Professional Documents

Culture Documents

Primary Water by Ramesh

Primary Water by Ramesh

Uploaded by

Komma RameshCopyright:

Available Formats

You might also like

- Citroen C-Elysee - Peugeot 301 (2012-2017) Service ManualDocument2,104 pagesCitroen C-Elysee - Peugeot 301 (2012-2017) Service ManualHector Alfonso100% (1)

- Module 2 Lesson 3 MISSIONARY RESPONSEDocument1 pageModule 2 Lesson 3 MISSIONARY RESPONSEHarriz Diether DomingoNo ratings yet

- Hydrogen Cooling of Electrical GeneratorsDocument80 pagesHydrogen Cooling of Electrical GeneratorsFahad Khalil83% (6)

- Prsentation: Ball and Tube MillDocument39 pagesPrsentation: Ball and Tube Millmkoelreal100% (2)

- Ball and Race MillDocument76 pagesBall and Race Millsandeep19861986100% (2)

- Forced Cooling of Steam Turbines: Answers For EnergyDocument2 pagesForced Cooling of Steam Turbines: Answers For EnergyShameer Majeed100% (2)

- Power Plant Chemistry by Ramesh PDFDocument62 pagesPower Plant Chemistry by Ramesh PDFKomma Ramesh50% (2)

- 210 MW Ash Evacuation System: R. K. Shelke (Assistant Engineer)Document44 pages210 MW Ash Evacuation System: R. K. Shelke (Assistant Engineer)AhemadNo ratings yet

- Primary Water SystemDocument15 pagesPrimary Water SystemSantoshkumar GuptaNo ratings yet

- Bottom Ash Hopper CollectionsDocument11 pagesBottom Ash Hopper Collectionsatgsganesh0% (1)

- Generator Hydrogen Cooling InfoDocument21 pagesGenerator Hydrogen Cooling InfovarsbsNo ratings yet

- Turbine Side PumpsDocument25 pagesTurbine Side PumpsPrakash Choudhary67% (3)

- Superheaters and ReheaterDocument16 pagesSuperheaters and ReheaterBudi Norton100% (1)

- Generator AuxiliariesDocument45 pagesGenerator Auxiliariesrapoluprakash143100% (1)

- Combustion TuningDocument9 pagesCombustion TuningRamakrishnan NatarajanNo ratings yet

- Condenser Vac PumpDocument20 pagesCondenser Vac Pumpbarphani100% (1)

- Turbine Protection & InterlockDocument7 pagesTurbine Protection & InterlockSony Rama100% (2)

- Basics of Thermal Power PlantDocument119 pagesBasics of Thermal Power Plantsiva7448163100% (1)

- Ash Handling SystemDocument7 pagesAsh Handling Systemrbdubey2020No ratings yet

- Coal MillDocument22 pagesCoal Millritesh MishraNo ratings yet

- PocketDiary SantaldihDocument198 pagesPocketDiary SantaldihJoydev GangulyNo ratings yet

- Hydrogen Cooled GeneratorsDocument4 pagesHydrogen Cooled GeneratorsRigoberto Urrutia100% (2)

- Technical DiaryDocument127 pagesTechnical Diarytushar67100% (1)

- Vacuum SystemDocument28 pagesVacuum SystemHamid Ariz100% (1)

- Coal MillsDocument44 pagesCoal Millsashish364No ratings yet

- Secondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Document3 pagesSecondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Bineet Kumar VarmaNo ratings yet

- How Diesel Engines WorkDocument3 pagesHow Diesel Engines WorkVivek Tiwari100% (1)

- Turbine Glands Steam CondenserDocument6 pagesTurbine Glands Steam Condenserryan hardianto100% (1)

- GEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingDocument24 pagesGEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingAkasthiyanNo ratings yet

- Mill & Mill Rejects WriteupDocument10 pagesMill & Mill Rejects WriteupEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- SOP of Coal Mill Coal FeederDocument5 pagesSOP of Coal Mill Coal FeederChandra PratamaNo ratings yet

- Coal Mill in Thermal Power PlantDocument3 pagesCoal Mill in Thermal Power Plantkiki270977No ratings yet

- Online Monitoring of Bottom Ash Hopper TemperatureDocument6 pagesOnline Monitoring of Bottom Ash Hopper Temperaturerama jenaNo ratings yet

