Professional Documents

Culture Documents

Example PDF

Example PDF

Uploaded by

hugur soCopyright:

Available Formats

You might also like

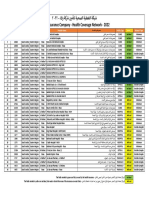

- Walaa Network 2022 شبكة التغطية الصحية-تامين شركة ولاءDocument1 pageWalaa Network 2022 شبكة التغطية الصحية-تامين شركة ولاءMohammed SulimanNo ratings yet

- Scrib 2Document4 pagesScrib 2Aldwin Abidin50% (2)

- Manual AndoverDocument190 pagesManual AndoverDennis Brenes RodríguezNo ratings yet

- Case Digest - Peralta vs. Civil Service Commission 212 SCRA 425, G.R. No. 95832, Aug. 10, 1992Document2 pagesCase Digest - Peralta vs. Civil Service Commission 212 SCRA 425, G.R. No. 95832, Aug. 10, 1992Lu Cas100% (3)

- Dynamic Analysis of Crank-Connecting Rod-Piston Mechanism of S195 Diesel Engine Based On MATLABDocument5 pagesDynamic Analysis of Crank-Connecting Rod-Piston Mechanism of S195 Diesel Engine Based On MATLAByangee1201No ratings yet

- Rotor-Dynamics Analysis Process: Polar Moment of Inertia About The Axis of SpinDocument16 pagesRotor-Dynamics Analysis Process: Polar Moment of Inertia About The Axis of SpinpavanpppNo ratings yet

- Stress Analysis and Weight Reduction of A One-CyliDocument18 pagesStress Analysis and Weight Reduction of A One-CyliAnonymous K3FaYFlNo ratings yet

- Oscillating Tech-The BeenDocument6 pagesOscillating Tech-The Been88622033No ratings yet

- ID201612272Document12 pagesID201612272amit896012No ratings yet

- Convex Optimization For Spring Design in Series Elastic Actuators From Theory To PracticeDocument6 pagesConvex Optimization For Spring Design in Series Elastic Actuators From Theory To PracticeYuan HUANGNo ratings yet

- Adaptation of The ESPSS Platform For The Design and Analysis of Liquid Propellant Rocket EnginesDocument10 pagesAdaptation of The ESPSS Platform For The Design and Analysis of Liquid Propellant Rocket Enginesjakub_gramolNo ratings yet

- Kinematic of Marine Piston-Crankshaft System: Lech MurawskiDocument8 pagesKinematic of Marine Piston-Crankshaft System: Lech MurawskiCojocaru TiberiuNo ratings yet

- Horizontal Axis Wind Turbine Working at Maximum Power Coefficient ContinuouslyDocument6 pagesHorizontal Axis Wind Turbine Working at Maximum Power Coefficient ContinuouslyLiviu MateescuNo ratings yet

- Measuring The Performance Characteristics of A MotDocument6 pagesMeasuring The Performance Characteristics of A Motdani chNo ratings yet

- Kinematics and Kinetic Analysis of The Slider-Crank Mechanism in Otto Linear Four Cylinder Z24 EngineDocument11 pagesKinematics and Kinetic Analysis of The Slider-Crank Mechanism in Otto Linear Four Cylinder Z24 Enginekiran_wakchaureNo ratings yet

- Experiment 3: 300035 - Kinematics and Kinetics of Machines (Kinematics Half)Document9 pagesExperiment 3: 300035 - Kinematics and Kinetics of Machines (Kinematics Half)uzair jahanzebNo ratings yet

- 92 GT 054Document10 pages92 GT 054Alberto ValleNo ratings yet

- IMAC XV 15th Int 15-49-3 Optimization Techniques RotordynamicsDocument7 pagesIMAC XV 15th Int 15-49-3 Optimization Techniques Rotordynamicsuamiranda3518No ratings yet

- Arindam Seminar 11Document6 pagesArindam Seminar 11Arindam BhattacharjeeNo ratings yet

- Franscis Runner Finite Element AnalysisDocument13 pagesFranscis Runner Finite Element AnalysisAnonymous HtYWpEtXGzNo ratings yet

- JMD000645 PDFDocument7 pagesJMD000645 PDFTadveer Singh HoraNo ratings yet

- Simulation of Slider Crank Mechanism Using Adams ViesDocument5 pagesSimulation of Slider Crank Mechanism Using Adams Vieskiran_wakchaureNo ratings yet

- TruptiDocument7 pagesTruptidebanshushekharNo ratings yet

- Engineering Structures: I. Bel Mabrouk, A. El Hami, L. Walha, B. Zghal, M. HaddarDocument10 pagesEngineering Structures: I. Bel Mabrouk, A. El Hami, L. Walha, B. Zghal, M. Haddarpalash22No ratings yet

- Analysis of Multi-Speed Transmission and ElectricaDocument12 pagesAnalysis of Multi-Speed Transmission and ElectricaBalachander RkNo ratings yet

- Axial Vibrations of A Marine Shaft Lines. Calculations Measurements ComparisonDocument10 pagesAxial Vibrations of A Marine Shaft Lines. Calculations Measurements ComparisonCojocaru TiberiuNo ratings yet

- Model Development and Simulation of Transient Behavior of Heavy Duty Gas TurbinesDocument6 pagesModel Development and Simulation of Transient Behavior of Heavy Duty Gas TurbineswaleligneNo ratings yet

- Design Optimization of A Centrifugal Pump Impeller and Volute Using Computational Fluid Design PDFDocument10 pagesDesign Optimization of A Centrifugal Pump Impeller and Volute Using Computational Fluid Design PDFhachanNo ratings yet

- AMME2500 Assignment 3Document12 pagesAMME2500 Assignment 3Drago6678No ratings yet

- Aerodynamics For Students - BladeDocument6 pagesAerodynamics For Students - BladeGaurang 'TottaPhilic' GuptaNo ratings yet

- Normalized Dynamic Simulation of 3-Phase Induction Motor Using Matlab/SimulinkDocument6 pagesNormalized Dynamic Simulation of 3-Phase Induction Motor Using Matlab/SimulinkMallikarjunBhiradeNo ratings yet

