Professional Documents

Culture Documents

Fluorescent Magnetic Particle Premix: Product Data Sheet

Fluorescent Magnetic Particle Premix: Product Data Sheet

Uploaded by

Sandro ChiliquingaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fluorescent Magnetic Particle Premix: Product Data Sheet

Fluorescent Magnetic Particle Premix: Product Data Sheet

Uploaded by

Sandro ChiliquingaCopyright:

Available Formats

Product Data Sheet

20B

Fluorescent Magnetic Particle Premix

20B is a highly-sensitive magnetic particle premix powder for locating fine discontinuities in high volume

applications, such as forging, casting, stamping and welding.

Combining Magnaflux’s best-in-industry 14A magnetic particles, corrosion inhibitors and wetting agents,

20B is an easy-to-use premix for making magnetic particle water bath. The ultra-sensitive 14A particles

provide clear, bright, fluorescent green indications under ultra-violet black light for unbeatable inspection

quality and accuracy, and the water conditioners provide corrosion protection and complete surface

wetting.

20B is a great choice for baths which need to be changed out frequently due to drag-in or heavy-use

and is ideal for in-process testing to detect cracks, seams, inclusions, laps, tears and flakes.

20B meets all major industry and NDT specification requirements, including automotive, API and ASTM

standards.

BENEFITS

Increases indication detection with 14A particles Improve inspection consistency and reliability

• Find smaller, finer indications in critical • Maintain magnetic particle system

applications using the highly sensitive, performance over greater periods of

strong ferromagnetic 14A particles time thanks to the highly-durable, easily-

• Optimized particle size and shape help dispersed 14A particles

particles move freely to stick to a wide • Reduced particle clumping helps maintain

variety of discontinuities with less particle particle concentration in the suspension

clumping bath for dependable inspections

Minimizes inspection time Convenient to use

• Clear, bright fluorescent indications form • Fast, reliable particle bath prep with

quickly due to the highly fluorescent, highly the easy-to-use premix of 14A magnetic

mobile 14A particles particles, water conditioners and corrosion

• Minimal background fluorescence help preventatives

indications stand out more so inspectors • Designed to mix with water in low

need to spend less time examining each concentrations for an ideal balance of

part performance and economy

Revised: December 2017 magnaflux.com

Product Data Sheet

FEATURES • Steel

• Premix powder for quick, reliable bath prep • Iron alloys

• High sensitivity • Nickel alloys

• Excellent fluorescent contrast Defect examples:

• Excellent particle mobility • Inclusions

• Optimized particle size and shape distribution • Seams

• Durable particles • Shrink cracks

• Easily dispersed • Tears

• Great concentration consistency • Laps

• Corrosion protection • Flakes

• Non-foaming • Welding defects

• Easy post-testing clean up • Grinding cracks

• Good dispersion stability • Quenching cracks

• Good surface wetting • Fatigue cracks

SPECIFICATION COMPLIANCE PREPARATION INSTRUCTIONS

• AMS 3044 Mix 20B with water for use. Fill tank or container

• ASTM E709 with water. Measure or weigh out 20B, add a small

amount of water and mix to form a thick paste.

• ASTM E1444

Add the paste to water in the tank or container.

• ASME Mix for a minimum of 15 minutes, until the particles

• MIL-STD-2132 are completely and evenly dispersed in the

• MIL-STD-271 suspension. Check concentration before use.

Using warm water (100°F / 38°C) to prepare the

• NAVSEA 250-1500-1

suspension will help the 20B mix faster.

• NAVSEA T9074-AS-GIB-010/271

Do not mix 20B with petroleum distillate (oil).

APPLICATIONS A measuring scoop is included with container of

Defect location: Surface and slightly subsurface 20B. The scoop measures enough 20B powder

for one gallon of water.

Ideal for:

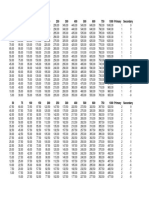

• Detecting fine discontinuities Water 20B

• Smooth surface finish 1 gallon 1.5 ounces

• High volume testing 1 liter 11.2 grams

• After secondary processing

• In-service inspections REMOVAL

• Castings All components, parts, or inspection areas must

• Forging be properly demagnetized before cleaning to

ensure easy particle removal. Cleaned parts

• Stamped parts

may be treated with a temporary film protective

• Ferromagnetic metals coating if longer corrosion protection is required.

