Professional Documents

Culture Documents

Ultratech TDS Leaflet - TileFixo-NT

Ultratech TDS Leaflet - TileFixo-NT

Uploaded by

Rabish ACopyright:

Available Formats

You might also like

- Portrait of an Industrial City: 'Clanging Belfast' 1750-1914From EverandPortrait of an Industrial City: 'Clanging Belfast' 1750-1914No ratings yet

- South Bihar Progress Report June 22Document22 pagesSouth Bihar Progress Report June 22Shinning GarimaNo ratings yet

- Volume1 CCTVDocument96 pagesVolume1 CCTVtender teamNo ratings yet

- Cement Suppliers in IndoreDocument10 pagesCement Suppliers in Indoresourabh_gupta_54No ratings yet

- After Sales Service Support Dealer Network Across IndiaDocument12 pagesAfter Sales Service Support Dealer Network Across IndiaAvijitSinharoyNo ratings yet

- Faridabad DataDocument364 pagesFaridabad DataDeepak GoyalNo ratings yet

- Appd List of Contractros of CEEC As On 27 Dec 2019Document187 pagesAppd List of Contractros of CEEC As On 27 Dec 2019RR PatelNo ratings yet

- Top 20 Construction Companies in India - Engineering HintDocument7 pagesTop 20 Construction Companies in India - Engineering HintMelwin PaulNo ratings yet

- List of Registered Contractors 04.01.2024Document43 pagesList of Registered Contractors 04.01.2024kamlesh.tayade9No ratings yet

- Contractor List June15Document32 pagesContractor List June15MINAKSHI SINGHNo ratings yet

- PWD TamilnaduDocument19 pagesPWD Tamilnadutagore 87No ratings yet

- List of Registered ProjectsDocument232 pagesList of Registered ProjectsAjay SinghNo ratings yet

- AssamDocument6 pagesAssamSarang MohideNo ratings yet

- Builders ListDocument265 pagesBuilders ListagrilandncrNo ratings yet

- List of In-Principle ApprovalsDocument9 pagesList of In-Principle ApprovalsManasvi MehtaNo ratings yet

- R&C Business ProfileDocument79 pagesR&C Business ProfileVedant KapoorNo ratings yet

- List of Enlisted Vendors Civil /electrical / Miscellaneous WorksDocument61 pagesList of Enlisted Vendors Civil /electrical / Miscellaneous Workssri projectssNo ratings yet

- Rubicon Cables IndustriesDocument11 pagesRubicon Cables IndustriesKiran patelNo ratings yet

- Latest Vendor Directory SignedDocument8 pagesLatest Vendor Directory SignedSuresh SharmaNo ratings yet

- List of Empanelled RIs Karnataka State PDFDocument2 pagesList of Empanelled RIs Karnataka State PDFLasik DelhiNo ratings yet

- SSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurDocument6 pagesSSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurMohit DagaNo ratings yet

- Black Listed ProfessionalsDocument6 pagesBlack Listed Professionalsvenkateswara rao PothinaNo ratings yet

- Times of IndiaDocument50 pagesTimes of IndianedunchiNo ratings yet

- Bai Gurdaspur PunjabDocument6 pagesBai Gurdaspur PunjabWinning SpiritNo ratings yet

- SubContractor Registration FormDocument18 pagesSubContractor Registration FormJagadeesan S MNo ratings yet

- Gim 2010 On 31.10.2014Document10 pagesGim 2010 On 31.10.2014SK Business groupNo ratings yet

- CraneDocument10 pagesCraneaitcpurchaseNo ratings yet

- Approved Material Suppliers CIDCODocument136 pagesApproved Material Suppliers CIDCOVikram SanghaviNo ratings yet

- List of Contractor Piu-BhopalDocument2 pagesList of Contractor Piu-BhopalMCS SBINo ratings yet

- Fmai 5 PDFDocument53 pagesFmai 5 PDFvenkatesh_1829No ratings yet

- List of Civil Contractors Registered in The CIDCO LTDDocument99 pagesList of Civil Contractors Registered in The CIDCO LTDMINAKSHI SINGHNo ratings yet

- Is 278 2009 PDFDocument11 pagesIs 278 2009 PDFjaianit89No ratings yet

- 05132015173818KOLDocument250 pages05132015173818KOLAman Dubey100% (2)

- CPWD Enlistment Rule 2022Document73 pagesCPWD Enlistment Rule 2022Assistant Engineer Elect CED III CCUNo ratings yet

- BookDocument44 pagesBookBinay ShawNo ratings yet

- List of Autorised Recovery AgenciesDocument94 pagesList of Autorised Recovery Agenciesgsonal975No ratings yet

