Professional Documents

Culture Documents

Cored Wires: Cement Industry

Cored Wires: Cement Industry

Uploaded by

munal23Copyright:

Available Formats

You might also like

- U1CDocument4 pagesU1CAdriana HernandezNo ratings yet

- CAVSMA1Document2 pagesCAVSMA1Bill MurrayNo ratings yet

- Astm A700Document40 pagesAstm A700geav25653855No ratings yet

- TDS Hardcarb 60 (#ETT - EN - 20.1)Document2 pagesTDS Hardcarb 60 (#ETT - EN - 20.1)Jimit ShahNo ratings yet

- F10 09 Ref Eng Macropoxy FTDocument2 pagesF10 09 Ref Eng Macropoxy FTsaul xool mayNo ratings yet

- Steel Sheet Pile CatalogueDocument80 pagesSteel Sheet Pile CatalogueBrian TanNo ratings yet

- Alambre SoudokayDocument8 pagesAlambre SoudokayEzequielNo ratings yet

- MIL-C-16173D (Corrosion Preventive)Document28 pagesMIL-C-16173D (Corrosion Preventive)Sinan ChenNo ratings yet

- WM Dry Lubricants GB Fiche A4 R0120 BDDocument2 pagesWM Dry Lubricants GB Fiche A4 R0120 BDDr ZoggNo ratings yet

- Abratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeDocument2 pagesAbratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeCasa de Adoración ConcepciónNo ratings yet

- Soudokay Flux Cored Wires GBDocument8 pagesSoudokay Flux Cored Wires GBkamals55No ratings yet

- High Performance: Properties & General DataDocument4 pagesHigh Performance: Properties & General DataRaghNo ratings yet

- Icf 296T8 Unv Eb81 UDocument2 pagesIcf 296T8 Unv Eb81 UstevencjzNo ratings yet

- Dioda U1620gDocument5 pagesDioda U1620gNayla AzzahraNo ratings yet

- Teromatec An 4617Document2 pagesTeromatec An 4617erikaNo ratings yet

- Mil F 18870eDocument32 pagesMil F 18870eblissliNo ratings yet

- Carbon & Alloy SteelDocument10 pagesCarbon & Alloy SteelMaswindo CikarangNo ratings yet

- Bohler Welding Catalogue EriksDocument32 pagesBohler Welding Catalogue Eriksfarshid KarpasandNo ratings yet

- Product Data Sheet S KA BA V - ENDocument12 pagesProduct Data Sheet S KA BA V - ENdaniela hritucNo ratings yet

- Economical, Quick and Easy: CatalogueDocument44 pagesEconomical, Quick and Easy: CatalogueFreza Hadi PratamaNo ratings yet

- Carbodur 600 B-E6um60Document1 pageCarbodur 600 B-E6um60ali torabiNo ratings yet

- UTP Raiilways BrochureDocument8 pagesUTP Raiilways Brochurekamals55No ratings yet

- ITT American Electric Bay Beam Luminaire Series 56-57-156-157 Spec Sheet 9-81Document12 pagesITT American Electric Bay Beam Luminaire Series 56-57-156-157 Spec Sheet 9-81Alan MastersNo ratings yet

- WJ 2013 05Document128 pagesWJ 2013 05Matija BušićNo ratings yet

- 12 Excavator AttachmentsDocument31 pages12 Excavator AttachmentsAndrey GyrychNo ratings yet

- Data SheetDocument12 pagesData SheetArellano ArellanoNo ratings yet

- Precast Concrete PilesDocument4 pagesPrecast Concrete PilesFreddie KooNo ratings yet

- Amcrps Gen Cat GB 2012-2Document52 pagesAmcrps Gen Cat GB 2012-2VardhanNo ratings yet

- AWS - Welding Journal - 2004 - 02Document117 pagesAWS - Welding Journal - 2004 - 02arnoldbatista55No ratings yet

