Professional Documents

Culture Documents

Young Touchtone Radiators DS - Brochure PDF

Young Touchtone Radiators DS - Brochure PDF

Uploaded by

Andresan507Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Young Touchtone Radiators DS - Brochure PDF

Young Touchtone Radiators DS - Brochure PDF

Uploaded by

Andresan507Copyright:

Available Formats

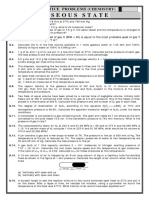

DS1 and DS2

configurations

FE VM HM

vertical core vertical core horizontal core

skid mount remote mount remote mount

fan-on-engine motor-driven fan motor-driven fan

4 sq. ft. to 4 sq. ft. to 4 sq. ft. to

73 sq. ft. core 19 sq. ft. core 19 sq. ft. core

face areas face areas face areas

FR VB HB

Vertical core vertical core Horizontal core

skid mount remote mount remote mount

fan-on-radiator motor-driven fan motor-driven fan

12 sq. ft. to 24 sq. ft. to 24 sq. ft. to

94 sq. ft. core 115 sq. ft. core 115 sq. ft. core

face areas face areas face areas

C O O L I N G S O L U T I O N S F O R P O W E R G E N E R A T I O N

Jackson, Tennessee Lexington, Tennessee Racine, Wisconsin

200 Smith Lane 1000 Young Drive Sales office

Jackson, TN 38308 Lexington, TN 38351 2825 Four Mile Road

PH: 731-424-5045 PH: 731-968-3617 Racine, WI 53404

FX: 731-424-4625 FX: 731-967-7752 PH: 262-639-1010

www.wabtec.com TF: 1-800-238-8230 FX: 262-639-1013

YOUNG TOUCHSTONE … DS1 and DS2 … Modular construction and A Durable FLAT-ROUND mechanical-bond core.

Our signature core provides leak-free

LEADING THROUGH INNOVATION Combining durability and speed. assembly for exactly the C radiators and air-to-air charge air cooling in

radiator you need. even the most punishing diesel and gas

DS1 was developed to combine the proven

engine cooling applications. Single and dual

Durability of Young Touchstone’s B core designs, in side-by-side and front-to-

Nearly a century of heat transfer experience FLAT-ROUND® mechanical-bond radiators with E back arrangements, can be configured with

various tube row and fin densities for

the production Speed of a new modular design

optimal performance and lowest cost.

has made Young Touchstone the leader in system. Our signature FLAT-ROUND radiator core

B Reliable o-ring tank seals. Exclusive o-ring

has delivered exceptional performance for decades in

tank flange seal eliminates leaks due to

heavy-duty cooling system development and the toughest diesel and gas engine cooling applications. gasket failure.

DS1 pre-engineered radiator sub-components can be instantly configured into A C Engine-specific tank designs. Coolant

production. Our innovative products and thousands of combinations for quick proposals and short lead-time deliveries. Young connection types, locations, and sizes are

Touchstone’s application sizing software quickly optimizes your cooling system solution specified for the most common engines

processes have made us the standard by G in power generation service. Coolant

and configures precisely the radiator you need … no more, no less. Our modular

F operating pressure, expansion volume,

production system quickly pulls together the needed pre-configured components for drawdown volume, deaeration, filling, and

which others are judged in power generation, your unique cooling system solution, so your units are assembled and shipped in venting requirements meet each engine

H

record time. DS1 models include vertical core (VM, VB) and horizontal core (HM,HB) D manufacturer’s specific requirements.

rail, off-highway, and transit applications. remote-mounted radiators and genset-mounted fan-on-radiator (FR) and fan-on-engine D Diesel fuel cooler. Innovative packaging

(FE) designs. From 300 kW to 3000 kW, the comprehensive range of DS1 solutions I incorporates fuel cooler inside fan shroud

box with no additional space requirements.

With over 100 patents and unique can meet your power gen cooling requirements for durability and speed.

I E Optimized shroud box. Deep plenums,

DS2 builds on the success of DS1 by incorporating the latest CuproBraze heat ®

close fit fan rings, and large fan openings

manufacturing capabilities, our components maximize airflow distribution across

transfer technology. Young Touchstone’s significant investment in CuproBraze

radiator core.

development and production pays off for you in the new DS2 system.

and systems have consistently met or F High efficiency fans. Airfoil fan blades deliver

maximum cooling airflow with minimal

exceeded our customers’ requirements for FLAT-ROUND® CuproBraze® Technology … horsepower requirements. Fans can be

configured for “Quiet” and “Extra Quiet”

for stronger, more efficient cooling systems sound levels or additional static air

performance, quality, delivery, and cost. restrictions for specific site conditions.