- Infratech Limited Apco Construction Pvt. LTD.: Purchase OrderDocument2 pagesInfratech Limited Apco Construction Pvt. LTD.: Purchase OrderRajeshKumarJainNo ratings yet

- Core Vendor PDFDocument215 pagesCore Vendor PDFSakar EngitechNo ratings yet

- Bikaner: SR No DetailsDocument10 pagesBikaner: SR No DetailsWinning Spirit100% (1)

- AA Class ContractorDocument60 pagesAA Class ContractorVijay SinghNo ratings yet

- Brief Industrial Profile of Bhilwara District: LR Eso T RsDocument33 pagesBrief Industrial Profile of Bhilwara District: LR Eso T RsAbha SinghNo ratings yet

- GS Delhi.76155956Document3 pagesGS Delhi.76155956mek00sNo ratings yet

- Et AcetechDocument6 pagesEt Acetechfucker6777No ratings yet

- ENGGContractor Master ReportDocument124 pagesENGGContractor Master ReportUTTAL RAY100% (1)

- 96-100 OrganizedDocument7 pages96-100 OrganizedTechnetNo ratings yet

- Industries at GhaziabadDocument15 pagesIndustries at GhaziabadShashikant Jaisingha100% (1)

- List of Accredited Consultants Up To 30th April 2019 PDFDocument5 pagesList of Accredited Consultants Up To 30th April 2019 PDFKamalsingh RathoreNo ratings yet

- Mumbai Port Civil Contractors PDFDocument2 pagesMumbai Port Civil Contractors PDFParth DamaNo ratings yet

- Empanelment of Consultants5773060562 PDFDocument41 pagesEmpanelment of Consultants5773060562 PDFAshish KulshresthaNo ratings yet

- ResultDocument9 pagesResultanon_981731217No ratings yet

- BMRCL Contractor ListDocument8 pagesBMRCL Contractor ListKarthik VarnaNo ratings yet

- Amravati Dips 12-13Document32 pagesAmravati Dips 12-13Samar KhanNo ratings yet

- Budhpura Ground Zero' Sandstone Quarrying in India: by P. Madhavan Dr. Sanjay RajDocument32 pagesBudhpura Ground Zero' Sandstone Quarrying in India: by P. Madhavan Dr. Sanjay RajPragya UpadhyayNo ratings yet

- List of Manufacturers Situated at Krishna DistrictDocument3 pagesList of Manufacturers Situated at Krishna DistrictSriram Industries Surya GreasesNo ratings yet

- 28061805Document3 pages28061805Jagadamba RealtorNo ratings yet

- Accredited ConsultantsDocument195 pagesAccredited ConsultantsRaja Mani100% (1)

- 60223918-Vendor-Directory Railway PDFDocument112 pages60223918-Vendor-Directory Railway PDFPACWELNo ratings yet

- Design ConsultantsDocument35 pagesDesign ConsultantsYogesh ChhaprooNo ratings yet

- O2018 IIIDocument409 pagesO2018 IIIYogesh Chhaproo100% (1)

- Ultratech TDS Leaflet - FixoblockDocument1 pageUltratech TDS Leaflet - FixoblockRabish ANo ratings yet

- Guruvayur Accomodation: Kousthubham Rest House (Phone No: 0487 2556537, Fax: 04872554844)Document2 pagesGuruvayur Accomodation: Kousthubham Rest House (Phone No: 0487 2556537, Fax: 04872554844)Rabish ANo ratings yet

- Guruvayur AccomodationDocument2 pagesGuruvayur AccomodationRabish ANo ratings yet

- Edited - 04 Application - Well - Built - Residential - AwardsDocument6 pagesEdited - 04 Application - Well - Built - Residential - AwardsRabish ANo ratings yet

- Efficient Test Setup For Determining The Water-Permeability of ConcreteDocument6 pagesEfficient Test Setup For Determining The Water-Permeability of ConcreteRabish ANo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofRabish A100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofRabish A100% (1)

- COVID-19 Construction Workplace SafetyDocument20 pagesCOVID-19 Construction Workplace SafetyRabish A100% (3)

- UltraTech Mailer - Various Aspects of Making Your Homes GreenDocument5 pagesUltraTech Mailer - Various Aspects of Making Your Homes GreenRabish ANo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofRabish A75% (4)

- Product TrackerDocument1 pageProduct TrackerRabish ANo ratings yet

- Dinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiDocument7 pagesDinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiRabish ANo ratings yet