- Brochure Catalogue EnglishDocument20 pagesBrochure Catalogue EnglishHukleberipenNo ratings yet

- 200A, 15 KV Class Loadbreak ElbowDocument4 pages200A, 15 KV Class Loadbreak ElbowJose Reinoso MendezNo ratings yet

- TDS Hardcarb 70 (#ET - EN - 20.1)Document2 pagesTDS Hardcarb 70 (#ET - EN - 20.1)Jimit ShahNo ratings yet

- Aws WJ 201306 PDFDocument170 pagesAws WJ 201306 PDFRenato Barreto100% (1)

- Carbo L Ag 40 SN eDocument1 pageCarbo L Ag 40 SN efadfadg2No ratings yet

- Thông số kĩ thuật Bê Tông Chịu Nhiệt 2015-English VersionDocument2 pagesThông số kĩ thuật Bê Tông Chịu Nhiệt 2015-English VersionĐức BkNo ratings yet

- Material Listing & Specification (Structural Metals)Document18 pagesMaterial Listing & Specification (Structural Metals)myn maliQueNo ratings yet

- CCWDocument2 pagesCCWspearboraNo ratings yet

- Ampco Alloy BrochureDocument6 pagesAmpco Alloy BrochureCopper AmpcometalNo ratings yet

- Mild Steel Mig Welding WireDocument2 pagesMild Steel Mig Welding WireDheebika MurugesanNo ratings yet

- Irf644N, Irf644Ns, Irf644Nl, Sihf644N, Sihf644Ns, Sihf644Nl: Vishay SiliconixDocument8 pagesIrf644N, Irf644Ns, Irf644Nl, Sihf644N, Sihf644Ns, Sihf644Nl: Vishay SiliconixLuiz LuizNo ratings yet

- Vertical Lineshaft Turbine PumpsDocument8 pagesVertical Lineshaft Turbine PumpsHudson de Andrade e SilvaNo ratings yet

- Steel Foundation Solutions: General Catalogue 2017Document64 pagesSteel Foundation Solutions: General Catalogue 2017Imran HaiderNo ratings yet

- AM General Catalogue 2018 PDFDocument64 pagesAM General Catalogue 2018 PDFAde SetiawanNo ratings yet

- Kemet Metallographic BrochureDocument24 pagesKemet Metallographic Brochurevantuan17792No ratings yet

- ºÀ° - Ä Å Î × ¿ ® ÃÖÁDocument14 pagesºÀ° - Ä Å Î × ¿ ® ÃÖÁabhijit.ghotaneNo ratings yet

- Catalog Sheet Piles ARCELORDocument64 pagesCatalog Sheet Piles ARCELORpolpositionNo ratings yet

- Amtech Inv Handout Rev 1115 PDFDocument2 pagesAmtech Inv Handout Rev 1115 PDFTom TomNo ratings yet

- Asia Roadshow 2017 ShortDocument72 pagesAsia Roadshow 2017 ShortjparsbNo ratings yet

- Multi-Set II Drop-In AnchorsDocument5 pagesMulti-Set II Drop-In AnchorsReinel OrjuelaNo ratings yet

- Aurora: AE MC-120BD SeriesDocument2 pagesAurora: AE MC-120BD SeriestasoNo ratings yet

- Technical Specifi Cations: SL-KZ-001 Rev. DDocument2 pagesTechnical Specifi Cations: SL-KZ-001 Rev. DFernando SalamancaNo ratings yet

- Genaral Catalogue Sheet Piling 2019Document64 pagesGenaral Catalogue Sheet Piling 2019santanu mukherjeeNo ratings yet

- Hardfacing: WA Cored WiresDocument15 pagesHardfacing: WA Cored WiresThanh TamNo ratings yet

- Xuper 646 XHDDocument2 pagesXuper 646 XHDJuan LondonoNo ratings yet

- Ni Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsDocument6 pagesNi Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsLeandro Dilkin ConsulNo ratings yet

