh the fwo-foot length of pibe and which leaves o Undamatea pipe cannot be

lomteg ag Ammonium Nitrate Ferien.

SECTION3.0 ANALYTICAL METHODS

2.1 Nitrogen

3.1.1 Reterarce

Official Methods of Analysis. AOAC Eleventh Edition, 1870, Prodedure 2.068.

3.12 Reagents

Formadenyde, approximately 37%

Socium nydraxice, 0.25 0.SN. Standardize aginst primary standard

2.1.8 Procedure

Revie y weigh and transfer 1.89 of ungroune sample to a 250m Erlenmeyer task,

Dissolve sample wits above 50 ™L ciileg water ane ada 15 mi. forma dehy,

Dilvtete 150-200 mL and let stand ive minutes, Titrate wits 0.25.°0.5 8 soclom

hydracide using § drops ot phenolpnhalein os indicator or to 94 of 8.6 i electro.

metre end point is preerred, If colorimevie eng points usea, urate unt! there

fo Bereeatble colar change at ont of contact Determine Blank on formalahyae

olson

et mt NOH x Nx 2.8014

ware

9% Nitrogen =

321

Moaitatign af Sampling and Analysis of Carbon and Alloy Steels by U.S. Stel

hems, Reithotd Bubitaning Company. “

3.2.2 Princigle

Organic sdaitives in ammonium nitrate fertilizer can be determined by measuring

the exibon dioxide evalved upon combustion of the ample." oxygen. Water an

the AN are added to Freshly gnitad magnesium oxide and the mixture heated £0

7002C in guarez combustion tube. ‘The carbon dioxide i absorded In Barurh

hhydroside solution and determined by a gravimetrie or turbisimetre method. Less

‘than 0.1% carbon n AN can be determined The total carbon Gotainew DY

{combustion must be corrected if earbonates are present in tie AN. The exbonate

ontent is determined by 2 sancard method, eg, 290 ac to 9 imple of the AN in

1 closed system, aerate, and aos0rb CO in BalOrilg azn the combustion text,

3.23 Reagene

Magnesium oxiae, reagent grade

Copper oxide, reagent grade

Siver gauze, reagent grade

Bartum hyatoxide, IM ~ Dissolve 315 9 83(0H)2.8H20, reagent grade,

INCOD tree distiled water and aiute fo ane iter, ‘Allow ta sete

owen

Oxygen, US®.

3.24 Agparstus

Quartz combustion tube, one-inch 0,

2 Electric heating furnaces

| Fused sites bos, 16 mm x 100 mn

| Fett gists washing botte, 125 mL

3.25 Procedure

A stream of oxygen is pase through the combustion apparatus which consiss of

‘one-inch diameter quart tobe connected t0 2 125m trated disk gs worming Sote

Containing 75 mL barium hydroxide siution, Tha quart combustion tube

Backed with copser oxige wire 3 length of 3 inches and with svar gouref0 8

length ot 1 inch, aa this section is heated witha savionary electric fornace, The

samples heated with « movable furnace 0° Fisher burn,

Place 1.5 g magnesium oxide inthe fused sca boat and heat to 7O09C jn the

Combustion tube, Disconnect the abaoroer baie during this nial heating. After

{en minute, connect the soaorDur Dotle nd remove the boat from the combustion

{ube ma Op tree atmosphere. Freshly ignited magnesium axige 2bs0"0s CO

very easily

‘Add 4g AN and ? mL COp-tee water tothe beat. Carefully heat the sample unl

the arsnonia and water have been removed then continue to heat for 30 minutes

{8 7008C. The aroun of berium carbonate n the absorber bottle can be de

tecrires (7) gravimerrialy by fitering the preciotee through a medium sintered

iam ftercrusible, masnng with COzree water. and drying to a constant weight

ELT10°C. (2) by visually comparing fhe turbiclty In the absorber Bore with known

[mounts of sodium eartonate added to 75 mu of IW barium nydroxie solucon. A

‘Tank must be rum on reagent grace AN. Oxygen must be used for blank and

22.6 galevstion

WC = WeSample apt Ws Blank pot x 6.08

Wr of Sample

3.3 Elemental Meta

3.3.1 Reference

Procecure presented to The Fertilizer Institute by the Nitrogen Division, Allied

(Chemical Company Teennial Service Group, Hopewel, Virginia,

3.3.2 Principle

Strong acid is regcted with elemental metals and hyGrogen liberated is measuree

Biter any CO? liberated is absorbed with NaQl. [nthe ever all the aluminum does

fot react wth the aid, it wl fact with the caustic Yo liberate hydrogen under

the conditions preseribec

39.3 Agpantus

See Figure 1. If desired, the apparatus coule be improves by having the f

Borer constructed with 9 ball or werd font.

