Professional Documents

Culture Documents

Bhopal Incident-35th Anniversary

Bhopal Incident-35th Anniversary

Uploaded by

Anonymous gWKgdUBOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bhopal Incident-35th Anniversary

Bhopal Incident-35th Anniversary

Uploaded by

Anonymous gWKgdUBCopyright:

Available Formats

BIRTH OF PROCESS SAFETY MANAGEMENT

BHOPAL INCIDENT-1984

35 years back, on 2-3 December 1984, in Bhopal, India the villagers were sound asleep as methyl

isocyanate gas leaked from a nearby pesticide plant owned by Union Carbide India Limited. The

deadly gas spread and not only killed but caused significant morbidity and premature death for

thousands. Even after nearly 35 years, the aftermath of the tragedy continues to haunt villagers in

the area, physically and psychologically. This incident eventually led to development of Process

Safety Management System by OSHA,CCPS & EPA .

EXTENT OF DISATER:

MIC (methyl isocyanate) Exposure: Over 500,000

people

Immediate Deaths: 2,259 persons

Gas Release related deaths: 3,787 deaths

Leak caused injuries: 558,125

Estimate of overall fatalities reported over the

years: 16,000 Snake Found from

Hafiz

EMAta: Might be alive; had

Residence

Factors leading to Gas Leakage he worn seat belt and

• Storing MIC in large tanks beyond recommended followed speed limits

levels

• Poor plant maintenance

Locking Bracket

• Several De-activated safety systems due to

financial reasons e.g. refrigeration system which

could have mitigated the disaster severity

• Plant location close to a densely populated area

• Dependence on manual operations

• Plant management deficiencies

• Lack of skilled operators,

• Insufficient plant maintenance,

• Inadequate emergency action plans.

• In the early 1980s, the demand for pesticides had

fallen, but production continued, leading to

buildup of stores of unused MIC

Pivot Support Deformed

Process Safety Action Items To Avoid

Recurrence

• Inherently Safer Design of plants

• Quality Process Hazard Analysis & PSSR

• Rigorous compliance of Inventory Management

System of chemicals

• Emergency Management System

• Consideration to facility siting Main CGT Duct

• Asset integrity and Reliability

twisted at DBN

Bellow

03/12/19 Issued By: Hamza Hameed | HSE Engineer

You might also like

- An Interview With Elon MuskDocument2 pagesAn Interview With Elon MuskGiselle Medina Maximiano67% (3)

- BP Texas ExplosionDocument24 pagesBP Texas ExplosionPillai Sreejith92% (12)

- Humber RefineryDocument2 pagesHumber RefineryRatna Paramitha SariNo ratings yet

- Process SafetyDocument48 pagesProcess SafetyIbtida Sultana67% (3)

- Chemical Process Safety For ChE 405-September 2019Document49 pagesChemical Process Safety For ChE 405-September 2019Tanjina Tarannum PrithulaNo ratings yet

- Chemical Process SafetyDocument46 pagesChemical Process SafetyTowfiq Ahmed100% (1)

- Application of Infinite Uptime's Industrial Data Enabler in Chemical IndustryDocument26 pagesApplication of Infinite Uptime's Industrial Data Enabler in Chemical IndustryInfiniteUptimeNo ratings yet

- Bhopal PDFDocument2 pagesBhopal PDFRatna Paramitha SariNo ratings yet

- G.chem Bhopal Gas TragedyDocument16 pagesG.chem Bhopal Gas Tragedymrmy88tm46No ratings yet

- Bio Armour Presentationver 2Document17 pagesBio Armour Presentationver 2Antonio NabaisNo ratings yet

- MTK - The Real World Impact of ISA 18.2 On Process IndustriesDocument32 pagesMTK - The Real World Impact of ISA 18.2 On Process Industriesdavidjpaulson100% (1)

- Hirak Dutta Executive Director Oil Industry Safety DirectorateDocument21 pagesHirak Dutta Executive Director Oil Industry Safety DirectorateprabhuarunkumarNo ratings yet

- MQL Metal CuttingDocument14 pagesMQL Metal CuttingShawn DillonNo ratings yet

- PALM OIL MILL SAFETY AND MAINTENANCE - pptx1Document18 pagesPALM OIL MILL SAFETY AND MAINTENANCE - pptx1Nadia Asyiqin75% (4)

- Case Study for Bhopal Gas TragedyDocument7 pagesCase Study for Bhopal Gas Tragedypanjabivanushka37No ratings yet