Revised: December 2017 magnaflux.com

Product Data Sheet

PRODUCT PROPERTIES Suspension concentration and contamination

should be monitored at least once a day,

Appearance Dry powder or according to applicable specifications.

Color in Visible Light Brown Contaminated suspensions, or those in use

for an extended length of time, should be

Color in UV Light Fluorescent yellow-green

replaced. Properly cleaning all components,

Odor Mild parts, or inspection areas before testing helps

Mean Particle Size* 6 microns to significantly reduce particle suspension

contamination.

SAE Sensitivity** 8-9

Particle concentration should be determined

* As determined by industry-typical method for measuring particle size

** Representative of the number of indications on a tool steel ring as

after initial bath preparation and at least once a

defined in ASTM E1444. day, or according to applicable specifications,

to maintain the proper level of particles in the

USE RECOMMENDATIONS suspension. The most widely used method of

control is by settling volume measurement in a

Magnetic Particle Testing, graduated ASTM pear-shaped centrifuge tube.

NDT Method

Fluorescent, Wet Method For testing 20B, Magnaflux centrifuge tube 8493

Suspension Vehicle Water is recommended: 100 ml capacity, stem graduated

Magnetizing device, from 0 to 1 mL in 0.05 mL increments.

Required Equipment

UV light source

Temperature Range† 32 to 120°F / 0 to 49°C STORAGE

Store in a well-ventilated area away from

Settling Volume 0.10 – 0.40 mL

magnetizing equipment and heat sources. Product

† Particle integrity and mobility may decline beyond these age, exposure to elevated temperatures, and/or

temperature limits.

exposure to a strong magnetic field may adversely

affect particle redistribution.

INSTRUCTIONS FOR USE Protect from sunlight. 20B is a hygroscopic

Use 20B with appropriate magnetization (moisture absorbing) powder so storage

procedure and equipment. For best results, all containers should be tightly sealed when not

components, parts, or areas to be tested should in use. Cool, dry storage location is preferred.

be clean and dry prior to testing to provide Refer to Safety Data Sheet for additional storage

an optimal test surface and reduce particle instructions.

suspension contamination. Particle suspension

must be properly mixed and continuously PACKAGING

agitated when in use to ensure uniformity and 1 lb / 453 g jar (case of 6) 01-0179-71

concentration. 15 lb / 6.8 kg pail 01-0179-70

The suspension can be applied by gently spraying 30 lb / 13.6 kg pail 01-0179-84

or flooding the area to be tested using the

continuous or residual application method. Inspect HEALTH AND SAFETY

under ultra-violet black light. Check particle

concentration before use. Review all relevant health and safety information

before using this product. For complete health and

Maintenance Recommendations safety information, refer to the product Safety Data

Magnetic particle suspensions need to be Sheet, which is available at www.magnaflux.com.

properly maintained to provide consistent results.

Revised: December 2017 magnaflux.com

You might also like

- TDS VETOBOND pb434Document4 pagesTDS VETOBOND pb434PeshteenNo ratings yet

- Barrafer ADocument2 pagesBarrafer ADoby YuniardiNo ratings yet

- Miconium Ctac29: Quaternary Ammonium SaltDocument1 pageMiconium Ctac29: Quaternary Ammonium Saltanon_993394650No ratings yet

- Wet Method Fluorescent Magnetic Particles: Product Data SheetDocument3 pagesWet Method Fluorescent Magnetic Particles: Product Data SheetLuis Yupa TapiaNo ratings yet

- Oil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetDocument4 pagesOil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetSandro ChiliquingaNo ratings yet

- 14A Product Data Sheet EnglishDocument4 pages14A Product Data Sheet EnglishInaamNo ratings yet

- QB1 Quick Break Tester - Operating Manual - Jun18Document3 pagesQB1 Quick Break Tester - Operating Manual - Jun18aravindanNo ratings yet