3.3.4 Reagents

Sodium carbonate

Te ysroeriare acid

2N Sodium hysronice

Os serorol O Solution, Fiaher Scientific Company, Cat No. SO.A.292

3.3.5 Procecure

Place $0 20.1 gof ammonium nivvate in 8 400 mL beaker, Add, 10 + 1g of sosium

carboreta anc shout 200 oof water. Filter through a Gooeh crucible having &

separable perforated bottom. Tracer al residue, which contain any merle

reser, trom the beaker tothe erucibie ano wash thoroughly

Remove the perforated bottom along withthe asbestos mat and resicue from the

crucible and place ina 125 mL “ter fase. Attach an oblique bore topeock to the

Sdearr of the fate and clom the fiask with a No. 1/2 rubber stapper through

‘which inserted cloud end 50 mc gas Duret ax shown in Figure |

336

‘Aluminum

‘Ades.

Evacuite the task and buret with a vacuum pump {10 minutes} and elo the ston

oek. Remove the vacuum puma line. Inge the outlet en of the stopcock in Y

hydroshiore acic and turn the stopcock to admit about TO mL af the ela. Let

‘and ‘or thirty minutes. ‘The pressnee of metals or carbonates wil be anparent By

En evolution of gos rom the acc, insentthe outlet end af tre stopcock mo # 250

IMC beaker filed with seaium hydronige solution of about 2 Netrength. The

Seiten of 23 erope of wetting agent {10% seroxo! OT Solution! to the sodium

hiyarosige solution wil sign preventing scherence o! ga bubbies to the wall o! the

apparatus, invert the apporetus two or three times to siodge them.

Recoré the volume of gas (hydrogen, the remperature adjacent to the buret, anc

the Barometric pressure. Run aban In the same manner a8 tre sample to account

for devorbed gases trom the reagents an or air orewent n the outlet end of the

stopcock. “Convert the volume of hyaragen to standard condones 0 lows

Correted mL (STP) = Barometric Presure x mk Hp x 273

WAI= mL Hycrogen STP) x 0.0802

Magnesiam

(273+ £90) x 760

Per Gent Ades

(Sg Sample Bax)

Corrections for water vapor volume and hydrogen solubility are not appli in the

{lculsion ance ter ence appear to be nes able "

3.3.7 Experimental Reslts

Test ofthis method with knows amourts of aluminum and magnesium save the

following recovery value

Per Cent M5 or

‘lfound

(sogSampe Sans)

o.o108

S.0082

oornt

0.0128

34 Glamental Sulfur Memos 1

34.1 Reference

(Oficial Methods of Analysis, AAC 13th Eeition, 1980, Procedure 2.160.

3.4.2 Reacerts

Aromine in carbon tetrachloriel®l «10%. Ada 10.9 Ba to 90 reagent orade

Gig. Sei une homogeneous. Stove in glasestoppered Dost

concentrated HNO

Concentrates HC!

Sromopherol Bue indicator - Grind 0.1 get the powder with 1.5 mL.OIN

NaOH solution and elute ro 25 me

yam enlorige elution 10%, Dissolve 100 9 B4Ci2.2+20 in 900 mL H20

‘nd Hiter through Whatman No. 42 paper. me = 3895,

2.4.3 Procedure

Weigh 0 + 0.1 gof sample into a 400 mL beaker and ads about 200 mL of water.

Finer tie alution through a Goch crucible. Transfer all reegue from Seaeer fo,

‘rucibi and wash thoroughly with cited water

Transfer residue 1 2 250 mL beaker. Evaporate the water to dryness then 00! %0

room temperature, Adé TO mL of bromine In carbon tetrachiorise, cover ane allow

forstans about thirty minute, suiting vera times. Add TB mL concentrated

HINO, cover and allow to stand about thirty minutes, stirring several mes.