- NDT Book For Printing17022015Document181 pagesNDT Book For Printing17022015Rabish A100% (1)

- Ultratech TDS Leaflet - FixoblockDocument1 pageUltratech TDS Leaflet - FixoblockRabish ANo ratings yet

- 01 Outstanding Concrete Engineer.Document1 page01 Outstanding Concrete Engineer.Rabish ANo ratings yet

- Test Paper 29-4-2015Document1 pageTest Paper 29-4-2015Rabish ANo ratings yet

- Oct 2009 Pnthombare Twin Baby NamesDocument260 pagesOct 2009 Pnthombare Twin Baby NamesRabish A100% (1)

- What Is Steel Reinforcement? Why Is It Required in A Concrete Structure?Document11 pagesWhat Is Steel Reinforcement? Why Is It Required in A Concrete Structure?Rabish ANo ratings yet

- Willcocks 2021b Chapter 1 PDFDocument20 pagesWillcocks 2021b Chapter 1 PDFMarc SeignarbieuxNo ratings yet

- Comparison Kist Between Sulzer Original and Diesel United SulzerDocument12 pagesComparison Kist Between Sulzer Original and Diesel United SulzerFahmi WahyudheeNo ratings yet

- Joyseeker Tarot - Guidebook - SMDocument174 pagesJoyseeker Tarot - Guidebook - SMLinda100% (1)

- CLC 12 - Capstone Draft Proposal WorksheetDocument3 pagesCLC 12 - Capstone Draft Proposal Worksheetapi-634204531No ratings yet

- Deloitte - Wikipedia, The Free EncyclopediaDocument9 pagesDeloitte - Wikipedia, The Free Encyclopediakimmu5100% (1)

- Smart Code FullDocument490 pagesSmart Code FullAnonymous Dm7FwOJXUNo ratings yet

- Rev 0 - OMM 120A 2.75T Rough Terrain Forklift PDFDocument146 pagesRev 0 - OMM 120A 2.75T Rough Terrain Forklift PDFChristian NkomayombiNo ratings yet

- 08 PRGM CustomizingDocument40 pages08 PRGM CustomizingAbdelmadjid BouamamaNo ratings yet

- Diagonals of TilesDocument2 pagesDiagonals of TileskheyNo ratings yet

- Plastic Methods For Steel and Concrete StructuresDocument118 pagesPlastic Methods For Steel and Concrete Structurescall1986100% (1)

- Hongleong StatementDocument43 pagesHongleong StatementHaziq “AjiBoy” MhnBzNo ratings yet

- Instruction Manual: FVR-E11S-7EN FVR-E11S-4ENDocument116 pagesInstruction Manual: FVR-E11S-7EN FVR-E11S-4ENminh đạo nguyễnNo ratings yet

- Op CdmaDocument19 pagesOp Cdmarosev15No ratings yet

- Search My TongueDocument4 pagesSearch My TonguemahaNo ratings yet

- Assignment 1 - Topographic Maps - 22 - Mauro AlessiDocument5 pagesAssignment 1 - Topographic Maps - 22 - Mauro AlessiMauro AlessiNo ratings yet

- Article-Bioinspired "Wooden Armor" Based On Micro-Nano Lignocellulose With Bouligand StructureDocument6 pagesArticle-Bioinspired "Wooden Armor" Based On Micro-Nano Lignocellulose With Bouligand StructureYashwant MahajanNo ratings yet

- Clinical GoalsDocument13 pagesClinical GoalsHycient PaulNo ratings yet

- 8086 Assembler Directives: Unit 1 Presented by Mrs.M.P.SasirekhaDocument16 pages8086 Assembler Directives: Unit 1 Presented by Mrs.M.P.SasirekhaSasirekha KosalramNo ratings yet

- p5sd2-fm SDocument68 pagesp5sd2-fm SDavid Rueda LejarragaNo ratings yet

- Declaration of Principles Concerning Activities Following The Detection of Extraterrestrial IntelligenceDocument5 pagesDeclaration of Principles Concerning Activities Following The Detection of Extraterrestrial IntelligenceCRAS-SARCNo ratings yet

- N3110 2 PDFDocument147 pagesN3110 2 PDFnedalqasemNo ratings yet

- Hand-Out - Social Penetration and Exchange TheoryDocument1 pageHand-Out - Social Penetration and Exchange TheoryBeanca Jhanine M. Samiano100% (1)

- Salt Analysis - Lead AcetateDocument2 pagesSalt Analysis - Lead AcetateSwarnabha BhattacharyyaNo ratings yet