- 14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionDocument3 pages14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionSandro ChiliquingaNo ratings yet

- Fluorescent Magnetic Particles: Product Data SheetDocument3 pagesFluorescent Magnetic Particles: Product Data Sheetஅன்புடன் அஸ்வின்No ratings yet

- 11 Crystalseal enDocument2 pages11 Crystalseal enYoussef ElgendyNo ratings yet

- CBentonite DispersionsDocument4 pagesCBentonite DispersionsMOIZM100% (2)

- Hydrophilic Emulsifier: Product Data SheetDocument3 pagesHydrophilic Emulsifier: Product Data SheetMiguelNo ratings yet

- #8A Red: Non-Fluorescent Magnetic ParticlesDocument2 pages#8A Red: Non-Fluorescent Magnetic ParticlesSankar KrishnanNo ratings yet

- ZL 67 Product Data Sheet EnglishDocument3 pagesZL 67 Product Data Sheet EnglishKadirOzturkNo ratings yet

- Foodlube Multipaste - GBDocument2 pagesFoodlube Multipaste - GBtKc1234No ratings yet

- 14HF, 410HF: Oil-Based Fluorescent Magnetic InksDocument3 pages14HF, 410HF: Oil-Based Fluorescent Magnetic InksaravindanNo ratings yet

- Mixing: ChemicalsDocument4 pagesMixing: ChemicalsMehrad KarimiNo ratings yet

- FeovertDocument1 pageFeovertBhavik Dhami100% (2)

- #2 Yellow: Non-Fluorescent Magnetic ParticlesDocument2 pages#2 Yellow: Non-Fluorescent Magnetic ParticlesSandro ChiliquingaNo ratings yet

- #1 Gray: Non-Fluorescent Magnetic ParticlesDocument2 pages#1 Gray: Non-Fluorescent Magnetic ParticlesReadersmoNo ratings yet

- Cepsa Circulante 150Document1 pageCepsa Circulante 150RamonNo ratings yet

- Rapidfix: Construction Fasteners Group Rapidfix E18Document2 pagesRapidfix: Construction Fasteners Group Rapidfix E18Heramb TrifaleyNo ratings yet

- ZL 440 Product Data SheetDocument3 pagesZL 440 Product Data SheetVishal ChudasamaNo ratings yet

- 1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesDocument2 pages1 Grey, 8A Red: Visible Dry-Method Magnetic ParticlesaravindanNo ratings yet

- Steelshield Ve: Product DescriptionDocument2 pagesSteelshield Ve: Product DescriptionMoin AltafNo ratings yet

- DuraproofDocument2 pagesDuraproofM HAFEEZ RAJANo ratings yet

- Carboguard 504 PDSDocument4 pagesCarboguard 504 PDSNicholas ColesNo ratings yet

- Dolphin Bitumimous TDS - CompressedDocument2 pagesDolphin Bitumimous TDS - CompressedMohanned KhalidNo ratings yet

- Lanko 702 Durabed Data Sheet April 2006Document4 pagesLanko 702 Durabed Data Sheet April 2006Lenard BuenaventuraNo ratings yet

- PO Lapox EpogroutDocument4 pagesPO Lapox Epogroutjohn paulNo ratings yet

- Water-Based Single Component High Gloss Acrylic For DTM and Topcoat ApplicationsDocument6 pagesWater-Based Single Component High Gloss Acrylic For DTM and Topcoat ApplicationsamitNo ratings yet

- TDS - Pioneer Non Sag Epoxy - 022019Document3 pagesTDS - Pioneer Non Sag Epoxy - 022019Nancy AndriannaNo ratings yet

- 3M Series 740B Cartridges LDocument2 pages3M Series 740B Cartridges LdegrillonNo ratings yet

- ROYALPOXY UW 410-tdsDocument3 pagesROYALPOXY UW 410-tdsSyed FaridNo ratings yet

- Aquavers™ 405: Potable Water Spray PolyureaDocument4 pagesAquavers™ 405: Potable Water Spray PolyureaSuresh YadavNo ratings yet

- Sonolastic Ultra Asean 0509Document2 pagesSonolastic Ultra Asean 0509Andri AjaNo ratings yet