Evapdtate on Rot plate to about 5 mL. Aga 20 mc concentrated HC! and evaporate

about SimU_ Add about 80 mL wate, liter and wash with 2% MCl. Add tno

‘irops bromapheno) blue ndeator and then ammonium nydroxige to first eolor

hange Aes HC! dropwise unt distinetiy ae, than five Srope im excest diate to

“80 mL, heat fo boling, and ade barium enlriée solution slowly dropwise Unt

about 0% excess present. Cover beaker and gigest on steam” bath atleast one

hous. Coo! to room semparature and ite on 4 Gooch crucible previously ited at

{800% anc weighea. Wash ten times with hot water. Ignite in mute at BOOSC for

atleast twenty minutes Cool in Gescestor and weigh 38 8350

3.4.4 Caleulsion

Sulfur as $= We 88504 x 32.06 x 100 oF We B3S04 x 3.796

Ws Sample x 233.42 We Sample

(a) NOTE: Bromine isan iritant ane should be hanced with caution. Carbon tera

TS" Chloride ie carcinogen and should be used with extreme caution.

35° Sulfur Methoa 2

3.5.1 Reference | ASTM Method 0126-8

35:2 Apparatus

Photometer - Preterabiy a spectrophotometer having ettactve bend width ot

SuFBO'TM and esuipped with a bive wvative pnototube for use at #00 Ne,

tr alternatively a fiter snotareter equipped wit #2010" filter Paving 8

Paximum wanemision at approximately 425 nm,

‘Absorption Cele - Cells having optical path lengths of Sem are preterted

‘Widrune, the Gale may become coatec witha film, To remove this fim,

wath the calls with a detergent using a soft brush, Rinse thoreugniy with

‘elonized water folowing clearing

NOTE: The procedure es written asures an ebsorbance change of about 0.100 for

‘ich 0.1 me of sutra 50 mL of solution measured in a'5 em cel. Photo

‘eters employing cells of shorter optical paths give proportionately poorer

Sreeision

Secop - Capable of cispersing 0.30 + 0.01 got 20 10 30 mesh barium

‘horde dinvarate

Magnetic Strrer - Equipped with 11/4 ine tetatiuoraethylene (Tetlon)

Sea an

353 Reagents

Alcohol ~ Giveerin Mixture - Mie 2 volumes of 95% eth! alcoho! with 1

Wotvne of antyarourivserin. To this solution na titer valsmetsc fash,

38d TO mL ot HpSOq {1 mL = img) and makeup tovolume with

Sheoho” giycerih solution. Each miliiterof tie resulting toluton is thet

‘auivlent to about 0.07 mg of stu

{Barium Chloride Dinyorate ~ (BxCl2.2H0), 20 0 30 mesh erystale

NOTE: The erysta sige ofthe 82.2470 is an important variable that effets the

evelopment of turbidity.” 2°

Hyrochlore Acid 1 + 12) - Add 77 mt of concentrated hydrochloric acid

(HEtip- or 18) toe THe volumetric Mase and cute tothe mark wih de

lonzed aisilles water.

Suture Acid (1 mL = 1.0mgs) - Dilute 62.4 20.1 mt of 1N sulfuric aca

iHegb gio etscy Tie! widsteioneed iniled war” Check the siuon

Dy titration agains standara sodium hyeroxide (NaOH) solution of ebout the

Same normality and adjum the concentration, it necessary, 50 that each mil

Iiterof ths solution isequnvalent to 1.0 mg of sulfur

Sulluric Acid (1 mL * 0.100 mgs) - Dilute 6.24 2 0,01 mL of 1 N suture

Scie (HpS0q) to exacTy Tier with deconies cited water. Check the

ition by freration agenst stnard NsOM solution of about the same

normality and adjust the concentration, f necessary, $0 that each milter

Of tis solution i equivalent t6 0.160 mg ofS

Wore, Deionizes Distilled - Percolate distil water through 8 column of

‘ined anion and cation exchange resins

NOTE: A means for determining when to replace the exchange resins should be

soplied. Use of a simple electrical conductivity mesa has been fOund

Stistatory for this purpose.