- Cutouts and Cutout-Arrester Combinations: (Standard, Linkbreak & Loadbreak)Document16 pagesCutouts and Cutout-Arrester Combinations: (Standard, Linkbreak & Loadbreak)GennaroNo ratings yet

- HGM 420Document42 pagesHGM 420last730100% (1)

- Class 10 ICSE PROJECTS (SESSION 2020-2021) : Rehmat Singh)Document19 pagesClass 10 ICSE PROJECTS (SESSION 2020-2021) : Rehmat Singh)AnanyaNo ratings yet

- Bluetooth Hands Free Car Kit Audio Compactpact: Installation Instructions & Operating ManualDocument48 pagesBluetooth Hands Free Car Kit Audio Compactpact: Installation Instructions & Operating ManualIonut RabaNo ratings yet

- Pneumatic Circuit DesignDocument17 pagesPneumatic Circuit DesignSriram SastryNo ratings yet

- Name: Makavana Ashish Adm. No: I19PH019 AimDocument6 pagesName: Makavana Ashish Adm. No: I19PH019 AimAnkit PatelNo ratings yet

- S006 - Suicide in An Airpla PDFDocument19 pagesS006 - Suicide in An Airpla PDFruso1900No ratings yet

Ultratech TDS Leaflet - TileFixo-NT

Ultratech TDS Leaflet - TileFixo-NT

Uploaded by

Rabish AOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultratech TDS Leaflet - TileFixo-NT

Ultratech TDS Leaflet - TileFixo-NT

Uploaded by

Rabish ACopyright:

Available Formats

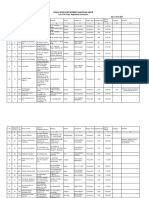

TECHNICAL DATA

AS PER RELEVANT IS AND ASTM STANDARDS

T

TILEFIXO-NT

TILEFIXO-NT

BU I

I

I

1450-1550 kg/m3

I

Bulk density

PRODUCTS

Water powder ratio 25%

Series: TFNT0009

Month: April 2017 Pot life 1 hour

Supersedes all earlier TDS

Description Open time 30 minutes

ULTRATECH

ULTRATECH

UltraTech TILEFIXO-NT is a polymer modified cement based high performance, high strength, and high quality tile adhesive Adjustable time 30 minutes

developed to fix large size tiles/slabs of granite, marble, stones. Suitable for both internal and external, thin bed applications. Usage time post application 24 hours

Specification Compressive strength @ 28 days 10-12 N/mm2

Technical Parameters complies with IS 15477, EN 1348. Slip resistance @ 40 kg/sq.m. 0 mm

Coverage @ 6 mm per kg 2 Sq.ft.

Features & Benefits Tensile adhesion strength @ 28 days - IS 15477 Values

● Dry condition 900-950 N

● Single component, no ● No shrinkage ● No curing required

hassles of mixing the ● High slip resistance ● Wet condition 700-800 N

ingredients

● Economical

● Nil wastages ● Consistent in quality Shear adhesion strength

● Excellent bond strength

● Easy to spread ● Dry condition @ 24 hour 5- 6 KN

● Dry condition @ 14 days 10-11 KN

Areas of Application ● Wet condition @ 28 days 6-7 KN

UltraTech TILEFIXO-NT is recommended for fixing large size tiles/slabs of granite, marble, stone wall cladding and flooring.

● Heat ageing condition @ 28 days 6-7 KN

It can be used over cementitious substrates only.

Note Shelf Life

METHOD OF APPLICATION

Allow a minimum of 24 hours for the subsequent usage of the UltraTech TILEFIXO-NT has a shelf life of 12 months from the

Surface tile fixed areas. Do not tile if temperatures are likely to drop to date of manufacture. Store at cool and dry place.

● Prepare the surfaces before the Tile adhesive application by removing oil, bond inhibiting agents, dirt, below 5°C or exceed 50°C. For temperatures below 20°C

Preparation dust and laitance. The cleaning can be carried out with suitable methods like by using wire brush, water allow the adhesive to cure for an extended period of time. Pot Safety Directions

jetting, mopping, etc. life, open time and adjusting time depends on the surface

absorption, wind factor, temperature, humidity conditions at site. UltraTech TILEFIXO-NT is non-toxic. Use of gloves and

● UltraTech BASEKRETE is recommended over vertical surfaces and UltraTech FLOORKRETE for goggles recommended. Any splashes to the skin or eyes

The technical data provided in this technical data sheet is as

horizontal floor areas to level the surface in case of higher undulations or for any repair works to per our internal lab testing and may vary as per the actual should be washed off with clean water immediately.

attain the flat, stable and normal absorption background prior to UltraTech TILEFIXO-NT application method of application at sites. In case of prolonged irritation, medical advice should be

Consult UltraTech Building Products Division Technical sought. UltraTech TILEFIXO-NT is non-flammable.