- Yousuf S A: 1 Year BCA (2 Sem) ST - Philomen As College (Autonomo Us)Document25 pagesYousuf S A: 1 Year BCA (2 Sem) ST - Philomen As College (Autonomo Us)Gns HarishNo ratings yet

- Rbi Aiche 2005Document19 pagesRbi Aiche 2005barry nancooNo ratings yet

- Bhopal Gas Tragedy - The Scar of Process Safety: SIESO MedalDocument3 pagesBhopal Gas Tragedy - The Scar of Process Safety: SIESO Medaljdur jhdoisj curjfNo ratings yet

- Bielomatik MMS Prospekt enDocument16 pagesBielomatik MMS Prospekt enAnonymous 67TvRPYdRBNo ratings yet

- 2.1 History, General, Optimization, Line Staff FunctionDocument54 pages2.1 History, General, Optimization, Line Staff FunctionKarthik SoundarrajanNo ratings yet

- Section 01Document54 pagesSection 01Shahid HussainNo ratings yet

- TRAC HIPPS Eng Rev01Document21 pagesTRAC HIPPS Eng Rev01Nam PhanNo ratings yet

- Longford Incident Summary 25 Sep 98Document1 pageLongford Incident Summary 25 Sep 98Иван ШвыряевNo ratings yet

- UC169986 PTY 0313 Insight Gaseous Fire Suppression System - tcm2538-373444Document3 pagesUC169986 PTY 0313 Insight Gaseous Fire Suppression System - tcm2538-373444Maxmore KarumamupiyoNo ratings yet

- Mass Process Safety Management PDFDocument66 pagesMass Process Safety Management PDFgustav agudeloNo ratings yet

- Bhopal TragedyDocument21 pagesBhopal TragedyROHIT SAGARNo ratings yet

- Safety Engineering of Process Plants (CH 404)Document79 pagesSafety Engineering of Process Plants (CH 404)ibuddhaNo ratings yet

- Fire Protection of Computer RoomsDocument4 pagesFire Protection of Computer RoomsManuel MartosNo ratings yet

- Bhopal Disaster: of Chemical Disasters by Sibel TekmenDocument10 pagesBhopal Disaster: of Chemical Disasters by Sibel TekmenReeta MauryaNo ratings yet

- CSB Investigations of Incidents During Startups and ShutdownsDocument4 pagesCSB Investigations of Incidents During Startups and ShutdownsSebastian iacopiNo ratings yet

- SEPT 2022 - CLD 20002 - Chap 1 - Industrial SafetyDocument104 pagesSEPT 2022 - CLD 20002 - Chap 1 - Industrial SafetyAirish AirishNo ratings yet

- Bhopal IncidentDocument22 pagesBhopal IncidentAnonymous MwhZ2eVnB100% (1)

- Assignment 3 Title Bhopal Disaster PRESEDocument32 pagesAssignment 3 Title Bhopal Disaster PRESEMedysia Novittaqa SuryaNo ratings yet

- Prevent Disastrous DecisionsDocument7 pagesPrevent Disastrous Decisions홍인기No ratings yet

- Hazards in Processing Light HydrocarbonsDocument4 pagesHazards in Processing Light HydrocarbonsNestramiNo ratings yet

- HAZOPDocument57 pagesHAZOPcut suci almadianaNo ratings yet

- DR Mahendra SharmaDocument39 pagesDR Mahendra Sharmasumana86_ghoshNo ratings yet

- Presentation - 4 - Industrial Hygiene and Technical SupportDocument25 pagesPresentation - 4 - Industrial Hygiene and Technical SupporttaofikNo ratings yet

- Case Studies of 6 Big Accidents Which Created The Recent AttentionDocument15 pagesCase Studies of 6 Big Accidents Which Created The Recent AttentionChaitanya MyneniNo ratings yet

- Oilfield MicrobiologyDocument2 pagesOilfield MicrobiologyCPFormanNo ratings yet

- Root Causes For IOTDocument2 pagesRoot Causes For IOTYokesh RNo ratings yet

- Kidde HP Co: High-Pressure Carbon Dioxide Fire Suppression SystemDocument2 pagesKidde HP Co: High-Pressure Carbon Dioxide Fire Suppression SystemDiepreye BinaebiNo ratings yet

- Bhopal Case StudyDocument41 pagesBhopal Case StudyVivek GurjarNo ratings yet

- HSSE Alert - Bhopal Incident - MIC Gas Exposure - December 3rdDocument3 pagesHSSE Alert - Bhopal Incident - MIC Gas Exposure - December 3rdOsedebamen Irabor100% (1)