- Dura FlexDocument2 pagesDura FlexMuktaf Ajib El WatsiNo ratings yet

- Total Vulsol 5200 MSFDocument2 pagesTotal Vulsol 5200 MSFMajdin ZahirovicNo ratings yet

- Victor-Reinz Agri MWMDocument3 pagesVictor-Reinz Agri MWMAugustine DharmarajNo ratings yet

- Zincanode 402: Two Pack Zinc Rich Epoxy PrimerDocument2 pagesZincanode 402: Two Pack Zinc Rich Epoxy PrimerlivefreakNo ratings yet

- Colloid Mills Bulletin 4Document4 pagesColloid Mills Bulletin 4Francisco Jesús Infante PérezNo ratings yet

- Solvent-Based Developer: Product Data SheetDocument3 pagesSolvent-Based Developer: Product Data SheetaravindanNo ratings yet

- CarbolineDocument18 pagesCarbolineimaduddinshaNo ratings yet

- No-Bake: Product Line OverviewDocument14 pagesNo-Bake: Product Line OverviewkarahandevrimNo ratings yet

- MasterProtect HB 400 Formerly Thorocoat Product Data 2010646Document5 pagesMasterProtect HB 400 Formerly Thorocoat Product Data 2010646isaiasvinicius80No ratings yet

- Mapefer1K TDS EADocument4 pagesMapefer1K TDS EAAbdessamad EladakNo ratings yet

- Water Soluble Developer: Product Data SheetDocument3 pagesWater Soluble Developer: Product Data SheetDarwin EnriqueNo ratings yet

- Ecoratio Betopro 570: Environmentally Friendly Waterbased Release AgentDocument2 pagesEcoratio Betopro 570: Environmentally Friendly Waterbased Release AgentCatherine Fatima Mae LeynoNo ratings yet

- VPCL 378Document2 pagesVPCL 378rihtak123No ratings yet

- Preserva Natural Stone Enhancer: Features / Benefits SubstratesDocument3 pagesPreserva Natural Stone Enhancer: Features / Benefits Substratesannayya.chandrashekar Civil EngineerNo ratings yet

- Carbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- AJ220335-LCV-CVL-MTL-0001 - Cement & Civil Repair MaterialsDocument8 pagesAJ220335-LCV-CVL-MTL-0001 - Cement & Civil Repair Materialsmohammed mustafaNo ratings yet

- Salt Spray ChamberDocument9 pagesSalt Spray ChamberSijo Kaviyil JosephNo ratings yet

- Clean Water For Life: New Generation MembranesDocument8 pagesClean Water For Life: New Generation MembranesGabriel Montoya CorreaNo ratings yet

- 4010 TDS EnglishDocument1 page4010 TDS EnglishJose Luis Ramirez RamirezNo ratings yet

- Cap Water RepellentDocument1 pageCap Water RepellentEng-Medrar AlkateryNo ratings yet

- Basf MasterFlow 400 BDocument2 pagesBasf MasterFlow 400 Babdul majeedNo ratings yet

- Rilsan 3Document6 pagesRilsan 3Gustavo PradoNo ratings yet

- Mastertop 410: High Performance Nonmetallic Aggregate Surface HardenerDocument2 pagesMastertop 410: High Performance Nonmetallic Aggregate Surface Hardenercandra_sugiantoNo ratings yet

- SpECcoat PE400 TDS8 PDFDocument4 pagesSpECcoat PE400 TDS8 PDFnang homNo ratings yet

- Rubber Nanocomposites: Preparation, Properties, and ApplicationsFrom EverandRubber Nanocomposites: Preparation, Properties, and ApplicationsNo ratings yet

- English Pedagogical Module 1: Back To School!Document24 pagesEnglish Pedagogical Module 1: Back To School!Sandro ChiliquingaNo ratings yet

- 2800 Series Digital Panel Meters: Inputs SpecificationsDocument2 pages2800 Series Digital Panel Meters: Inputs SpecificationsSandro ChiliquingaNo ratings yet

- Wide-Vue Analog Panel Meters: Ordering InformationDocument10 pagesWide-Vue Analog Panel Meters: Ordering InformationSandro ChiliquingaNo ratings yet