354 Calinertion

Ingo 50:m. volumetric flasks introduce, by means ofa buret, 0.25, 0.50, 0.75, 1.00,

1150, 2.00 3.00 ana 5.00 mi of HaS04 (Tents 0.100 mg $). Ace 3.0 mL ot HCl

(7+ 12) to each fas, lute vo volome with water, ane mix thoroughly. Prepare

reapert blank standard ina similar way, omitting the 250g,

Pour the entice contents ofeach tek into 2 100 mL beaker, add by means of #

pipet 1020.1 mL of alcohol glycerin mixwre, and mix for’ minutes on the

magnetic ritrer” Selecta rirring speed jus below that whieh mignt cause los of

Smple througn splashing. Maintain this speed throughout the entire procedure.

Allow the solution to sand unciaturbed for 4 minutes. Transfer to an absorption

alt and reasire te initial absorbance, using water as celerence

Return the solution to the beaker and ade 0.30 £0.01 got BaCiz.2420 crystals,

‘ithe by weighing this amour or by use ofthe coop. Sti wih the magnetic

Sure favexacly'3 minutes. Allow to sare foram addtional # minutes, transfer

{othe cel, and again maasute the absorbance lative tO water,

Following steps described in 2nd, Sr, 4th paragraphs above, obtain a reagent blank

‘eading by subtracting the nal sboreance oF tne reagent Blane standace on rat

btained her acction of BaCig 2420. Thisreacing owie not exceed 0.108

{ines influence of adced suRun.

‘Obtain the net absorbance for each standard by abtracting the inital absorbance

{nd reagent blank reading trom the absorbance obtained in aacordance withthe

‘4th paragraph above. Plat the net absoroance of each standard apeinat miligarss

‘of sifurconteined in 50 mL of solution, and draw a smooth curve through the

points

Check the calibration curve dally by making single determinations to detect possible

sik.

Procedu

Weigh 2 t 4 got sample into 2 400 mt beaker and ade about 200 mt. of water

Filter thasolstin through a Gooe® racibia. Transfer al residue t70m beace® (0

crucible and wash thoroughly with cited water

“Transfer residue 103 250 mL beaker. Evaporate the water to dryness then coo! to

room tenperature, Add 10 mL bromine In carbon setraclorige, cover and arOw

to stand sbovt thirry minutes, sting several times. Add 13 mL concentrates

HINO, cover and allow to stand about thirty minutes, string svera “ee.

Evaporate on hot pate to about 5 mL. Add 20 mL concantrated HC and evaporate

{about S mL, transfer toa 50 mL volumetric Mask with analyieal rinsing practice

snd diate volume,

Pour the entire contants of the 50 mL volumevic task containing the solution to

be analyzed int a 100 mL beaker and proceed ss directed nthe 290, Sr, and ath

Daragraphs of the ealipration procecure. Treat ablank inthe ame way and abtain

Feagant blank reading by suberactng is inal absorbance from thay obtained af

seuition of Bac. 2820,

NOTE: Srould the blank reading excwad 0.120, the prcison obtainable will be imsed

In thi went, make ar anaiyns of the reagents lone Yo determine which reagents

stain te net absorbance of the analysis solution by aubracting the initial ab+

sorbance snd reagent Bank reading from that Obtained after adelon of Bel

2h0.

Convert net absorbance to milligrams of sulfur by using the calibration curve

386 Galeuton

Cleulate the emount of sulfur in the sample as follows

Sufur content, ppm = A x 1000

We

A= milligrams of sifur reac from the calibration curve,

We Gramsor somgie

F = sliquet traction of the sample solution used for analysis:

38 _Chioriger

36.1 Reference

Oficial Methods of Analysis, AOAC, 13th Edition, 1960, Method 2.119 2.120,

38.2 Aesgente

Sliver Nitrate Solution - Dissolve 6 y AgNO in water ane dilute 101 L.

araize agar pure, dry NaCl. Potassium Chromate Indicstor- Dissolve

Sak ycrOg mater anc giute to 100 me.

3.6.3 Procadur

Weigh 1009 of simple, transfer to 250 mL Erlenmeyer tase anc cissove in about

40m. dilled water. Diluse to 60 mL, add 1 mL potassium enromate naleator

land virte wth mandardized siver vate toa perastantredoisorown colo!

uring the ciation dropwise aduiton of the Sives nitrate while constanty swirling

the flank wil yela the bet end point.

