Professional Documents

Culture Documents

OB2279 On Bright PDF

OB2279 On Bright PDF

Uploaded by

Amit BiswasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OB2279 On Bright PDF

OB2279 On Bright PDF

Uploaded by

Amit BiswasCopyright:

Available Formats

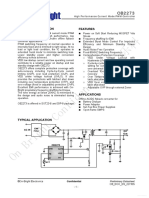

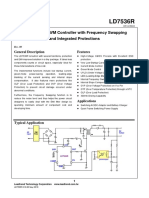

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

FEATURES

GENERAL DESCRIPTION ■ On-Bright Proprietary Frequency Shuffling

OB2279 is a highly integrated current mode PWM Technology for Improved EMI Performance

control IC optimized for high performance, low ■ Power On Soft Start

standby power and cost effective offline flyback ■ Extended Burst Mode Control For Improved

converter applications. Efficiency and Minimum Standby Power Design

PWM switching frequency at normal operation is ■ Audio Noise Free Operation

externally programmable and trimmed to tight range. ■ External Programmable PWM Switching

At no load or light load condition, the IC operates in Frequency

extended ‘burst mode’ to minimize switching loss. ■ Internal Synchronized Slope Compensation

Lower standby power and higher conversion ■ Low VIN/VDD Startup Current(3uA) and Low

efficiency is thus achieved. Operating Current (2.3mA)

VDD low startup current and low operating current ■ Leading Edge Blanking on Current Sense Input

contribute to a reliable power on startup design with ■ Complete Protection Coverage with selective

OB2279. A large value resistor could thus be used in protections for Latch Shutdown

the startup circuit for reduced power loss. o VDD Over Voltage Protection(OVP) – Latch

The internal slope compensation improves system Shutdown

D 8 Y

large signal stability and reduces the possible sub- o Over Temperature Protection(OTP) – Auto

AP 6 P

harmonic oscillation at high PWM duty cycle output. recovery or Latch Shutdown

00 CO

Leading-edge blanking on current sense input o Over Load Protection. (OLP) – Auto recovery

removes the signal glitch due to snubber circuit diode or Latch Shutdown

reverse recovery and greatly reduces the external o VDD Under Voltage Lockout with Hysteresis

component count and system cost in the design. (UVLO)

ED O: N L

To 9 T

OB2279 offers comprehensive protection coverage o Gate Output Voltage Clamp (16.5V)

AS N DO IA

27 O

including Cycle-by-Cycle current limiting(OCP), o Built-in OCP Compensation to Achieve

VDD Under Voltage Lockout(UVLO), VDD Over

LE IAL E NT

Minimum OPP Variation over Universal AC

Voltage Protection(OVP), VDD Clamp, Gate Clamp, Input Range.

Over Load protection(OLP) and Over Temperature

RE R AS IDE

protection (OTP), etc. APPLICATIONS

Different latch shutdown options are offered on Offline AC/DC flyback converter for

OB2279 in different device version. V version has ■ Adaptor

SE E F

OVP Latch shutdown. T version supports both OVP ■ Notebook Adaptor

and OTP latch shutdown. L version provides all OVP,

PL ON

■ LCD Monitor/TV/PC/Set-Top Box Power

OTP and OLP latch shutdown control. Supplies

Excellent EMI performance is achieved with On- ■ Open-frame SMPS

C

Bright proprietary frequency shuffling technique ■ Printer Power

together with soft switching control at the totem pole

gate drive output.

OB2279 is offered in SOP-8 and DIP-8 packages.

TYPICAL APPLICATION

©On-Bright Electronics Confidential

-1- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

OB2279CP-L SOP8, tube package, L

GENERAL INFORMATION version with OVP/OTP/OLP

Pin Configuration latch

The pin map of OB2279 in DIP8 and SOP8 package OB2279CPA-L SOP8, taping package, L

is shown as below. version with OVP/OTP/OLP

latch

Note: All Devices are offered in Pb-free Package if not otherwise

noted.