- Consumable and Accessory Warranty StatementDocument2 pagesConsumable and Accessory Warranty StatementSandro ChiliquingaNo ratings yet

- Secondary Primary 1000 750 600 500 400 300 250 200 150 100 75 50Document5 pagesSecondary Primary 1000 750 600 500 400 300 250 200 150 100 75 50Sandro ChiliquingaNo ratings yet

- 14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionDocument3 pages14A Aqua-Glo™: Water-Based Fluorescent Magnetic Particle SuspensionSandro ChiliquingaNo ratings yet

- #2 Yellow: Non-Fluorescent Magnetic ParticlesDocument2 pages#2 Yellow: Non-Fluorescent Magnetic ParticlesSandro ChiliquingaNo ratings yet

- Oil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetDocument4 pagesOil-Based Fluorescent Magnetic Particle Suspension: Product Data SheetSandro ChiliquingaNo ratings yet

- Nickel-Iron For Cast Iron: Data SheetDocument3 pagesNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaNo ratings yet

- Lower Explosive Limits of Combustible GasesDocument1 pageLower Explosive Limits of Combustible GasesSandro ChiliquingaNo ratings yet

- Megohmmeter/IR TesterDocument2 pagesMegohmmeter/IR TesterSandro ChiliquingaNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetdediekosNo ratings yet

- Series 1500/2500 Safety Relief ValvesDocument12 pagesSeries 1500/2500 Safety Relief ValvesSandro ChiliquingaNo ratings yet

- 8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsDocument12 pages8K Series Pumps: Stainless Steel Multistage Centrifugal PumpsSandro ChiliquingaNo ratings yet

- Data Sheet of The Machine.Document4 pagesData Sheet of The Machine.Sandro ChiliquingaNo ratings yet

- Addendum - Cross Reference Factors - Multilingual - 10111833 - R000 PDFDocument1 pageAddendum - Cross Reference Factors - Multilingual - 10111833 - R000 PDFSandro ChiliquingaNo ratings yet

- User Maintenance Manual: Europa Advanced 4520 Venus Advanced 4951 Calisto Advanced 4953Document48 pagesUser Maintenance Manual: Europa Advanced 4520 Venus Advanced 4951 Calisto Advanced 4953Sandro ChiliquingaNo ratings yet

- Smart Senso AS8900Document12 pagesSmart Senso AS8900Sandro ChiliquingaNo ratings yet

- Multiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderDocument1 pageMultiple Files Are Bound Together in This PDF Package.: Click Here To Download The Latest Version of Adobe ReaderSandro ChiliquingaNo ratings yet

- Calibration Report For Digital Thermometer: Sample Customer S/N: XXXXXXX Report Number: W186693Document4 pagesCalibration Report For Digital Thermometer: Sample Customer S/N: XXXXXXX Report Number: W186693Sandro ChiliquingaNo ratings yet

- Datasheet Inductance Sensor 8 MMDocument2 pagesDatasheet Inductance Sensor 8 MMSandro ChiliquingaNo ratings yet

- Basic Examinations ExamDocument2 pagesBasic Examinations ExamSandro ChiliquingaNo ratings yet

- Flotation Frother Mixtures - Decoupling The Sub-Processes of Froth Stability, Froth Recovery and EntrainmentDocument8 pagesFlotation Frother Mixtures - Decoupling The Sub-Processes of Froth Stability, Froth Recovery and EntrainmentJose Luis Barrientos RiosNo ratings yet

- 20221128materi - 21027141 - Polimer (MKP) - Q - 9Document12 pages20221128materi - 21027141 - Polimer (MKP) - Q - 9Frizka VietantiNo ratings yet

- NRT-06A OYM P1&2 14-01-2024 SolDocument23 pagesNRT-06A OYM P1&2 14-01-2024 Solaarya LahaneNo ratings yet

- Elemental Speciation New Approach For Trace Element Analysis (2000)Document579 pagesElemental Speciation New Approach For Trace Element Analysis (2000)ravenhotrods64No ratings yet