We’ve combined the unique FLAT-ROUND mechanical-

• FLAT-ROUND tubing combines the superior airflow and heat transfer of flat tubes

bond designs and processes (originally developed by G Long-life bearings. Taper lock roller bearings

with reliable tube-to-header mechanical bonding for exceptional durability.

Young Touchstone’s ISO 9001:2000 certified Young Touchstone) with the latest CuproBraze technology with contact seals provide trouble-free

operation and long L10 life.

to produce the toughest, most efficient cooling systems • Mechanically bonded, roller-expanded tube-to-header joint prevents coolant leaks

facilities include extensive R&D, engineering, because there’s no solder to corrode or crack, no braze to fatigue, no rubber H Wide range of electric motors. Three-phase

in the industry. Patent-pending designs integrate proven

motors for any voltage or duty can be

mechanical-bond tube-to-header construction with the superior performance grommets to replace.

configured for electrical requirements

and lean manufacturing operations that characteristics of brazed copper alloy cores. The result is a system that stands up anywhere in the world.

• Half-inch thick steel header plate with machined o-ring tank seal provides incredible

to years of heavy-duty service. I Heavy-duty framework. Through Finite

rigidity and strength and additional protection against coolant leaks.

support our pre-configured and custom Element Analysis (FEA) and testing, our

CuproBraze combines high strength copper fins with flat brass tubes to provide heat heavy gauge steel framework minimizes

• Heavy-wall brass tubing provides strength and damage resistance. With our welded

engineered products. exchangers that are more durable, compact and efficient than fan drive vibration. Frame options for

seam construction, there are no soldered lockseams to corrode or leak.

conventional brazed aluminum. With greater thermal conductivity Seismic Zone 4 and 150-mph hurricane

• DS1 cores use flat copper plate fins soldered to brass tubes for maximum core wind load requirements are available.

and superior corrosion resistance, compact CuproBraze

heat exchangers perform reliably in even the most strength in prime power and CHP applications. All DS1 and DS2 radiators are protected

challenging operating environments. from the elements by a powder coat paint

• DS2 cores use louvered serpentine fins brazed to brass tubes with CuproBraze

finish. For severe environments such as

Young Touchstone’s core design and technology for highly efficient cooling and lowest cost in standby applications. coastal or landfill applications, galvanized

construction incorporates features that frames and Heresite® coated cores may be

Young Touchstone has developed unique processes for machining header holes and specified. Grade 8 premium hardware is

provide maximum radiator durability …

o-ring grooves, transforming tubes from flat to round, annealing and sizing tubes, used to secure components. Yellow zinc

especially important in applications where dichromate finish keeps all wire fan guards,

and mechanically bonding tubes into headers for superior quality using Wabtec’s

severe thermal stress, excessive shock and vibra- bolts, washers and nuts rust free.

lean manufacturing principles. Our CuproBraze furnace and manufacturing capabilities

tion, thermal cycling, or high operating pressures up Supplemental Expansion Deaeration and

can handle core sizes for virtually any power generation cooling requirement.

to 60 psi are present. Drawdown (SEDD) tanks are available to

meet coolant volume requirements of any

installation.

FLAT-ROUND is a registered trademark of Young Touchstone

CuproBraze is a registered trademark of the International Copper Association Ltd.

YOUNG TOUCHSTONE … DS1 and DS2 … Modular construction and A Durable FLAT-ROUND mechanical-bond core.

Our signature core provides leak-free

LEADING THROUGH INNOVATION Combining durability and speed. assembly for exactly the C radiators and air-to-air charge air cooling in

radiator you need. even the most punishing diesel and gas

DS1 was developed to combine the proven

engine cooling applications. Single and dual

Durability of Young Touchstone’s B core designs, in side-by-side and front-to-

Nearly a century of heat transfer experience FLAT-ROUND® mechanical-bond radiators with E back arrangements, can be configured with

various tube row and fin densities for

the production Speed of a new modular design

optimal performance and lowest cost.

has made Young Touchstone the leader in system. Our signature FLAT-ROUND radiator core

B Reliable o-ring tank seals. Exclusive o-ring

has delivered exceptional performance for decades in

tank flange seal eliminates leaks due to

heavy-duty cooling system development and the toughest diesel and gas engine cooling applications. gasket failure.