- Jawed AkhtarDocument36 pagesJawed Akhtarmohamed Abo-EwishaNo ratings yet

- Introduction To Chemical Process Safety: Instructor: Dr. Tamaghna Chakraborti Ph. No.: +91 9892770980Document44 pagesIntroduction To Chemical Process Safety: Instructor: Dr. Tamaghna Chakraborti Ph. No.: +91 9892770980Ishaat HussainNo ratings yet

- Lessons and Learnings From Vizag Gas Leak-Disaster: Efficaz Consulting & Solutions Nov 2020Document10 pagesLessons and Learnings From Vizag Gas Leak-Disaster: Efficaz Consulting & Solutions Nov 2020Hamid MasoodNo ratings yet

- Eldar Lundanes Subsea Chemical Storage and InjectionDocument14 pagesEldar Lundanes Subsea Chemical Storage and InjectionIainShepherdNo ratings yet

- Case Study AnalysisDocument11 pagesCase Study Analysisaruneshgowda79No ratings yet

- Hydraulic System Inspection: Service Data SheetDocument2 pagesHydraulic System Inspection: Service Data SheetAnonymous alQXB11EgQNo ratings yet

- Biobar RangeDocument4 pagesBiobar RangecarmaNo ratings yet

- PreservativeTrendsinWetWipes SFW 2011Document10 pagesPreservativeTrendsinWetWipes SFW 2011Ahmad AlShahrourNo ratings yet

- Reliability of Flexible HosesDocument28 pagesReliability of Flexible HosesPakdee KammungkunNo ratings yet

- Industrial - Cybersecurity - Risks - Oil - Gas - Operations - 1692140874 2023-08-17 12 - 49 - 47Document8 pagesIndustrial - Cybersecurity - Risks - Oil - Gas - Operations - 1692140874 2023-08-17 12 - 49 - 47gabo1No ratings yet

- Cyber Security Risks of CISTAR Facilities - Purdue, Abhijit TalpadeDocument25 pagesCyber Security Risks of CISTAR Facilities - Purdue, Abhijit Talpade312poojaNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Lessons and Learnings From Vizag Gas Leak-Disaster: Efficaz Consulting & Solutions Nov 2020Document11 pagesLessons and Learnings From Vizag Gas Leak-Disaster: Efficaz Consulting & Solutions Nov 2020Pushpa SinghNo ratings yet

- Beacon Flixborough PDFDocument1 pageBeacon Flixborough PDFjargiaNo ratings yet

- 1 - Welcome and Introductions, Overview of Workshop - KCS-SOM2022Document15 pages1 - Welcome and Introductions, Overview of Workshop - KCS-SOM2022Ismail Abdi AliNo ratings yet

- Mains 2020 Supplement 3: Sample Question - Answers For Mains 2020Document7 pagesMains 2020 Supplement 3: Sample Question - Answers For Mains 2020PriyankaNo ratings yet

- P03 Cox SS in Rail IndustryDocument15 pagesP03 Cox SS in Rail IndustryDoru ToaderNo ratings yet

- Inherent Risk Assessment - Ammonia Plant - 12032020Document6 pagesInherent Risk Assessment - Ammonia Plant - 12032020Anonymous gWKgdUBNo ratings yet

- Adre SXP/ 408 Dspi: Product DatasheetDocument29 pagesAdre SXP/ 408 Dspi: Product DatasheetAnonymous gWKgdUBNo ratings yet

- Shree S Ad Vidya Mandal Inst. of TechnologyDocument23 pagesShree S Ad Vidya Mandal Inst. of TechnologyAnonymous gWKgdUBNo ratings yet

- Turbine 1st Stage Nozzle - DPTDocument15 pagesTurbine 1st Stage Nozzle - DPTAnonymous gWKgdUBNo ratings yet

- 2018 Gleeble Solutions Guide 10 18 PDFDocument16 pages2018 Gleeble Solutions Guide 10 18 PDFAnonymous gWKgdUB100% (1)

- 1.mech SealDocument64 pages1.mech SealAnonymous gWKgdUBNo ratings yet

- Inspection Unit Technical Services Department Fatima Fertilizers Company LimitedDocument8 pagesInspection Unit Technical Services Department Fatima Fertilizers Company LimitedAnonymous gWKgdUBNo ratings yet

- WFH Daily Activities Templates 200420 v02Document1 pageWFH Daily Activities Templates 200420 v02Anonymous gWKgdUBNo ratings yet

- Vocabulary HSC 22 PDFDocument28 pagesVocabulary HSC 22 PDFMadara Uchiha83% (6)

