Professional Documents

Culture Documents

Piston Ring Installation Generic

Piston Ring Installation Generic

Uploaded by

MinibikeTechOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piston Ring Installation Generic

Piston Ring Installation Generic

Uploaded by

MinibikeTechCopyright:

Available Formats

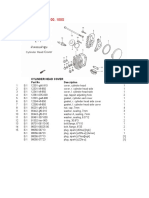

RING INSTALLATION RING INSTALLATION

RING DIAMETER PART # RING DIAMETER PART #

mm mm

Most Powroll piston rings are oversize to enable re-ringing of Most Powroll piston rings are oversize to enable re-ringing of

cylinders which have worn within acceptable limits. Ring ends cylinders which have worn within acceptable limits. Ring ends

may need to be filed before installation. may need to be filed before installation.

Excess gap is not critical. Insufficient gap can cause damage. Excess gap is not critical. Insufficient gap can cause damage.

Ring Diameter Ring Diameter Minimum Ring Diameter Ring Diameter Minimum

Inches Millimeters End Gap Inches Millimeters End Gap

1.731” - 1.968” 44mm - 50mm .004” 1.731” - 1.968” 44mm - 50mm .004”

1.969” - 2.675” 50.25mm - 68mm .007” 1.969” - 2.675” 50.25mm - 68mm .007”

2.676” - 3.120” 68.10mm - 79.25mm .010” 2.676” - 3.120” 68.10mm - 79.25mm .010”

3.121” - 4.016” 79.35mm - 102mm .013” 3.121” - 4.016” 79.35mm - 102mm .013”

4.017” - 4.173” 102.25mm - 106mm .016” 4.017” - 4.173” 102.25mm - 106mm .016”

CHECK CYLINDER CLEARANCE AND WEAR CHECK CYLINDER CLEARANCE AND WEAR

Inspect cylinder wall for wear or scoring. Boring to an oversize is advisable Inspect cylinder wall for wear or scoring. Boring to an oversize is advisable

with any ridge of .005” or more. with any ridge of .005” or more.

Measure cylinder in six places (front-to-back top, middle, bottom and side- Measure cylinder in six places (front-to-back top, middle, bottom and side-

to-side top, middle, bottom) using quality measuring tools. Variations of to-side top, middle, bottom) using quality measuring tools. Variations of

more than .003” require boring to larger size. more than .003” require boring to larger size.

Check piston clearance against Powroll recommendations. More than Check piston clearance against Powroll recommendations. More than

.0025” over original recommended clearance requires boring to larger .0025” over original recommended clearance requires boring to larger

size. size.

Lightly hone cylinder to remove glaze (with 320 to 360 grit). Lightly hone cylinder to remove glaze (with 320 to 360 grit).

CHECK PISTON WEAR CHECK PISTON WEAR

Don’t re-use siezed pistons. Seizure causes partial collapse of the piston Don’t re-use siezed pistons. Seizure causes partial collapse of the piston

skirt and results in poor ring seal and smoking. skirt and results in poor ring seal and smoking.

Gently remove carbon (use acetone). Inspect for: Gently remove carbon (use acetone). Inspect for:

Skirt: Scoring, wear spots, cracks (replace piston). Skirt: Scoring, wear spots, cracks (replace piston).

Valve Pockets: Valve damage, cracks (replace piston). Valve Pockets: Valve damage, cracks (replace piston).

Ring Lands: Cracking, pieces missing (replace piston). Ring Lands: Cracking, pieces missing (replace piston).

Ring Grooves: Check clearance with a new ring in the groove, if a .005” Ring Grooves: Check clearance with a new ring in the groove, if a .005”

feeler gauge fits between the top ring groove and the new ring, replace feeler gauge fits between the top ring groove and the new ring, replace

piston. piston.

Pin and Clips: Wear on pin, piston clip grooves pushed out or worn (replace Pin and Clips: Wear on pin, piston clip grooves pushed out or worn (replace

piston, pin and clips). piston, pin and clips).

RING END GAP RING END GAP

Be certain you have the correct ring set. Ring thickness must be the same Be certain you have the correct ring set. Ring thickness must be the same

as the piston ring groove. Ring width must not be more than ring groove as the piston ring groove. Ring width must not be more than ring groove

depth. depth.