DS1 pre-engineered radiator sub-components can be instantly configured into A C Engine-specific tank designs. Coolant

production. Our innovative products and thousands of combinations for quick proposals and short lead-time deliveries. Young connection types, locations, and sizes are

Touchstone’s application sizing software quickly optimizes your cooling system solution specified for the most common engines

processes have made us the standard by G in power generation service. Coolant

and configures precisely the radiator you need … no more, no less. Our modular

F operating pressure, expansion volume,

production system quickly pulls together the needed pre-configured components for drawdown volume, deaeration, filling, and

which others are judged in power generation, your unique cooling system solution, so your units are assembled and shipped in venting requirements meet each engine

H

record time. DS1 models include vertical core (VM, VB) and horizontal core (HM,HB) D manufacturer’s specific requirements.

rail, off-highway, and transit applications. remote-mounted radiators and genset-mounted fan-on-radiator (FR) and fan-on-engine D Diesel fuel cooler. Innovative packaging

(FE) designs. From 300 kW to 3000 kW, the comprehensive range of DS1 solutions I incorporates fuel cooler inside fan shroud

box with no additional space requirements.

With over 100 patents and unique can meet your power gen cooling requirements for durability and speed.

I E Optimized shroud box. Deep plenums,

DS2 builds on the success of DS1 by incorporating the latest CuproBraze heat ®

close fit fan rings, and large fan openings

manufacturing capabilities, our components maximize airflow distribution across

transfer technology. Young Touchstone’s significant investment in CuproBraze

radiator core.

development and production pays off for you in the new DS2 system.

and systems have consistently met or F High efficiency fans. Airfoil fan blades deliver

maximum cooling airflow with minimal

exceeded our customers’ requirements for FLAT-ROUND® CuproBraze® Technology … horsepower requirements. Fans can be

configured for “Quiet” and “Extra Quiet”

for stronger, more efficient cooling systems sound levels or additional static air

performance, quality, delivery, and cost. restrictions for specific site conditions.

We’ve combined the unique FLAT-ROUND mechanical-

• FLAT-ROUND tubing combines the superior airflow and heat transfer of flat tubes

bond designs and processes (originally developed by G Long-life bearings. Taper lock roller bearings

with reliable tube-to-header mechanical bonding for exceptional durability.

Young Touchstone’s ISO 9001:2000 certified Young Touchstone) with the latest CuproBraze technology with contact seals provide trouble-free

operation and long L10 life.

to produce the toughest, most efficient cooling systems • Mechanically bonded, roller-expanded tube-to-header joint prevents coolant leaks

facilities include extensive R&D, engineering, because there’s no solder to corrode or crack, no braze to fatigue, no rubber H Wide range of electric motors. Three-phase

in the industry. Patent-pending designs integrate proven

motors for any voltage or duty can be

mechanical-bond tube-to-header construction with the superior performance grommets to replace.

configured for electrical requirements

and lean manufacturing operations that characteristics of brazed copper alloy cores. The result is a system that stands up anywhere in the world.

• Half-inch thick steel header plate with machined o-ring tank seal provides incredible

to years of heavy-duty service. I Heavy-duty framework. Through Finite

rigidity and strength and additional protection against coolant leaks.

support our pre-configured and custom Element Analysis (FEA) and testing, our

CuproBraze combines high strength copper fins with flat brass tubes to provide heat heavy gauge steel framework minimizes

• Heavy-wall brass tubing provides strength and damage resistance. With our welded

engineered products. exchangers that are more durable, compact and efficient than fan drive vibration. Frame options for

seam construction, there are no soldered lockseams to corrode or leak.

conventional brazed aluminum. With greater thermal conductivity Seismic Zone 4 and 150-mph hurricane

• DS1 cores use flat copper plate fins soldered to brass tubes for maximum core wind load requirements are available.