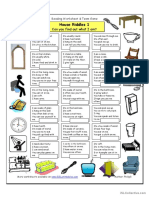

- House Riddles (1) - EasyDocument3 pagesHouse Riddles (1) - EasyMiyasar AzatbaevaNo ratings yet

- 20-Appendices PeriodicitySchedule Bright FuturesDocument1 page20-Appendices PeriodicitySchedule Bright FuturesdrjohnckimNo ratings yet

- 10 Atypical PneumoniaDocument4 pages10 Atypical PneumoniaKevinTevesYupanquiNo ratings yet

- Chemostat Recycle (Autosaved)Document36 pagesChemostat Recycle (Autosaved)Zeny Naranjo0% (1)

- Nonlinear Fiber Optics: Its History and Recent ProgressDocument10 pagesNonlinear Fiber Optics: Its History and Recent ProgressEwerton Gustavo Soares GomesNo ratings yet

- Motion in 1 D Jee Main LevelDocument7 pagesMotion in 1 D Jee Main LevelShashwat KhuranaNo ratings yet

- Ideal Op-Amp Equivalent CircuitDocument20 pagesIdeal Op-Amp Equivalent CircuitPiyush DubeyNo ratings yet

- 7-Day Metabolism Repair Rapid Fat LossDocument27 pages7-Day Metabolism Repair Rapid Fat LossLennart Bjurstrom100% (1)

- United International University: EEE 424: Microprocessor and Interfacing Laboratory Experiment#5Document7 pagesUnited International University: EEE 424: Microprocessor and Interfacing Laboratory Experiment#5Nura Alam ProtikNo ratings yet

- Brain Computer InterfacesDocument4 pagesBrain Computer InterfacesDavidNo ratings yet

- GJ 2278 MasterflexApplicationsDocument48 pagesGJ 2278 MasterflexApplicationsMarcello Aires RomãoNo ratings yet

- 463-287. 23.09. Lap Udm Proyek Pembangunan Jalan Tol Ancol Timur - Pluit (Elevated) (Rao16 Bp05)Document18 pages463-287. 23.09. Lap Udm Proyek Pembangunan Jalan Tol Ancol Timur - Pluit (Elevated) (Rao16 Bp05)Ikan AsinNo ratings yet

- 1st Grade VocabularyDocument1 page1st Grade VocabularyamirNo ratings yet

- Industry ProfileDocument41 pagesIndustry Profile727821TPMB018 ARAVINTH S.No ratings yet

- Vehicle Tracking SystemDocument21 pagesVehicle Tracking SystemkailasasundaramNo ratings yet

- SLE MCQDocument9 pagesSLE MCQAsif NewazNo ratings yet

- Impact of Electricity Power OutagesDocument13 pagesImpact of Electricity Power OutagesGaspard UkwizagiraNo ratings yet

- Jap-Motor General v1Document52 pagesJap-Motor General v1Pankaj Poonia100% (1)

- CSR of TI Company NotesDocument3 pagesCSR of TI Company NotesjemNo ratings yet

- Danby Dac12507ee User ManualDocument13 pagesDanby Dac12507ee User ManualElla MariaNo ratings yet

- Freudian Revolution 2020Document6 pagesFreudian Revolution 2020Faith Vica Dela CruzNo ratings yet

- A8VO80Document27 pagesA8VO80Jose Salvador100% (1)

- DKMU Fulfilled Wishes Fulfilled LivesDocument22 pagesDKMU Fulfilled Wishes Fulfilled LivesRick DHMNo ratings yet

- Your Space 1 Skills Test 10Document2 pagesYour Space 1 Skills Test 10Maxi ComasNo ratings yet

- Selective Red Cell Variables in Chippiparai Hound Breeds of Tamil Nadu - A Pilot Study in 30 DogsDocument6 pagesSelective Red Cell Variables in Chippiparai Hound Breeds of Tamil Nadu - A Pilot Study in 30 DogsIndian Journal of Veterinary and Animal Sciences RNo ratings yet

- Gis PortefolioDocument12 pagesGis PortefolioruimauricioferreiraNo ratings yet

- 4.0 Environmental Impacts and Mitigation Measures Potential Environmental ImpactsDocument7 pages4.0 Environmental Impacts and Mitigation Measures Potential Environmental ImpactsCirilo Jr. LagnasonNo ratings yet

- Sadhana Chatushtaya - Detailed DescriptionDocument50 pagesSadhana Chatushtaya - Detailed DescriptionSwami AjatanandaNo ratings yet