Package Dissipation Rating

Package RθJA (°C/W)

DIP8 90

SOP8 150

Absolute Maximum Ratings

Parameter Value

D 8 Y

VDD Clamp Voltage (Vclamp) 35 V

VDD Clamp Continuous 10 mA

AP 6 P

Current

00 CO

Ordering Information VIN / VDD Input Voltage -0.3V to Vclamp

Part Number Description FB Input Voltage -0.3 to 7V

OB2279AP-V DIP8, tube package, V Sense Input Voltage -0.3 to 7V

ED O: N L

version with OVP Latch

To 9 T

RT Input Voltage -0.3 to 7V

AS N DO IA

OB2279AP-T DIP8, tube package, T RI Input Voltage -0.3 to 7V

27 O

version with OVP/OTP latch Min/Max Operating Junction -20 to 150 oC

LE IAL E NT

OB2279AP-L DIP8, tube package, L Temperature TJ

version with OVP/OTP/OLP Min/Max Storage Temperature -55 to 150 oC

latch

RE R AS IDE

Tstg

OB2279CP-V SOP8, tube package, V Lead Temperature (Soldering, 260 oC

version with OVP latch 10 seconds)

OB2279CPA-V SOP8, taping package, V

SE E F

Note: Stresses beyond those listed under “absolute maximum

version with OVP latch ratings” may cause permanent damage to the device. These are

PL ON

OB2279CP-T SOP8, tube package, T stress ratings only, functional operation of the device at these or

any other conditions beyond those indicated under

version with OVP/OTP latch “recommended operating conditions” is not implied. Exposure to

OB2279CPA-T SOP8, taping package, T absolute maximum-rated conditions for extended periods may

C

affect device reliability.

version with OVP/OTP latch

©On-Bright Electronics Confidential

-2- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

Marking Information

D 8 Y

AP 6 P

00 CO

TERMINAL ASSIGNMENTS

ED O: N L

Pin Num Pin Name I/O Description

To 9 T

1 GND P Ground

AS N DO IA

27 O

2 FB I Feedback input pin. PWM duty cycle is determined by voltage level into this

LE IAL E NT

pin and current-sense signal level at Pin 6.

3 VIN I Connected through a large value resistor to rectified line input for startup

and line voltage sensing.

RE R AS IDE

4 RI I Internal oscillator frequency setting pin. A resistor connected between RI

and GND sets the PWM frequency.

5 RT I Dual function pin. Either connected through a NTC resistor to GND for over

SE E F

temperature shutdown control or used as latch shutdown control input.

PL ON

6 SENSE I Current sense input pin. Connected to MOSFET current sensing resistor

node.

7 VDD P DC power supply pin.

C

8 GATE O Totem-pole gate drive output for power MOSFET.

©On-Bright Electronics Confidential

-3- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

BLOCK DIAGRAM

D 8 Y

AP 6 P

00 CO

ED O: N L

To 9 T

AS N DO IA

27 O

LE IAL E NT

RE R AS IDE

SE E F

PL ON

RECOMMENDED OPERATING CONDITION

C

Symbol Parameter Min Max Unit

VDD VDD Supply Voltage 11.5 25 V

o

TA Operating Ambient Temperature -20 85 C

©On-Bright Electronics Confidential

-4- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

ELECTRICAL CHARACTERISTICS

(TA = 25℃, RI=100K ohm, VDD=16V, if not otherwise noted)

Symbol Parameter Test Conditions Min Typ Max Unit

Supply Voltage (VDD)

I_VDD_Startup VDD Start up Current VDD =15VMeasure 3 20 uA

current into VDD

I_VDD_Ops Operation Current VFB=3V 2.3 mA

UVLO(Enter) VDD Under Voltage 8.8 9.8 10.8 V

Lockout Enter

UVLO(Exit) VDD Under Voltage 15.5 16.5 17.5 V

Lockout Exit

(Startup)

OVP(Latch) VDD Over Voltage 26.5 28 29.5 V

Latch Trigger

D 8 Y

OVP(De-Latch) VDD Latch Release 7.5 V

AP 6 P

Voltage Threshold

00 CO

I(Vdd)_latch VDD bleeding current 45 uA

at latch shutdown

when VDD = 9V

ED O: N L

TD_OVP VDD OVP Debounce 80 uSec

To 9 T

AS N DO IA

time

27 O

VDD_Clamp VDD Zener Clamp I(VDD ) = 5 mA 35 V

LE IAL E NT

Voltage

T_Softstart Soft Start Time 3 mSec

Feedback Input Section(FB Pin)

RE R AS IDE

AVCS PWM Input Gain ΔVFB /ΔVcs 2.8 V/V

VFB_Open VFB Open Voltage 6.2 V

SE E F

IFB_Short FB pin short circuit Short FB pin to GND, 0.75 mA

PL ON

current measure current

VTH_0D Zero Duty Cycle FB 0.95 V

Threshold Voltage

C

VTH_BM Burst Mode FB 1.6 V

Threshold Voltage

VTH_PL Power Limiting FB 4.4 V

Threshold Voltage

TD_PL Power limiting 80 mSec

Debounce Time

ZFB_IN Input Impedance 9.0 Kohm

Current Sense Input(Sense Pin)