and superior corrosion resistance, compact CuproBraze

heat exchangers perform reliably in even the most strength in prime power and CHP applications. All DS1 and DS2 radiators are protected

challenging operating environments. from the elements by a powder coat paint

• DS2 cores use louvered serpentine fins brazed to brass tubes with CuproBraze

finish. For severe environments such as

Young Touchstone’s core design and technology for highly efficient cooling and lowest cost in standby applications. coastal or landfill applications, galvanized

construction incorporates features that frames and Heresite® coated cores may be

Young Touchstone has developed unique processes for machining header holes and specified. Grade 8 premium hardware is

provide maximum radiator durability …

o-ring grooves, transforming tubes from flat to round, annealing and sizing tubes, used to secure components. Yellow zinc

especially important in applications where dichromate finish keeps all wire fan guards,

and mechanically bonding tubes into headers for superior quality using Wabtec’s

severe thermal stress, excessive shock and vibra- bolts, washers and nuts rust free.

lean manufacturing principles. Our CuproBraze furnace and manufacturing capabilities

tion, thermal cycling, or high operating pressures up Supplemental Expansion Deaeration and

can handle core sizes for virtually any power generation cooling requirement.

to 60 psi are present. Drawdown (SEDD) tanks are available to

meet coolant volume requirements of any

installation.

FLAT-ROUND is a registered trademark of Young Touchstone

CuproBraze is a registered trademark of the International Copper Association Ltd.

DS1 and DS2

configurations

FE VM HM

vertical core vertical core horizontal core

skid mount remote mount remote mount

fan-on-engine motor-driven fan motor-driven fan

4 sq. ft. to 4 sq. ft. to 4 sq. ft. to

73 sq. ft. core 19 sq. ft. core 19 sq. ft. core

face areas face areas face areas

FR VB HB

Vertical core vertical core Horizontal core

skid mount remote mount remote mount

fan-on-radiator motor-driven fan motor-driven fan

12 sq. ft. to 24 sq. ft. to 24 sq. ft. to

94 sq. ft. core 115 sq. ft. core 115 sq. ft. core

face areas face areas face areas

C O O L I N G S O L U T I O N S F O R P O W E R G E N E R A T I O N

Jackson, Tennessee Lexington, Tennessee Oak Creek, Wisconsin

200 Smith Lane 1000 Young Drive Sales office

Jackson, TN 38308 Lexington, TN 38351 7270 S 13th St, Ste 201

PH: 731-424-5045 PH: 731-968-3617 Oak Creek, WI 53154

FX: 731-424-4625 FX: 731-967-7752 PH: 414-768-7420

www.wabtec.com TF: 1-800-238-8230 FX: 414-762-0632

You might also like

- J. M. Haile Molecular Dynamics Simulation Elementary Methods 1992Document505 pagesJ. M. Haile Molecular Dynamics Simulation Elementary Methods 1992Anonymous HijNGQtN100% (4)

- Eagleburgmann Compressor Seals: Dry Gas Seal UpgradesDocument30 pagesEagleburgmann Compressor Seals: Dry Gas Seal UpgradesTasawwur TahirNo ratings yet

- Siemens Energy Turblex Full Line BulletinDocument6 pagesSiemens Energy Turblex Full Line BulletinKunming WangNo ratings yet

- Quick Connectors Catalog PDFDocument15 pagesQuick Connectors Catalog PDFSivakumar AmbikapathyNo ratings yet

- Iso 17640 2017 en PDFDocument11 pagesIso 17640 2017 en PDFTanveer Ahmed Quadri100% (1)

- Pentair Series H ValveDocument78 pagesPentair Series H Valvea_osorioNo ratings yet

- Manual HGDocument36 pagesManual HGF Sisniegas GCNo ratings yet

- SAE Automobile Heat Transfer 2Document281 pagesSAE Automobile Heat Transfer 2sardhan.rajender84100% (1)

- A Short Course On Cooling SystemsDocument21 pagesA Short Course On Cooling Systemsnemo_nadalNo ratings yet

- TRV 99778 Marathon Oil Ef LLC 6002Document14 pagesTRV 99778 Marathon Oil Ef LLC 6002Hero BassballNo ratings yet

- Content ServerDocument21 pagesContent ServerÁngelCarlosGarcíaNo ratings yet

- Saidur2010 - Energy, Exergy and Economic Analysis of Industrial Boilers PDFDocument10 pagesSaidur2010 - Energy, Exergy and Economic Analysis of Industrial Boilers PDFRuben Alejandro Velandia UsugaNo ratings yet

- Walterscheidt Metric Tube FittingsDocument68 pagesWalterscheidt Metric Tube FittingsM MNo ratings yet