- Coal Fired Boiler - PrincipalsDocument145 pagesCoal Fired Boiler - PrincipalsArfan AnwarNo ratings yet

- Bcw-Pump: Hayward Tyler TorishimaDocument29 pagesBcw-Pump: Hayward Tyler TorishimaSAROJNo ratings yet

- 800 MWDocument6 pages800 MWRamesh Babu K100% (2)

- Condensate Cycle SystemDocument26 pagesCondensate Cycle SystemBhumit Sagathiya100% (4)

- DPBC Question BankDocument10 pagesDPBC Question BankshubhamNo ratings yet

- Operation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleDocument31 pagesOperation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleAshish Lanjewar100% (3)

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDocument41 pagesReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonNo ratings yet

- Effect of Air Ingress in BoilersDocument6 pagesEffect of Air Ingress in BoilersAnvita Chebrolu100% (1)

- Hydrazine DosingDocument2 pagesHydrazine DosingAnonymous 3HTgMDO100% (1)

- Feed Water HeaterDocument19 pagesFeed Water HeaterMarzouk Abdel Wahed Marzouk100% (1)

- Mill - PerformanceDocument51 pagesMill - PerformanceRavi Satyapal100% (1)

- Turbine OperationDocument30 pagesTurbine OperationGanesh Dasara100% (3)

- Gov Simulator 23.12.06Document46 pagesGov Simulator 23.12.06Sam100% (4)

- CondenserDocument57 pagesCondenserEzhil Vendhan Palanisamy100% (2)

- NDCTDocument127 pagesNDCTYousuf Ali100% (1)

- Aph FireDocument25 pagesAph Firesekhar_ntpcNo ratings yet

- Design Features of Governing System LMW and Kwu TurbinesDocument34 pagesDesign Features of Governing System LMW and Kwu Turbinespankaj100% (1)

- 500mw Boiler Operating InstructionsDocument8 pages500mw Boiler Operating InstructionsRavindrababu Banothu100% (2)

- Thermal Power PlantDocument13 pagesThermal Power PlantSanat KumarNo ratings yet

- Parameter 500 MWDocument3 pagesParameter 500 MWBalraj Padmashali100% (1)

- Stator Water System Case StudyDocument26 pagesStator Water System Case Studyroy1920100% (1)

- Stator Water System ChemistryDocument33 pagesStator Water System ChemistrySudhanshu Sekhar Dash100% (3)

- Presentation On: "Boiler & Auxiliary "Document47 pagesPresentation On: "Boiler & Auxiliary "shivabhaNo ratings yet

- Major Equipments: FOR Asam-Asam Coal Fired Steam Power Plant 2X65 MW (UNIT 3 & 4) Oleh: Arief Daru WibawantoDocument34 pagesMajor Equipments: FOR Asam-Asam Coal Fired Steam Power Plant 2X65 MW (UNIT 3 & 4) Oleh: Arief Daru Wibawantosaiful anwarNo ratings yet

- Boiler and AuxDocument47 pagesBoiler and AuxRajani Kanta Munda100% (1)

- Final Ska CondensorDocument100 pagesFinal Ska Condensor77errorsNo ratings yet

- Cooing Tower PPT (1) HurlDocument36 pagesCooing Tower PPT (1) Hurlpriyajit sahoo100% (1)

- Cooling Water SystemDocument48 pagesCooling Water SystemSandeep Joshi100% (1)

- Primary Water System AbhiDocument17 pagesPrimary Water System Abhisatyanand lakkojuNo ratings yet

- JB ThesisDocument65 pagesJB ThesisSanThosh ChInnuNo ratings yet

- Coal and MillDocument85 pagesCoal and MillKomma Ramesh100% (2)

- BGR Energy Systems LTD Power Projects Division Kakatiya PTP O&M Manual GID-082-ME-BS-1123Document39 pagesBGR Energy Systems LTD Power Projects Division Kakatiya PTP O&M Manual GID-082-ME-BS-1123Komma Ramesh100% (1)

- DM Plant Block by RameshDocument1 pageDM Plant Block by RameshKomma RameshNo ratings yet

- Pre Treatment by RameshDocument6 pagesPre Treatment by RameshKomma RameshNo ratings yet