T_blanking Sense Input Leading 300 nSec

Edge Blanking Time

ZSENSE_IN Sense Input 30 Kohm

Impedance

TD_OC Over Current CL=1nf at GATE, 70 nSec

Detection and Control

Delay

VTH_OC_0 Current Limiting I(VIN) = 0uA 0.85 0.90 0.95 V

Threshold at No

Compensation

©On-Bright Electronics Confidential

-5- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

VTH_OC_1 Current Limiting I(VIN) = 150uA, 0.80 V

Threshold at

Compensation

Oscillator

FOSC Normal Oscillation 60 65 70 KHZ

Frequency

∆f_Temp Central Frequency -20oC to 100 oC 3 %

Temperature Stability

∆f_VDD Central Frequency VDD = 12-28V, 3 %

Voltage Stability

RI_range Operating RI Range 50 100 250 Kohm

V_RI_open RI open voltage 2.0 V

F_BM Burst Mode Base 20 KHZ

Frequency

Gate Drive Output

VOL Output Low Level Io = 20 mA 0.3 V

D 8 Y

VOH Output High Level Io = 20 mA 11 V

AP 6 P

VG_Clamp Output Clamp 16.5 V

Voltage Level

00 CO

T_r Output Rising Time CL = 1nf 120 nSec

T_f Output Falling Time CL = 1nf 50 nSec

ED O: N L

Over Temperature Protection

To 9 T

I_RT Output Current of RT 70 uA

AS N DO IA

27 O

pin

LE IAL E NT

VTH_OTP OTP Threshold 1.015 1.065 1.115 V

Voltage

VTH_OTP_off OTP Recovery 1.165 V

RE R AS IDE

(Version V Only) Threshold Voltage

VTH_RT_latch RT Input Latch 0.6 V

(Version V Only) Threshold Voltage

SE E F

TD_OTP OTP De-bounce Time 100 uSec

PL ON

V_RT_Open RT Pin Open Voltage 3.7 V

Frequency Shuffling

∆f_OSC Frequency -3 3 %

C

Modulation range

/Base frequency

Freq_Shuffling Shuffling Frequency 32 HZ

©On-Bright Electronics Confidential

-6- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

CHARACTERIZATION PLOTS

VDD Startup Current vs. VDD I_vdd Startup vs. Temperature

20 8

18

16 6

I_vdd (uA)

14

I_vdd(uA)

12

10 4

8

6

4 2

2

0 0

0 2 4 6 8 10 12 14 16 -20 0 20 40 60 80 100 120

D 8 Y

VDD(V) Temp (C)

AP 6 P

00 CO

ED O: N L

To 9 T

VDD UVLO and Ops Current VDD Operation Current vs. Load

AS N DO IA

27 O

3 Fosc 50Khz Fosc 65Khz Fosc 100Khz

LE IAL E NT

2.5

6

I_VDD (mA)

2

I(VDD) (mA)

5

RE R AS IDE

1.5 4

1 3

SE E F

0.5 2

PL ON

0 1

0 4 8 12 16 20 24 28 0 500 1000 1500 2000

VDD (V) Gatedrive Loading (pf)

C

UVLO(enter) vs. Temp UVLO(exit) vs. Temp

9.9 16.6

16.5

UVLO(enter) (V)

UVLO(exit) (V)

9.8

16.4

9.7 16.3

9.6 16.2

9.5 16.1

16

9.4 15.9

9.3 15.8

-20 0 20 40 60 80 100 120 -20 0 20 40 60 80 100 120

Temp (C) Temp (C)

©On-Bright Electronics Confidential

-7- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

Fosc vs. RI Fosc vs. Temperature

140

120 67.5

67

100

Fosc (Khz)

Fosc (Khz)

66.5

80 66

60 65.5

40 65

20 64.5

0 64

50 70 90 110 130 150 170 190 210 230 250 -20 0 20 40 60 80 100 120

Temp (C)

RI (Kohm)

D 8 Y

AP 6 P

Vth_OC(V) vs Ivin(uA) I_RT vs. Temp

00 CO

1.0

70.6

70.4

0.9

Vth_OC(V)

I_RT (uA) w/

ED O: N L

70.2

RI=100Kohm

To 9 T

70

AS N DO IA

0.8

27 O

69.8

69.6

LE IAL E NT

0.7 69.4

69.2

0.6 69

RE R AS IDE

0 50 100 150 200 250 300 -20 0 20 40 60 80 100 120

Ivin(uA) Temp (C)