- MODINE Service TrainingDocument37 pagesMODINE Service TrainingSeshagiri DeenadayaluNo ratings yet

- Centrifugal Damper CatDocument8 pagesCentrifugal Damper CatAdil Shahzad100% (2)

- High Ductility Aluminum Alloy Made From Powder by Friction ExtrusionDocument6 pagesHigh Ductility Aluminum Alloy Made From Powder by Friction ExtrusionRaistlin1No ratings yet

- Micro Channel Heat ExchangersDocument2 pagesMicro Channel Heat ExchangersVishal SaxenaNo ratings yet

- Noxon Butt Weld FittingsDocument28 pagesNoxon Butt Weld FittingsZoran DanilovNo ratings yet

- Unilab Microchannel: Over 300 Customers in 50 CountriesDocument2 pagesUnilab Microchannel: Over 300 Customers in 50 CountriesUnilabNo ratings yet

- Danfoss Scroll CompressorsDocument6 pagesDanfoss Scroll Compressorsfaizan abbasiNo ratings yet

- kfp3 Ball ValvesDocument20 pageskfp3 Ball ValvesKristy DavisNo ratings yet

- 3D Printing of Core and Cavity InsertsDocument15 pages3D Printing of Core and Cavity InsertsSushmaNo ratings yet

- "Development of Single Cylinder Four Stroke Low Heat Rejection Engine Using Piston Coating"-A ReviewDocument5 pages"Development of Single Cylinder Four Stroke Low Heat Rejection Engine Using Piston Coating"-A Reviewnityam100% (1)

- Coolling System CalculusDocument33 pagesCoolling System CalculusȘtefan PravățNo ratings yet

- Ammonia Converter FailureDocument15 pagesAmmonia Converter FailureAnonymous UoHUagNo ratings yet

- An Analytical Study On Heat Transfer Performance ofDocument18 pagesAn Analytical Study On Heat Transfer Performance ofsanchez_1256No ratings yet

- Design Co2 EvaporatorsDocument7 pagesDesign Co2 EvaporatorsYutt Watt100% (1)

- Dynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene BlendsDocument11 pagesDynamic Reaction Inside Co-Rotating Twin Screw Extruder. II. Waste Ground Rubber Tire Powder - Polypropylene Blendspickpocket27No ratings yet

- Aluminum - Min Bend Radius PDFDocument5 pagesAluminum - Min Bend Radius PDFmimi_chan_17No ratings yet

- Product Catalog Samson at A Glance: Production Sites StaffDocument174 pagesProduct Catalog Samson at A Glance: Production Sites Staffkhaled saeedNo ratings yet

- Anti-Surge - Valve - ROI - REXA - 2Document10 pagesAnti-Surge - Valve - ROI - REXA - 2Hash LalaNo ratings yet

- Standart 0508Document3 pagesStandart 0508carlosNo ratings yet

- AKG enDocument10 pagesAKG encarlosNo ratings yet

- Challenges in Supercritical CO2 Power Cycle Technology and First OperationalDocument16 pagesChallenges in Supercritical CO2 Power Cycle Technology and First OperationalAdven Brilian100% (1)

- I-Manager 4.41.00 English OperationManual (EM07A052B) tcm135-72968Document146 pagesI-Manager 4.41.00 English OperationManual (EM07A052B) tcm135-72968Luka LazovicNo ratings yet

- Technical Guidance Notes M16 Monitoring Volatile Organic Compounds in Stack Gas Emissions Environment Agency UKDocument16 pagesTechnical Guidance Notes M16 Monitoring Volatile Organic Compounds in Stack Gas Emissions Environment Agency UKheljoalNo ratings yet

- Controlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingDocument9 pagesControlling Ejector Performance: BY C. G. Blatchley Schutte & KoertingCan YıldırımNo ratings yet

- Heat Cycles, Heat Engines, & Real Devices: John Jechura - Jjechura@mines - Edu Updated: January 4, 2015Document21 pagesHeat Cycles, Heat Engines, & Real Devices: John Jechura - Jjechura@mines - Edu Updated: January 4, 2015Jennifer Sophia Tapia Huamani100% (1)

- How Chemical Engineering Will Drive The 21st CenturyDocument71 pagesHow Chemical Engineering Will Drive The 21st CenturyAjeya Bandyopadhyay100% (1)