- DMCW System in Thermal Power PlantDocument2 pagesDMCW System in Thermal Power PlantKomma Ramesh88% (8)

- Coal by RameshDocument9 pagesCoal by RameshKomma RameshNo ratings yet

- Mills or Pulvarisers in Thermal Power Plant: BY Ramesh Komma Senior Chemist /TSGENCO Ktpp-ChelpurDocument6 pagesMills or Pulvarisers in Thermal Power Plant: BY Ramesh Komma Senior Chemist /TSGENCO Ktpp-ChelpurKomma RameshNo ratings yet

- Excise Duty in IndiaDocument3 pagesExcise Duty in IndiaKomma RameshNo ratings yet

- Project Profile On Bakery Products: Mixing of Ingredients Except Flour in Required Proportion in Paste FormDocument4 pagesProject Profile On Bakery Products: Mixing of Ingredients Except Flour in Required Proportion in Paste FormKomma RameshNo ratings yet

- Compasison ChartDocument1 pageCompasison ChartKomma RameshNo ratings yet

- Ion Exchange PDFDocument14 pagesIon Exchange PDFKomma RameshNo ratings yet

- Safety For ChemistsDocument26 pagesSafety For ChemistsKomma RameshNo ratings yet

- Telugu Dictionary PDFDocument221 pagesTelugu Dictionary PDFananthoju90% (50)

- MilsDocument97 pagesMilsKomma Ramesh100% (1)

- Com PaintDocument2 pagesCom PaintKomma RameshNo ratings yet

- Jasmine F Slaughter - Day&Zimmerman - Fall2011Document22 pagesJasmine F Slaughter - Day&Zimmerman - Fall2011studentATtempleNo ratings yet

- National Drug Policy/Generics Law: Romeo R. Andaya, MD, MSCPD, PHD, Fpafp Chair, DPMCH Uph-DjgtmuDocument14 pagesNational Drug Policy/Generics Law: Romeo R. Andaya, MD, MSCPD, PHD, Fpafp Chair, DPMCH Uph-DjgtmuKatNo ratings yet

- CV Sayeed TeachingDocument8 pagesCV Sayeed TeachingGopal ReddyNo ratings yet

- New Haven AnalysisDocument2 pagesNew Haven AnalysisHelen BennettNo ratings yet

- Notified Vide SRO No. 575 Dated 22 May 2019Document3 pagesNotified Vide SRO No. 575 Dated 22 May 2019Hussain RahibNo ratings yet

- Penguin - Magnetic Drive Pump M SeiresDocument4 pagesPenguin - Magnetic Drive Pump M SeiresMiguel Angel LòpezNo ratings yet

- 20T Wheat Flour Milling PlantDocument12 pages20T Wheat Flour Milling Plantshio29100% (2)

- Senate Hearing, 110TH Congress - Scrambling For Health Insurance Coverage: Health Security For People in Late Middle AgeDocument87 pagesSenate Hearing, 110TH Congress - Scrambling For Health Insurance Coverage: Health Security For People in Late Middle AgeScribd Government DocsNo ratings yet

- King Propose Volume 1Document225 pagesKing Propose Volume 1Lorenzo FaddaNo ratings yet

- 13.revised Rate ListDocument51 pages13.revised Rate ListAsif Icbal100% (1)

- Reglarea EmotiilorDocument3 pagesReglarea EmotiilorIulia JudeanuNo ratings yet

- Air Pollution 4. Noise & Light PollutionDocument3 pagesAir Pollution 4. Noise & Light Pollutionclara olsenNo ratings yet

- Hypertension Dash DietDocument32 pagesHypertension Dash DietKAUSHAL ARYA100% (1)

- Average Average Set Ii Set I SampleDocument1 pageAverage Average Set Ii Set I Samplevenkateswara rao PothinaNo ratings yet

- Mazda 3 BrochureDocument16 pagesMazda 3 BrochurebacooNo ratings yet

- Papermaking Little BookDocument8 pagesPapermaking Little BookAkbar Ramadhan SyambasNo ratings yet

- Een Liefdesbrief Aan Amsterdam (By Ryan Bartek)Document5 pagesEen Liefdesbrief Aan Amsterdam (By Ryan Bartek)Ryan Bartek100% (1)