- Draft AeronauticalJournalDocument34 pagesDraft AeronauticalJournalzb566yss9cNo ratings yet

- Arfmtsv96 N1 P82 95Document14 pagesArfmtsv96 N1 P82 95shayant nandiNo ratings yet

- Analytical Approach To Determine Speed-Torque Curve of Induction Motor From Manufacturer DataDocument4 pagesAnalytical Approach To Determine Speed-Torque Curve of Induction Motor From Manufacturer DataRingoNo ratings yet

- 144 0067Document4 pages144 0067Antony BanderasNo ratings yet

- Sustainability 10 02067 PDFDocument19 pagesSustainability 10 02067 PDFDeenanathNo ratings yet

- Design Analysis of Spur Gear With The Usage of The Advanced ComputerDocument6 pagesDesign Analysis of Spur Gear With The Usage of The Advanced ComputerPradeep AdsareNo ratings yet

- Naf Ems 2013 RotorDocument12 pagesNaf Ems 2013 Rotorletter_ashish4444No ratings yet

- Contribution To The Definition of The Torsional Stiffness of The Crankshaft of A Diesel Engine Used in Heavy-Duty VehiclesDocument11 pagesContribution To The Definition of The Torsional Stiffness of The Crankshaft of A Diesel Engine Used in Heavy-Duty VehiclesTushar SharmaNo ratings yet

- Crankshaft VibrationDocument8 pagesCrankshaft VibrationjohansolNo ratings yet

- Adrc - PMSG - Good2Document6 pagesAdrc - PMSG - Good2Dileep VarmaNo ratings yet

- Metaheuristic Algorithms for Parameter Estimation of DC Servo Motors With Quantized Sensor Measurements. (1)Document18 pagesMetaheuristic Algorithms for Parameter Estimation of DC Servo Motors With Quantized Sensor Measurements. (1)b320059No ratings yet

- Me 8594 Dynamics of Machinery Unit 1 Online Video LectureDocument42 pagesMe 8594 Dynamics of Machinery Unit 1 Online Video LecturesankarNo ratings yet

- Important Short Questions DYNAMICS AND DESIGN OF MACHINERYDocument32 pagesImportant Short Questions DYNAMICS AND DESIGN OF MACHINERYramos mingoNo ratings yet

- Dynamic Loading and Stress Analysis On Crankshaft of Reciprocating Mud PumpDocument11 pagesDynamic Loading and Stress Analysis On Crankshaft of Reciprocating Mud PumpchcruzgNo ratings yet

- (Journal of Agricultural Engineering Research Vol. 19 Iss. 2) Kolozsi, McCarthy - The Prediction of Tractor Field Performance (1974)Document6 pages(Journal of Agricultural Engineering Research Vol. 19 Iss. 2) Kolozsi, McCarthy - The Prediction of Tractor Field Performance (1974)Sergey ZlenkoNo ratings yet

- Ajme 10 1 4Document7 pagesAjme 10 1 4nitishsharma19712No ratings yet

- Design and Optimization of Backstepping Controller For An Underactuated Autonomous Quadrotor Unmanned Aerial VehicleDocument18 pagesDesign and Optimization of Backstepping Controller For An Underactuated Autonomous Quadrotor Unmanned Aerial VehicleSteve DemirelNo ratings yet

- Aerodynamics For StudentsDocument6 pagesAerodynamics For StudentsSelva RajNo ratings yet

- Advances in Vector Control Ofac Motor Drives A Review PDFDocument24 pagesAdvances in Vector Control Ofac Motor Drives A Review PDFBook4AllNo ratings yet

- Selection of Smooth Motion Profile For A Tube Locator Module of An Inspection DeviceDocument15 pagesSelection of Smooth Motion Profile For A Tube Locator Module of An Inspection DeviceIAES International Journal of Robotics and AutomationNo ratings yet

- JWST Brushless DC Motor Characteristics Analysis 2-5-2016Document13 pagesJWST Brushless DC Motor Characteristics Analysis 2-5-2016anhntran4850No ratings yet

- Mathematical Modeling and Control Law Design For 1dof Quadcopter Flight DynamicsDocument6 pagesMathematical Modeling and Control Law Design For 1dof Quadcopter Flight Dynamicsmatteorocco99No ratings yet

- V12 04 07 Hac From Mme PDFDocument18 pagesV12 04 07 Hac From Mme PDFHariharanNo ratings yet

- 0011 Static and Dynamic Analysis of Wind Turbine Blades Using The Finite Element MDocument18 pages0011 Static and Dynamic Analysis of Wind Turbine Blades Using The Finite Element MKhalil DeghoumNo ratings yet

- Parametric Study and Design Optimization of A Radial Flow Pump ImpellerDocument9 pagesParametric Study and Design Optimization of A Radial Flow Pump ImpellerErnad BešlagićNo ratings yet

- Mechanics of Machines (314205) : Design, Fabrication and Analysis of Dual Can CrusherDocument10 pagesMechanics of Machines (314205) : Design, Fabrication and Analysis of Dual Can Crushersaqlain05No ratings yet

- Numerical Simulation of Turbulent Flow Through A Francis Turbine RunnerDocument6 pagesNumerical Simulation of Turbulent Flow Through A Francis Turbine RunnerAngel CerriteñoNo ratings yet

- Gearbox Design by ChitaleDocument34 pagesGearbox Design by ChitaleNagu Srirama60% (5)

- Conceptual Study of A Rocket-Ramjet Combined-Cycle Engine For An Aerospace PlaneDocument9 pagesConceptual Study of A Rocket-Ramjet Combined-Cycle Engine For An Aerospace PlaneSyed MohtasimNo ratings yet

- ResumoDocument10 pagesResumovothanhbinh311099No ratings yet

- Design and Analysis of Crankshaft For Single Cylinder 4-Stroke Deisel EngineDocument3 pagesDesign and Analysis of Crankshaft For Single Cylinder 4-Stroke Deisel EngineChetan GuptaNo ratings yet

- Modeling of Complex Systems: Application to Aeronautical DynamicsFrom EverandModeling of Complex Systems: Application to Aeronautical DynamicsNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Modelling and Simulation Based On Matlab/Simulink: A Press MechanismDocument5 pagesModelling and Simulation Based On Matlab/Simulink: A Press Mechanismhugur soNo ratings yet