- Slab EM Mold RefList-yearDocument4 pagesSlab EM Mold RefList-yearBhoomaiah SunkenapalliNo ratings yet

- Amphenol Pyle Starline and EX CatalogDocument82 pagesAmphenol Pyle Starline and EX Catalogari suburNo ratings yet

- An 4633Document2 pagesAn 4633erikaNo ratings yet

- Copper Electrodeposition for Nanofabrication of Electronics DevicesFrom EverandCopper Electrodeposition for Nanofabrication of Electronics DevicesNo ratings yet

- Catalogue English PDFDocument71 pagesCatalogue English PDFmunal23No ratings yet

- DIN EN ISO 9001:2000 Certificate Reg. No: 01 100 75147Document39 pagesDIN EN ISO 9001:2000 Certificate Reg. No: 01 100 75147munal23No ratings yet

- Wing Fan 1 PDFDocument2 pagesWing Fan 1 PDFmunal23No ratings yet

- Equipment Critical Analysis: The Need For An Effective Maintenance ProgramDocument7 pagesEquipment Critical Analysis: The Need For An Effective Maintenance Programmunal23No ratings yet

- Benefits of Lubricant Oil Analysis For Maintenance Decision Support: A Case StudyDocument8 pagesBenefits of Lubricant Oil Analysis For Maintenance Decision Support: A Case Studymunal23No ratings yet

- Neuer Rostfreier Maraging-Stahl Mit Hoher Festigkeif Für Komplexe Federn Aus BandDocument7 pagesNeuer Rostfreier Maraging-Stahl Mit Hoher Festigkeif Für Komplexe Federn Aus BandHagen_of_TronjeNo ratings yet

- Pressure Vessel - Example 62Document78 pagesPressure Vessel - Example 62Mohamedsabry96No ratings yet

- CSWIP 3 1 Exam Question and AnswersDocument23 pagesCSWIP 3 1 Exam Question and AnswersIyappan Balu100% (1)

- API Recommended Practice 583: Corrosion Under Insulation and FireproofingDocument4 pagesAPI Recommended Practice 583: Corrosion Under Insulation and FireproofingOgnjen Vukasinovic100% (1)

- Masoneilan CatalogDocument24 pagesMasoneilan CatalogsumsolcaggNo ratings yet

- BSPDocument94 pagesBSPAchalaShrotey0% (1)

- Industrial Policy APDocument6 pagesIndustrial Policy APapi-3711789No ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- Ancon Masonry Support, Windposts & LintelsDocument44 pagesAncon Masonry Support, Windposts & LintelsMelissa GrahamNo ratings yet

- 1045 Steel Flat BarDocument4 pages1045 Steel Flat BarFebri SSNo ratings yet

- SM2-3 Physics and Metallurgy of Welded Joints: Dr. Tarek BEN AMEUR, ProfessorDocument23 pagesSM2-3 Physics and Metallurgy of Welded Joints: Dr. Tarek BEN AMEUR, ProfessorAhmedNo ratings yet

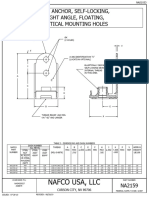

- NA2159Document2 pagesNA2159Bogdan RusuNo ratings yet

- Australian Military Forces Identification ListDocument55 pagesAustralian Military Forces Identification Listpercyolivas100% (1)

- Full Test 2 (Key) PDFDocument5 pagesFull Test 2 (Key) PDFhoang lichNo ratings yet

- DO - 033 - S2013 Generic Specs For Rockfall Protection Systems Item 522Document14 pagesDO - 033 - S2013 Generic Specs For Rockfall Protection Systems Item 522Andrei AlidoNo ratings yet

- Prepared By:-Sumant Sahu Metallurgy 3203808302Document21 pagesPrepared By:-Sumant Sahu Metallurgy 3203808302Rahul PandeyNo ratings yet