- Cub Cadet Parts Manual For Model 1211 SN 756300 799999Document9 pagesCub Cadet Parts Manual For Model 1211 SN 756300 799999shirley100% (56)

- Nutrition Mopnth Celebration ScriptDocument4 pagesNutrition Mopnth Celebration ScriptLilian Laurel Cariquitan100% (9)

- Biology Laboratory ManualDocument314 pagesBiology Laboratory ManualLeroyJones91% (11)

- Transposition: Shubhangi ShuklaDocument24 pagesTransposition: Shubhangi ShuklaShubhangi ShuklaNo ratings yet

- Aquac Uno HDocument218 pagesAquac Uno Hivancalderon867374No ratings yet

- Psychology Semi-Final ExamDocument2 pagesPsychology Semi-Final ExamMonroe OrtizanoNo ratings yet

- ELSci Q2 Lesson 6 - Organ Systems of Representative AnimalsDocument51 pagesELSci Q2 Lesson 6 - Organ Systems of Representative AnimalsItsClarence100% (2)

- Titration of Vinegar Lab ReportDocument8 pagesTitration of Vinegar Lab ReportIbrahim Abdulkadir JumaNo ratings yet

- Journal of Adolescence: Nele Laporte, Bart Soenens, Katrijn Brenning, Maarten VansteenkisteDocument17 pagesJournal of Adolescence: Nele Laporte, Bart Soenens, Katrijn Brenning, Maarten Vansteenkisterisa agustinaNo ratings yet

- Drug Calculations Reviewer For NursesDocument6 pagesDrug Calculations Reviewer For NursesBreezy ReveloNo ratings yet

- 02 IVD-R Deep-Dive Deck NewDocument215 pages02 IVD-R Deep-Dive Deck Newrajiveacharya100% (1)

Primary Water by Ramesh

Primary Water by Ramesh

Uploaded by

Komma RameshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Primary Water by Ramesh

Primary Water by Ramesh

Uploaded by

Komma RameshCopyright:

Available Formats

‘

P R I M A R Y WAT E R F O R

G E N E R AT O R C O O L I N G

IN THERMAL POWER PLANT

TSGENCO

BY

RAMESH KOMMA

Senior Chemist /TSGENCO

KTPP-CHELPUR

KOMMA RAMESH SENIOR CHEMIST TSGENCO KTPP-CHELPUR Page 1

NTRODUCTION

Kinetic energy from Turbine converts in electrical energy by generator

When mechanical energy do the work against electromagnetic force electricity is produced, during this

process high current flow through stator of generator and heat is generated in stator coil

Demineralized water is used to remove the heat from stator coil is called primary water or Stator

water

There are three types of cooling systems

Air cooling Below 150MW

Hydrogen cooling 150-400MW

Hydrogen & water cooling Above 400MW

In KTPP 500 and 600MW Hydrogen & water cooling system used remove the heat from stator coil

For stator water cooling the stator bars are equipped with hallow strands

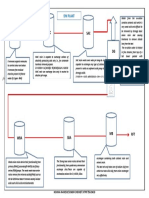

SCHEMATIC DIAGRAM OF HYDROGEN AND WATER COOLING OF GENERATOR

KOMMA RAMESH SENIOR CHEMIST TSGENCO KTPP-CHELPUR Page 2

WATER COOLING SYSTEM

MAKE UP

WATER

MAKE UP FILTER

GENERATOR

STORAGE

MAIN FILTER

TANK

PHE

DEIONIZER

PHE

2PUMPS

NaOH

NOTE :- Filters are used to remove the debris in stator water circuits that may block stator coil because

stator coil hallow conductors are typically 1 to 3mm wide and 3500 to 12000mm long they are packed in to

the stator bar with numeric bends

Deionizer used to remove dissolved solids in stator water, in this deionizer strong acid cation and strong base

anion resin used in 1:1 ration. The deionizer resin is replaced when primary water conductivity is raised

Plate heat exchanger are used to cool the circulating stator water which gains heat in generator

KOMMA RAMESH SENIOR CHEMIST TSGENCO KTPP-CHELPUR Page 3

COOLING WATER CHEMISTRY

Generator provided with hallows strands/conductors connected to common header at inlet and outlet of the

winding. The conductors and headers are commonly made up of copper

As the water enters into the hallow conductor , Copper comes in contact with water and forms cuprous oxide

( Cu2O) red colour and cupric Oxide (CuO) black colour depends on the electrochemical potential which

varies with temperature and PH of water. The copper Oxide forms passive layer on the inner surface hallow

copper conductor, the stability of the passive layer increases with increase in pH.