If end gap is not listed, gap using this formula: .0035” x Bore Size (in If end gap is not listed, gap using this formula: .0035” x Bore Size (in

inches). inches).

Compression & Scraper Rings, One Piece Oil Rings: Position each ring Compression & Scraper Rings, One Piece Oil Rings: Position each ring

squarely in the cylinder from bottom (use the piston to push the rings into squarely in the cylinder from bottom (use the piston to push the rings into

the cylinder). Using a feeler gauge, measure the gap. File rings to the the cylinder). Using a feeler gauge, measure the gap. File rings to the

end gap listed. end gap listed.

Three Piece Oil Rings: Center (corrugated) piece will not need to be Three Piece Oil Rings: Center (corrugated) piece will not need to be

gapped. Check and file rails in the same manner as the compression and gapped. Check and file rails in the same manner as the compression and

scraper rings. scraper rings.

RING INSTALLATION RING INSTALLATION

Many modern ring sets contain a high Many modern ring sets contain a high

performance oil control ring. We recommend performance oil control ring. We recommend

using a quality ring compressor to avoid using a quality ring compressor to avoid

damage to the piston, ring, or cylinder damage to the piston, ring, or cylinder

during installation. during installation.

Install ring end gaps according to diagram. Install ring end gaps according to diagram.

1. Place Oil Ring Expander (wavy shaped 1. Place Oil Ring Expander (wavy shaped

ring segment) into the oil ring groove. Be ring segment) into the oil ring groove. Be

sure tips of the expander are visible and properly butted (see below). sure tips of the expander are visible and properly butted (see below).

Overlap of Oil Ring Expander tips will cause severe smoking and possible Overlap of Oil Ring Expander tips will cause severe smoking and possible

engine damage. engine damage.

2. Thin Rail Rings can be installed with either side up. One rail ring below 2. Thin Rail Rings can be installed with either side up. One rail ring below

oil expander ring and one above. oil expander ring and one above.

3. Once rails are installed, be sure the expander tips are still butted and 3. Once rails are installed, be sure the expander tips are still butted and

not overlapped. not overlapped.

4. Middle (scraper) ring: Middle ring can be either silver or black. Markings 4. Middle (scraper) ring: Middle ring can be either silver or black. Markings

face up. face up.

5. Top (Compression) ring. Usually silver faced. Markings face up. If no 5. Top (Compression) ring. Usually silver faced. Markings face up. If no

markings are evident, ring can be installed with either side facing up. markings are evident, ring can be installed with either side facing up.

You might also like

- Lifan 125cc 1P52FMI Parts List ManualDocument33 pagesLifan 125cc 1P52FMI Parts List ManualMinibikeTech92% (12)

- Automotive Technology: Principles, Diagnosis, and ServiceDocument14 pagesAutomotive Technology: Principles, Diagnosis, and Servicedawit dejeneNo ratings yet

- BGM Parts ManaualDocument58 pagesBGM Parts ManaualDaniel Wellner86% (7)

- PITPRO 125cc Parts ListDocument16 pagesPITPRO 125cc Parts ListMinibikeTech67% (3)

- 2zr Fe Engine Mechanical Cylinder Head Gasket Installation 2009 Matrix PDFDocument7 pages2zr Fe Engine Mechanical Cylinder Head Gasket Installation 2009 Matrix PDFruben carranza100% (1)

- PITPRO 125cc Parts ListDocument16 pagesPITPRO 125cc Parts ListMinibikeTech67% (3)

- Lifan 150cc Parts ListDocument20 pagesLifan 150cc Parts ListMinibikeTech50% (8)

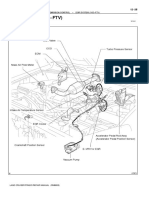

- 2KD-FTV Engine MechanicalDocument1 page2KD-FTV Engine Mechanicaladdis gilleNo ratings yet

- Thumpstar 125cc Engine Parts ListDocument17 pagesThumpstar 125cc Engine Parts ListMinibikeTech67% (3)

- YX140 Engine SplitDocument2 pagesYX140 Engine SplitMinibikeTech100% (2)