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- FlenderTechnicalHandbook PDFDocument79 pagesFlenderTechnicalHandbook PDFWagner OliveiraNo ratings yet

- Leo Workshop: JSW Steels Ltd. Vijayanagara WorksDocument16 pagesLeo Workshop: JSW Steels Ltd. Vijayanagara WorksBinod Kumar PadhiNo ratings yet

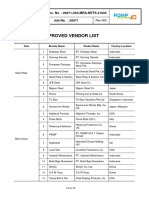

- Approved Vendor ListDocument8 pagesApproved Vendor ListHery MukhlisNo ratings yet

- Thesis 1984 Austin PDFDocument481 pagesThesis 1984 Austin PDFZain Al AbidinNo ratings yet

- Steel Glossary SBBDocument36 pagesSteel Glossary SBBshraktuNo ratings yet

- Surface Cladding and Hardfacing MethodsDocument6 pagesSurface Cladding and Hardfacing MethodsEduardo GonzálezNo ratings yet

- TurnbuckleDocument6 pagesTurnbuckleAbi Latiful HakimNo ratings yet

- Friday: For Subscription Please Contact Phone: 67231665Document2 pagesFriday: For Subscription Please Contact Phone: 67231665Gopi NathNo ratings yet

- Bs 15610Document13 pagesBs 15610Jamil SalmanNo ratings yet

- Hilti Hit Hy 170Document37 pagesHilti Hit Hy 170Adhil RamsurupNo ratings yet

- PISR1-En-US SiC Shell & Tube Heat Exchanger - SR SeriesDocument2 pagesPISR1-En-US SiC Shell & Tube Heat Exchanger - SR SeriesViajante_santosNo ratings yet

- Welding Filler MetalDocument1 pageWelding Filler MetalBharath KumarNo ratings yet

Cored Wires: Cement Industry

Cored Wires: Cement Industry

Uploaded by

munal23Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cored Wires: Cement Industry

Cored Wires: Cement Industry

Uploaded by

munal23Copyright:

Available Formats

CORED WIRES

Designed for Rebuilding & Hardfacing applications in the CEMENT INDUSTRY

I Soudokay,

within the Böhler

Welding Group, is

specialised in research,

production and sales of

flux cored wire for hardfacing

and strip/flux products for

strip cladding.

Please contact us for more information.

I SOUDOKAY SA I

I RUE DE L’YSER 2 I

I B-7180 SENEFFE I BELGIUM I

I T +32 (0)64 510 225 I F +32 (0)64 510 230 I

I soudokay@soudokay.be I www.soudokay.com I

I Soudokay can modify this document without any previous notice.

The list of products present in the Soudokay catalogue is not restrictive.

0298·08·0063

Doc FCAW•2008•EN•Cement Industry•Rev 01

I The range of Soudokay products is much wider.

1 I SELECTION OF MOST APPLIED PRODUCTS Complete catalogue is available on request: doc•FCAW•SMAW•S•03/08•EN

e-mail: soudokay@soudokay.be

WELDING PROCESS 2 I SOME OF OUR APPLICATIONS

PRODUCT HARDNESS DESCRIPTION

OA GS SA

SK AP-O x I All purpose alloy, rebuilding and joining of carbon and 14% Manganese steels,

REBUILDING OR BUFFER

200HB buffer layer prior to deposit hard overlay. Railway rails and crossovers,

45HRc* mill shaft drive ends, gyratory crusher mantles, repointing of shovel teeth,

SK AP-S x buffer layer for inter-particles crushers...

LAYER

160HB I Austenitic alloy type 18 Cr8Ni7Mn designed for joining dissimilar metals and

SK 402-O x 45HRc* for buffer layer deposits prior to hard surfacing...

I SK 162-O

SK BU-O x 285HB I All purpose alloy, rebuilding of carbon steels, buffer layer prior to deposit hard overlay...