- Solution Datum at Lowest Point Solving For The: Find Study ResourcesDocument1 pageSolution Datum at Lowest Point Solving For The: Find Study Resourceshugur soNo ratings yet

- Hsk1 6 VocabDocument144 pagesHsk1 6 VocabsusanarutaNo ratings yet

- Torque On Current Loop: FD Iba B Ibab IbaDocument13 pagesTorque On Current Loop: FD Iba B Ibab Ibahugur soNo ratings yet

- नामांकन म/ Enrolment No.: 0636/00306/52054: Vid: VID: 9170 3011 4031 7083 9170 3011 4031 7083Document1 pageनामांकन म/ Enrolment No.: 0636/00306/52054: Vid: VID: 9170 3011 4031 7083 9170 3011 4031 7083Punam PanditNo ratings yet

- A Spam Transformer Model For SMS Spam DetectionDocument11 pagesA Spam Transformer Model For SMS Spam Detectionsireesha payyavulaNo ratings yet

- People of The Philippines V. Marissa Bayker G.R. No. 170192, February 10, 2016, BERSAMIN, J., FIRST DIVISION FactsDocument64 pagesPeople of The Philippines V. Marissa Bayker G.R. No. 170192, February 10, 2016, BERSAMIN, J., FIRST DIVISION FactsDonna Ingusan-BollozosNo ratings yet

- Literature Review Early Childhood EducationDocument10 pagesLiterature Review Early Childhood Educationafmzzulfmzbxet100% (1)

- History of Educ - TechDocument5 pagesHistory of Educ - Techjiggly popNo ratings yet

- Seminar ReportDocument29 pagesSeminar ReportUrja DhabardeNo ratings yet

- Afar 2704 Home Office Branch AgencyDocument33 pagesAfar 2704 Home Office Branch Agencylijeh312No ratings yet

- Chapter - 2 Marketing Research Problem and Developing ApproachDocument32 pagesChapter - 2 Marketing Research Problem and Developing ApproachAyushman UpretiNo ratings yet

- Maintenance of Building ComponentsDocument4 pagesMaintenance of Building ComponentsIZIMBANo ratings yet

- G.R. NO. 184535, SEPTEMBER 03, 2019 Sister Pilar Versoza, Petitioner, vs. People of The Philippines, Et Al., Respondents. FactsDocument2 pagesG.R. NO. 184535, SEPTEMBER 03, 2019 Sister Pilar Versoza, Petitioner, vs. People of The Philippines, Et Al., Respondents. FactsRoxanne Valino100% (1)

- Case Study For 1st AssignmentDocument17 pagesCase Study For 1st AssignmentMaher Ahmed100% (1)

- Phil. Export v. VP EusebioDocument2 pagesPhil. Export v. VP EusebioCZARINA ANN CASTRONo ratings yet

- EB 06 LightingDocument45 pagesEB 06 LightingTamNo ratings yet

- Caso 2 - Gerencia de Operaciones 2023Document3 pagesCaso 2 - Gerencia de Operaciones 2023Eyner PeñaNo ratings yet

- Todo Sobre Sintonizadores Equivalencias PDFDocument39 pagesTodo Sobre Sintonizadores Equivalencias PDFSantiago BonabelloNo ratings yet

- Textbook Planning and Design of Engineering Systems Third Edition Graeme Dandy Ebook All Chapter PDFDocument53 pagesTextbook Planning and Design of Engineering Systems Third Edition Graeme Dandy Ebook All Chapter PDFthomas.bishop281100% (6)

- At-The-Restaurant A2Document4 pagesAt-The-Restaurant A2Mjn AbbasiNo ratings yet

- Group:4: Delhi-Mumbai Industrial Corridor: India's Road To Prosperity?Document9 pagesGroup:4: Delhi-Mumbai Industrial Corridor: India's Road To Prosperity?shahin selkarNo ratings yet

- Timothy - Chap 11Document24 pagesTimothy - Chap 11Chaeyeon JungNo ratings yet

- Data Quality SalesforceDocument190 pagesData Quality SalesforceLariNo ratings yet

- EFL IS User ManualDocument26 pagesEFL IS User Manualarupamguria05No ratings yet

- Substantive ProceduressDocument8 pagesSubstantive ProceduressayyazmNo ratings yet

- QualitativeDocument8 pagesQualitativeCmc Corpuz AbrisNo ratings yet

- DEA Report-MA Camp LimitedDocument145 pagesDEA Report-MA Camp LimitedCEG BangladeshNo ratings yet

- استردادDocument2 pagesاستردادnn1129374No ratings yet

- Air PollutionDocument35 pagesAir PollutionNur HazimahNo ratings yet

Example PDF

Example PDF

Uploaded by

hugur soOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Example PDF

Example PDF

Uploaded by

hugur soCopyright:

Available Formats

Proceedings of the World Congress on Engineering 2009 Vol II

WCE 2009, July 1 - 3, 2009, London, U.K.

Computer Aided Kinematic and Dynamic

Analysis of a Horizontal Slider Crank

Mechanism Used For Single-Cylinder Four

Stroke Internal Combustion Engine

H. D. Desai

Abstract - The reciprocating engine mechanism is often Also, once the algebraic form of the solution

analysed, since it serves all the demands required for has been derived, it can be programmed for the com-

the convenient utilization of natural sources of energy, puter solution.

such as steam, gaseous and liquid fuels, for generation

of power. Further, it is widely employed as suitable Dynamic analysis of the engine includes

mechanism for pumps and compressors. In this paper static and inertia force analysis for all the possible

the complete kinematic and combined static and inertia

phases of the engine which leads to an important

force analysis of a horizontal, single – cylinder, four-

stroke internal combustion engine is discussed. The aspect of the estimation of the loads carried by differ-

analytical approach is used as it is more accurate and is ent members of the engine. The complete force

less time consuming if it is programmed for the com- analysis of the reciprocating engine mechanism using

puter solution. The data for the analysis of the engine principle of superposition is carried out neglecting

has been taken from the available literature. The pre- the effect of friction by a summation of the individual

sent investigation furnishes the complete kinematic his- effects of gas forces and inertia forces. With the help

tory of the driven links and the bearing loads for the of analytical expressions derived, a complete kine-

complete working cycle of the engine mechanism. The matic and dynamic analysis of the horizontal single-

complete force analysis of the engine is simplified by a

cylinder, four-stroke internal combustion engine with

summation of the static forces and inertia forces ignor-

ing the friction forces which makes the analysis linear. small crank interval of 150 is made. With engine pa-

The computer program is prepared in fortran language rameters available in the literature an investigation of

for both kinematic and dynamic analysis of the engine variation of crankpin load, pistonpin load and main

at the crank interval of 150. bearing load is carried out for all the above phases

with help of programming.