- MB G100-12Document4 pagesMB G100-12rowan0% (1)

- 1NZ-FE Engine Description PDFDocument17 pages1NZ-FE Engine Description PDFjuanNo ratings yet

- 4AT Automatic TransDocument132 pages4AT Automatic TransvarelafNo ratings yet

- # Proton Preve CFE Spare Part ListDocument30 pages# Proton Preve CFE Spare Part ListKyo KusanagiNo ratings yet

- Honda Wave 100, 100S 2005Document88 pagesHonda Wave 100, 100S 2005hwahydNo ratings yet

- PCT-00059-SCORPIO RHD DIESEL CHAIN DRIVE M2Di & GEAR DRIVE m2DiCR Ex - BSIII & BSIV 2WD - VERSIO PDFDocument218 pagesPCT-00059-SCORPIO RHD DIESEL CHAIN DRIVE M2Di & GEAR DRIVE m2DiCR Ex - BSIII & BSIV 2WD - VERSIO PDFneo_1314100% (1)

- Cylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsDocument8 pagesCylinder Head Gasket - Installation (08 - 2013 - ) (Cylinder Head Assembly) - Toyota Sienna 3.5ltsFran SanchezNo ratings yet

- Piston RingsDocument1 pagePiston RingsOlimpiu Vuia100% (1)

- Tech Daytona 115/125/119 Engine Maintenance/InfoDocument1 pageTech Daytona 115/125/119 Engine Maintenance/InfoMinibikeTechNo ratings yet

- Mahindra Parts CatalogDocument91 pagesMahindra Parts CatalogTara ChandNo ratings yet

- Preparation 2zr-Fe Engine Mechanical SST PDFDocument3 pagesPreparation 2zr-Fe Engine Mechanical SST PDFAlbert BriceñoNo ratings yet

- Gt250 PartsDocument353 pagesGt250 PartsLandynut100% (1)

- 1kd FTV PDFDocument2 pages1kd FTV PDFDayro Jose Geney OrtizNo ratings yet

- Yamaha LCDocument63 pagesYamaha LCjoshuaNo ratings yet

- Jetting How ToDocument1 pageJetting How ToMinibikeTechNo ratings yet

- Minibike Engine AssemblyDocument2 pagesMinibike Engine AssemblyMinibikeTech100% (1)

- Jetting How ToDocument1 pageJetting How ToMinibikeTechNo ratings yet

- ELKA Suspension MiniSeries 50 Owners Service ManualDocument15 pagesELKA Suspension MiniSeries 50 Owners Service ManualMinibikeTechNo ratings yet

- Tech Daytona 115/125/119 Engine Maintenance/InfoDocument1 pageTech Daytona 115/125/119 Engine Maintenance/InfoMinibikeTechNo ratings yet

- PITPRO 107cc 3 Valve Parts ListDocument16 pagesPITPRO 107cc 3 Valve Parts ListMinibikeTechNo ratings yet

- Tech Daytona 115/125/119 Engine Maintenance/InfoDocument1 pageTech Daytona 115/125/119 Engine Maintenance/InfoMinibikeTechNo ratings yet

- Removing Flywheel and StatorDocument1 pageRemoving Flywheel and StatorMinibikeTechNo ratings yet

- Piston Ring Assembly Tips 4strk - Ringinstall2!24!05Document2 pagesPiston Ring Assembly Tips 4strk - Ringinstall2!24!05michaelmangaaNo ratings yet

- Spec For Perodua Viva EliteDocument8 pagesSpec For Perodua Viva EliteSite Engineer.2p2No ratings yet

- GPX 125 EngineDocument17 pagesGPX 125 Engineapts9752100% (1)

- Engine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDocument4 pagesEngine Mechanical (2Rz-Fe, 3Rz-Fe) : Service DataDavid R PaucaraNo ratings yet

- CarburetorDocument29 pagesCarburetorCecilia GilNo ratings yet

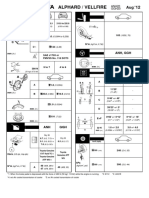

- ALPHARD/VELLFIRE Service SheetDocument2 pagesALPHARD/VELLFIRE Service SheetNyhcnaw100% (1)

