Professional Documents

Culture Documents

Technical Information Letter: Purpose

Technical Information Letter: Purpose

Uploaded by

Chidiebere Samuel OkogwuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Information Letter: Purpose

Technical Information Letter: Purpose

Uploaded by

Chidiebere Samuel OkogwuCopyright:

Available Formats

g

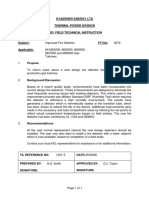

TIL 1304-3

GE ENERGY SERVICES

PRODUCT SERVICE

11 June 2001

TECHNICAL INFORMATION LETTER

9TH STAGE STATOR CASING HOOK

FIT (EXTRACTION SLOT) CRACKING

APPLICABLE TO:

Frame 5-1 and 5-2 Gas Turbines

PURPOSE

To provide information related to circumferential

cracking and corrective action available at the

9th stage of the compressor hook fit. RECOMMENDATION

GE recommends that a thorough inspection of

BACKGROUND / DISCUSSION this location be performed at every major

There have been several reported cases of inspection and during any maintenance activity

cracks found at the 9th stage of the compressor involving compressor casing removal. In most

casing hook fit. The issue is usually discovered cases, the crack can be seen visually. If no

on units with greater than 5 years of service or visual indications are present, an FPI should be

greater than 15,000 hours of peaking operation. performed to verify the absence of the crack.

A photo of a typical crack is attached (See figure

1). The crack begins at the horizontal flange GE Service Centers have a repair technique

and progresses in the circumferential direction. developed to resolve this issue. The Service

The thin metal ligament at this location Centers have all the necessary tooling and

combined with corrosion initiates the crack. In a methods to perform the full repair in the field.

few instances, the thin ligament has broken and Please contact the local GE repair services for

caused secondary damage. details.

Contact your local GE representative for

assistance or for additional information.

Figure 1. Typical 9th stage hook fit crack

TIL Category: E, F, & G

COPYRIGHT 2001, GE

The information published in this Technical Information Letter is offered to you by GE in consideration of its ongoing sales and service

relationship with your organization. However, since the operation of your plant involves many factors not within our knowledge, and since

operation of the plant is in your control and ultimate responsibility for its continuing successful operation rests with you, GE specifically

disclaims any responsibility for liability based on claims for damage of any type, i.e. direct, consequential or special that may be alleged to

have been incurred as result of applying this information regardless of whether it is claimed that GE is strictly liable, in breach of contract,

in breach of warranty, negligent, or is in other respects responsible for any alleged injury or damage sustained by your organization as a

result of applying this information.

You might also like

- The Design of High Efficiency Turbomachinery and Gas Turbines PDFDocument625 pagesThe Design of High Efficiency Turbomachinery and Gas Turbines PDFPhyo ThihabookNo ratings yet

- Technical Information Letter: GE PowerDocument10 pagesTechnical Information Letter: GE PowerRichard Puicon PuyenNo ratings yet

- T 1966Document4 pagesT 1966hasan099100% (1)

- Man Turbo THM Gas TurbineDocument51 pagesMan Turbo THM Gas Turbineaiabbasi9615100% (1)

- Chapter 03Document16 pagesChapter 03t1m0thyNo ratings yet

- Psib 20130813a - R1Document4 pagesPsib 20130813a - R1Léandre Ettekri NdriNo ratings yet

- t1068r3 IGV ClearanceDocument5 pagest1068r3 IGV ClearanceWest Damietta2100% (1)

- Computers: Acer - N20H2 : SF114-33Document2 pagesComputers: Acer - N20H2 : SF114-33Alhams TorrentNo ratings yet

- Instruction Manual Im-364Document39 pagesInstruction Manual Im-364Manuel L LombarderoNo ratings yet

- F Class Gas Turbine Compressor Water Wash SystemDocument8 pagesF Class Gas Turbine Compressor Water Wash SystemAbdelaziz Eldeeb100% (2)

- 3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Document6 pages3202.31.DIES - INSTRUMENT CABLE SCHEDULE.24015 - Rev02Chidiebere Samuel OkogwuNo ratings yet