I. INTRODUCTION

The internal combustion engine employs a very II. THEORETICAL ANALYSIS

popular mechanism known as slider crank mecha-

nism. In this paper, complete kinematic and dynamic Kinematic Analysis by Complex – Algebra Method

analysis of reciprocating group of machines is carried

out, as it has reached to high state of development

and is of more general interest than other group of

machines.

Kinematic analysis of the slider-crank

mechanism helps to answer many questions pertain-

ing to the motions of various links of the mechanism

viz. displacement, velocity and accelerations of

driven members like connecting rod and piston. In

the present work, the complete kinematic analysis of

the engine has been carried out by analytical method

using complex-algebra method as this method is

more accurate than graphical method and can give The kinematic drawing of slider-crank mechanism is

results for all the phases of the mechanism. shown in Fig .1 (a). This planar mechanism is repre-

sented by a vector equation as shown in Fig. 1 (b) for

H. D. Desai, Asst. Professor, Department of Mechanical Engineer- any phase diagram as

ing, S.V. National Institute of Technology, Surat- 395007, Gujarat,

India. (e-mail: hdd@med.svnit.ac.in). uur uur uur

R1 + R 2 + R 3 = 0 (1)

ISBN:978-988-18210-1-0 WCE 2009

Proceedings of the World Congress on Engineering 2009 Vol II

WCE 2009, July 1 - 3, 2009, London, U.K.

Ap = Acceleration of the piston, cm/sec.2.

Expressing the above vectors in complex rectangular

notation, With the use of above equations the values of all the

( −r1 + j0) + ( r2Cosθ + jr2Sinθ ) + ( r3Cosβ − jr3Sinβ) = 0 above kinematic parameters at the crank angle of 150

are calculated with the help of computer program.

……..(2)

III. STATIC FORCE ANALYSIS

Where,

r1 = Linear Displacement of the Slider, cm. The gas force acts on the piston due to the combus-

r2 = Radius of the crank, cm tion of fuel and this force varies during the cycle of

r3 = Length of the connecting rod, cm operation. The gas force variation is obtained from

θ = Angular displacement of the crank, deg. the engine indicator diagram [9]. Fig. 2 shows

β = Angular displacement of connecting rod, deg. graphical analysis of the gas force. From the force

polygon,

Therefore

− r1 + r2 cos θ + r1 cos β = 0 (3)

r2 sin θ − r3 sin β = 0 (4)

As the mobility of the mechanism is one and the rota-

tional speed of the crankshaft is constant, input pa-

rameters are r2, r3, ω2 and θ. Differentiation of Eqn. 3

and 4 gives the expressions of displacement, velocity FIG: 2 ANALYSIS OF GAS FORCES

and acceleration of the driven members, connecting

rod (link 3) and the slider (link 4) [9].

F14' = P tan β j (10)

β = sin −1

(r2 sin θ / r3 ) (5)

F34' = P / Cos β (11)

(r ω cos θ)

ω3 = 2 2 (6)

(r3 cos β)

Where,

P = Gas Force, N.

Vp = r1. = ( r2 ω2 sin θ + r3ω3 sin β ) (7)

Crankshaft torque or turning moment delivered to the

crank is obtained by taking the product of the gas

α3 =

(r 2 cos θ − r2ω2 sin θ + r3ω3 sin β

2 2

) force and piston coordinate x. Therefore crankshaft

torque in vector form is,

(r3Cos β)

---------- (8) ( )

T21' = F14' .x k (12)

( 2 2

A p = &&r1 = r2 sin θ + r2 ω2 Cosθ + r3ω3 Cosβ + r3Sin β ) IV. INERTIA FORCE ANALYSIS

---------- (9) The resultant bearing loads are made up of the fol-

lowing components:

Where,

ω2 = Angular velocity of the crank, rad/sec. 1. The gas force components, designated by a

ω3 = Angular velocity of the connecting rod, rad/sec. single prime.

α2 = Angular acceleration of the crank, rad/sec.2 2. Inertia force due to the weight of the piston

α3 = Angular acceleration of connecting rod, rad/sec.2 assembly, designated by a double prime.

Vp = Velocity of the piston, cm/sec.

ISBN:978-988-18210-1-0 WCE 2009

Proceedings of the World Congress on Engineering 2009 Vol II

WCE 2009, July 1 - 3, 2009, London, U.K.

3. Inertia force of that part of the connecting of the mass of the connecting rod which is assumed

rod assigned to the pistonpin end, triple to exist at the pistonpin center is given.

primed.

4. Connecting rod inertia force at the crankpin The analytical expressions for the forces are given as

end, quadruple primed.

F41''' = − m3B &&

x tan β j (16)

Equations for the gas force components have been

determined earlier and reference shall be made to F =F

'''

34

'''

41 (17)

them in finding the total bearing loads. Fig. 3, shows

graphical analysis of the forces in the engine mecha-

nism with zero gas force and subjected to an inertia F32''' = − m3B &&

xi + m3B &&

x tan β j (18)

force resulting only from the weight of the piston

assembly. Where m3B = Mass of connecting rod lumped at

wristpin B, Kg.

From Fig. 3, the analytical expressions for the forces Fig. 5, shows the forces which result because of that

are given as part of the connecting rod mass which is concentrated

at the crankpin end.

F41'' = − m 4 &&

x tan β j (13)

The analysis gives ,

F34'' = m 4 &&

x i − m 4 &&

x tan β j (14)

F32'' = − F34'' (15)

Where,

m4 = Mass of the piston assembly, Kg.