- Manual de Calibracion de Valvulas Del Daihatsu Toyota TeriosDocument10 pagesManual de Calibracion de Valvulas Del Daihatsu Toyota Teriosahmed zhranNo ratings yet

- Daytona 125cc Repairing Locating Arm (Gearshift Fix)Document7 pagesDaytona 125cc Repairing Locating Arm (Gearshift Fix)MinibikeTech100% (2)

- Carburetor Tuning For Kawasaki Triples: Mikuni Carburetor Circuits Carb Sync Tuning (Cont.) Effects of Jetting VariablesDocument32 pagesCarburetor Tuning For Kawasaki Triples: Mikuni Carburetor Circuits Carb Sync Tuning (Cont.) Effects of Jetting VariablesJoseNo ratings yet

- Removal: 2Tr-Fe Engine Mechanical - Timing ChainDocument15 pagesRemoval: 2Tr-Fe Engine Mechanical - Timing ChainNacho Akiba-keiNo ratings yet

- Naza Ria Rover KV6 Engine Cam Marking ManualDocument7 pagesNaza Ria Rover KV6 Engine Cam Marking ManualLee Ming Fee100% (1)

- Toyota Engine Oil Pressure TestDocument3 pagesToyota Engine Oil Pressure TestAmon Kiay100% (1)

- Proton Gen 2 2014 AUDocument4 pagesProton Gen 2 2014 AUFajri JoeNo ratings yet

- Manual Transmission 5mtt200aDocument93 pagesManual Transmission 5mtt200aChai KailingNo ratings yet

- Toyota GD Series Diesel EnginesDocument17 pagesToyota GD Series Diesel Enginesrafaelrgr100% (1)

- PDF At115 2002 NouvoDocument293 pagesPDF At115 2002 NouvoSyahrom NiezamNo ratings yet

- Honda Unicorn Cdi Wiring Diagram PDFDocument3 pagesHonda Unicorn Cdi Wiring Diagram PDFSleep Care0% (2)

- Honda Wave Parts Manual enDocument61 pagesHonda Wave Parts Manual enVinz CustodioNo ratings yet

- Yamaha 125ZR Technical SpecsDocument2 pagesYamaha 125ZR Technical SpecsStanley Ochieng' Ouma100% (2)

- Saga 1.3 FLX Executive (M) PDFDocument11 pagesSaga 1.3 FLX Executive (M) PDFGameMedia SurabayaNo ratings yet

- Parts Catalogue Karisma 125Document93 pagesParts Catalogue Karisma 125syakira ajieraNo ratings yet

- Daytona 150cc T-REX Installing Instructions - Chain RollerDocument5 pagesDaytona 150cc T-REX Installing Instructions - Chain RollerMinibikeTechNo ratings yet

- PC KarismaDocument62 pagesPC KarismaoggutNo ratings yet

- Valve Body PDFDocument9 pagesValve Body PDFTimur TOT100% (1)

- Owner's Manual PLATINA 100 110 BS VI PDFDocument48 pagesOwner's Manual PLATINA 100 110 BS VI PDFUlagaariyan Premkumar0% (1)

- Mitsubishi Motor 1.5,11B 2007-2017 InglesDocument51 pagesMitsubishi Motor 1.5,11B 2007-2017 InglesmanualNo ratings yet

- MANUALTRANSMISSIONDocument51 pagesMANUALTRANSMISSIONIan AriestaNo ratings yet

- GR00000600-11E 4G69 Engine MechanicalDocument56 pagesGR00000600-11E 4G69 Engine MechanicalHarold SarmientoNo ratings yet

- Honda 2.0L R20A-R20Z Engine Specs, Problems, ReliabilityDocument4 pagesHonda 2.0L R20A-R20Z Engine Specs, Problems, Reliabilityedson.acordiNo ratings yet

- Engine Kv6 RepairDocument78 pagesEngine Kv6 RepairSören Christopher Lax100% (1)

- Xenon 2 2l Dicor LHD e IVDocument570 pagesXenon 2 2l Dicor LHD e IVgavinNo ratings yet