SE E F

PL ON

Ivdd_lacth(uA) vs Vdd(V)

C

50.0

Ivdd_lacth(umA

45.0

40.0

35.0

30.0

7.5 7.8 8.1 8.4 8.7 9.0

Vdd(V)

©On-Bright Electronics Confidential

-8- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

OPERATION DESCRIPTION

OB2279 is a highly integrated PWM controller IC loss thus reduce the standby power consumption to

optimized for offline flyback converter applications the greatest extend.

with requirement in latch shutdown or auto recovery. The nature of high frequency switching also reduces

The extended burst mode control greatly reduces the the audio noise at any loading conditions.

standby power consumption and helps the design

easily meet the international power conservation z Oscillator Operation

requirements. A resistor connected between RI and GND sets the

constant current source to charge/discharge the

z Startup Current and Start up Control internal cap and thus the PWM oscillator frequency

Startup current of OB2279 is designed to be very low is determined. The relationship between RI and

so that VDD could be charged up above UVLO(exit) switching frequency follows the below equation

threshold level and device starts up quickly. A large within the specified RI in Kohm range at nominal

value startup resistor can therefore be used to loading operational condition.

minimize the power loss yet reliable startup in

application. For a typical AC/DC adaptor with 6500

FOSC =

D 8 Y

universal input range design, a 2 MΩ, 1/8 W startup ( Khz )

RI ( Kohm)

AP 6 P

resistor could be used together with a VDD capacitor

to provide a fast startup and yet low power

00 CO

dissipation design solution. z Current Sensing and Leading Edge Blanking

(LEB)

z Operating Current Cycle-by-Cycle current limiting is offered in

ED O: N L

OB2279 current mode PWM control. The switch

To 9 T

The Operating current of OB2279 is low at 2.3mA.

AS N DO IA

current is detected by a sense resistor into the sense

27 O

Good efficiency is achieved with OB2279 low

operating current together with extended burst mode pin. An internal leading edge blanking circuit chops

LE IAL E NT

control schemes. off the sense voltage spike at initial MOSFET on

state due to snubber diode reverse recovery so that

the external RC filtering on sense input is no longer

RE R AS IDE

z Frequency shuffling for EMI improvement

The frequency Shuffling/jittering (switching needed. The current limit comparator is disabled and

frequency modulation) is implemented in OB2279. cannot turn off the external MOSFET during the

The oscillation frequency is modulated with a blanking period. The PWM duty cycle is determined

SE E F

internally generated random source so that the tone by the current sense input voltage and the FB input

PL ON

energy is evenly spread out. The spread spectrum voltage.

minimizes the conduction band EMI and therefore

eases the system design in meeting stringent EMI z Internal Synchronized Slope Compensation

C

requirement. Built-in slope compensation circuit adds voltage

ramp onto the current sense input voltage for PWM

z Burst Mode Operation generation. This greatly improves the close loop

At zero load or light load condition, most of the stability at CCM and prevents the sub-harmonic

power dissipation in a switching mode power supply oscillation and thus reduces the output ripple voltage.

is from switching loss of the MOSFET transistor, the

core loss of the transformer and the loss in the z Over Temperature Protection with Latch

snubber circuit. The magnitude of power loss is in Shutdown(Only to T and L version)

proportion to the number of switching events within A NTC resistor in series with a regular resistor

a fixed period of time. Reducing switching events should be connected between RT and GND for

leads to the reduction on the power loss and thus temperature sensing and protection. NTC resistor

conserves the energy. value becomes lower when the ambient temperature

OB2279 self adjusts the switching mode according to rises. With the fixed internal current IRT flowing

the loading condition. At no load or light load through the resistors, the voltage at RT pin becomes

condition, the FB input drops below burst mode lower at high temperature. The internal OTP circuit

threshold level. Device enters Burst Mode control. is triggered and shutdown the MOSFET when the

The Gate drive output switches only when VDD sensed input voltage is lower than VTH_OTP.

voltage drops below a preset level and FB input is OTP is a latched shutdown.

actived to output an on state. Otherwise the gate

drive remains at off state to minimize the switching

©On-Bright Electronics Confidential

-9- OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

z RT Pin Used as Latch Shutdown Input z Protection Controls

Control Good system reliability is achieved with OB2279’s

RT pin could also be used as a control input to rich protection features including Cycle-by-Cycle

implement system latch shutdown function. current limiting (OCP), Over Load Protection (OLP)

An example is to implement system OVP protection with auto-recovery(V and T version) or latch

with a latch shutdown function through a photo shutdown(L version), over temperature protection

coupler and affiliated circuits. When OVP detection (OTP) with auto-recovery(V version) or latch

signal connected to RT is lower than VTH_OTP for shutdown(T and L version), on-chip VDD over

Version T/L device, (or VTH_OT_Latch for Version voltage protection (OVP) with latch shutdown and

V), OB2279 controls system into latch shutdown. under voltage lockout (UVLO).