I SK 260NbC-O

SK AP-O x I All purpose alloy, rebuilding and joining of carbon and 14% Manganese steels,

HIGH IMPACT AND

200HB

LOW ABRASION

buffer layer prior to deposit hard overlay. Railway rails and crossovers,

450HB* mill shaft drive ends, gyratory crusher mantles, repointing of shovel teeth,

SK AP-S x buffer layer for inter-particles crushers...

SK 402-O x 160HB I Austenitic alloy type 18 Cr8Ni7Mn designed for joining dissimilar metals and

45HRc* for buffer layer deposits prior to hard surfacing...

I SK A45-O

I SK 258TiC-O

SK 242-O/S x x 40HRc

MEDIUM IMPACT

AND MEDIUM

ABRASION

I Rebuilding and hard surfacing alloy for carbon steel parts,

SK 252-O/S x x 44HRc subject to adhesive wear with impact...

I SK 866-O

I SK 258NbC-SA

SK 350-O/S x x 360HB

SK 256-O x 63HRc

LOW IMPACT AND HIGH ABRASION

I High chromium carbide alloy designed to resist high stress grinding abrasion

SK 162-O x 62HRc coupled with low impact. The deposits will readily show stress relief cracks...

SK 866-O x 60HRc

I Chromium-Niobium alloy designed to resist high stress grinding abrasion at service

SK A43-O x 63HRc temperature not exceeding 450°C. The deposits will readily show stress relief cracks...

I Chromium-Niobium-Molybdenum alloy with addition of Tungsten and Vanadium designed

SK A45-O x 63HRc to resist high stress grinding abrasion with low impact and solid erosion at service I SK AP-O

temperatures up to 650°C. The deposits will readily show stress relief cracks... I SK AP-O + SK A43-0

I Martensitic Chromium-Titanium alloy designed to resist high stress abrasion

SK 258TiC-O x 58HRc

HIGH IMPACT AND HIGH

with heavy impact. Deposits usually do not relief cracks...

SK 258NbC-O x

ABRASION

54HRc

SK 258NbC-SA x I Martensitic Chromium-Niobium alloy designed to resist high stress abrasion

with heavy impact. Deposits usually do not relief cracks...

SK 260NbC-O x

60HRc I SK A43-O

SK 260NbC-SA x

*After Work Hardening I The list of products is not a limiting list. Please do not hesitate to contact us for other available products.

You might also like

- U1CDocument4 pagesU1CAdriana HernandezNo ratings yet

- CAVSMA1Document2 pagesCAVSMA1Bill MurrayNo ratings yet

- Astm A700Document40 pagesAstm A700geav25653855No ratings yet

- TDS Hardcarb 60 (#ETT - EN - 20.1)Document2 pagesTDS Hardcarb 60 (#ETT - EN - 20.1)Jimit ShahNo ratings yet

- F10 09 Ref Eng Macropoxy FTDocument2 pagesF10 09 Ref Eng Macropoxy FTsaul xool mayNo ratings yet

- Steel Sheet Pile CatalogueDocument80 pagesSteel Sheet Pile CatalogueBrian TanNo ratings yet

- Alambre SoudokayDocument8 pagesAlambre SoudokayEzequielNo ratings yet

- MIL-C-16173D (Corrosion Preventive)Document28 pagesMIL-C-16173D (Corrosion Preventive)Sinan ChenNo ratings yet

- WM Dry Lubricants GB Fiche A4 R0120 BDDocument2 pagesWM Dry Lubricants GB Fiche A4 R0120 BDDr ZoggNo ratings yet

- Abratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeDocument2 pagesAbratec 6710 XHD: Multi-Carbide Hardfacing ElectrodeCasa de Adoración ConcepciónNo ratings yet

- Soudokay Flux Cored Wires GBDocument8 pagesSoudokay Flux Cored Wires GBkamals55No ratings yet