The copper corrosion low at high oxygen level but has the maximum in the 100 to 500ppb range. Also an

increase in PH reduces copper corrosion considerably, it suggest that alkalization of stator water could

bebeneficial. the rate of corrosion depends on PH and DO

The makeup water enters into low DO type stator water system, copper release copper oxide excess of the

solubility limit at operating temperature (85oC ). One part of copper oxide forms passive layer another part

moves in circuit and deposits at critical areas of the winding it is called plugging. The re deposition of copper

oxides causes blockage of strands. The solubility of the copper oxides depends up on PH and temperature of

water

KOMMA RAMESH SENIOR CHEMIST TSGENCO KTPP-CHELPUR Page 4

In low oxygen system and neutral PH cuprous oxide Cu2O will be predominant, while in high oxygen and

alkaline system the oxide will be mainly cupric oxide CuO

Stator Water Treatment Options

1. Low dissolved oxygen (<10ppb) and neutral PH

2. High dissolved oxygen (>200ppb) and neutral pH

3. Low dissolved oxygen(<10ppb) and at alkaline pH(8-9)

4. High dissolved oxygen (>200ppb)and at alkaline pH(8-9) not suitable for cooling due to clip corrosion

Problems In Stator Water Coil

1. Leaks in stator winding at brazed connections

2. Water box leakage combined with strand to strand leakage

3. Small leakage will not damage winding in normal operation because H2 gas pressure maintained

above the stator cooling water but causes when generator is degassed

4. Leakage in stator hydraulic components and connections

5. Clip to strand leakage due to crevice corrosion

Primary Water Parameters

pH 8 to 9

DO <100

CONDUCTIVITY

<2

at 25oC µS/cm

Total Cu µg/l <20

Total Fe µg/l <20

KOMMA RAMESH SENIOR CHEMIST TSGENCO KTPP-CHELPUR Page 5

You might also like

- Citroen C-Elysee - Peugeot 301 (2012-2017) Service ManualDocument2,104 pagesCitroen C-Elysee - Peugeot 301 (2012-2017) Service ManualHector Alfonso100% (1)

- Module 2 Lesson 3 MISSIONARY RESPONSEDocument1 pageModule 2 Lesson 3 MISSIONARY RESPONSEHarriz Diether DomingoNo ratings yet

- Hydrogen Cooling of Electrical GeneratorsDocument80 pagesHydrogen Cooling of Electrical GeneratorsFahad Khalil83% (6)

- Prsentation: Ball and Tube MillDocument39 pagesPrsentation: Ball and Tube Millmkoelreal100% (2)

- Ball and Race MillDocument76 pagesBall and Race Millsandeep19861986100% (2)

- Forced Cooling of Steam Turbines: Answers For EnergyDocument2 pagesForced Cooling of Steam Turbines: Answers For EnergyShameer Majeed100% (2)

- Power Plant Chemistry by Ramesh PDFDocument62 pagesPower Plant Chemistry by Ramesh PDFKomma Ramesh50% (2)

- 210 MW Ash Evacuation System: R. K. Shelke (Assistant Engineer)Document44 pages210 MW Ash Evacuation System: R. K. Shelke (Assistant Engineer)AhemadNo ratings yet

- Primary Water SystemDocument15 pagesPrimary Water SystemSantoshkumar GuptaNo ratings yet

- Bottom Ash Hopper CollectionsDocument11 pagesBottom Ash Hopper Collectionsatgsganesh0% (1)

- Generator Hydrogen Cooling InfoDocument21 pagesGenerator Hydrogen Cooling InfovarsbsNo ratings yet

- Turbine Side PumpsDocument25 pagesTurbine Side PumpsPrakash Choudhary67% (3)

- Superheaters and ReheaterDocument16 pagesSuperheaters and ReheaterBudi Norton100% (1)