- Dcam PT 66 Training Module 15.4 CompressorsDocument72 pagesDcam PT 66 Training Module 15.4 CompressorsSThaneasMurNo ratings yet

- Aircraft Engine OptimizationDocument242 pagesAircraft Engine OptimizationAirtech AeroNo ratings yet

- TIL 1352 R3 - MS6001B Stator 17 and Exit Guide Vane DistressDocument6 pagesTIL 1352 R3 - MS6001B Stator 17 and Exit Guide Vane DistressBouazzaNo ratings yet

- Technical Information Letter: Thermal Engineering Product Service TIL 1931Document6 pagesTechnical Information Letter: Thermal Engineering Product Service TIL 1931Hashim Bukhari100% (1)

- TIL 2373 - 7E Stage 2 Bucket Tip Shroud DistressDocument8 pagesTIL 2373 - 7E Stage 2 Bucket Tip Shroud DistressBouazzaNo ratings yet

- TIL 1469 2R1 - DC Emergency Pump RecommendationsDocument6 pagesTIL 1469 2R1 - DC Emergency Pump RecommendationsBouazzaNo ratings yet

- TIL 1879 - TIL 1879 Installation and Maintenance Recommendations For Exhaust ThermocouplesDocument26 pagesTIL 1879 - TIL 1879 Installation and Maintenance Recommendations For Exhaust ThermocouplesBouazzaNo ratings yet

- NIC 12.02 - Rev.01 Axial Displacement Inspection Procedure For Axial Andcentrifugal Compressors PDFDocument29 pagesNIC 12.02 - Rev.01 Axial Displacement Inspection Procedure For Axial Andcentrifugal Compressors PDFDjaber ElhaicharNo ratings yet

- TIL 1067 R4 - E Class Stage 2 Bucket Tip Shroud DeflectionDocument15 pagesTIL 1067 R4 - E Class Stage 2 Bucket Tip Shroud DeflectionBouazzaNo ratings yet

- GTD 111 AlloyDocument7 pagesGTD 111 AlloyJJNo ratings yet

- Journal Bearing UpgradingDocument2 pagesJournal Bearing UpgradingjasonNo ratings yet

- Content:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualDocument8 pagesContent:: Saudi Arabian Oil Company (Saudi Aramco) General Instruction ManualJayvee Baradas ValdezNo ratings yet

- 2 1 01 Auxiliary Gear BoxDocument30 pages2 1 01 Auxiliary Gear BoxHeryanto SyamNo ratings yet

- TIL 1382 R4 - 6B Compressor Rotor Stage 1 BLADE (R1) InspectionDocument8 pagesTIL 1382 R4 - 6B Compressor Rotor Stage 1 BLADE (R1) InspectionBouazza100% (1)

- Compressor Blade Corrosion Limits: Applicable ToDocument2 pagesCompressor Blade Corrosion Limits: Applicable ToKeesNo ratings yet

- Gas Turbine ConsultancyDocument4 pagesGas Turbine ConsultancyAek JayNo ratings yet

- المستندDocument5 pagesالمستندMahdi HassanNo ratings yet

- 6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFDocument1 page6FA DLN 2.6 Extended Interval Combustion System - GEA17898 PDFLenin RamonNo ratings yet

- Some Practical Aspects of Balancing An Ultracentrifuge RotorDocument10 pagesSome Practical Aspects of Balancing An Ultracentrifuge RotorGustavo da SilvaNo ratings yet

- Alstom Code of Ethics GB 2016Document28 pagesAlstom Code of Ethics GB 2016sujit5584No ratings yet

- Safety Bulletin: GE Power & Water 6B Endcover Damage PSSB 20140714A - R1 Product ServiceDocument2 pagesSafety Bulletin: GE Power & Water 6B Endcover Damage PSSB 20140714A - R1 Product ServiceLéandre Ettekri Ndri100% (1)

- Major InspectionDocument54 pagesMajor InspectionPhong leNo ratings yet

- 200Document16 pages200raka9009No ratings yet

- Frame6BHighwheelspacetemperaturerev 2Document17 pagesFrame6BHighwheelspacetemperaturerev 2partha6789100% (1)

