Professional Documents

Culture Documents

Spreading Sop

Spreading Sop

Uploaded by

TANYA TANYACopyright:

Available Formats

You might also like

- 1400 Calorie Meal PlanDocument4 pages1400 Calorie Meal PlanChris Theberge100% (68)

- Star Trek Adventures - Starship Sheet PDFDocument1 pageStar Trek Adventures - Starship Sheet PDFPanNo ratings yet

- Mccs Presentation Flange ManagementDocument21 pagesMccs Presentation Flange ManagementBuddy Eko100% (1)

- Carnation Production Flow ChartDocument1 pageCarnation Production Flow Chartsampriti.roy.589No ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Process Flow Chart: Stocks/ Raw Mats./ArtworksDocument1 pageProcess Flow Chart: Stocks/ Raw Mats./ArtworksJotechPackagingNo ratings yet

- Process Flow of Trims StoreDocument1 pageProcess Flow of Trims StoreVishwanath KrNo ratings yet

- SK FormsDocument1 pageSK FormsJholly JumadayNo ratings yet

- Appendix - IX Plant LayoutDocument9 pagesAppendix - IX Plant LayoutniftNo ratings yet

- Project RevisedDocument1 pageProject RevisedMD Ayub AlamNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- PAT (Process Analytical Technology) For "LIQUID PARENTERAL" Pharmaceuticals I.E. SVP & LVP Manufacturing Line ...Document3 pagesPAT (Process Analytical Technology) For "LIQUID PARENTERAL" Pharmaceuticals I.E. SVP & LVP Manufacturing Line ...Alfinovita KabanNo ratings yet

- Merchandising Flow ChartDocument1 pageMerchandising Flow ChartshahinrezaNo ratings yet

- Template For New Item Master Creation - Kcsa Accredited Standards (Ansi) FormDocument5 pagesTemplate For New Item Master Creation - Kcsa Accredited Standards (Ansi) FormKennedy MsimukoNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- CBM-SCM N Link of Import - ExportDocument15 pagesCBM-SCM N Link of Import - ExportAsfand375yar KhanNo ratings yet

- Starship Registry Entry: Name: Designation: Service Date: Space Frame: Mission Profile: RefitDocument1 pageStarship Registry Entry: Name: Designation: Service Date: Space Frame: Mission Profile: RefitNicolas Peltier100% (1)

- 13.3 Starship Sheet 3-7-17Document1 page13.3 Starship Sheet 3-7-17dalahmahrNo ratings yet

- Appearance Approval ReportDocument2 pagesAppearance Approval ReportJosué PérezNo ratings yet

- Liquid Parenteral SCDocument3 pagesLiquid Parenteral SCKamran AlamNo ratings yet

- Top Management: Client Estimation/ Contract DivDocument2 pagesTop Management: Client Estimation/ Contract DivbuddhikaNo ratings yet

- Starship Registry Entry: Designation: Space Refit: Name: Service Date: Mission Profile: TraitsDocument1 pageStarship Registry Entry: Designation: Space Refit: Name: Service Date: Mission Profile: TraitsOberrootNo ratings yet

- Star Trek Adventures - Starship Registry Form PDFDocument1 pageStar Trek Adventures - Starship Registry Form PDFGorka DiazNo ratings yet

- Starship Registry FormDocument1 pageStarship Registry FormJacques BarciaNo ratings yet

- STA Starship Registry Entry - Form FillableDocument1 pageSTA Starship Registry Entry - Form FillableSgt. MushroomNo ratings yet

- Star Trek Adventures - Starship Registry Entry - Form Fillable PDFDocument1 pageStar Trek Adventures - Starship Registry Entry - Form Fillable PDFGorka Diaz100% (1)

- WBS HeathrowDocument1 pageWBS HeathrowShakil Reddy BhimavarapuNo ratings yet

- Aap-Br - 04 - 24 RDocument1 pageAap-Br - 04 - 24 ROmair QureshiNo ratings yet

- Profeco Vehicle RepairDocument4 pagesProfeco Vehicle RepairScribdTranslationsNo ratings yet