- Design, Manufacture, Installation, Operation, and Maintenance of Valves Used in Liquid Oxygen and Cold Gaseous Oxygen SystemsDocument35 pagesDesign, Manufacture, Installation, Operation, and Maintenance of Valves Used in Liquid Oxygen and Cold Gaseous Oxygen SystemsAndika PratamaNo ratings yet

- Tutorial SCO2 WilkesDocument99 pagesTutorial SCO2 WilkesAshraf Zoubi100% (1)

- TEP10 LNG Heat Exchangers 2008Document43 pagesTEP10 LNG Heat Exchangers 2008yusuf100% (1)

- Cylinder Rings Design Assessment High Performance Pistons PDFDocument5 pagesCylinder Rings Design Assessment High Performance Pistons PDFTalha UsmaniNo ratings yet

- 22 G3512 C555Document4 pages22 G3512 C555texwan_No ratings yet

- Aspen Phys Prop Models V7.3.2 PDFDocument338 pagesAspen Phys Prop Models V7.3.2 PDFBamrung SungnoenNo ratings yet

- Steam Air Ejector Performance and Its Dimensional ParametersDocument296 pagesSteam Air Ejector Performance and Its Dimensional ParametersGuru Raja Ragavendran NagarajanNo ratings yet

- Dry Gas Seals2FDocument20 pagesDry Gas Seals2FwmefatihNo ratings yet

- Magnetic Bearing Oil Free Technology MN Ashrae PDFDocument27 pagesMagnetic Bearing Oil Free Technology MN Ashrae PDFtpqnhat100% (1)

- Hitachi Scroll CompressorsDocument6 pagesHitachi Scroll CompressorstarunNo ratings yet

- Centrif Compr Droplet ErosionDocument6 pagesCentrif Compr Droplet ErosionrossifrancescoNo ratings yet

- Eagleburgmann Compressor Seals Traditional Barrier SealsDocument20 pagesEagleburgmann Compressor Seals Traditional Barrier SealsTasawwur TahirNo ratings yet

- LMF-GP LX15-8 - 10 - 13Document2 pagesLMF-GP LX15-8 - 10 - 13MAZEN0% (1)

- Hetland Lynum Santen GarveriDocument16 pagesHetland Lynum Santen GarveriMarco Bruto HorseshoeNo ratings yet

- Effect of Piston Design and Optimization ReciprocatingDocument129 pagesEffect of Piston Design and Optimization ReciprocatingRajendra JadhavNo ratings yet

- Internal Combustion Engines and Gas Turbines: Prof S. K. AcharyaDocument61 pagesInternal Combustion Engines and Gas Turbines: Prof S. K. AcharyaAtul Samal100% (1)

- 17-03 Overpressure Blowdown PDFDocument9 pages17-03 Overpressure Blowdown PDFJoyNo ratings yet

- Dresser-Rand Group Inc - FinalDocument24 pagesDresser-Rand Group Inc - FinalMatt JonesNo ratings yet

- Castor Oil Thermodynamic Model For HysysDocument6 pagesCastor Oil Thermodynamic Model For HysystenrebracNo ratings yet

- Optimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073Document6 pagesOptimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073fujiman35No ratings yet

- Catalogue Tan Hung 17 (1) .9.09Document48 pagesCatalogue Tan Hung 17 (1) .9.09ngocdhxd92No ratings yet

- Retrofits CatalogDocument7 pagesRetrofits CatalogSuhas JadhavNo ratings yet

- Morelli Motori AVRDocument2 pagesMorelli Motori AVRAndresan507No ratings yet

- Easygen-3000 Series (Package P1) Genset Control: ConfigurationDocument348 pagesEasygen-3000 Series (Package P1) Genset Control: ConfigurationAndresan507No ratings yet

- Olympian 4001 OmniMetrix Installation Guide PDFDocument2 pagesOlympian 4001 OmniMetrix Installation Guide PDFAndresan507No ratings yet

- Arctic PlatinumDocument2 pagesArctic PlatinumAndresan507100% (1)

- Cat Electronic Control ModuleDocument2 pagesCat Electronic Control ModuleAndresan50767% (6)

- Microporous and Mesoporous Materials: Christoph Buttersack, Jens M Ollmer, J Org Hofmann, Roger GL AserDocument8 pagesMicroporous and Mesoporous Materials: Christoph Buttersack, Jens M Ollmer, J Org Hofmann, Roger GL AserKatiaPeraltaNo ratings yet