- Generator AuxiliariesDocument45 pagesGenerator Auxiliariesrapoluprakash143100% (1)

- Combustion TuningDocument9 pagesCombustion TuningRamakrishnan NatarajanNo ratings yet

- Condenser Vac PumpDocument20 pagesCondenser Vac Pumpbarphani100% (1)

- Turbine Protection & InterlockDocument7 pagesTurbine Protection & InterlockSony Rama100% (2)

- Basics of Thermal Power PlantDocument119 pagesBasics of Thermal Power Plantsiva7448163100% (1)

- Ash Handling SystemDocument7 pagesAsh Handling Systemrbdubey2020No ratings yet

- Coal MillDocument22 pagesCoal Millritesh MishraNo ratings yet

- PocketDiary SantaldihDocument198 pagesPocketDiary SantaldihJoydev GangulyNo ratings yet

- Hydrogen Cooled GeneratorsDocument4 pagesHydrogen Cooled GeneratorsRigoberto Urrutia100% (2)

- Technical DiaryDocument127 pagesTechnical Diarytushar67100% (1)

- Vacuum SystemDocument28 pagesVacuum SystemHamid Ariz100% (1)

- Coal MillsDocument44 pagesCoal Millsashish364No ratings yet

- Secondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Document3 pagesSecondary Air Damper Control (Sadc) : C.R.PAL, SR MGR (PS)Bineet Kumar VarmaNo ratings yet

- How Diesel Engines WorkDocument3 pagesHow Diesel Engines WorkVivek Tiwari100% (1)

- Turbine Glands Steam CondenserDocument6 pagesTurbine Glands Steam Condenserryan hardianto100% (1)

- GEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingDocument24 pagesGEECO Enercon Pvt. Limited: Raph - Esp - CFD - Fea - Fes - Testing - TrainingAkasthiyanNo ratings yet

- Mill & Mill Rejects WriteupDocument10 pagesMill & Mill Rejects WriteupEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- SOP of Coal Mill Coal FeederDocument5 pagesSOP of Coal Mill Coal FeederChandra PratamaNo ratings yet

- Coal Mill in Thermal Power PlantDocument3 pagesCoal Mill in Thermal Power Plantkiki270977No ratings yet

- Online Monitoring of Bottom Ash Hopper TemperatureDocument6 pagesOnline Monitoring of Bottom Ash Hopper Temperaturerama jenaNo ratings yet

- Coal Fired Boiler - PrincipalsDocument145 pagesCoal Fired Boiler - PrincipalsArfan AnwarNo ratings yet

- Bcw-Pump: Hayward Tyler TorishimaDocument29 pagesBcw-Pump: Hayward Tyler TorishimaSAROJNo ratings yet

- 800 MWDocument6 pages800 MWRamesh Babu K100% (2)

- Condensate Cycle SystemDocument26 pagesCondensate Cycle SystemBhumit Sagathiya100% (4)

- DPBC Question BankDocument10 pagesDPBC Question BankshubhamNo ratings yet

- Operation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleDocument31 pagesOperation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleAshish Lanjewar100% (3)

- Report #1: Alternating-Current Project: Steam-Electric Power PlantDocument41 pagesReport #1: Alternating-Current Project: Steam-Electric Power PlantKian TecsonNo ratings yet

- Effect of Air Ingress in BoilersDocument6 pagesEffect of Air Ingress in BoilersAnvita Chebrolu100% (1)

- Hydrazine DosingDocument2 pagesHydrazine DosingAnonymous 3HTgMDO100% (1)

- Feed Water HeaterDocument19 pagesFeed Water HeaterMarzouk Abdel Wahed Marzouk100% (1)

- Mill - PerformanceDocument51 pagesMill - PerformanceRavi Satyapal100% (1)

- Turbine OperationDocument30 pagesTurbine OperationGanesh Dasara100% (3)

- Gov Simulator 23.12.06Document46 pagesGov Simulator 23.12.06Sam100% (4)

- CondenserDocument57 pagesCondenserEzhil Vendhan Palanisamy100% (2)

- NDCTDocument127 pagesNDCTYousuf Ali100% (1)

- Aph FireDocument25 pagesAph Firesekhar_ntpcNo ratings yet

- Design Features of Governing System LMW and Kwu TurbinesDocument34 pagesDesign Features of Governing System LMW and Kwu Turbinespankaj100% (1)