- Sop For Cad DepartmentDocument12 pagesSop For Cad DepartmentAmrita MitraNo ratings yet

- Bread and Pastry Production Ncii Workshop Layout: Proofing CabinetDocument1 pageBread and Pastry Production Ncii Workshop Layout: Proofing CabinetCyvie Fate Antolin100% (1)

- Explain The First Step Inside This RectangleDocument1 pageExplain The First Step Inside This RectangleClint Bryan VirayNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

- Presentation 1Document6 pagesPresentation 1Home Grown Digital AdvertisingNo ratings yet

- Primary Member Process Flow ChartDocument3 pagesPrimary Member Process Flow Chartmadhu krishnaNo ratings yet

- Manufacturing Control ProcessDocument9 pagesManufacturing Control ProcessDadang AbdurrazakNo ratings yet

- Courtesy by MODEC, Inc. Courtesy by MODEC, Inc.: The Yokohama Rubber Co., LTDDocument2 pagesCourtesy by MODEC, Inc. Courtesy by MODEC, Inc.: The Yokohama Rubber Co., LTDlalitNo ratings yet

- Client'S Information: 118 Perea Street, Legaspi Village, Makati City 1229 88938103 77500047 88236757Document1 pageClient'S Information: 118 Perea Street, Legaspi Village, Makati City 1229 88938103 77500047 88236757Laica Olei SinenseNo ratings yet

- HVAC Invoice Template FreeDocument1 pageHVAC Invoice Template FreetmamputsiNo ratings yet

- Daily Production Cost and Efficiency ReportDocument1 pageDaily Production Cost and Efficiency Reportkrishna.greenhrNo ratings yet

- KMD Workflow Process Software DeliverablesDocument1 pageKMD Workflow Process Software Deliverableskaroui.anouerNo ratings yet

- Org Ani GramDocument1 pageOrg Ani GramGerald OdayenNo ratings yet

- SMALL Special Vehicle SheetDocument1 pageSMALL Special Vehicle SheetJose Luis Ingelmo ZorrillaNo ratings yet

- SteamDocument1 pageSteamPAul JoHn MeNdozaNo ratings yet

- Theory of Architecture RefresherDocument15 pagesTheory of Architecture RefresherjaysonNo ratings yet

- Bastion Kain S Small Vehicle Sheet Fill AbleDocument1 pageBastion Kain S Small Vehicle Sheet Fill AbleJose Luis Ingelmo ZorrillaNo ratings yet

- Training Manual For MerchandisersDocument15 pagesTraining Manual For MerchandisersDhanwaria67% (3)

- Tailoring Ncii Workshop Lay-Out: Entrance/ ExitDocument1 pageTailoring Ncii Workshop Lay-Out: Entrance/ ExitWendy ArnidoNo ratings yet

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- Dfma WorkflowDocument1 pageDfma WorkflowAljohn AmbatNo ratings yet

- Form Inspection JIS RFITDocument7 pagesForm Inspection JIS RFITBadrunNo ratings yet

- Alpha Engineers: Patroling SheetDocument2 pagesAlpha Engineers: Patroling SheetHarsh KachhawaNo ratings yet

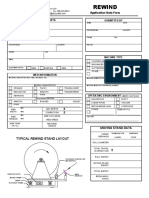

- Customer Data Submitted By: Typical Rewind Stand LayoutDocument2 pagesCustomer Data Submitted By: Typical Rewind Stand Layoutjroyal69No ratings yet

- 4M Change Summary Sheet - PRFDocument4 pages4M Change Summary Sheet - PRFkumar QANo ratings yet

- Future Landscape and RoadmapDocument17 pagesFuture Landscape and RoadmapMARIA SELES TELES SOUSANo ratings yet