The recovery of the AC/DC system could only start VDD OVP protection is a latched shutdown in

by resetting internal latch when VDD voltage drops OB2279.

below VDD_De-latch value. This could be achieved The OCP threshold value is self adjusted lower at

by unplugging/re-plugging of AC source in AC start- higher current into VIN pin. This OCP threshold

up configuration. slope adjustment helps to compensate the increased

output power limit at higher AC voltage caused by

z Gate Drive inherent Over-Current sensing and control delay. A

D 8 Y

OB2279 Gate is connected to the Gate of an external constant output power limit is achieved with

AP 6 P

MOSFET for power switch control. Too weak the recommended OCP compensation scheme.

00 CO

gate drive strength results in higher conduction and At output overload condition, FB voltage is set

switch loss of MOSFET while too strong gate drive higher. When FB input exceeds power limit

output compromises the EMI. threshold value for more than 80mS, control circuit

ED O: N L

Good tradeoff is achieved through the built-in totem reacts to turnoff the power MOSFET. This is so

To 9 T

AS N DO IA

pole gate drive design with right output strength and called OLP shutdown. It is either auto-recovery or

27 O

dead time control. The low idle loss and good EMI latched shutdown depending on version of OB2279.

LE IAL E NT

system design is easier to achieve with this dedicated Similarly, control circuit shutdowns the power

control scheme. An internal 16.5V clamp is added for MOSFET when an Over Temperature condition is

MOSFET gate protection at higher than expected detected. This shuts down is either auto-recovery or

RE R AS IDE

VDD input. latched depending on version of OB2279 been used.

VDD is supplied with transformer auxiliary winding

output. It is clamped when VDD is higher than 35V.

SE E F

MOSFET is shut down when VDD drops below

PL ON

UVLO(enter) limit and device enters power on start-

up sequence thereafter.

C

©On-Bright Electronics Confidential

- 10 - OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

PACKAGE MECHANICAL DATA

8-Pin Plastic DIP

D 8 Y

AP 6 P

00 CO

ED O: N L

To 9 T

AS N DO IA

27 O

LE IAL E NT

RE R AS IDE

SE E F

PL ON

C

©On-Bright Electronics Confidential

- 11 - OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

8-Pin Plastic SOP

D 8 Y

AP 6 P

00 CO

ED O: N L

To 9 T

AS N DO IA

27 O

LE IAL E NT

RE R AS IDE

SE E F

PL ON

C

©On-Bright Electronics Confidential

- 12 - OB_DOC_DS_79A1

OB2279

Freq Shuffling with Latch Shutdown

Current Mode PWM Controller

IMPORTANT NOTICE

RIGHT TO MAKE CHANGES

On-Bright Electronics Corp. reserves the right to make corrections, modifications, enhancements,

improvements and other changes to its products and services at any time and to discontinue any product or

service without notice. Customers should obtain the latest relevant information before placing orders and should

verify that such information is current and complete.

WARRANTY INFORMATION

On-Bright Electronics Corp. warrants performance of its hardware products to the specifications applicable at

the time of sale in accordance with its standard warranty. Testing and other quality control techniques are used

to the extent it deems necessary to support this warranty. Except where mandated by government requirements,

testing of all parameters of each product is not necessarily performed.

On-Bright Electronics Corp. assumes no liability for application assistance or customer product design.

Customers are responsible for their products and applications using On-Bright’s components, data sheet and

application notes. To minimize the risks associated with customer products and applications, customers should

D 8 Y

provide adequate design and operating safeguards.

AP 6 P

00 CO

LIFE SUPPORT

On-Bright Electronics Corp.’s products are not designed to be used as components in devices intended to

support or sustain human life. On-bright Electronics Corp. will not be held liable for any damages or claims

ED O: N L

resulting from the use of its products in medical applications.

To 9 T

AS N DO IA

27 O

MILITARY

LE IAL E NT

On-Bright Electronics Corp.’s products are not designed for use in military applications. On-Bright Electronics

Corp. will not be held liable for any damages or claims resulting from the use of its products in military

applications.