FIG. 5: GRAPHICAL ANALYSIS OF FORCES RESULT-

ING SOLELY FROM THE MASS OF THE CONNECTING

ROD, ASSUMED TO BE CONCENTRATED AT THE

CRANK PIN END.

The analysis gives,

F32'''' = m3A r2 ω2 2 (Cosθ i + Sin θ j) (19)

Where,

m3A = Mass of connecting rod lumped at crankpin

A, Kg.

From the above analysis of inertia forces the total

force of the piston against the cylinder wall, piston-

pin and crankpin respectively is given by,

In Fig. 4, the analysis neglecting all forces except

those which result because of the inertia of that part

ISBN:978-988-18210-1-0 WCE 2009

Proceedings of the World Congress on Engineering 2009 Vol II

WCE 2009, July 1 - 3, 2009, London, U.K.

' '' '''

(

F41 = F41 + F41 + F41 = − m3B + m 4 && )

x + P tan β j

Mass of piston, pistonpin and main bearing, m4 =

1.125 Kg.

…...(20) Mass of connecting rod, m3 = 1.75 Kg.

Centre of gravity of connecting rod is 7.44 cm from

F34 = ( m 4 &&

x + P ) i − ( m3B + m 4 ) &&

the crankpin centre.

x + P tan β j

…...(21) From the above data,

F32 = m3A r2 ω2 2 Cos θ − ( m3B + m 4 ) &&

x − P i m3B = [7.44 /(16.86+7.44)] x 1.75 = 0.535 Kg.

{

+ m3A r2 ω2 2 Sin θ + ( m3B + m 4 ) &&

x + P tan β j } m3A = 1.75 – 0.535 = 1.215 Kg.

…..(22) RESULTS AND DISCUSSION

The results computed from the program developed

Where, for kinematic analysis of the engine for the complete

F34 = Wristpin load, N. working cycle are given at the crank interval of 60

F32 = Crankpin load, N. degree.

F41 = Cylinder wall force, N.

TABLE 2: KINEMATIC VALUES

The crankshaft torque or turning moment delivered

by the engine is obtained from the equation θ r1 β ω2 Vp α3 Ap.

(degree) (cm) (degree) (rad/s) (cm/s) (rad/s2) (cm/s2)

0 31.30 0.00 54.30 0.00 0.00 -320375.20

T21 = − ( F41.x ) k = ( m3B + m 4 ) &&

x + P x tan β k 60 27.03 14.45 26.29 -1307.31 -9190.64 -88538.17

120 20.03 14.45 -26.29 -978.13 -9190.64 160187.60

….(23) 180 17.30 0.00 -54.30 0.00 0.00 177076.40

240 20.03 -14.45 -26.29 978.13 9190.64 160187.60

The computer program has been developed in fortran 300 27.03 -14.45 26.29 1307.31 9190.64 -88538.32

language to compute the total bearing loads for the

horizontal single-cylinder, four-stroke petrol engine The results computed from the computer program

for the complete working cycle at the crank interval developed for complete dynamic analysis of the en-

of 150. The analysis of the engine is carried out for gine are shown in the Table: 3.

the gas forces available in the literature which have

been obtained from the ideal air standard Otto cycle TABLE 3: BEARING LOADS

and the data is given in the Table: 1.

θ F32 F34 F41 T21

TABLE 1: GAS FORCES (Degree) (N) (N) (N) (N-cm)

0.00 7174.25 2438.22 0.00 0.00

SUCTION COMPRESSION EXPANSION EXHAUST 60.00 3121.14 188.81 78.49 -24.57

θ P θ P θ P θ P 120.00 6437.44 3126.72 -985.17 308.36

(Deg) (N) (Deg) (N) (Deg) (N) (Deg) (N)

180.00 7127.49 3158.11 0.00 0.00

0 1166 360 14210 360 36309 720 1166

240.00 6772.19 3480.17 1073.53 336.02

15 1166 345 12348 375 30772 705 1166

30 1166 330 8524 390 21560 690 1166 300.00 3386.20 3000.94 633.56 -198.30

45 1166 15 5733 405 14308 675 1166 360.00 27968.76 10605.78 0.00 0.00

60 1166 300 3930 420 9800 660 1166 420.00 8317.13 9061.03 -2145.78 671.63

75 1166 285 2852 435 7105 645 1166 480.00 9019.11 5815.45 -1656.78 518.57

90 1166 270 2254 450 5439 630 1166 540.00 8862.49 4893.11 0.00 0.00

105 1166 255 1725 465 4302 615 1166 600.00 6437.44 3126.72 985.17 -308.36

120 1166 240 1509 480 3773 600 1166 660.00 3121.14 186.61 -78.49 24.57

135 1166 225 1328 495 3308 585 1166 720.00 7124.25 2438.22 0.00 0.00

150 1166 210 1235 510 3087 570 1166

165 1166 195 1191 525 2960 555 1166

The results of the kinematic analysis of the engine

180 1166 180 1166 540 2901 540 1166

depicts the variation of the kinematic parameters like

displacement, velocity and acceleration of the driven

Crank speed = 1800 rpm.

members i.e. connecting rod, link 3 and slider, link 4.

Stroke = 14 cm.

The results of the combined static and inertia force

r2/r3 = 0.228.

ISBN:978-988-18210-1-0 WCE 2009

Proceedings of the World Congress on Engineering 2009 Vol II

WCE 2009, July 1 - 3, 2009, London, U.K.

analysis show variation of the bearing loads F32, F34,

F41 and turning moment T21. The knowledge of these

forces is essential for the design of the bearings. The

present investigation can be applied to multicylinder

in-line engines, radial engines and V-engines.

REFERENCES

[1] Noxling, R. L., 1978, “Continuous Time

Simulation of Forces and Motion within an

Automobile Engine”, SAE Paper No. 780665.

[2] Shiao, Y. J., Pan C. H., and Moskwa, J. J.,

1994, “Advanced Dynamic Spark Ignition

Engine Modeling for Diagnostics and Control,

Int. J. Veh. Des., 15, PP. 578-596 (Inspec)

[ISI].

[3] Suh, C. H., and Smith, C. G., 1997, “Dynamic

Simulation of Engine – Mount Systems”, SAE

Paper No. 971940.