- SunscreenDocument44 pagesSunscreenArtyom FreemanNo ratings yet

- Elastic Potential Energy: English For PhysicsDocument2 pagesElastic Potential Energy: English For Physicshaura 30anNo ratings yet

- Finished Version of L & CDocument94 pagesFinished Version of L & Crakesh yadavNo ratings yet

- Pvsyst Trial Pvsyst Trial Pvsyst Trial Pvsyst Trial: Grid-Connected System: Simulation ParametersDocument5 pagesPvsyst Trial Pvsyst Trial Pvsyst Trial Pvsyst Trial: Grid-Connected System: Simulation ParametersgaladrialNo ratings yet

- CH 6 Hoist & Traveling GearDocument36 pagesCH 6 Hoist & Traveling GearEbrahim AliNo ratings yet

- Student Exploration: Ripple Tank: Vocabulary: Constructive Interference, Crest, Destructive InterferenceDocument7 pagesStudent Exploration: Ripple Tank: Vocabulary: Constructive Interference, Crest, Destructive InterferenceMadison zzstu MorsonNo ratings yet

- Se Commercial Three Phase Inverters For Medium Voltage GridDocument2 pagesSe Commercial Three Phase Inverters For Medium Voltage GridDaniel CastroNo ratings yet

- API-650 Preguntas y Respuestas ImpresoDocument49 pagesAPI-650 Preguntas y Respuestas ImpresoJuan Bedolla FloresNo ratings yet

- Cambridge International AS & A Level: Chemistry 9701/12Document16 pagesCambridge International AS & A Level: Chemistry 9701/12nilu23No ratings yet

- 0) Administrative Affairs: Instructor: Sebastian Wüster, IISER Bhopal, 2018Document9 pages0) Administrative Affairs: Instructor: Sebastian Wüster, IISER Bhopal, 2018Hussain Mahammad Habib 19142No ratings yet

- Geotechnical Engineering 5Document1 pageGeotechnical Engineering 5YeddaMIlaganNo ratings yet

- Spe 182660 PaDocument29 pagesSpe 182660 PaSanjay singhNo ratings yet

- LG 55ub8500 Sa LJ41V.Document131 pagesLG 55ub8500 Sa LJ41V.manoranjan0% (1)

- The Transistor As A SwitchDocument9 pagesThe Transistor As A SwitchSoodamany Ponnu Pandian80% (5)

- Energy Recovery From Landing AircraftDocument8 pagesEnergy Recovery From Landing AircraftRaniero FalzonNo ratings yet

- Rcd-I SyllabusDocument2 pagesRcd-I SyllabusDr. M.V.Krishna RaoNo ratings yet

- Nord Tanami 12Document5 pagesNord Tanami 12Nagyné ErikaNo ratings yet

- Cpp-Gaseous State - RGVDocument2 pagesCpp-Gaseous State - RGVGauri KabraNo ratings yet

- CH 101: Physical Chemistry Practicals: Determination of The Equilibrium Constant For A Chemical ReactionDocument34 pagesCH 101: Physical Chemistry Practicals: Determination of The Equilibrium Constant For A Chemical ReactionEvelyn MushangweNo ratings yet

- Abaagalwa MwennaDocument2 pagesAbaagalwa Mwennasekyanzi pascalNo ratings yet

- Truss BridgeDocument18 pagesTruss BridgeAkashNo ratings yet

- Topics in Mechanical Behavior of Materials: DislocationsDocument13 pagesTopics in Mechanical Behavior of Materials: DislocationsAman Kumar VermaNo ratings yet

- Care and MaintenanceDocument15 pagesCare and MaintenanceIonut Marian PenciuNo ratings yet

- L4-6KR Using ManualDocument18 pagesL4-6KR Using ManualАлексей ЖижченкоNo ratings yet

- Flygt 2670 Dewatering Pump: Designed Without CompromiseDocument2 pagesFlygt 2670 Dewatering Pump: Designed Without CompromiseEdy Renato Zapeta100% (1)

- Studies 2019 May P1Document25 pagesStudies 2019 May P1nathan.kimNo ratings yet

- Eland Cables Power Networks CatalogueDocument68 pagesEland Cables Power Networks CatalogueRyo TevezNo ratings yet