- High Performance: Properties & General DataDocument4 pagesHigh Performance: Properties & General DataRaghNo ratings yet

- Icf 296T8 Unv Eb81 UDocument2 pagesIcf 296T8 Unv Eb81 UstevencjzNo ratings yet

- Dioda U1620gDocument5 pagesDioda U1620gNayla AzzahraNo ratings yet

- Teromatec An 4617Document2 pagesTeromatec An 4617erikaNo ratings yet

- Mil F 18870eDocument32 pagesMil F 18870eblissliNo ratings yet

- Carbon & Alloy SteelDocument10 pagesCarbon & Alloy SteelMaswindo CikarangNo ratings yet

- Bohler Welding Catalogue EriksDocument32 pagesBohler Welding Catalogue Eriksfarshid KarpasandNo ratings yet

- Product Data Sheet S KA BA V - ENDocument12 pagesProduct Data Sheet S KA BA V - ENdaniela hritucNo ratings yet

- Economical, Quick and Easy: CatalogueDocument44 pagesEconomical, Quick and Easy: CatalogueFreza Hadi PratamaNo ratings yet

- Carbodur 600 B-E6um60Document1 pageCarbodur 600 B-E6um60ali torabiNo ratings yet

- UTP Raiilways BrochureDocument8 pagesUTP Raiilways Brochurekamals55No ratings yet

- ITT American Electric Bay Beam Luminaire Series 56-57-156-157 Spec Sheet 9-81Document12 pagesITT American Electric Bay Beam Luminaire Series 56-57-156-157 Spec Sheet 9-81Alan MastersNo ratings yet

- WJ 2013 05Document128 pagesWJ 2013 05Matija BušićNo ratings yet

- 12 Excavator AttachmentsDocument31 pages12 Excavator AttachmentsAndrey GyrychNo ratings yet

- Data SheetDocument12 pagesData SheetArellano ArellanoNo ratings yet

- Precast Concrete PilesDocument4 pagesPrecast Concrete PilesFreddie KooNo ratings yet

- Amcrps Gen Cat GB 2012-2Document52 pagesAmcrps Gen Cat GB 2012-2VardhanNo ratings yet

- AWS - Welding Journal - 2004 - 02Document117 pagesAWS - Welding Journal - 2004 - 02arnoldbatista55No ratings yet

- Brochure Catalogue EnglishDocument20 pagesBrochure Catalogue EnglishHukleberipenNo ratings yet

- 200A, 15 KV Class Loadbreak ElbowDocument4 pages200A, 15 KV Class Loadbreak ElbowJose Reinoso MendezNo ratings yet

- TDS Hardcarb 70 (#ET - EN - 20.1)Document2 pagesTDS Hardcarb 70 (#ET - EN - 20.1)Jimit ShahNo ratings yet

- Aws WJ 201306 PDFDocument170 pagesAws WJ 201306 PDFRenato Barreto100% (1)

- Carbo L Ag 40 SN eDocument1 pageCarbo L Ag 40 SN efadfadg2No ratings yet

- Thông số kĩ thuật Bê Tông Chịu Nhiệt 2015-English VersionDocument2 pagesThông số kĩ thuật Bê Tông Chịu Nhiệt 2015-English VersionĐức BkNo ratings yet

- Material Listing & Specification (Structural Metals)Document18 pagesMaterial Listing & Specification (Structural Metals)myn maliQueNo ratings yet

- CCWDocument2 pagesCCWspearboraNo ratings yet

- Ampco Alloy BrochureDocument6 pagesAmpco Alloy BrochureCopper AmpcometalNo ratings yet

- Mild Steel Mig Welding WireDocument2 pagesMild Steel Mig Welding WireDheebika MurugesanNo ratings yet

- Irf644N, Irf644Ns, Irf644Nl, Sihf644N, Sihf644Ns, Sihf644Nl: Vishay SiliconixDocument8 pagesIrf644N, Irf644Ns, Irf644Nl, Sihf644N, Sihf644Ns, Sihf644Nl: Vishay SiliconixLuiz LuizNo ratings yet