- Especificaciones de Ajuste Toyota 2kd-ftvDocument3 pagesEspecificaciones de Ajuste Toyota 2kd-ftvyonth faiber rivasNo ratings yet

- 2012 45P2 Byson 1l45p460e1Document64 pages2012 45P2 Byson 1l45p460e1Ilham IsmailNo ratings yet

- Einbau Kolbenringsaetze Piston Ring Sets enDocument3 pagesEinbau Kolbenringsaetze Piston Ring Sets enEdimilson RodriguesNo ratings yet

- GY6 Big Bore Kit InstallationDocument80 pagesGY6 Big Bore Kit InstallationAndrew McGovern100% (2)

- P250-250S Cap 07 (CYLINDER PISTON)Document9 pagesP250-250S Cap 07 (CYLINDER PISTON)Minh ChuNo ratings yet

- klr685 Kit InstructionsDocument3 pagesklr685 Kit InstructionsGabriel GonzalezNo ratings yet

- KXR50 Cap 08 (Cilindro Pistone)Document18 pagesKXR50 Cap 08 (Cilindro Pistone)tutifruti649No ratings yet

- VDL Service ManualDocument13 pagesVDL Service ManualSergio Martín BrionesNo ratings yet

- Procedure Changing Piston RingDocument12 pagesProcedure Changing Piston RingAdhitya WisnuNo ratings yet

- TTR125 150BigBore Update2Document4 pagesTTR125 150BigBore Update2eddielindermannNo ratings yet

- Engine Service Manual Renegade 300 SeriesDocument76 pagesEngine Service Manual Renegade 300 SeriesArul Gnana JohnNo ratings yet

- Propeller Fitting InstructionsDocument7 pagesPropeller Fitting Instructionsrubens0001No ratings yet

- Wossner Piston Installation Instructions and Ring End GapDocument1 pageWossner Piston Installation Instructions and Ring End GapkyriakosNo ratings yet

- Stompracing PDI Sheet (Assembly & Running Check)Document2 pagesStompracing PDI Sheet (Assembly & Running Check)MinibikeTechNo ratings yet

- Daytona 150cc T-REX Installing Instructions - Chain RollerDocument5 pagesDaytona 150cc T-REX Installing Instructions - Chain RollerMinibikeTechNo ratings yet

- Daytona 125cc Repairing Locating Arm (Gearshift Fix)Document7 pagesDaytona 125cc Repairing Locating Arm (Gearshift Fix)MinibikeTech100% (2)

- Daytona Parts 150ccDocument10 pagesDaytona Parts 150ccMinibikeTechNo ratings yet

- GPX 125 EngineDocument17 pagesGPX 125 Engineapts9752100% (1)

- Design Symbols - Spark PlugsDocument2 pagesDesign Symbols - Spark Plugsmechkarov1100% (1)

- Trialtech Vapor Sensor Install InstructionsDocument2 pagesTrialtech Vapor Sensor Install InstructionsMinibikeTechNo ratings yet

- Mikuni VM CarburatorDocument20 pagesMikuni VM Carburatorgiacummo100% (3)

- Installing Takegawa Hyper Cam (KLX110/DRZ110)Document1 pageInstalling Takegawa Hyper Cam (KLX110/DRZ110)MinibikeTechNo ratings yet

- Mikuni 26mm Carb Kit Setup For KLX/DRZ 110Document1 pageMikuni 26mm Carb Kit Setup For KLX/DRZ 110MinibikeTechNo ratings yet

- CRF50 Borekit Fitting How To (82cc)Document6 pagesCRF50 Borekit Fitting How To (82cc)MinibikeTech100% (1)

- Fault Finding For Charging System Diagnostic/TroubleshootingDocument4 pagesFault Finding For Charging System Diagnostic/TroubleshootingMinibikeTechNo ratings yet

- CDI To Loom Wiring DiagramDocument1 pageCDI To Loom Wiring DiagramMinibikeTechNo ratings yet

- Offroad Motorcycling How ToDocument10 pagesOffroad Motorcycling How ToMinibikeTechNo ratings yet