[4] Hoffman, D. M. W. and Dowling, D. R.,

1999, “Modeling Fully coupled Rigid Engine

Dynamics and Vibrations”, SAE Paper No.

1999-01-1749, Proceedings, 1999 SAE Norse

and Vibration Conference, Vol. 2, Traverse

City, MI, Society of Automotive Engineers,

Warrendale, PA, PP 747-755.

[5] Hoffman, D. M. W., 1999, “In-Line Internal

Combustion Engine Dynamics and Vibra-

tion”, Ph. D. thesis, University of Michigan,

Ann Arbor, MI.

[6] Hoffman, D. M. W., and Dowling, D. R.,

2001, “Fully Coupled Rigid Engine Dynamics

and Vibrations Part – II: Model Experiment

Comparisons” ASME J. Eng. Gas Turbine

Power, 123, pp. 685-692 [ISI].

[7] Cowie, A., 1961, “Kinematics and Design of

Mechanisms”, International Textbook com-

pany, Scranton, Pennsylvania.

[8] Charles E. Wilson, J., Peter Sadler, Walter, J.

Michels, 1983,“Kinematics and Dynamics of

Machinery“, Haper and Row Publisher, New

York.

[9] Shigley, Joseph Edward, 2003, “Theory of

Machines and Mechanisms”, Tata McGraw

Hill, New York.

[10] Greenwood, D. T., 1988, “Principles of Dy-

namics”, 2nd Ed. Prentice-Hall.

ISBN:978-988-18210-1-0 WCE 2009

You might also like

- Walaa Network 2022 شبكة التغطية الصحية-تامين شركة ولاءDocument1 pageWalaa Network 2022 شبكة التغطية الصحية-تامين شركة ولاءMohammed SulimanNo ratings yet

- Scrib 2Document4 pagesScrib 2Aldwin Abidin50% (2)

- Manual AndoverDocument190 pagesManual AndoverDennis Brenes RodríguezNo ratings yet

- Case Digest - Peralta vs. Civil Service Commission 212 SCRA 425, G.R. No. 95832, Aug. 10, 1992Document2 pagesCase Digest - Peralta vs. Civil Service Commission 212 SCRA 425, G.R. No. 95832, Aug. 10, 1992Lu Cas100% (3)

- Dynamic Analysis of Crank-Connecting Rod-Piston Mechanism of S195 Diesel Engine Based On MATLABDocument5 pagesDynamic Analysis of Crank-Connecting Rod-Piston Mechanism of S195 Diesel Engine Based On MATLAByangee1201No ratings yet

- Rotor-Dynamics Analysis Process: Polar Moment of Inertia About The Axis of SpinDocument16 pagesRotor-Dynamics Analysis Process: Polar Moment of Inertia About The Axis of SpinpavanpppNo ratings yet

- Stress Analysis and Weight Reduction of A One-CyliDocument18 pagesStress Analysis and Weight Reduction of A One-CyliAnonymous K3FaYFlNo ratings yet

- Oscillating Tech-The BeenDocument6 pagesOscillating Tech-The Been88622033No ratings yet

- ID201612272Document12 pagesID201612272amit896012No ratings yet

- Convex Optimization For Spring Design in Series Elastic Actuators From Theory To PracticeDocument6 pagesConvex Optimization For Spring Design in Series Elastic Actuators From Theory To PracticeYuan HUANGNo ratings yet

- Adaptation of The ESPSS Platform For The Design and Analysis of Liquid Propellant Rocket EnginesDocument10 pagesAdaptation of The ESPSS Platform For The Design and Analysis of Liquid Propellant Rocket Enginesjakub_gramolNo ratings yet

- Kinematic of Marine Piston-Crankshaft System: Lech MurawskiDocument8 pagesKinematic of Marine Piston-Crankshaft System: Lech MurawskiCojocaru TiberiuNo ratings yet

- Horizontal Axis Wind Turbine Working at Maximum Power Coefficient ContinuouslyDocument6 pagesHorizontal Axis Wind Turbine Working at Maximum Power Coefficient ContinuouslyLiviu MateescuNo ratings yet

- Measuring The Performance Characteristics of A MotDocument6 pagesMeasuring The Performance Characteristics of A Motdani chNo ratings yet

- Kinematics and Kinetic Analysis of The Slider-Crank Mechanism in Otto Linear Four Cylinder Z24 EngineDocument11 pagesKinematics and Kinetic Analysis of The Slider-Crank Mechanism in Otto Linear Four Cylinder Z24 Enginekiran_wakchaureNo ratings yet

- Experiment 3: 300035 - Kinematics and Kinetics of Machines (Kinematics Half)Document9 pagesExperiment 3: 300035 - Kinematics and Kinetics of Machines (Kinematics Half)uzair jahanzebNo ratings yet

- 92 GT 054Document10 pages92 GT 054Alberto ValleNo ratings yet

- IMAC XV 15th Int 15-49-3 Optimization Techniques RotordynamicsDocument7 pagesIMAC XV 15th Int 15-49-3 Optimization Techniques Rotordynamicsuamiranda3518No ratings yet

- Arindam Seminar 11Document6 pagesArindam Seminar 11Arindam BhattacharjeeNo ratings yet

- Franscis Runner Finite Element AnalysisDocument13 pagesFranscis Runner Finite Element AnalysisAnonymous HtYWpEtXGzNo ratings yet

- JMD000645 PDFDocument7 pagesJMD000645 PDFTadveer Singh HoraNo ratings yet

- Simulation of Slider Crank Mechanism Using Adams ViesDocument5 pagesSimulation of Slider Crank Mechanism Using Adams Vieskiran_wakchaureNo ratings yet

- TruptiDocument7 pagesTruptidebanshushekharNo ratings yet

- Engineering Structures: I. Bel Mabrouk, A. El Hami, L. Walha, B. Zghal, M. HaddarDocument10 pagesEngineering Structures: I. Bel Mabrouk, A. El Hami, L. Walha, B. Zghal, M. Haddarpalash22No ratings yet

- Analysis of Multi-Speed Transmission and ElectricaDocument12 pagesAnalysis of Multi-Speed Transmission and ElectricaBalachander RkNo ratings yet