- Bastion Kains Smalland Large Vehicle Sheets FillableDocument2 pagesBastion Kains Smalland Large Vehicle Sheets FillableJose Luis Ingelmo ZorrillaNo ratings yet

- CIM DatabaseDocument14 pagesCIM Databasenuha zargarNo ratings yet

- Yildiz Teknik Üniversitesi İnşaat Mühendisliği Bölümü İnşaat Fakültesi Yapi Anabilim DaliDocument1 pageYildiz Teknik Üniversitesi İnşaat Mühendisliği Bölümü İnşaat Fakültesi Yapi Anabilim DaliAli DemirezenNo ratings yet

- Compiled by - Tanya (BFT/18/639) : Assignment 1Document12 pagesCompiled by - Tanya (BFT/18/639) : Assignment 1TANYA TANYANo ratings yet

- Apparel Quality ManagementDocument17 pagesApparel Quality ManagementTANYA TANYANo ratings yet

- The Planning Process in Clothing ManufactureDocument9 pagesThe Planning Process in Clothing ManufactureTANYA TANYANo ratings yet

- Capacity PlanningDocument58 pagesCapacity PlanningTANYA TANYANo ratings yet

- Retail Management of A Hand BrandDocument30 pagesRetail Management of A Hand BrandTANYA TANYANo ratings yet

- Origin of Costumes: - Protection Theory - Modesty Theory - Self AdornmentDocument8 pagesOrigin of Costumes: - Protection Theory - Modesty Theory - Self AdornmentTANYA TANYANo ratings yet

- Starbucks 12021Document21 pagesStarbucks 12021TANYA TANYA100% (1)

- One Hundred Years of Women's Fashion: by Shannon PerryDocument11 pagesOne Hundred Years of Women's Fashion: by Shannon PerryTANYA TANYA100% (1)

- Beginning of CostumesDocument20 pagesBeginning of CostumesTANYA TANYANo ratings yet

- Factors Influecing FashionDocument34 pagesFactors Influecing FashionTANYA TANYA75% (4)

- Phulkari - Reviving Parental Love PDFDocument46 pagesPhulkari - Reviving Parental Love PDFTANYA TANYANo ratings yet

- Satelite & Cable TVDocument67 pagesSatelite & Cable TVGanesan KandasamyNo ratings yet

- User Manual - Garment ModuleDocument8 pagesUser Manual - Garment ModuleAredaNo ratings yet

- Mozart - 19 Sonatas For The Piano PDFDocument313 pagesMozart - 19 Sonatas For The Piano PDFCarla_con_CNo ratings yet

- Sa-600 User MenuDocument2 pagesSa-600 User MenuAllan RamosNo ratings yet

- Pe FinalsDocument18 pagesPe FinalsNicole PauigNo ratings yet

- Grana - A3 All Day Menu - 100124Document2 pagesGrana - A3 All Day Menu - 100124Katherine StapelsNo ratings yet

- Alcatel-Lucent 9600 USY: Sdhmedium-Orhigh-CapacitydigitalmicrowavelinksDocument4 pagesAlcatel-Lucent 9600 USY: Sdhmedium-Orhigh-Capacitydigitalmicrowavelinksaltus_aryaNo ratings yet

- Travelling Expressions: Complete The Sentences (1-14) With The Expressions (A-N)Document1 pageTravelling Expressions: Complete The Sentences (1-14) With The Expressions (A-N)Lucia LopezNo ratings yet

- African Theater and CultureDocument12 pagesAfrican Theater and CulturegadinizNo ratings yet

- Date Night PDFDocument1 pageDate Night PDFNitesh Kumar PatelNo ratings yet

- BG3 BuildsDocument8 pagesBG3 BuildsLincon BilibioNo ratings yet

- Interior Design PortfolioDocument88 pagesInterior Design PortfolioSurangana AcharyaNo ratings yet

- DND Shorts Monster Showdown RulesDocument2 pagesDND Shorts Monster Showdown Rulesnimz 203No ratings yet