RE R AS IDE

SE E F

PL ON

C

©On-Bright Electronics Confidential

- 13 - OB_DOC_DS_79A1

You might also like

- Thermodynamics ExperimentDocument5 pagesThermodynamics ExperimentRishabh Nagda100% (1)

- Iso 20816 8 2018 en PDFDocument11 pagesIso 20816 8 2018 en PDFEdwin Bermejo75% (4)

- Eric Priest - Magnetohydrodynamics of The Sun-Cambridge University Press (2014) PDFDocument580 pagesEric Priest - Magnetohydrodynamics of The Sun-Cambridge University Press (2014) PDFLaura Mora100% (1)

- High Voltage Green-Mode PWM Controller With Over Temperature ProtectionDocument19 pagesHigh Voltage Green-Mode PWM Controller With Over Temperature ProtectionHugo BarrosoNo ratings yet

- LD7523 PDFDocument18 pagesLD7523 PDFAmalio MamaniNo ratings yet

- 1ch Boost Up Type White LED Driver For Large LCD: DatasheetDocument37 pages1ch Boost Up Type White LED Driver For Large LCD: DatasheetWeex HRNo ratings yet

- Green-Mode PWM Controller With High-Voltage Start-Up Circuit and Adjustable OLP Delay TimeDocument19 pagesGreen-Mode PWM Controller With High-Voltage Start-Up Circuit and Adjustable OLP Delay TimeЕвгений ПNo ratings yet

- LD7522PS Psu IcDocument17 pagesLD7522PS Psu IcJerryMungoNo ratings yet

- LD7575B DS 00 PDFDocument17 pagesLD7575B DS 00 PDFjeovanevsNo ratings yet

- Green-Mode PWM Controller With High-Voltage Start-Up CircuitDocument17 pagesGreen-Mode PWM Controller With High-Voltage Start-Up Circuitserrano.flia.coNo ratings yet

- Uc3863 Utc U863 PDFDocument9 pagesUc3863 Utc U863 PDFShailesh VajaNo ratings yet

- Ob2262 Datasheet PDFDocument13 pagesOb2262 Datasheet PDFjesus cautivoNo ratings yet

- Ob2262 Ver2.0 Datasheet PDFDocument13 pagesOb2262 Ver2.0 Datasheet PDFjesus cautivoNo ratings yet

- General Description: EMI Filter Ac in DC OutDocument13 pagesGeneral Description: EMI Filter Ac in DC Outjesus cautivoNo ratings yet

- bd9285f eDocument39 pagesbd9285f eUncle PaneNo ratings yet

- LD7523Document18 pagesLD7523AssembleiaDeDeusSepherEloahNo ratings yet

- Ob 2269 CapDocument13 pagesOb 2269 Caporkun burkayNo ratings yet

- OB2276A-On-Bright ElectronicsDocument11 pagesOB2276A-On-Bright Electronicsparsastar2010No ratings yet

- LD7578J LeadtrendDocument19 pagesLD7578J Leadtrendnagahara.eduardoNo ratings yet

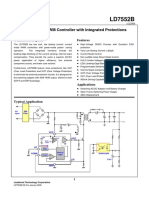

- Green-Mode PWM Controller With Integrated Protections: General Description FeaturesDocument16 pagesGreen-Mode PWM Controller With Integrated Protections: General Description Featuresgulhshan khanNo ratings yet

- OB2263 On-Bright PDFDocument13 pagesOB2263 On-Bright PDFamaliah bamesuNo ratings yet

- OB2273 On BrightDocument12 pagesOB2273 On BrightCarlos PosadaNo ratings yet

- EM8635 ExcellianceMOSDocument13 pagesEM8635 ExcellianceMOSBruno MartinsNo ratings yet

- Apl5916 AnpecDocument20 pagesApl5916 Anpecايهاب فوزيNo ratings yet

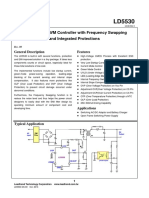

- Green-Mode PWM Controller With Frequency Swapping and Integrated ProtectionsDocument16 pagesGreen-Mode PWM Controller With Frequency Swapping and Integrated Protectionsshamsudin yassinNo ratings yet

- Datasheet PDFDocument15 pagesDatasheet PDFDhiran NishantNo ratings yet

- OB2203 On-BrightElectronicsDocument13 pagesOB2203 On-BrightElectronicsعلي محمدعبدالله الردينيNo ratings yet

- GR8830Document13 pagesGR8830Mario Gabriel MoralliNo ratings yet

- High Voltage Green-Mode PWM Controller With Over Temperature ProtectionDocument19 pagesHigh Voltage Green-Mode PWM Controller With Over Temperature ProtectionIvan ZuñigaNo ratings yet