- Axial Vibrations of A Marine Shaft Lines. Calculations Measurements ComparisonDocument10 pagesAxial Vibrations of A Marine Shaft Lines. Calculations Measurements ComparisonCojocaru TiberiuNo ratings yet

- Model Development and Simulation of Transient Behavior of Heavy Duty Gas TurbinesDocument6 pagesModel Development and Simulation of Transient Behavior of Heavy Duty Gas TurbineswaleligneNo ratings yet

- Design Optimization of A Centrifugal Pump Impeller and Volute Using Computational Fluid Design PDFDocument10 pagesDesign Optimization of A Centrifugal Pump Impeller and Volute Using Computational Fluid Design PDFhachanNo ratings yet

- AMME2500 Assignment 3Document12 pagesAMME2500 Assignment 3Drago6678No ratings yet

- Aerodynamics For Students - BladeDocument6 pagesAerodynamics For Students - BladeGaurang 'TottaPhilic' GuptaNo ratings yet

- Normalized Dynamic Simulation of 3-Phase Induction Motor Using Matlab/SimulinkDocument6 pagesNormalized Dynamic Simulation of 3-Phase Induction Motor Using Matlab/SimulinkMallikarjunBhiradeNo ratings yet

- Draft AeronauticalJournalDocument34 pagesDraft AeronauticalJournalzb566yss9cNo ratings yet

- Arfmtsv96 N1 P82 95Document14 pagesArfmtsv96 N1 P82 95shayant nandiNo ratings yet

- Analytical Approach To Determine Speed-Torque Curve of Induction Motor From Manufacturer DataDocument4 pagesAnalytical Approach To Determine Speed-Torque Curve of Induction Motor From Manufacturer DataRingoNo ratings yet

- 144 0067Document4 pages144 0067Antony BanderasNo ratings yet

- Sustainability 10 02067 PDFDocument19 pagesSustainability 10 02067 PDFDeenanathNo ratings yet

- Design Analysis of Spur Gear With The Usage of The Advanced ComputerDocument6 pagesDesign Analysis of Spur Gear With The Usage of The Advanced ComputerPradeep AdsareNo ratings yet

- Naf Ems 2013 RotorDocument12 pagesNaf Ems 2013 Rotorletter_ashish4444No ratings yet

- Contribution To The Definition of The Torsional Stiffness of The Crankshaft of A Diesel Engine Used in Heavy-Duty VehiclesDocument11 pagesContribution To The Definition of The Torsional Stiffness of The Crankshaft of A Diesel Engine Used in Heavy-Duty VehiclesTushar SharmaNo ratings yet

- Crankshaft VibrationDocument8 pagesCrankshaft VibrationjohansolNo ratings yet

- Adrc - PMSG - Good2Document6 pagesAdrc - PMSG - Good2Dileep VarmaNo ratings yet

- Metaheuristic Algorithms for Parameter Estimation of DC Servo Motors With Quantized Sensor Measurements. (1)Document18 pagesMetaheuristic Algorithms for Parameter Estimation of DC Servo Motors With Quantized Sensor Measurements. (1)b320059No ratings yet

- Me 8594 Dynamics of Machinery Unit 1 Online Video LectureDocument42 pagesMe 8594 Dynamics of Machinery Unit 1 Online Video LecturesankarNo ratings yet

- Important Short Questions DYNAMICS AND DESIGN OF MACHINERYDocument32 pagesImportant Short Questions DYNAMICS AND DESIGN OF MACHINERYramos mingoNo ratings yet

- Dynamic Loading and Stress Analysis On Crankshaft of Reciprocating Mud PumpDocument11 pagesDynamic Loading and Stress Analysis On Crankshaft of Reciprocating Mud PumpchcruzgNo ratings yet

- (Journal of Agricultural Engineering Research Vol. 19 Iss. 2) Kolozsi, McCarthy - The Prediction of Tractor Field Performance (1974)Document6 pages(Journal of Agricultural Engineering Research Vol. 19 Iss. 2) Kolozsi, McCarthy - The Prediction of Tractor Field Performance (1974)Sergey ZlenkoNo ratings yet

- Ajme 10 1 4Document7 pagesAjme 10 1 4nitishsharma19712No ratings yet

- Design and Optimization of Backstepping Controller For An Underactuated Autonomous Quadrotor Unmanned Aerial VehicleDocument18 pagesDesign and Optimization of Backstepping Controller For An Underactuated Autonomous Quadrotor Unmanned Aerial VehicleSteve DemirelNo ratings yet

- Aerodynamics For StudentsDocument6 pagesAerodynamics For StudentsSelva RajNo ratings yet

- Advances in Vector Control Ofac Motor Drives A Review PDFDocument24 pagesAdvances in Vector Control Ofac Motor Drives A Review PDFBook4AllNo ratings yet

- Selection of Smooth Motion Profile For A Tube Locator Module of An Inspection DeviceDocument15 pagesSelection of Smooth Motion Profile For A Tube Locator Module of An Inspection DeviceIAES International Journal of Robotics and AutomationNo ratings yet

- JWST Brushless DC Motor Characteristics Analysis 2-5-2016Document13 pagesJWST Brushless DC Motor Characteristics Analysis 2-5-2016anhntran4850No ratings yet

- Mathematical Modeling and Control Law Design For 1dof Quadcopter Flight DynamicsDocument6 pagesMathematical Modeling and Control Law Design For 1dof Quadcopter Flight Dynamicsmatteorocco99No ratings yet

- V12 04 07 Hac From Mme PDFDocument18 pagesV12 04 07 Hac From Mme PDFHariharanNo ratings yet

- 0011 Static and Dynamic Analysis of Wind Turbine Blades Using The Finite Element MDocument18 pages0011 Static and Dynamic Analysis of Wind Turbine Blades Using The Finite Element MKhalil DeghoumNo ratings yet

- Parametric Study and Design Optimization of A Radial Flow Pump ImpellerDocument9 pagesParametric Study and Design Optimization of A Radial Flow Pump ImpellerErnad BešlagićNo ratings yet