- PDS 55910Document2 pagesPDS 55910daimaheshNo ratings yet

- Summary of HSE Control Framework Requirements and ChecklistDocument15 pagesSummary of HSE Control Framework Requirements and Checklistfadhil AbdullahNo ratings yet

- Risk Assessment On Combined Cycle Power Plant Mechanical Maintenanance 24 PagesDocument24 pagesRisk Assessment On Combined Cycle Power Plant Mechanical Maintenanance 24 PagesknabpshoNo ratings yet

- TIL 1304 3 - 9th Stage Stator Casing Hook Fit CrackingDocument4 pagesTIL 1304 3 - 9th Stage Stator Casing Hook Fit Crackinghernang100% (1)

- EngDocument44 pagesEngzomglolzscribdNo ratings yet

- 26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air SystemDocument5 pages26, Til 1621 Prevention of Water Accumulation Inside The Atomizing Air Systemankarao69No ratings yet

- TIL 1420-2r1 Lube Oil Logic EnhancementDocument4 pagesTIL 1420-2r1 Lube Oil Logic EnhancementManuel L LombarderoNo ratings yet

- Exide Life Income Advantage Plan BrochureDocument14 pagesExide Life Income Advantage Plan BrochureAravind AruviNo ratings yet

- Stage 1 Shroud For FS7001BDocument1 pageStage 1 Shroud For FS7001Bteedee1100% (1)

- TIL 1132 2R1 - VIGV Inspection, Thrust WasherDocument5 pagesTIL 1132 2R1 - VIGV Inspection, Thrust WasherHernan Giraut100% (2)

- Advanced Compressor Less Purge ControlsDocument32 pagesAdvanced Compressor Less Purge ControlsMaha BlueNo ratings yet

- 2006 - Training ScheduleDocument2 pages2006 - Training ScheduleDAVIS VELASQUEZNo ratings yet

- Continuous Monitoring SystemDocument3 pagesContinuous Monitoring SystemsamiNo ratings yet

- GE 6FA TurbineDocument1 pageGE 6FA TurbinehenriquezrsNo ratings yet

- Safety Bulletin: GE Power & Water PDA Cable Packaging PSSB 20140613A Product ServiceDocument2 pagesSafety Bulletin: GE Power & Water PDA Cable Packaging PSSB 20140613A Product ServiceLéandre Ettekri NdriNo ratings yet

- GE Frame 9E Turbine Stator and Rotor ConstructionDocument14 pagesGE Frame 9E Turbine Stator and Rotor ConstructionArash100% (1)

- Til 2086Document4 pagesTil 2086makarov.olegNo ratings yet

- Customer Course CatalogDocument119 pagesCustomer Course CatalogNguyễn Vạn ThắngNo ratings yet

- Scope of Work For Gas TurbineDocument47 pagesScope of Work For Gas TurbinePhong le100% (1)

- Mandatory Recommended SparesDocument14 pagesMandatory Recommended Sparesprasana balaji100% (1)

- CombustionSystems RR DLE CourseAssignment 2e PDFDocument6 pagesCombustionSystems RR DLE CourseAssignment 2e PDFJarnodeJongNo ratings yet

- Gas Turbine Compressor IssuesDocument9 pagesGas Turbine Compressor IssuesJJ100% (1)

- Technical Information Letter: Thermal Engineering Product Service TIL 1881Document11 pagesTechnical Information Letter: Thermal Engineering Product Service TIL 1881Ignacio Moratinos Castañeda100% (1)

- Technical Information Letter: Energy Services Engineering Product Service TIL 1607Document6 pagesTechnical Information Letter: Energy Services Engineering Product Service TIL 1607Hashim BukhariNo ratings yet

- Aero Grid Stability PAPER Sept 2011Document25 pagesAero Grid Stability PAPER Sept 2011igunhakam55No ratings yet

- GE MS 900 SeriesDocument18 pagesGE MS 900 SeriesMagoroku D. YudhoNo ratings yet

- Failure Analysis of Hydroelectric Power PlantDocument19 pagesFailure Analysis of Hydroelectric Power PlantDeepak Manihar (M20CI002)No ratings yet