3.84 Caleuiation

Sc) = MLABNOg x Fx 100

wesarple

Where F = @CvmLAgNO3

SECTION 40 SURNING TEST

41 tntrodveton

‘The following information sat forth the findings of our Teehnicsl Committee with

fermect tothe burning tet

Efforts ro make this burning procedure sufficient sensitive and quantitative to

allow dist action between Aramonium Nivate Fertilizer and Ammonium Nitrate

Eertizer to which ay ite at 0.5 wt % ful oll was aed were unucenssul,

Distinction beween Ammonium Nitvae Fertlgr and Ammonium Nitrate Fertilizer

plus @ we & fue 01 can easily be Ginguianed

42

43

ln the ests conaucted to develop this definition of Ammonium Nitrate Fertilizer,

the analytical procedures and/or the detonation test dlaqualifies materials that

‘would rot have been clsqualfie ay tis burning procedure. However, there s the

‘pomibilty that new materials may contain suorances which will caaiytically

Increase the decomposition rate of somanium nitrate Sut are not specie inthe

Definition. The burning fests designed to screen such materi

Eauigment (see Figure 2)

Burnin tower - Two S5-allon 18 gauge steel drum frames welded rogetner

{erm the outer wall ané two 30aalon 18 gauge see! rum frames welaed

‘ojether form the inner wall. The inner wall ean ais be fabricated from 16

ioe Caraon ses shectng wih the me diantion at he 0 galon ras

fe scace between the inner ar outer walls sled with rock woo! I

sulation, Stel rings are welded between the two wall athe top ond bottom

{9provide aciowa isulgtion chamber. ATS" 1S" tight tock fire G00” it

located atthe bortem of the tower

Fie grate « A circular triple gratescreen of diameter slighty less than the

“Gantt the inner tomer win Vs 1/2" onenngy Pe rears occa

‘or top ofeach other with opening positions staggered 45 doprees. A stand

‘or rate holder ef appropriate design ana dimensions and 12° high

faonicated from 1” angie Fen.

‘Gui pan - Staines ste! pan of » diameter slighty less than te diameter of

‘einer tower ane 6 hah

‘ewer (top) cover - 1/8 thickness by 26" diameter carbon see piste,

Proceoure

‘The burring ower i ed novizontl onthe ground. The fre grate and stand resting

inside the caseh an are nipped into the nner chamber, The eauipment sembly

|s then raised to e vertical pontion. Top of the fire rate ix approximetely 16° from

the bottom of the tower Dir is piled around ene bottom circumference ofthe

rower tou peight of 1215" except atthe fre door,

‘Two 80-p0und Kraft paper bags of the materia to be tested are placed in the tower.

One extra paper bag, ut or torn into pieces approximately 2 on aside, miked 35

‘uniformly 25 posibie withthe material i each beg

Ten pourds of soft pire wood, 1/2" (T) x 2” [Wi x 8” (LI pieces, ae piled loosely

i place nthe space beneath the fire gra

[A standard railroad fuse is ignited and placed atthe canter beneath the wood pile.

When the fre has reached such an intensity that molten ammonivm nitrate sarts

‘rooping nt the fire, the fire door ls close, dirt sped wound "an the op

over is aut place. Personnel should then retire toa safe potion for observation

The burning is observed for rate of ges evolution visually and auraly, flames, oxides

‘of nitrogen and other means by whieh ‘ate oF burning can be estimaed, In general

ompositons which contain appreciable quantities of oxicaable material wit

Miberate iss nitrogen dioxige, tthe evoWwad geses wil be fess highly coloted

‘The tests considered complete whenever

1 98s evolution becomes extremely sow

48

Evaluation of Rests

[Ammann nitrate formulations in whieh the ammonium nitrate is completely

Gecomaosed in ore hour or less ater the apparatus cowed oF sall not be

‘Seseribea at Ammonium Nitrate Feliz’ for purposes of transportation,

Notes

4} The burning test should not be attempted until the substance undergoing

‘esting hae met chemical specifications in the Devintion and passed tne detonation