- Mechanics of Machines (314205) : Design, Fabrication and Analysis of Dual Can CrusherDocument10 pagesMechanics of Machines (314205) : Design, Fabrication and Analysis of Dual Can Crushersaqlain05No ratings yet

- Numerical Simulation of Turbulent Flow Through A Francis Turbine RunnerDocument6 pagesNumerical Simulation of Turbulent Flow Through A Francis Turbine RunnerAngel CerriteñoNo ratings yet

- Gearbox Design by ChitaleDocument34 pagesGearbox Design by ChitaleNagu Srirama60% (5)

- Conceptual Study of A Rocket-Ramjet Combined-Cycle Engine For An Aerospace PlaneDocument9 pagesConceptual Study of A Rocket-Ramjet Combined-Cycle Engine For An Aerospace PlaneSyed MohtasimNo ratings yet

- ResumoDocument10 pagesResumovothanhbinh311099No ratings yet

- Design and Analysis of Crankshaft For Single Cylinder 4-Stroke Deisel EngineDocument3 pagesDesign and Analysis of Crankshaft For Single Cylinder 4-Stroke Deisel EngineChetan GuptaNo ratings yet

- Modeling of Complex Systems: Application to Aeronautical DynamicsFrom EverandModeling of Complex Systems: Application to Aeronautical DynamicsNo ratings yet

- Advanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkFrom EverandAdvanced Electric Drives: Analysis, Control, and Modeling Using MATLAB / SimulinkNo ratings yet

- Modelling and Simulation Based On Matlab/Simulink: A Press MechanismDocument5 pagesModelling and Simulation Based On Matlab/Simulink: A Press Mechanismhugur soNo ratings yet

- Solution Datum at Lowest Point Solving For The: Find Study ResourcesDocument1 pageSolution Datum at Lowest Point Solving For The: Find Study Resourceshugur soNo ratings yet

- Hsk1 6 VocabDocument144 pagesHsk1 6 VocabsusanarutaNo ratings yet

- Torque On Current Loop: FD Iba B Ibab IbaDocument13 pagesTorque On Current Loop: FD Iba B Ibab Ibahugur soNo ratings yet

- नामांकन म/ Enrolment No.: 0636/00306/52054: Vid: VID: 9170 3011 4031 7083 9170 3011 4031 7083Document1 pageनामांकन म/ Enrolment No.: 0636/00306/52054: Vid: VID: 9170 3011 4031 7083 9170 3011 4031 7083Punam PanditNo ratings yet

- A Spam Transformer Model For SMS Spam DetectionDocument11 pagesA Spam Transformer Model For SMS Spam Detectionsireesha payyavulaNo ratings yet

- People of The Philippines V. Marissa Bayker G.R. No. 170192, February 10, 2016, BERSAMIN, J., FIRST DIVISION FactsDocument64 pagesPeople of The Philippines V. Marissa Bayker G.R. No. 170192, February 10, 2016, BERSAMIN, J., FIRST DIVISION FactsDonna Ingusan-BollozosNo ratings yet

- Literature Review Early Childhood EducationDocument10 pagesLiterature Review Early Childhood Educationafmzzulfmzbxet100% (1)

- History of Educ - TechDocument5 pagesHistory of Educ - Techjiggly popNo ratings yet

- Seminar ReportDocument29 pagesSeminar ReportUrja DhabardeNo ratings yet

- Afar 2704 Home Office Branch AgencyDocument33 pagesAfar 2704 Home Office Branch Agencylijeh312No ratings yet

- Chapter - 2 Marketing Research Problem and Developing ApproachDocument32 pagesChapter - 2 Marketing Research Problem and Developing ApproachAyushman UpretiNo ratings yet

- Maintenance of Building ComponentsDocument4 pagesMaintenance of Building ComponentsIZIMBANo ratings yet

- G.R. NO. 184535, SEPTEMBER 03, 2019 Sister Pilar Versoza, Petitioner, vs. People of The Philippines, Et Al., Respondents. FactsDocument2 pagesG.R. NO. 184535, SEPTEMBER 03, 2019 Sister Pilar Versoza, Petitioner, vs. People of The Philippines, Et Al., Respondents. FactsRoxanne Valino100% (1)

- Case Study For 1st AssignmentDocument17 pagesCase Study For 1st AssignmentMaher Ahmed100% (1)

- Phil. Export v. VP EusebioDocument2 pagesPhil. Export v. VP EusebioCZARINA ANN CASTRONo ratings yet

- EB 06 LightingDocument45 pagesEB 06 LightingTamNo ratings yet

- Caso 2 - Gerencia de Operaciones 2023Document3 pagesCaso 2 - Gerencia de Operaciones 2023Eyner PeñaNo ratings yet

- Todo Sobre Sintonizadores Equivalencias PDFDocument39 pagesTodo Sobre Sintonizadores Equivalencias PDFSantiago BonabelloNo ratings yet

- Textbook Planning and Design of Engineering Systems Third Edition Graeme Dandy Ebook All Chapter PDFDocument53 pagesTextbook Planning and Design of Engineering Systems Third Edition Graeme Dandy Ebook All Chapter PDFthomas.bishop281100% (6)

- At-The-Restaurant A2Document4 pagesAt-The-Restaurant A2Mjn AbbasiNo ratings yet

- Group:4: Delhi-Mumbai Industrial Corridor: India's Road To Prosperity?Document9 pagesGroup:4: Delhi-Mumbai Industrial Corridor: India's Road To Prosperity?shahin selkarNo ratings yet

- Timothy - Chap 11Document24 pagesTimothy - Chap 11Chaeyeon JungNo ratings yet

- Data Quality SalesforceDocument190 pagesData Quality SalesforceLariNo ratings yet

- EFL IS User ManualDocument26 pagesEFL IS User Manualarupamguria05No ratings yet

- Substantive ProceduressDocument8 pagesSubstantive ProceduressayyazmNo ratings yet

- QualitativeDocument8 pagesQualitativeCmc Corpuz AbrisNo ratings yet

- DEA Report-MA Camp LimitedDocument145 pagesDEA Report-MA Camp LimitedCEG BangladeshNo ratings yet

- استردادDocument2 pagesاستردادnn1129374No ratings yet

- Air PollutionDocument35 pagesAir PollutionNur HazimahNo ratings yet