- TIL 476C - Exhaust Temperature Spread GuidelinesDocument2 pagesTIL 476C - Exhaust Temperature Spread GuidelinesHernan Giraut100% (1)

- F Class Inspection Maintenance Fact SheetDocument1 pageF Class Inspection Maintenance Fact SheetMartinNo ratings yet

- Technical Information Letter: Load Coupling Nut EventDocument1 pageTechnical Information Letter: Load Coupling Nut EventChidiebere Samuel OkogwuNo ratings yet

- T 2119Document3 pagesT 2119bruno devinck100% (1)

- 3202.31.DIES.24097 - Rev01 - Instruments Material Take-off-R0Document19 pages3202.31.DIES.24097 - Rev01 - Instruments Material Take-off-R0Chidiebere Samuel OkogwuNo ratings yet

- Alternative Source For Gas Supply To Indorama ProjectDocument4 pagesAlternative Source For Gas Supply To Indorama ProjectChidiebere Samuel OkogwuNo ratings yet

- Start Time SN Job Step Hazard Harzard Controls Status CommentsDocument3 pagesStart Time SN Job Step Hazard Harzard Controls Status CommentsChidiebere Samuel OkogwuNo ratings yet

- Thin Material: Nozzle Segment Indication ZonesDocument1 pageThin Material: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuNo ratings yet

- Start Time SN Job Step Hazard Hazard Controls Status CommentsDocument3 pagesStart Time SN Job Step Hazard Hazard Controls Status CommentsChidiebere Samuel OkogwuNo ratings yet

- PM List I&C (1258)Document6 pagesPM List I&C (1258)Chidiebere Samuel OkogwuNo ratings yet

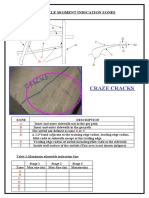

- Craze Cracks: Nozzle Segment Indication ZonesDocument1 pageCraze Cracks: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuNo ratings yet

- Nozzle Segment Indication Zones: A B C B D D E FDocument1 pageNozzle Segment Indication Zones: A B C B D D E FChidiebere Samuel OkogwuNo ratings yet

- Errosion: Nozzle Segment Indication ZonesDocument1 pageErrosion: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuNo ratings yet

- Bulging: Nozzle Segment Indication ZonesDocument1 pageBulging: Nozzle Segment Indication ZonesChidiebere Samuel OkogwuNo ratings yet

- Field Technical Instruction: John Brown Engineering Customer Service DivisionDocument2 pagesField Technical Instruction: John Brown Engineering Customer Service DivisionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument1 pageKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: TIL1365-2 Ge Energy Services Product Service 21 OCTOBER 2002Document3 pagesTechnical Information Letter: TIL1365-2 Ge Energy Services Product Service 21 OCTOBER 2002Chidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: Load Coupling Nut EventDocument1 pageTechnical Information Letter: Load Coupling Nut EventChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division C.S.D. Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Kvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionDocument2 pagesKvaerner Energy LTD Thermal Power Division CSD Field Technical InstructionChidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: Evaporative Cooler Commissioning ProcedureDocument2 pagesTechnical Information Letter: Evaporative Cooler Commissioning ProcedureChidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Document5 pagesTechnical Information Letter: Excessive Gas Fuel Flow at Start-Up (F-Class)Chidiebere Samuel Okogwu100% (1)

- 1208-3: Changes in Steam Turbine and Generator Parts Corrosion Protection PackagingDocument3 pages1208-3: Changes in Steam Turbine and Generator Parts Corrosion Protection PackagingChidiebere Samuel OkogwuNo ratings yet

- Kirsty Simone Bonner: Core Competencies and AchievementsDocument3 pagesKirsty Simone Bonner: Core Competencies and AchievementsChidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: TIL 1357-2 Ge Energy Services Product Service 15 JULY 2002Document2 pagesTechnical Information Letter: TIL 1357-2 Ge Energy Services Product Service 15 JULY 2002Chidiebere Samuel OkogwuNo ratings yet

- Donaldsong Control Box Datasheet1 47337Document1 pageDonaldsong Control Box Datasheet1 47337Chidiebere Samuel OkogwuNo ratings yet