- Exercise Equipment Quote: Inda Suppliers - Nairobi, Kenya, Tel: +254 722 549 225Document3 pagesExercise Equipment Quote: Inda Suppliers - Nairobi, Kenya, Tel: +254 722 549 225Paco MuhemediNo ratings yet

- CNX 2-11-13 PpeDocument29 pagesCNX 2-11-13 PpeMichael KovachNo ratings yet

- 30 Groove Master Bass Lines - Teymur Phell - SDocument38 pages30 Groove Master Bass Lines - Teymur Phell - SLeonardo Rafael González100% (3)

- Thaphad Sungwijit - Music Analysis: Article The Analysis of One Summer's Day Composed by Joe HisaishiDocument9 pagesThaphad Sungwijit - Music Analysis: Article The Analysis of One Summer's Day Composed by Joe HisaishiChatwalee ThongkumNo ratings yet

- Introduction To Computer NetworkDocument4 pagesIntroduction To Computer NetworkJescah JuneNo ratings yet

- 2018 Gongfarmer's AlmanacDocument442 pages2018 Gongfarmer's Almanacpgc97z2xhpNo ratings yet

- Digital Economy Compass 2018Document224 pagesDigital Economy Compass 2018sidhanthaNo ratings yet

- International Marketing Report - OrGDocument25 pagesInternational Marketing Report - OrGseemab.kanwal.87.skNo ratings yet

- What Is Celebrated On The 4th of July and Why Is This Date So ImportantDocument2 pagesWhat Is Celebrated On The 4th of July and Why Is This Date So ImportantAlexandra CanoNo ratings yet

- Buvette Dinner MenuDocument1 pageBuvette Dinner MenuEmily WeinsteinNo ratings yet

- Smart Phone FeaturesDocument8 pagesSmart Phone FeaturesveeraNo ratings yet

- Dcs-960l A1 Manual v1.00 WWDocument69 pagesDcs-960l A1 Manual v1.00 WWLuis Daniel Woiski GuilhermeNo ratings yet

- Tarea n0 1 Act 10Document18 pagesTarea n0 1 Act 10Sandra Patricia Estrada LopezNo ratings yet

- Apcpdcl JLM 2021Document30 pagesApcpdcl JLM 2021benilah jesniNo ratings yet

- Resume - Rajeev Sharma UpdatedDocument4 pagesResume - Rajeev Sharma UpdatedLeshop0% (1)

- NCSE 2011 Language Arts 2Document17 pagesNCSE 2011 Language Arts 2Christian Patrice33% (3)

Spreading Sop

Spreading Sop

Uploaded by

TANYA TANYAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spreading Sop

Spreading Sop

Uploaded by

TANYA TANYACopyright:

Available Formats

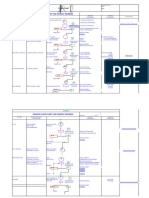

SPREADING AND CUTTING

PREPARATION FOR

PLANNING SPREADING CUTTING

SEWING

PLANNING SECTION

PLANNING

PATTERN CAD

MERCHANDISER

GIVE TECH PACK FILE RECEIVED

TO THE (BOM / TECH PACK)