Services Cell for any further technical assistance.

Other Product Categories available with

Precaution UltraTech Building Products Division

● Not suitable for tiling over flexible substrates, such as • Micro Concrete and Repair Product

Mixing ● UltraTech TILEFIXO-NT requires 25% of water by weight of material (4 parts of tile adhesive and 1 fibrous cement sheeting, plasterboard and timber • Industrial/Precision Grout and Anchors

part water) ● Not suitable for tiling directly onto timber, plywood, glass

● Mix UltraTech TILEFIXO-NT to the measures quantity of water using mechanical stirring for 2-3 • Water Proofing and Injection Grouting Material

● Not suitable for tiling directly on to metals or plastic

minutes to ensure a consistency free of lumps substrates • lasters and Jointing Mortar

● Allow to stand for 2 minutes for the mix to mature and then remix to use ● Not suitable for tiling directly onto polyurethane • Floor Screeds

● Do not add any extra water to alter the mix consistency or to extend the pot life. Further water membranes

• Autoclaved Aerated Lightweight Concrete Blocks

additions will hamper the adhesion strength of the Tile Adhesive ● Not suitable for moisture sensitive tiles or stone

● Do not mix or apply adhesives in temperatures below 5°C

and above 50°C and under extreme hot and windy

conditions

Application ● Apply the mixed UltraTech TILEFIXO-NT to the prepared substrate using the appropriate notched

trowels for the size of the tiles being laid Packaging

● A minimum of 6 mm bed thickness of Tile Adhesive for walls and floors must be achieved 25 Kg

● Lay tiles onto the adhesive, firmly press the tile on to the adhesive to ensure good initial bonding, and

do not disturb tiles until the adhesive has set

DISCLAIMER

● No pre-wetting of tiles is required while using UltraTech TILEFIXO-NT Information provided on this data sheet is the guideline for usage. Users are advised to undertake a trial for product suitability prior to it’s full scale usage.

There is no implied guaranty/warranty for the results and the company is not liable for any consequential damages.

● It is recommended to fix the tiles within 30 minutes of spreading of UltraTech TILEFIXO-NT to

achieve the adequate bonding as per the Technical data provided UltraTech Cement Limited (Building Products Division)

● Any tile fixing after 30 minutes will lead to improper adhesion and may result in de-bonding of tiles Regd. Office: 2nd Floor, B-Wing, Ahura Centre, Mahakali Caves Road, MIDC,Andheri (East),

● For vertical area applications, tiling should start from bottom to top Mumbai - 400 093. India | Tel.: +91-22 6692 8200 | Email: ultratech.care@adityabirla.com

Website: www.ultratechcement.com | Toll Free: 1800 425 2525

● For tile-on-tile, tile-on-mosaic, tile-on-old cement floor application, care should be taken to prepare Regional Offices: l Bangalore: 080 22250748 l Hyderabad: 040 42024194

the existing base with adequate interlocking friction effect by removing polish/ wax/ top smooth layers l Pune: 020 41486600 l Ahmedabad: 079 49004545 l Indore: 0731 2543206

l Delhi: 0120 4856000 l Kolkata: 033 30214100/4400

You might also like

- Portrait of an Industrial City: 'Clanging Belfast' 1750-1914From EverandPortrait of an Industrial City: 'Clanging Belfast' 1750-1914No ratings yet

- South Bihar Progress Report June 22Document22 pagesSouth Bihar Progress Report June 22Shinning GarimaNo ratings yet

- Volume1 CCTVDocument96 pagesVolume1 CCTVtender teamNo ratings yet

- Cement Suppliers in IndoreDocument10 pagesCement Suppliers in Indoresourabh_gupta_54No ratings yet

- After Sales Service Support Dealer Network Across IndiaDocument12 pagesAfter Sales Service Support Dealer Network Across IndiaAvijitSinharoyNo ratings yet

- Faridabad DataDocument364 pagesFaridabad DataDeepak GoyalNo ratings yet

- Appd List of Contractros of CEEC As On 27 Dec 2019Document187 pagesAppd List of Contractros of CEEC As On 27 Dec 2019RR PatelNo ratings yet

- Top 20 Construction Companies in India - Engineering HintDocument7 pagesTop 20 Construction Companies in India - Engineering HintMelwin PaulNo ratings yet