- Vertical Lineshaft Turbine PumpsDocument8 pagesVertical Lineshaft Turbine PumpsHudson de Andrade e SilvaNo ratings yet

- Steel Foundation Solutions: General Catalogue 2017Document64 pagesSteel Foundation Solutions: General Catalogue 2017Imran HaiderNo ratings yet

- AM General Catalogue 2018 PDFDocument64 pagesAM General Catalogue 2018 PDFAde SetiawanNo ratings yet

- Kemet Metallographic BrochureDocument24 pagesKemet Metallographic Brochurevantuan17792No ratings yet

- ºÀ° - Ä Å Î × ¿ ® ÃÖÁDocument14 pagesºÀ° - Ä Å Î × ¿ ® ÃÖÁabhijit.ghotaneNo ratings yet

- Catalog Sheet Piles ARCELORDocument64 pagesCatalog Sheet Piles ARCELORpolpositionNo ratings yet

- Amtech Inv Handout Rev 1115 PDFDocument2 pagesAmtech Inv Handout Rev 1115 PDFTom TomNo ratings yet

- Asia Roadshow 2017 ShortDocument72 pagesAsia Roadshow 2017 ShortjparsbNo ratings yet

- Multi-Set II Drop-In AnchorsDocument5 pagesMulti-Set II Drop-In AnchorsReinel OrjuelaNo ratings yet

- Aurora: AE MC-120BD SeriesDocument2 pagesAurora: AE MC-120BD SeriestasoNo ratings yet

- Technical Specifi Cations: SL-KZ-001 Rev. DDocument2 pagesTechnical Specifi Cations: SL-KZ-001 Rev. DFernando SalamancaNo ratings yet

- Genaral Catalogue Sheet Piling 2019Document64 pagesGenaral Catalogue Sheet Piling 2019santanu mukherjeeNo ratings yet

- Hardfacing: WA Cored WiresDocument15 pagesHardfacing: WA Cored WiresThanh TamNo ratings yet

- Xuper 646 XHDDocument2 pagesXuper 646 XHDJuan LondonoNo ratings yet

- Ni Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsDocument6 pagesNi Inco 4421 Weldingofflakeandspheroidalgraphiteni ResistcastingsLeandro Dilkin ConsulNo ratings yet

- Slab EM Mold RefList-yearDocument4 pagesSlab EM Mold RefList-yearBhoomaiah SunkenapalliNo ratings yet

- Amphenol Pyle Starline and EX CatalogDocument82 pagesAmphenol Pyle Starline and EX Catalogari suburNo ratings yet

- An 4633Document2 pagesAn 4633erikaNo ratings yet

- Copper Electrodeposition for Nanofabrication of Electronics DevicesFrom EverandCopper Electrodeposition for Nanofabrication of Electronics DevicesNo ratings yet

- Catalogue English PDFDocument71 pagesCatalogue English PDFmunal23No ratings yet

- DIN EN ISO 9001:2000 Certificate Reg. No: 01 100 75147Document39 pagesDIN EN ISO 9001:2000 Certificate Reg. No: 01 100 75147munal23No ratings yet

- Wing Fan 1 PDFDocument2 pagesWing Fan 1 PDFmunal23No ratings yet

- Equipment Critical Analysis: The Need For An Effective Maintenance ProgramDocument7 pagesEquipment Critical Analysis: The Need For An Effective Maintenance Programmunal23No ratings yet

- Benefits of Lubricant Oil Analysis For Maintenance Decision Support: A Case StudyDocument8 pagesBenefits of Lubricant Oil Analysis For Maintenance Decision Support: A Case Studymunal23No ratings yet