DEPARTMENT

PATTERN

PATTERN MADE

RECEIVED FROM

ACCORDING TO

PATTERN

THE TECH PACK

DEPARTMENT

PATTERN SEND TO RECEIVE 14

THE CAD PARAMETER

DEPARTMENT REPORT

PLANNING CUT

ORDER PLAN

MARKER MAKING

MORE

TAKE APPROVAL

CHECK FABRIC

FROM

CONSUMPTION

MERCHANDISER

ELSE

SEND

CONSUMPTION TO

MERCHANDISER

SEND LAY REPORT

TO CUTTING

DEPARTMENT

SPREADING SECTION

LAY REPORT FROM

CAD

RECEIVE 14

PARAMETER

REPORT

CONFIRMATION

FROM

SUPERVISOR

CHECKS

FABRIC DESIGN PINNED TABLE

STRIPES>1CM

SOLID

NORMAL TABLE

NAP

BOTH

DOWN VELVET /

SOLID FABRIC NAP DIRECTION

CORDUROY

FABRIC

PATTERNS

CHECKS / STRIPES

FABRIC

BASED ON

CSV OR

NON CSV FACE

PATTERNS UP VELVET /

SOLID FABRIC FACE DIRECTION

CORDUROY

FACE

TO

FACE

CHECKS / STRIPES

FABRIC

24

HRS SHELL FABRIC

FABRIC RELAXATION WITH LYCEA /

SPANDEX

48

HRS

BI- STRETCH

FABRIC

LAY HEIGHT = 1.8 SPREADING IS

60-70 PLIES

INCHES DONE

CUTTING SECTION

CUTTING

AUTOMATIC

MANUAL

CUTTING

SLEEVES,COLLAR,FACING

ALL PARTS FRONT OF

AND

OFCHECK

BACK PANELS

/ STRIPEOF CHECK/STRIPES

CHECK/STRIPE

FABRIC & COLLAR

FABRIC AND AND ALL OTHER

COLLAR

OF SOLID

OF SOLID

FABRIC

FABRIC PARTS OF SOLID

KNOT IS MADE FOR

ALL CHECK /

STRIPE PARTS

NUMBERING

CHECKING

PREPARATION FOR

SEWING

FUSING

BUNDLING

SEWING

DEPARTMENT

You might also like

- 1400 Calorie Meal PlanDocument4 pages1400 Calorie Meal PlanChris Theberge100% (68)

- Star Trek Adventures - Starship Sheet PDFDocument1 pageStar Trek Adventures - Starship Sheet PDFPanNo ratings yet

- Mccs Presentation Flange ManagementDocument21 pagesMccs Presentation Flange ManagementBuddy Eko100% (1)

- Carnation Production Flow ChartDocument1 pageCarnation Production Flow Chartsampriti.roy.589No ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- Process Flow Chart: Stocks/ Raw Mats./ArtworksDocument1 pageProcess Flow Chart: Stocks/ Raw Mats./ArtworksJotechPackagingNo ratings yet

- Process Flow of Trims StoreDocument1 pageProcess Flow of Trims StoreVishwanath KrNo ratings yet

- SK FormsDocument1 pageSK FormsJholly JumadayNo ratings yet

- Appendix - IX Plant LayoutDocument9 pagesAppendix - IX Plant LayoutniftNo ratings yet

- Project RevisedDocument1 pageProject RevisedMD Ayub AlamNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- PAT (Process Analytical Technology) For "LIQUID PARENTERAL" Pharmaceuticals I.E. SVP & LVP Manufacturing Line ...Document3 pagesPAT (Process Analytical Technology) For "LIQUID PARENTERAL" Pharmaceuticals I.E. SVP & LVP Manufacturing Line ...Alfinovita KabanNo ratings yet

- Merchandising Flow ChartDocument1 pageMerchandising Flow ChartshahinrezaNo ratings yet

- Template For New Item Master Creation - Kcsa Accredited Standards (Ansi) FormDocument5 pagesTemplate For New Item Master Creation - Kcsa Accredited Standards (Ansi) FormKennedy MsimukoNo ratings yet

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaDocument1 pageSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitNo ratings yet

- CBM-SCM N Link of Import - ExportDocument15 pagesCBM-SCM N Link of Import - ExportAsfand375yar KhanNo ratings yet

- Starship Registry Entry: Name: Designation: Service Date: Space Frame: Mission Profile: RefitDocument1 pageStarship Registry Entry: Name: Designation: Service Date: Space Frame: Mission Profile: RefitNicolas Peltier100% (1)

- 13.3 Starship Sheet 3-7-17Document1 page13.3 Starship Sheet 3-7-17dalahmahrNo ratings yet

- Appearance Approval ReportDocument2 pagesAppearance Approval ReportJosué PérezNo ratings yet