- Features General Description: 150Khz, 2A PWM Buck DC/DC ConverterDocument12 pagesFeatures General Description: 150Khz, 2A PWM Buck DC/DC ConverterАндрей ОлененкоNo ratings yet

- LD7577 DS 01 PDFDocument18 pagesLD7577 DS 01 PDFLucilia Dos Santos100% (2)

- AP2182Document17 pagesAP2182ابراهيم السعيديNo ratings yet

- Transition-Mode PFC Controller With Fault Condition ProtectionDocument20 pagesTransition-Mode PFC Controller With Fault Condition ProtectionMega BoxNo ratings yet

- OB2273A On BrightDocument10 pagesOB2273A On BrightHamza Abbasi AbbasiNo ratings yet

- LD7522Document18 pagesLD7522uyfcastellNo ratings yet

- Transition-Mode PFC Controller With Fault Condition ProtectionDocument16 pagesTransition-Mode PFC Controller With Fault Condition ProtectionAdailton SantosNo ratings yet

- Ob2262 Usado em Fonte Proview MLT 198aDocument13 pagesOb2262 Usado em Fonte Proview MLT 198aHeron Cesar VieiraNo ratings yet

- Low Cost Green-Power PWM Controller With Low EMI Technique FeaturesDocument12 pagesLow Cost Green-Power PWM Controller With Low EMI Technique FeaturesRogeriomgoNo ratings yet

- On-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesDocument14 pagesOn-Bright Confidential To Bona: Quasi-Resonant Flyback PWM Controller General Description FeaturesFlavio Tonello TavaresNo ratings yet

- Data SheetDocument16 pagesData SheetLeonildo CostaNo ratings yet

- OB2362 DatasheetDocument10 pagesOB2362 DatasheetTín SmpsNo ratings yet

- LD7576GS PWM CTRLR PDFDocument20 pagesLD7576GS PWM CTRLR PDFEdgar DauzonNo ratings yet

- AP8836Document15 pagesAP8836SamerNo ratings yet

- UC3842B/3843B: Unisonic Technologies Co., LTDDocument11 pagesUC3842B/3843B: Unisonic Technologies Co., LTDvannadioNo ratings yet

- L7900 Series: Negative Voltage RegulatorsDocument13 pagesL7900 Series: Negative Voltage Regulatorsmhd_almahayniNo ratings yet

- Datasheet PDFDocument18 pagesDatasheet PDFSửa Tivi Tại NhàNo ratings yet

- OB2269Document12 pagesOB2269Juan Ballon100% (1)

- Boost 1channel White Led Driver For Large LCDS: DatasheetDocument42 pagesBoost 1channel White Led Driver For Large LCDS: DatasheetkanakNo ratings yet

- Features General Description: 3A, Ultra Low Dropout (0.23V Typical) Linear RegulatorDocument17 pagesFeatures General Description: 3A, Ultra Low Dropout (0.23V Typical) Linear RegulatorLangllyNo ratings yet

- Green-Mode PWM Controller With Frequency Swapping and Integrated ProtectionsDocument16 pagesGreen-Mode PWM Controller With Frequency Swapping and Integrated Protectionsbiplob akandNo ratings yet

- AP7215Document11 pagesAP7215Farouk AnçaNo ratings yet

- LD7536R DS 01a PDFDocument16 pagesLD7536R DS 01a PDFvampiro_yiyo100% (1)

- R1202x Series: Step-Up DC/DC Converter With Shutdown Function OutlineDocument33 pagesR1202x Series: Step-Up DC/DC Converter With Shutdown Function OutlineajisardadiNo ratings yet

- 7915Document13 pages7915ysfhkNo ratings yet

- R7779 RichpowerDocument13 pagesR7779 RichpowerRuktandirNo ratings yet

- 3843ANDocument8 pages3843ANinfosolutionNo ratings yet

- General Description Features: High Performance Current Mode PWM ControllerDocument11 pagesGeneral Description Features: High Performance Current Mode PWM ControllerPhạm Tấn HảiNo ratings yet

- 7912CT EtcDocument13 pages7912CT EtcCuong TranNo ratings yet

- Power Supply Supervisor With PWM Controller: Description Pin Configuration (Top View)Document6 pagesPower Supply Supervisor With PWM Controller: Description Pin Configuration (Top View)GigaflopsTechnology2019No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- BD9848FV: 1 Should Be Deleted by 6.5mW/ at Ta 25 or More. When Mounted On A Glass Epoxy PCB of 70.0mm×70.0 mm×1.6 MMDocument7 pagesBD9848FV: 1 Should Be Deleted by 6.5mW/ at Ta 25 or More. When Mounted On A Glass Epoxy PCB of 70.0mm×70.0 mm×1.6 MMAmit BiswasNo ratings yet