- List of Registered Contractors 04.01.2024Document43 pagesList of Registered Contractors 04.01.2024kamlesh.tayade9No ratings yet

- Contractor List June15Document32 pagesContractor List June15MINAKSHI SINGHNo ratings yet

- PWD TamilnaduDocument19 pagesPWD Tamilnadutagore 87No ratings yet

- List of Registered ProjectsDocument232 pagesList of Registered ProjectsAjay SinghNo ratings yet

- AssamDocument6 pagesAssamSarang MohideNo ratings yet

- Builders ListDocument265 pagesBuilders ListagrilandncrNo ratings yet

- List of In-Principle ApprovalsDocument9 pagesList of In-Principle ApprovalsManasvi MehtaNo ratings yet

- R&C Business ProfileDocument79 pagesR&C Business ProfileVedant KapoorNo ratings yet

- List of Enlisted Vendors Civil /electrical / Miscellaneous WorksDocument61 pagesList of Enlisted Vendors Civil /electrical / Miscellaneous Workssri projectssNo ratings yet

- Rubicon Cables IndustriesDocument11 pagesRubicon Cables IndustriesKiran patelNo ratings yet

- Latest Vendor Directory SignedDocument8 pagesLatest Vendor Directory SignedSuresh SharmaNo ratings yet

- List of Empanelled RIs Karnataka State PDFDocument2 pagesList of Empanelled RIs Karnataka State PDFLasik DelhiNo ratings yet

- SSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurDocument6 pagesSSA Quotation For Factory Shead & Civil Work For Plotno 46, Bagru JaipurMohit DagaNo ratings yet

- Black Listed ProfessionalsDocument6 pagesBlack Listed Professionalsvenkateswara rao PothinaNo ratings yet

- Times of IndiaDocument50 pagesTimes of IndianedunchiNo ratings yet

- Bai Gurdaspur PunjabDocument6 pagesBai Gurdaspur PunjabWinning SpiritNo ratings yet

- SubContractor Registration FormDocument18 pagesSubContractor Registration FormJagadeesan S MNo ratings yet

- Gim 2010 On 31.10.2014Document10 pagesGim 2010 On 31.10.2014SK Business groupNo ratings yet

- CraneDocument10 pagesCraneaitcpurchaseNo ratings yet

- Approved Material Suppliers CIDCODocument136 pagesApproved Material Suppliers CIDCOVikram SanghaviNo ratings yet

- List of Contractor Piu-BhopalDocument2 pagesList of Contractor Piu-BhopalMCS SBINo ratings yet

- Fmai 5 PDFDocument53 pagesFmai 5 PDFvenkatesh_1829No ratings yet

- List of Civil Contractors Registered in The CIDCO LTDDocument99 pagesList of Civil Contractors Registered in The CIDCO LTDMINAKSHI SINGHNo ratings yet

- Is 278 2009 PDFDocument11 pagesIs 278 2009 PDFjaianit89No ratings yet

- 05132015173818KOLDocument250 pages05132015173818KOLAman Dubey100% (2)

- CPWD Enlistment Rule 2022Document73 pagesCPWD Enlistment Rule 2022Assistant Engineer Elect CED III CCUNo ratings yet

- BookDocument44 pagesBookBinay ShawNo ratings yet

- List of Autorised Recovery AgenciesDocument94 pagesList of Autorised Recovery Agenciesgsonal975No ratings yet

- Infratech Limited Apco Construction Pvt. LTD.: Purchase OrderDocument2 pagesInfratech Limited Apco Construction Pvt. LTD.: Purchase OrderRajeshKumarJainNo ratings yet

- Core Vendor PDFDocument215 pagesCore Vendor PDFSakar EngitechNo ratings yet

- Bikaner: SR No DetailsDocument10 pagesBikaner: SR No DetailsWinning Spirit100% (1)

- AA Class ContractorDocument60 pagesAA Class ContractorVijay SinghNo ratings yet

- Brief Industrial Profile of Bhilwara District: LR Eso T RsDocument33 pagesBrief Industrial Profile of Bhilwara District: LR Eso T RsAbha SinghNo ratings yet

- GS Delhi.76155956Document3 pagesGS Delhi.76155956mek00sNo ratings yet

- Et AcetechDocument6 pagesEt Acetechfucker6777No ratings yet

- ENGGContractor Master ReportDocument124 pagesENGGContractor Master ReportUTTAL RAY100% (1)

- 96-100 OrganizedDocument7 pages96-100 OrganizedTechnetNo ratings yet

- Industries at GhaziabadDocument15 pagesIndustries at GhaziabadShashikant Jaisingha100% (1)