- YX140 Cam RemovalDocument5 pagesYX140 Cam RemovalMinibikeTechNo ratings yet

- Teleflex NFB Safe T II Steering System Instruction ManualDocument2 pagesTeleflex NFB Safe T II Steering System Instruction ManualJulie LafranceNo ratings yet

- Landing Gear: BK117 C-2 Training Manual CAT B1 Landing GearDocument7 pagesLanding Gear: BK117 C-2 Training Manual CAT B1 Landing GearЕвгений КасьяновNo ratings yet

- KTA50 Engine Parts CatalogueDocument213 pagesKTA50 Engine Parts CatalogueGaly Hossam100% (4)

- Avm 10 Front AxleDocument3 pagesAvm 10 Front AxlePilar TorquemadaNo ratings yet

- 905 - Crankshaft & Thrust BearingDocument19 pages905 - Crankshaft & Thrust BearingVuHongNhatNo ratings yet

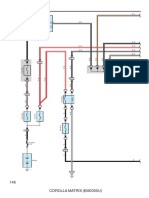

- Cruise Control: 146 Corolla Matrix (Em0350U)Document6 pagesCruise Control: 146 Corolla Matrix (Em0350U)Cejas MicroNo ratings yet

- c90 Part - List - 2005-2007Document73 pagesc90 Part - List - 2005-2007Leonardo HalonNo ratings yet

- Toro50 SpecDocument3 pagesToro50 SpecAli Narváez quispeNo ratings yet

- Avionics Tools: CM WP ME HA AP LG EP CS IN EL AV TO PS BVDocument1 pageAvionics Tools: CM WP ME HA AP LG EP CS IN EL AV TO PS BVjoel alvaradoNo ratings yet

- Solex Manual S3800Document84 pagesSolex Manual S3800Kieran Coveney100% (1)

- Ervice AND Arts Anual: Elmhults Konstruktions AbDocument39 pagesErvice AND Arts Anual: Elmhults Konstruktions AbMelanie GerdesNo ratings yet

- IX. Replacement Parts: Mastercraft 12 1/2" Thickness Planer With Work Stand 55-5503-4Document4 pagesIX. Replacement Parts: Mastercraft 12 1/2" Thickness Planer With Work Stand 55-5503-4Robert TourangeauNo ratings yet

- WSM - 0000693 - en - Steering GearDocument4 pagesWSM - 0000693 - en - Steering GearNoeRtjahya AhmadNo ratings yet

- Drawing (Electrical) - CompressedDocument13 pagesDrawing (Electrical) - CompressedMUHAMMAD AZRI ABD WAHABNo ratings yet

- SM 1Document345 pagesSM 1Percival Alvaro100% (1)

- Lab Manual-H & P-1me2603Document40 pagesLab Manual-H & P-1me2603Hi helloNo ratings yet

- Pipe Properties and DimensionsDocument6 pagesPipe Properties and DimensionsJanzxhel Alva OlazoNo ratings yet

- Doosan Engine de 12 Maintenance ManualDocument10 pagesDoosan Engine de 12 Maintenance ManualJoseph100% (57)

- 3230F350 PARTS CatalogDocument5 pages3230F350 PARTS CatalogLIONN TESTE2021No ratings yet

- Assembly Transmission 777DDocument62 pagesAssembly Transmission 777DKeron TrotzNo ratings yet

- Siemens-SQM1 SQM2 enDocument7 pagesSiemens-SQM1 SQM2 enserg minimeNo ratings yet

- Triplex Service DropDocument3 pagesTriplex Service DropEvan Merkel0% (1)

- Volvo l120f SchematicsDocument10 pagesVolvo l120f Schematicsclyde100% (66)

- Bosch Motronic Mp3 2-Multipoint-Xu10j2cte RGX 406 Peugeot Fan ClubDocument7 pagesBosch Motronic Mp3 2-Multipoint-Xu10j2cte RGX 406 Peugeot Fan ClubMohamed TarekNo ratings yet

- M4002432211d102a2 - 2528CH 41 60Document20 pagesM4002432211d102a2 - 2528CH 41 60NaimahSulistianingsih100% (1)

- EC140D Hyd - GB20029183A - HDocument24 pagesEC140D Hyd - GB20029183A - HHoàng QuânNo ratings yet