- Neuer Rostfreier Maraging-Stahl Mit Hoher Festigkeif Für Komplexe Federn Aus BandDocument7 pagesNeuer Rostfreier Maraging-Stahl Mit Hoher Festigkeif Für Komplexe Federn Aus BandHagen_of_TronjeNo ratings yet

- Pressure Vessel - Example 62Document78 pagesPressure Vessel - Example 62Mohamedsabry96No ratings yet

- CSWIP 3 1 Exam Question and AnswersDocument23 pagesCSWIP 3 1 Exam Question and AnswersIyappan Balu100% (1)

- API Recommended Practice 583: Corrosion Under Insulation and FireproofingDocument4 pagesAPI Recommended Practice 583: Corrosion Under Insulation and FireproofingOgnjen Vukasinovic100% (1)

- Masoneilan CatalogDocument24 pagesMasoneilan CatalogsumsolcaggNo ratings yet

- BSPDocument94 pagesBSPAchalaShrotey0% (1)

- Industrial Policy APDocument6 pagesIndustrial Policy APapi-3711789No ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- Ancon Masonry Support, Windposts & LintelsDocument44 pagesAncon Masonry Support, Windposts & LintelsMelissa GrahamNo ratings yet

- 1045 Steel Flat BarDocument4 pages1045 Steel Flat BarFebri SSNo ratings yet

- SM2-3 Physics and Metallurgy of Welded Joints: Dr. Tarek BEN AMEUR, ProfessorDocument23 pagesSM2-3 Physics and Metallurgy of Welded Joints: Dr. Tarek BEN AMEUR, ProfessorAhmedNo ratings yet

- NA2159Document2 pagesNA2159Bogdan RusuNo ratings yet

- Australian Military Forces Identification ListDocument55 pagesAustralian Military Forces Identification Listpercyolivas100% (1)

- Full Test 2 (Key) PDFDocument5 pagesFull Test 2 (Key) PDFhoang lichNo ratings yet

- DO - 033 - S2013 Generic Specs For Rockfall Protection Systems Item 522Document14 pagesDO - 033 - S2013 Generic Specs For Rockfall Protection Systems Item 522Andrei AlidoNo ratings yet

- Prepared By:-Sumant Sahu Metallurgy 3203808302Document21 pagesPrepared By:-Sumant Sahu Metallurgy 3203808302Rahul PandeyNo ratings yet

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- FlenderTechnicalHandbook PDFDocument79 pagesFlenderTechnicalHandbook PDFWagner OliveiraNo ratings yet

- Leo Workshop: JSW Steels Ltd. Vijayanagara WorksDocument16 pagesLeo Workshop: JSW Steels Ltd. Vijayanagara WorksBinod Kumar PadhiNo ratings yet

- Approved Vendor ListDocument8 pagesApproved Vendor ListHery MukhlisNo ratings yet

- Thesis 1984 Austin PDFDocument481 pagesThesis 1984 Austin PDFZain Al AbidinNo ratings yet

- Steel Glossary SBBDocument36 pagesSteel Glossary SBBshraktuNo ratings yet

- Surface Cladding and Hardfacing MethodsDocument6 pagesSurface Cladding and Hardfacing MethodsEduardo GonzálezNo ratings yet

- TurnbuckleDocument6 pagesTurnbuckleAbi Latiful HakimNo ratings yet

- Friday: For Subscription Please Contact Phone: 67231665Document2 pagesFriday: For Subscription Please Contact Phone: 67231665Gopi NathNo ratings yet

- Bs 15610Document13 pagesBs 15610Jamil SalmanNo ratings yet

- Hilti Hit Hy 170Document37 pagesHilti Hit Hy 170Adhil RamsurupNo ratings yet

- PISR1-En-US SiC Shell & Tube Heat Exchanger - SR SeriesDocument2 pagesPISR1-En-US SiC Shell & Tube Heat Exchanger - SR SeriesViajante_santosNo ratings yet

- Welding Filler MetalDocument1 pageWelding Filler MetalBharath KumarNo ratings yet