- Technical Information Letter: Energy Services Engineering Product Service TIL 1576Document4 pagesTechnical Information Letter: Energy Services Engineering Product Service TIL 1576Chidiebere Samuel Okogwu100% (2)

- Technical Information Letter: TIL 1378-1 Ge Energy Services Product Service 12 December 2002Document1 pageTechnical Information Letter: TIL 1378-1 Ge Energy Services Product Service 12 December 2002Chidiebere Samuel OkogwuNo ratings yet

- Antisurge Control SystemDocument10 pagesAntisurge Control Systemsopan saNo ratings yet

- Experimental and Computational Studies On Oil Injected Twin-Screw CompressorDocument195 pagesExperimental and Computational Studies On Oil Injected Twin-Screw CompressorIhsan AhmedNo ratings yet

- UCH Power Plant 990 MWDocument17 pagesUCH Power Plant 990 MWAdnan119No ratings yet

- Sustainability 11 05409Document18 pagesSustainability 11 05409SalNo ratings yet

- Essentials of Turbo Machinery in CFD: Ideen SadrehaghighiDocument9 pagesEssentials of Turbo Machinery in CFD: Ideen SadrehaghighisolidwormNo ratings yet

- Axial Turbine Flow Path Design For An Organic Rankine Cycle Using R 245FADocument8 pagesAxial Turbine Flow Path Design For An Organic Rankine Cycle Using R 245FALijie WangNo ratings yet

- Rotating Machineries - Aspects of Operation and Maintenance (PDFDrive)Document110 pagesRotating Machineries - Aspects of Operation and Maintenance (PDFDrive)paulo cesar hernandez mijangosNo ratings yet

- Troubleshooting Pt6a27Document7 pagesTroubleshooting Pt6a27Okky Pangestoe WibowoNo ratings yet

- Chapter 14 TurbomachineryDocument125 pagesChapter 14 TurbomachineryThe Real Napster100% (1)

- Compressors: Operating Principle of CompressorDocument12 pagesCompressors: Operating Principle of CompressorNikka Briones DomingoNo ratings yet

- 2 ID FansDocument43 pages2 ID Fansshubham vermaNo ratings yet

- Donaldson Filter For SullairDocument5 pagesDonaldson Filter For SullairBhavesh PatelNo ratings yet

- Numerical and Experimental Comparison of A Tandem and Single Vane Deswirler Used in An Aero Engine Centrifugal CompressorDocument10 pagesNumerical and Experimental Comparison of A Tandem and Single Vane Deswirler Used in An Aero Engine Centrifugal CompressorBrahimABDNo ratings yet

- Chapter 5 Centrifugal Compressor (Complete Slide)Document17 pagesChapter 5 Centrifugal Compressor (Complete Slide)Azhan FikriNo ratings yet

- Application Chart For Various Turbine TypesDocument18 pagesApplication Chart For Various Turbine TypescortforceNo ratings yet

- Fan EquipmentDocument16 pagesFan Equipmentpenglei jiNo ratings yet

- 2047 AxialinletDocument2 pages2047 AxialinletNistha ChakrabortyNo ratings yet

- Speedrunfile 1Document26 pagesSpeedrunfile 1Adrian AquinoNo ratings yet

- Brayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsDocument15 pagesBrayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsmechturboNo ratings yet

- GE - LNG SolutionDocument18 pagesGE - LNG Solutionman_y2kNo ratings yet

- Fans and Blowers: College of Engineering and Technology Department of Mechanical EngineeringDocument10 pagesFans and Blowers: College of Engineering and Technology Department of Mechanical EngineeringKeanu EspinaNo ratings yet

- Martin J.L. Turner Turbomachinery Design andDocument404 pagesMartin J.L. Turner Turbomachinery Design andFebrian Nur AsaNo ratings yet

- Compressor SectionDocument79 pagesCompressor SectionMustakim shahrinNo ratings yet

- Ch4 - PPT - AIR AND WATER DISTRIBUTION PDFDocument50 pagesCh4 - PPT - AIR AND WATER DISTRIBUTION PDFBLa Production100% (1)

- Mini ProjectDocument44 pagesMini ProjectVenkata Sai M60% (5)