®)_The burning tes should only be conducted by fully qualitieg personne! in

soecially csigned equipment, and uncer carefully contlles cona:tons,

¢), Urknown subsances conser gotrilyNeardous soul st be sreened

By conducting the test withthe fire Soo” and Yop partly open. When ticr systems

te berg ems, personel soul eae the mediate vn of te em spoareay

sssoon asthe fre eared

) if the sults are marginal (60 minutes + 10 minutes its recommended thatthe

burn te repeated at east two testo otermin sma resuts teat two

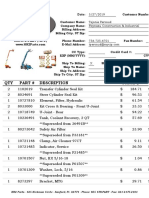

Apparatus For

Determination of Elemental

Metals in Ammonium Nitrate Fertilizer

Closed £0 ML or

‘Smaiter Buret

uber Stopper

Capitiary Tubing

125 ML Buchner

7

sed end buret with ground ball

flask with matching joint and

stopcock Side arm can be made by most laboratory

Glassware manutacturers,

26" Dia “Top Cover (18* carbon steel)

23%" Dia Circular Stee! Bands

Rock Woo! insu

30Gal. Drum

Thermocouple 48" from bottom” .

— $5 Gal Drum

Figure 2 : . .

Feleer Too $8 gallon ste! ermocouple 36” trom bottom:

(18 gauge) drums welded to-

‘gether for outer wall and

two 30.gallon stee\ arums

welded together for inner

wail

Thermocouple wells 1” in tower

(18° trom center of fire

Soor-circumterence)

“Thermocouple 24” trom bottom

55 Gal, Drum

Thermocouple 1$* tram bottom”

Fire Door 15° x 18°

Tight lock

Fire Grate Triple Screen

iB" x Y4" openings

Stainless Stee! Caten Pan

(Sy crc si ann

QE) pottom of Daum

“optena!

15%" Dia, x 5:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5822)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Textran TDH Premium: Universal Tractor Transmission OilDocument3 pagesTextran TDH Premium: Universal Tractor Transmission OilRobert RobertsNo ratings yet

- This Content Downloaded From 72.14.99.86 On Mon, 31 Jan 2022 16:35:05 UTCDocument4 pagesThis Content Downloaded From 72.14.99.86 On Mon, 31 Jan 2022 16:35:05 UTCRobert RobertsNo ratings yet

- Equipamento de Solda Ronch Stick 315max Manual ENDocument29 pagesEquipamento de Solda Ronch Stick 315max Manual ENRobert RobertsNo ratings yet

- Directory Collection Form: Referral (Wind) Who Fires Are To Be Placed With Within FlowerDocument2 pagesDirectory Collection Form: Referral (Wind) Who Fires Are To Be Placed With Within FlowerRobert RobertsNo ratings yet

- Part I Description of Drill Rig Operation and Maintenance: Section I Use, Application Scope and Technical ParametersDocument73 pagesPart I Description of Drill Rig Operation and Maintenance: Section I Use, Application Scope and Technical ParametersRobert RobertsNo ratings yet

- PC350 350LC-8 Cen00222-05 PDFDocument14 pagesPC350 350LC-8 Cen00222-05 PDFRobert RobertsNo ratings yet

- Explained:: Fire Wind Earth WaterDocument2 pagesExplained:: Fire Wind Earth WaterRobert RobertsNo ratings yet

- Saint Lucia: Public Health (Smoking Control) RegulationsDocument13 pagesSaint Lucia: Public Health (Smoking Control) RegulationsRobert RobertsNo ratings yet

- Deep Learning For Identifying Metastatic Breast CancerDocument6 pagesDeep Learning For Identifying Metastatic Breast CancerRobert RobertsNo ratings yet

- Komatsu Parts Book Online Websites Komatsupartsbook Com: Page 1 / 8Document8 pagesKomatsu Parts Book Online Websites Komatsupartsbook Com: Page 1 / 8Robert RobertsNo ratings yet

- Breast CancerDocument8 pagesBreast CancerRobert RobertsNo ratings yet

- 24th January Part 2Document2 pages24th January Part 2Robert RobertsNo ratings yet

- Rayneau GajadharDocument2 pagesRayneau GajadharRobert RobertsNo ratings yet

- Rayneau Construction & Industrial Quote 3-27-19Document4 pagesRayneau Construction & Industrial Quote 3-27-19Robert RobertsNo ratings yet