- 500mw Boiler Operating InstructionsDocument8 pages500mw Boiler Operating InstructionsRavindrababu Banothu100% (2)

- Thermal Power PlantDocument13 pagesThermal Power PlantSanat KumarNo ratings yet

- Parameter 500 MWDocument3 pagesParameter 500 MWBalraj Padmashali100% (1)

- Stator Water System Case StudyDocument26 pagesStator Water System Case Studyroy1920100% (1)

- Stator Water System ChemistryDocument33 pagesStator Water System ChemistrySudhanshu Sekhar Dash100% (3)

- Presentation On: "Boiler & Auxiliary "Document47 pagesPresentation On: "Boiler & Auxiliary "shivabhaNo ratings yet

- Major Equipments: FOR Asam-Asam Coal Fired Steam Power Plant 2X65 MW (UNIT 3 & 4) Oleh: Arief Daru WibawantoDocument34 pagesMajor Equipments: FOR Asam-Asam Coal Fired Steam Power Plant 2X65 MW (UNIT 3 & 4) Oleh: Arief Daru Wibawantosaiful anwarNo ratings yet

- Boiler and AuxDocument47 pagesBoiler and AuxRajani Kanta Munda100% (1)

- Final Ska CondensorDocument100 pagesFinal Ska Condensor77errorsNo ratings yet

- Cooing Tower PPT (1) HurlDocument36 pagesCooing Tower PPT (1) Hurlpriyajit sahoo100% (1)

- Cooling Water SystemDocument48 pagesCooling Water SystemSandeep Joshi100% (1)

- Primary Water System AbhiDocument17 pagesPrimary Water System Abhisatyanand lakkojuNo ratings yet

- JB ThesisDocument65 pagesJB ThesisSanThosh ChInnuNo ratings yet

- Coal and MillDocument85 pagesCoal and MillKomma Ramesh100% (2)

- BGR Energy Systems LTD Power Projects Division Kakatiya PTP O&M Manual GID-082-ME-BS-1123Document39 pagesBGR Energy Systems LTD Power Projects Division Kakatiya PTP O&M Manual GID-082-ME-BS-1123Komma Ramesh100% (1)

- DM Plant Block by RameshDocument1 pageDM Plant Block by RameshKomma RameshNo ratings yet

- Pre Treatment by RameshDocument6 pagesPre Treatment by RameshKomma RameshNo ratings yet

- DMCW System in Thermal Power PlantDocument2 pagesDMCW System in Thermal Power PlantKomma Ramesh88% (8)

- Coal by RameshDocument9 pagesCoal by RameshKomma RameshNo ratings yet

- Mills or Pulvarisers in Thermal Power Plant: BY Ramesh Komma Senior Chemist /TSGENCO Ktpp-ChelpurDocument6 pagesMills or Pulvarisers in Thermal Power Plant: BY Ramesh Komma Senior Chemist /TSGENCO Ktpp-ChelpurKomma RameshNo ratings yet

- Excise Duty in IndiaDocument3 pagesExcise Duty in IndiaKomma RameshNo ratings yet

- Project Profile On Bakery Products: Mixing of Ingredients Except Flour in Required Proportion in Paste FormDocument4 pagesProject Profile On Bakery Products: Mixing of Ingredients Except Flour in Required Proportion in Paste FormKomma RameshNo ratings yet

- Compasison ChartDocument1 pageCompasison ChartKomma RameshNo ratings yet

- Ion Exchange PDFDocument14 pagesIon Exchange PDFKomma RameshNo ratings yet

- Safety For ChemistsDocument26 pagesSafety For ChemistsKomma RameshNo ratings yet

- Telugu Dictionary PDFDocument221 pagesTelugu Dictionary PDFananthoju90% (50)

- MilsDocument97 pagesMilsKomma Ramesh100% (1)

- Com PaintDocument2 pagesCom PaintKomma RameshNo ratings yet

- Jasmine F Slaughter - Day&Zimmerman - Fall2011Document22 pagesJasmine F Slaughter - Day&Zimmerman - Fall2011studentATtempleNo ratings yet