- Liquid Parenteral SCDocument3 pagesLiquid Parenteral SCKamran AlamNo ratings yet

- Top Management: Client Estimation/ Contract DivDocument2 pagesTop Management: Client Estimation/ Contract DivbuddhikaNo ratings yet

- Starship Registry Entry: Designation: Space Refit: Name: Service Date: Mission Profile: TraitsDocument1 pageStarship Registry Entry: Designation: Space Refit: Name: Service Date: Mission Profile: TraitsOberrootNo ratings yet

- Star Trek Adventures - Starship Registry Form PDFDocument1 pageStar Trek Adventures - Starship Registry Form PDFGorka DiazNo ratings yet

- Starship Registry FormDocument1 pageStarship Registry FormJacques BarciaNo ratings yet

- STA Starship Registry Entry - Form FillableDocument1 pageSTA Starship Registry Entry - Form FillableSgt. MushroomNo ratings yet

- Star Trek Adventures - Starship Registry Entry - Form Fillable PDFDocument1 pageStar Trek Adventures - Starship Registry Entry - Form Fillable PDFGorka Diaz100% (1)

- WBS HeathrowDocument1 pageWBS HeathrowShakil Reddy BhimavarapuNo ratings yet

- Aap-Br - 04 - 24 RDocument1 pageAap-Br - 04 - 24 ROmair QureshiNo ratings yet

- Profeco Vehicle RepairDocument4 pagesProfeco Vehicle RepairScribdTranslationsNo ratings yet

- Sop For Cad DepartmentDocument12 pagesSop For Cad DepartmentAmrita MitraNo ratings yet

- Bread and Pastry Production Ncii Workshop Layout: Proofing CabinetDocument1 pageBread and Pastry Production Ncii Workshop Layout: Proofing CabinetCyvie Fate Antolin100% (1)

- Explain The First Step Inside This RectangleDocument1 pageExplain The First Step Inside This RectangleClint Bryan VirayNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

- Presentation 1Document6 pagesPresentation 1Home Grown Digital AdvertisingNo ratings yet

- Primary Member Process Flow ChartDocument3 pagesPrimary Member Process Flow Chartmadhu krishnaNo ratings yet

- Manufacturing Control ProcessDocument9 pagesManufacturing Control ProcessDadang AbdurrazakNo ratings yet

- Courtesy by MODEC, Inc. Courtesy by MODEC, Inc.: The Yokohama Rubber Co., LTDDocument2 pagesCourtesy by MODEC, Inc. Courtesy by MODEC, Inc.: The Yokohama Rubber Co., LTDlalitNo ratings yet

- Client'S Information: 118 Perea Street, Legaspi Village, Makati City 1229 88938103 77500047 88236757Document1 pageClient'S Information: 118 Perea Street, Legaspi Village, Makati City 1229 88938103 77500047 88236757Laica Olei SinenseNo ratings yet

- HVAC Invoice Template FreeDocument1 pageHVAC Invoice Template FreetmamputsiNo ratings yet

- Daily Production Cost and Efficiency ReportDocument1 pageDaily Production Cost and Efficiency Reportkrishna.greenhrNo ratings yet

- KMD Workflow Process Software DeliverablesDocument1 pageKMD Workflow Process Software Deliverableskaroui.anouerNo ratings yet

- Org Ani GramDocument1 pageOrg Ani GramGerald OdayenNo ratings yet

- SMALL Special Vehicle SheetDocument1 pageSMALL Special Vehicle SheetJose Luis Ingelmo ZorrillaNo ratings yet

- SteamDocument1 pageSteamPAul JoHn MeNdozaNo ratings yet

- Theory of Architecture RefresherDocument15 pagesTheory of Architecture RefresherjaysonNo ratings yet

- Bastion Kain S Small Vehicle Sheet Fill AbleDocument1 pageBastion Kain S Small Vehicle Sheet Fill AbleJose Luis Ingelmo ZorrillaNo ratings yet