- Byk - P 4102 - TDS - 1643511993Document2 pagesByk - P 4102 - TDS - 1643511993swapon kumar shillNo ratings yet

- Jagannath's Grade SheetDocument1 pageJagannath's Grade SheetReetesh BiswalNo ratings yet

- Fiche Technique FerritineDocument3 pagesFiche Technique FerritineBenglia AbderrezzakNo ratings yet

- Shreya Realty Private Limited: Calibration Graph For NO2 in Ambient AirDocument7 pagesShreya Realty Private Limited: Calibration Graph For NO2 in Ambient AirKushal SharmaNo ratings yet

- Writing Ionic EquationsDocument2 pagesWriting Ionic EquationsAnand Kumar ShuklaNo ratings yet

- Daily Report Civil JMK 09-07-2023Document1 pageDaily Report Civil JMK 09-07-2023Raka PriaNo ratings yet

- Hazardous Materials List: Classification of Materials in The HMLDocument19 pagesHazardous Materials List: Classification of Materials in The HMLALPENGIRLNo ratings yet

- StainingDocument55 pagesStainingtenawNo ratings yet

- Aslan™ 400 Carbon Fiber Reinforced Polymer (CFRP) Laminates Product SheetDocument1 pageAslan™ 400 Carbon Fiber Reinforced Polymer (CFRP) Laminates Product Sheet192113No ratings yet

- SDS VV-P-236 Tech PetrolatumDocument4 pagesSDS VV-P-236 Tech PetrolatumNikolayNo ratings yet

- ANDRITZ BowScreen MicraScreen ENDocument2 pagesANDRITZ BowScreen MicraScreen ENkarimNo ratings yet

- PVC U 1Document5 pagesPVC U 1Ahmed WagihNo ratings yet

- Chapter 6 Physical and Chemical Changes - Free PDF AvailableDocument2 pagesChapter 6 Physical and Chemical Changes - Free PDF AvailableVicky SharmaNo ratings yet

- Evaluation and Comparison Between Crude Oil Straight Run Fractions and Its Commercial Fractions (Gasoline, Kerosene and Gas Oil) at Dura Oil RefineryDocument10 pagesEvaluation and Comparison Between Crude Oil Straight Run Fractions and Its Commercial Fractions (Gasoline, Kerosene and Gas Oil) at Dura Oil RefineryAdhityaEkoBagusNo ratings yet

- Uve Module 2 Lesson 2Document9 pagesUve Module 2 Lesson 2因特李No ratings yet

- PCBN PCD 2018Document84 pagesPCBN PCD 2018Rafael CardosoNo ratings yet

- Saponification: Esters, Soapless and Soapy DetergentsDocument17 pagesSaponification: Esters, Soapless and Soapy Detergentsp bergerNo ratings yet

- Introduction To Bet Isotherms PDFDocument19 pagesIntroduction To Bet Isotherms PDFLuana AndradeNo ratings yet

- Photodegradation of Pharmaceutical Antibiotics OnDocument13 pagesPhotodegradation of Pharmaceutical Antibiotics OnNAMRATA KAMATNo ratings yet

- PBD Zewail ScienceDocument2 pagesPBD Zewail ScienceMaram SyegNo ratings yet

- Batteries: What Is A Battery?Document5 pagesBatteries: What Is A Battery?Aayush AgrawalNo ratings yet

- Level 0 Bond Angle 1675003600641Document11 pagesLevel 0 Bond Angle 1675003600641bhimbasuliNo ratings yet

- Heterocyclic Chemistry and Spectroscopy C 22022/CHE 22022: Course Lecturer: Dr. Dinusha UdukalaDocument40 pagesHeterocyclic Chemistry and Spectroscopy C 22022/CHE 22022: Course Lecturer: Dr. Dinusha UdukalaDidula ThrimannaNo ratings yet

- EX AT: Equipment CategoriesDocument2 pagesEX AT: Equipment CategoriesAminNo ratings yet

- Article: Correspondence: Petra - Bajerova@upce - CZ Tel.: +420 466 037 078Document11 pagesArticle: Correspondence: Petra - Bajerova@upce - CZ Tel.: +420 466 037 078Ana-Maria CiobotaruNo ratings yet