- National Drug Policy/Generics Law: Romeo R. Andaya, MD, MSCPD, PHD, Fpafp Chair, DPMCH Uph-DjgtmuDocument14 pagesNational Drug Policy/Generics Law: Romeo R. Andaya, MD, MSCPD, PHD, Fpafp Chair, DPMCH Uph-DjgtmuKatNo ratings yet

- CV Sayeed TeachingDocument8 pagesCV Sayeed TeachingGopal ReddyNo ratings yet

- New Haven AnalysisDocument2 pagesNew Haven AnalysisHelen BennettNo ratings yet

- Notified Vide SRO No. 575 Dated 22 May 2019Document3 pagesNotified Vide SRO No. 575 Dated 22 May 2019Hussain RahibNo ratings yet

- Penguin - Magnetic Drive Pump M SeiresDocument4 pagesPenguin - Magnetic Drive Pump M SeiresMiguel Angel LòpezNo ratings yet

- 20T Wheat Flour Milling PlantDocument12 pages20T Wheat Flour Milling Plantshio29100% (2)

- Senate Hearing, 110TH Congress - Scrambling For Health Insurance Coverage: Health Security For People in Late Middle AgeDocument87 pagesSenate Hearing, 110TH Congress - Scrambling For Health Insurance Coverage: Health Security For People in Late Middle AgeScribd Government DocsNo ratings yet

- King Propose Volume 1Document225 pagesKing Propose Volume 1Lorenzo FaddaNo ratings yet

- 13.revised Rate ListDocument51 pages13.revised Rate ListAsif Icbal100% (1)

- Reglarea EmotiilorDocument3 pagesReglarea EmotiilorIulia JudeanuNo ratings yet

- Air Pollution 4. Noise & Light PollutionDocument3 pagesAir Pollution 4. Noise & Light Pollutionclara olsenNo ratings yet

- Hypertension Dash DietDocument32 pagesHypertension Dash DietKAUSHAL ARYA100% (1)

- Average Average Set Ii Set I SampleDocument1 pageAverage Average Set Ii Set I Samplevenkateswara rao PothinaNo ratings yet

- Mazda 3 BrochureDocument16 pagesMazda 3 BrochurebacooNo ratings yet

- Papermaking Little BookDocument8 pagesPapermaking Little BookAkbar Ramadhan SyambasNo ratings yet

- Een Liefdesbrief Aan Amsterdam (By Ryan Bartek)Document5 pagesEen Liefdesbrief Aan Amsterdam (By Ryan Bartek)Ryan Bartek100% (1)

- Cub Cadet Parts Manual For Model 1211 SN 756300 799999Document9 pagesCub Cadet Parts Manual For Model 1211 SN 756300 799999shirley100% (56)

- Nutrition Mopnth Celebration ScriptDocument4 pagesNutrition Mopnth Celebration ScriptLilian Laurel Cariquitan100% (9)

- Biology Laboratory ManualDocument314 pagesBiology Laboratory ManualLeroyJones91% (11)

- Transposition: Shubhangi ShuklaDocument24 pagesTransposition: Shubhangi ShuklaShubhangi ShuklaNo ratings yet

- Aquac Uno HDocument218 pagesAquac Uno Hivancalderon867374No ratings yet

- Psychology Semi-Final ExamDocument2 pagesPsychology Semi-Final ExamMonroe OrtizanoNo ratings yet

- ELSci Q2 Lesson 6 - Organ Systems of Representative AnimalsDocument51 pagesELSci Q2 Lesson 6 - Organ Systems of Representative AnimalsItsClarence100% (2)

- Titration of Vinegar Lab ReportDocument8 pagesTitration of Vinegar Lab ReportIbrahim Abdulkadir JumaNo ratings yet

- Journal of Adolescence: Nele Laporte, Bart Soenens, Katrijn Brenning, Maarten VansteenkisteDocument17 pagesJournal of Adolescence: Nele Laporte, Bart Soenens, Katrijn Brenning, Maarten Vansteenkisterisa agustinaNo ratings yet

- Drug Calculations Reviewer For NursesDocument6 pagesDrug Calculations Reviewer For NursesBreezy ReveloNo ratings yet

- 02 IVD-R Deep-Dive Deck NewDocument215 pages02 IVD-R Deep-Dive Deck Newrajiveacharya100% (1)