- List of Accredited Consultants Up To 30th April 2019 PDFDocument5 pagesList of Accredited Consultants Up To 30th April 2019 PDFKamalsingh RathoreNo ratings yet

- Mumbai Port Civil Contractors PDFDocument2 pagesMumbai Port Civil Contractors PDFParth DamaNo ratings yet

- Empanelment of Consultants5773060562 PDFDocument41 pagesEmpanelment of Consultants5773060562 PDFAshish KulshresthaNo ratings yet

- ResultDocument9 pagesResultanon_981731217No ratings yet

- BMRCL Contractor ListDocument8 pagesBMRCL Contractor ListKarthik VarnaNo ratings yet

- Amravati Dips 12-13Document32 pagesAmravati Dips 12-13Samar KhanNo ratings yet

- Budhpura Ground Zero' Sandstone Quarrying in India: by P. Madhavan Dr. Sanjay RajDocument32 pagesBudhpura Ground Zero' Sandstone Quarrying in India: by P. Madhavan Dr. Sanjay RajPragya UpadhyayNo ratings yet

- List of Manufacturers Situated at Krishna DistrictDocument3 pagesList of Manufacturers Situated at Krishna DistrictSriram Industries Surya GreasesNo ratings yet

- 28061805Document3 pages28061805Jagadamba RealtorNo ratings yet

- Accredited ConsultantsDocument195 pagesAccredited ConsultantsRaja Mani100% (1)

- 60223918-Vendor-Directory Railway PDFDocument112 pages60223918-Vendor-Directory Railway PDFPACWELNo ratings yet

- Design ConsultantsDocument35 pagesDesign ConsultantsYogesh ChhaprooNo ratings yet

- O2018 IIIDocument409 pagesO2018 IIIYogesh Chhaproo100% (1)

- Ultratech TDS Leaflet - FixoblockDocument1 pageUltratech TDS Leaflet - FixoblockRabish ANo ratings yet

- Guruvayur Accomodation: Kousthubham Rest House (Phone No: 0487 2556537, Fax: 04872554844)Document2 pagesGuruvayur Accomodation: Kousthubham Rest House (Phone No: 0487 2556537, Fax: 04872554844)Rabish ANo ratings yet

- Guruvayur AccomodationDocument2 pagesGuruvayur AccomodationRabish ANo ratings yet

- Edited - 04 Application - Well - Built - Residential - AwardsDocument6 pagesEdited - 04 Application - Well - Built - Residential - AwardsRabish ANo ratings yet

- Efficient Test Setup For Determining The Water-Permeability of ConcreteDocument6 pagesEfficient Test Setup For Determining The Water-Permeability of ConcreteRabish ANo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofRabish A100% (1)

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofRabish A100% (1)

- COVID-19 Construction Workplace SafetyDocument20 pagesCOVID-19 Construction Workplace SafetyRabish A100% (3)

- UltraTech Mailer - Various Aspects of Making Your Homes GreenDocument5 pagesUltraTech Mailer - Various Aspects of Making Your Homes GreenRabish ANo ratings yet

- Ultratech Cement: Particulars Test Results Requirements ofDocument1 pageUltratech Cement: Particulars Test Results Requirements ofRabish A75% (4)

- Product TrackerDocument1 pageProduct TrackerRabish ANo ratings yet

- Dinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiDocument7 pagesDinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiRabish ANo ratings yet

- NDT Book For Printing17022015Document181 pagesNDT Book For Printing17022015Rabish A100% (1)

- Ultratech TDS Leaflet - FixoblockDocument1 pageUltratech TDS Leaflet - FixoblockRabish ANo ratings yet

- 01 Outstanding Concrete Engineer.Document1 page01 Outstanding Concrete Engineer.Rabish ANo ratings yet

- Test Paper 29-4-2015Document1 pageTest Paper 29-4-2015Rabish ANo ratings yet

- Oct 2009 Pnthombare Twin Baby NamesDocument260 pagesOct 2009 Pnthombare Twin Baby NamesRabish A100% (1)

- What Is Steel Reinforcement? Why Is It Required in A Concrete Structure?Document11 pagesWhat Is Steel Reinforcement? Why Is It Required in A Concrete Structure?Rabish ANo ratings yet

- Willcocks 2021b Chapter 1 PDFDocument20 pagesWillcocks 2021b Chapter 1 PDFMarc SeignarbieuxNo ratings yet

- Comparison Kist Between Sulzer Original and Diesel United SulzerDocument12 pagesComparison Kist Between Sulzer Original and Diesel United SulzerFahmi WahyudheeNo ratings yet