- Training Manual For MerchandisersDocument15 pagesTraining Manual For MerchandisersDhanwaria67% (3)

- Tailoring Ncii Workshop Lay-Out: Entrance/ ExitDocument1 pageTailoring Ncii Workshop Lay-Out: Entrance/ ExitWendy ArnidoNo ratings yet

- Acc Fqap Rev 1 - DundigalDocument2 pagesAcc Fqap Rev 1 - DundigalHema NandhNo ratings yet

- Dfma WorkflowDocument1 pageDfma WorkflowAljohn AmbatNo ratings yet

- Form Inspection JIS RFITDocument7 pagesForm Inspection JIS RFITBadrunNo ratings yet

- Alpha Engineers: Patroling SheetDocument2 pagesAlpha Engineers: Patroling SheetHarsh KachhawaNo ratings yet

- Customer Data Submitted By: Typical Rewind Stand LayoutDocument2 pagesCustomer Data Submitted By: Typical Rewind Stand Layoutjroyal69No ratings yet

- 4M Change Summary Sheet - PRFDocument4 pages4M Change Summary Sheet - PRFkumar QANo ratings yet

- Future Landscape and RoadmapDocument17 pagesFuture Landscape and RoadmapMARIA SELES TELES SOUSANo ratings yet

- Bastion Kains Smalland Large Vehicle Sheets FillableDocument2 pagesBastion Kains Smalland Large Vehicle Sheets FillableJose Luis Ingelmo ZorrillaNo ratings yet

- CIM DatabaseDocument14 pagesCIM Databasenuha zargarNo ratings yet

- Yildiz Teknik Üniversitesi İnşaat Mühendisliği Bölümü İnşaat Fakültesi Yapi Anabilim DaliDocument1 pageYildiz Teknik Üniversitesi İnşaat Mühendisliği Bölümü İnşaat Fakültesi Yapi Anabilim DaliAli DemirezenNo ratings yet

- Compiled by - Tanya (BFT/18/639) : Assignment 1Document12 pagesCompiled by - Tanya (BFT/18/639) : Assignment 1TANYA TANYANo ratings yet

- Apparel Quality ManagementDocument17 pagesApparel Quality ManagementTANYA TANYANo ratings yet

- The Planning Process in Clothing ManufactureDocument9 pagesThe Planning Process in Clothing ManufactureTANYA TANYANo ratings yet

- Capacity PlanningDocument58 pagesCapacity PlanningTANYA TANYANo ratings yet

- Retail Management of A Hand BrandDocument30 pagesRetail Management of A Hand BrandTANYA TANYANo ratings yet

- Origin of Costumes: - Protection Theory - Modesty Theory - Self AdornmentDocument8 pagesOrigin of Costumes: - Protection Theory - Modesty Theory - Self AdornmentTANYA TANYANo ratings yet

- Starbucks 12021Document21 pagesStarbucks 12021TANYA TANYA100% (1)

- One Hundred Years of Women's Fashion: by Shannon PerryDocument11 pagesOne Hundred Years of Women's Fashion: by Shannon PerryTANYA TANYA100% (1)

- Beginning of CostumesDocument20 pagesBeginning of CostumesTANYA TANYANo ratings yet

- Factors Influecing FashionDocument34 pagesFactors Influecing FashionTANYA TANYA75% (4)

- Phulkari - Reviving Parental Love PDFDocument46 pagesPhulkari - Reviving Parental Love PDFTANYA TANYANo ratings yet

- Satelite & Cable TVDocument67 pagesSatelite & Cable TVGanesan KandasamyNo ratings yet

- User Manual - Garment ModuleDocument8 pagesUser Manual - Garment ModuleAredaNo ratings yet

- Mozart - 19 Sonatas For The Piano PDFDocument313 pagesMozart - 19 Sonatas For The Piano PDFCarla_con_CNo ratings yet