- Python Problem Solution: EncoderDocument2 pagesPython Problem Solution: EncoderAmit BiswasNo ratings yet

- Python Problem Solution: Repeat CheckerDocument2 pagesPython Problem Solution: Repeat CheckerAmit BiswasNo ratings yet

- Python Problem Solution: Password ValidationDocument2 pagesPython Problem Solution: Password ValidationAmit BiswasNo ratings yet

- CH 21 Hull Fundamentals 8 The DDocument23 pagesCH 21 Hull Fundamentals 8 The DjlosamNo ratings yet

- Bozzetto Denim Finishing HandbookDocument56 pagesBozzetto Denim Finishing HandbookAbrar Hussain100% (1)

- Micro X Ray Fluorescence Spectroscopy First Edition PDFDocument31 pagesMicro X Ray Fluorescence Spectroscopy First Edition PDFAlberto Núñez CardezoNo ratings yet

- Yarn Examining MachineDocument3 pagesYarn Examining MachineAbrõ Wazir100% (1)

- Class - 6 - Bar Graph - T - 8 - 3 PDFDocument6 pagesClass - 6 - Bar Graph - T - 8 - 3 PDFParul GuptaNo ratings yet

- Microwave Drying 2010Document7 pagesMicrowave Drying 2010Griet Van VaerenberghNo ratings yet

- Manual de Sensor de Velocidad RolfesDocument41 pagesManual de Sensor de Velocidad RolfesHenry LiraNo ratings yet

- Scentroid SS400-Operation Manual-V2.0Document21 pagesScentroid SS400-Operation Manual-V2.0delboni delboniNo ratings yet

- Practical 7 PDFDocument8 pagesPractical 7 PDFAjinkya PatilNo ratings yet

- 3 The MPEG Data StreamDocument12 pages3 The MPEG Data Streamanshab bedariNo ratings yet

- Square D Accusine Pcs Active Harmonic FilterDocument2 pagesSquare D Accusine Pcs Active Harmonic FilterMushfiqur RahmanNo ratings yet

- Math 203-1.1Document85 pagesMath 203-1.1Max ModiNo ratings yet

- SUZUMIDocument200 pagesSUZUMIDaniel MilosevskiNo ratings yet

- Weidmuller SAI PIDocument32 pagesWeidmuller SAI PIHrvoje HorvatNo ratings yet

- Brief Introduction To SSL: SSL Connection Using Tlsv1.2 SSL Connection Using Jks SSL Connection Using Oracle WalletsDocument23 pagesBrief Introduction To SSL: SSL Connection Using Tlsv1.2 SSL Connection Using Jks SSL Connection Using Oracle WalletspradeepNo ratings yet

- Oracle Linux 6.6 (64bit) InstallationDocument17 pagesOracle Linux 6.6 (64bit) InstallationtonygmnNo ratings yet

- 11Document9 pages11Saharah PundugNo ratings yet

- CH 8 AnswersDocument5 pagesCH 8 AnswersMark Anthony25% (4)

- Physics 7E: Practice MidtermDocument5 pagesPhysics 7E: Practice MidtermFUSION AcademicsNo ratings yet

- Properties of Solutions Electrolytes and Non Electrolytes by Dan HolmquistDocument4 pagesProperties of Solutions Electrolytes and Non Electrolytes by Dan HolmquistkumiristineNo ratings yet

- (Reid, Et Al.,2006) - Detailed Tire Modelling For Crash Applications PDFDocument11 pages(Reid, Et Al.,2006) - Detailed Tire Modelling For Crash Applications PDFchristos032No ratings yet

- Nature of NumbersDocument57 pagesNature of NumbersArun Kumar Upadhyay100% (3)

- Sample Question Paper - Object Oriented Programming-12063Document4 pagesSample Question Paper - Object Oriented Programming-12063amit_t4210% (1)

- Lesson Plan in Science 7Document6 pagesLesson Plan in Science 7gemima galvezNo ratings yet

- According To Use: Main Auxiliary According To Passage of Flue GasesDocument11 pagesAccording To Use: Main Auxiliary According To Passage of Flue GasesAbdallah MansourNo ratings yet

- KNN and Naive BayesDocument61 pagesKNN and Naive BayesvdjohnNo ratings yet

- Virtual Micro LabDocument5 pagesVirtual Micro LabP1No ratings yet