- Joyseeker Tarot - Guidebook - SMDocument174 pagesJoyseeker Tarot - Guidebook - SMLinda100% (1)

- CLC 12 - Capstone Draft Proposal WorksheetDocument3 pagesCLC 12 - Capstone Draft Proposal Worksheetapi-634204531No ratings yet

- Deloitte - Wikipedia, The Free EncyclopediaDocument9 pagesDeloitte - Wikipedia, The Free Encyclopediakimmu5100% (1)

- Smart Code FullDocument490 pagesSmart Code FullAnonymous Dm7FwOJXUNo ratings yet

- Rev 0 - OMM 120A 2.75T Rough Terrain Forklift PDFDocument146 pagesRev 0 - OMM 120A 2.75T Rough Terrain Forklift PDFChristian NkomayombiNo ratings yet

- 08 PRGM CustomizingDocument40 pages08 PRGM CustomizingAbdelmadjid BouamamaNo ratings yet

- Diagonals of TilesDocument2 pagesDiagonals of TileskheyNo ratings yet

- Plastic Methods For Steel and Concrete StructuresDocument118 pagesPlastic Methods For Steel and Concrete Structurescall1986100% (1)

- Hongleong StatementDocument43 pagesHongleong StatementHaziq “AjiBoy” MhnBzNo ratings yet

- Instruction Manual: FVR-E11S-7EN FVR-E11S-4ENDocument116 pagesInstruction Manual: FVR-E11S-7EN FVR-E11S-4ENminh đạo nguyễnNo ratings yet

- Op CdmaDocument19 pagesOp Cdmarosev15No ratings yet

- Search My TongueDocument4 pagesSearch My TonguemahaNo ratings yet

- Assignment 1 - Topographic Maps - 22 - Mauro AlessiDocument5 pagesAssignment 1 - Topographic Maps - 22 - Mauro AlessiMauro AlessiNo ratings yet

- Article-Bioinspired "Wooden Armor" Based On Micro-Nano Lignocellulose With Bouligand StructureDocument6 pagesArticle-Bioinspired "Wooden Armor" Based On Micro-Nano Lignocellulose With Bouligand StructureYashwant MahajanNo ratings yet

- Clinical GoalsDocument13 pagesClinical GoalsHycient PaulNo ratings yet

- 8086 Assembler Directives: Unit 1 Presented by Mrs.M.P.SasirekhaDocument16 pages8086 Assembler Directives: Unit 1 Presented by Mrs.M.P.SasirekhaSasirekha KosalramNo ratings yet

- p5sd2-fm SDocument68 pagesp5sd2-fm SDavid Rueda LejarragaNo ratings yet

- Declaration of Principles Concerning Activities Following The Detection of Extraterrestrial IntelligenceDocument5 pagesDeclaration of Principles Concerning Activities Following The Detection of Extraterrestrial IntelligenceCRAS-SARCNo ratings yet

- N3110 2 PDFDocument147 pagesN3110 2 PDFnedalqasemNo ratings yet

- Hand-Out - Social Penetration and Exchange TheoryDocument1 pageHand-Out - Social Penetration and Exchange TheoryBeanca Jhanine M. Samiano100% (1)

- Salt Analysis - Lead AcetateDocument2 pagesSalt Analysis - Lead AcetateSwarnabha BhattacharyyaNo ratings yet

- Cutouts and Cutout-Arrester Combinations: (Standard, Linkbreak & Loadbreak)Document16 pagesCutouts and Cutout-Arrester Combinations: (Standard, Linkbreak & Loadbreak)GennaroNo ratings yet

- HGM 420Document42 pagesHGM 420last730100% (1)

- Class 10 ICSE PROJECTS (SESSION 2020-2021) : Rehmat Singh)Document19 pagesClass 10 ICSE PROJECTS (SESSION 2020-2021) : Rehmat Singh)AnanyaNo ratings yet

- Bluetooth Hands Free Car Kit Audio Compactpact: Installation Instructions & Operating ManualDocument48 pagesBluetooth Hands Free Car Kit Audio Compactpact: Installation Instructions & Operating ManualIonut RabaNo ratings yet

- Pneumatic Circuit DesignDocument17 pagesPneumatic Circuit DesignSriram SastryNo ratings yet

- Name: Makavana Ashish Adm. No: I19PH019 AimDocument6 pagesName: Makavana Ashish Adm. No: I19PH019 AimAnkit PatelNo ratings yet

- S006 - Suicide in An Airpla PDFDocument19 pagesS006 - Suicide in An Airpla PDFruso1900No ratings yet