- Sa-600 User MenuDocument2 pagesSa-600 User MenuAllan RamosNo ratings yet

- Pe FinalsDocument18 pagesPe FinalsNicole PauigNo ratings yet

- Grana - A3 All Day Menu - 100124Document2 pagesGrana - A3 All Day Menu - 100124Katherine StapelsNo ratings yet

- Alcatel-Lucent 9600 USY: Sdhmedium-Orhigh-CapacitydigitalmicrowavelinksDocument4 pagesAlcatel-Lucent 9600 USY: Sdhmedium-Orhigh-Capacitydigitalmicrowavelinksaltus_aryaNo ratings yet

- Travelling Expressions: Complete The Sentences (1-14) With The Expressions (A-N)Document1 pageTravelling Expressions: Complete The Sentences (1-14) With The Expressions (A-N)Lucia LopezNo ratings yet

- African Theater and CultureDocument12 pagesAfrican Theater and CulturegadinizNo ratings yet

- Date Night PDFDocument1 pageDate Night PDFNitesh Kumar PatelNo ratings yet

- BG3 BuildsDocument8 pagesBG3 BuildsLincon BilibioNo ratings yet

- Interior Design PortfolioDocument88 pagesInterior Design PortfolioSurangana AcharyaNo ratings yet

- DND Shorts Monster Showdown RulesDocument2 pagesDND Shorts Monster Showdown Rulesnimz 203No ratings yet

- Exercise Equipment Quote: Inda Suppliers - Nairobi, Kenya, Tel: +254 722 549 225Document3 pagesExercise Equipment Quote: Inda Suppliers - Nairobi, Kenya, Tel: +254 722 549 225Paco MuhemediNo ratings yet

- CNX 2-11-13 PpeDocument29 pagesCNX 2-11-13 PpeMichael KovachNo ratings yet

- 30 Groove Master Bass Lines - Teymur Phell - SDocument38 pages30 Groove Master Bass Lines - Teymur Phell - SLeonardo Rafael González100% (3)

- Thaphad Sungwijit - Music Analysis: Article The Analysis of One Summer's Day Composed by Joe HisaishiDocument9 pagesThaphad Sungwijit - Music Analysis: Article The Analysis of One Summer's Day Composed by Joe HisaishiChatwalee ThongkumNo ratings yet

- Introduction To Computer NetworkDocument4 pagesIntroduction To Computer NetworkJescah JuneNo ratings yet

- 2018 Gongfarmer's AlmanacDocument442 pages2018 Gongfarmer's Almanacpgc97z2xhpNo ratings yet

- Digital Economy Compass 2018Document224 pagesDigital Economy Compass 2018sidhanthaNo ratings yet

- International Marketing Report - OrGDocument25 pagesInternational Marketing Report - OrGseemab.kanwal.87.skNo ratings yet

- What Is Celebrated On The 4th of July and Why Is This Date So ImportantDocument2 pagesWhat Is Celebrated On The 4th of July and Why Is This Date So ImportantAlexandra CanoNo ratings yet

- Buvette Dinner MenuDocument1 pageBuvette Dinner MenuEmily WeinsteinNo ratings yet

- Smart Phone FeaturesDocument8 pagesSmart Phone FeaturesveeraNo ratings yet

- Dcs-960l A1 Manual v1.00 WWDocument69 pagesDcs-960l A1 Manual v1.00 WWLuis Daniel Woiski GuilhermeNo ratings yet

- Tarea n0 1 Act 10Document18 pagesTarea n0 1 Act 10Sandra Patricia Estrada LopezNo ratings yet

- Apcpdcl JLM 2021Document30 pagesApcpdcl JLM 2021benilah jesniNo ratings yet

- Resume - Rajeev Sharma UpdatedDocument4 pagesResume - Rajeev Sharma UpdatedLeshop0% (1)

- NCSE 2011 Language Arts 2Document17 pagesNCSE 2011 Language Arts 2Christian Patrice33% (3)