Professional Documents

Culture Documents

Case No

Case No

Uploaded by

Govendan Gopalakrishnan0 ratings0% found this document useful (0 votes)

35 views13 pagesThis document provides the design calculations for the reinforcement of a two-way slab. The slab has a thickness of 175 mm and is designed to carry a total load of 29.06 kN/m2. Reinforcement is calculated for short and long span directions at support and mid-span locations. Y12 bars are specified with spacing ranging from 150 mm to 500 mm depending on the location to satisfy design requirements.

Original Description:

Original Title

slab_225

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides the design calculations for the reinforcement of a two-way slab. The slab has a thickness of 175 mm and is designed to carry a total load of 29.06 kN/m2. Reinforcement is calculated for short and long span directions at support and mid-span locations. Y12 bars are specified with spacing ranging from 150 mm to 500 mm depending on the location to satisfy design requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

0 ratings0% found this document useful (0 votes)

35 views13 pagesCase No

Case No

Uploaded by

Govendan GopalakrishnanThis document provides the design calculations for the reinforcement of a two-way slab. The slab has a thickness of 175 mm and is designed to carry a total load of 29.06 kN/m2. Reinforcement is calculated for short and long span directions at support and mid-span locations. Y12 bars are specified with spacing ranging from 150 mm to 500 mm depending on the location to satisfy design requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

Download as xls, pdf, or txt

You are on page 1of 13

Page 1 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

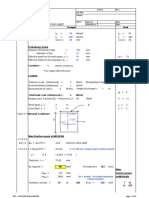

1.0 Design of two way Slab

1.0.1 Basic Data

Grade of concrete (fck) = M 30 ###

Grade of steel (fy) = Fe 500 ###

Thickness of slab (D) = 175 mm IS 456-2000 ###

Clear cover (cc) = 15 mm Table 16 Cl.26.4.2

###

Effective thickness of slab (deff)= 175 - 15 - 12 /2 = 154 mm ###

Unit weight of concrete = 25 KN/m 3

IS 456-2000 Cl 19.2.1

###

Effective Shorter Span (Lx) = 3.7 m ###

Effective Longer Span (Ly) = 6.4 m ###

Aspect ratio Ly/Lx = 1.73 Two way slab

Edge Condition : One Long edge discontinuous

1.0.2 Load Data

Dead Load = 0.18 x 25 = 4.375 KN/m2

Floor finish = 0.00 KN/m2 IS 875-1987

Imposed Load = 15.00 KN/m2 (Part 2) Table 1

Total load = 19.38 KN/m 2

IS 456-2000

Design load ( Wu ) = 1.5 x 19.375 = 29.06 KN/m 2

Table 18 Cl 36.4.1

1.0.3 Moment and Shear Calculations ax+

Case No

Short Span Direction ###

ax for positive moment 1.5 → 0.051 IS 456-2000 ###

1.75 → 0.059 Table 26 Cl D-1.1 ###

for 1.73 ax = 0.058 ###

Positive moment Mx 0.058 x 29.06 x 3.7 ^2 = 23.22 KN-m ###

ax for negative moment 1.5 → 0.067 IS 456-2000 ###

1.75 → 0.077 Table 26 Cl D-1.1 ###

for 1.73 ax = 0.076 ###

Negative moment Mx : 0.076 x 29.06 x 3.7 ^2 = 30.31 KN-m ###

Page 2 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

Long Span Direction One Long

For positive moment ay = 0.028 IS 456-2000

Positive moment My : 0.028 x 29.06 x 3.7 ^2 = 11.14 KN-m Table 26 Cl D-1.1

For negative moment ay = 0.037 IS 456-2000

Negative moment My : 0.037 x 29.06 x 3.7 ^2 = 14.72 KN-m Table 26 Cl D-1.1

Shear force V u = 29.06 x 3.7 x 0.5 = 53.77 KN

1.0.4 Check Effective Depth for Bending

Depth required = (Mx / (0.133x fck x b))1/2 = 87.16 mm SP 16 :1980 Table C

Depth provided = 175 - 15 - 12 /2 = 154 mm Cl 2.3

Hence O.K

1.0.5 Reinforcement calculations

Short Span Direction @ Support

Mu/bd2 = 30.31 x 10 ^ 6 = 1.278

1000 x 154 x ###

Pt = 0.31 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00310 x 1000 x 154 = 477.392 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 175 = 210.00 mm 2

Cl:26.5.2.1

Spacing of Y 12 bars 113.10 x 1000 / 477.39 = 236.786 mm

Check for Spacing

Minimum of 1) 3d = 462 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 236.79 mm

Therefore provide Y 12 @ 230 mm C/C

Short Span Direction @ Mid Span

Mu/bd2 = 23.22 x 10 ^ 6 = 0.979

1000 x 154 x ###

Pt = 0.234 % SP16 :1980 Table 2-4

Page 3 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

Area of steel Ast = 0.00234 x 1000 x 154 = 360.823 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 175 = 210.00 mm 2

Cl:26.5.2.1

Spacing of Y 12 bars 113.10 x 1000 / 360.82 = 313.284 mm

Check for Spacing

Minimum of 1) 3d = 462 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 313.28 mm

Therefore provide Y 12 @ 150 mm C/C 150

Provided % of Tension Reinforcement (pt) = 0.490 %

Long Span Direction @ Support

Mu/bd2 = 14.72 x 10 ^ 6 = 0.621

1000 x 154 x ###

Pt = 0.146 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00146 x 1000 x 154 = 225.356 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 175 = 210.00 mm 2

Cl:26.5.2.1

Spacing of Y 12 bars 113.10 x 1000 / 225.36 = 501.607 mm

Check for Spacing

Minimum of 1) 3d = 462 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 501.61 mm

Therefore provide Y 12 @ 300 mm C/C

Long Span Direction @ mid Span

Mu/bd2 = 11.14 x 10 ^ 6 = 0.470

1000 x 154 x ###

Pt = 0.110 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00110 x 1000 x 154 = 169.489 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 175 = 210.00 mm2 Cl:26.5.2.1

Page 4 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

Spacing of Y 12 bars 113.10 x 1000 / 210.00 = 538.286 mm

Check for Spacing

Minimum of 1) 3d = 462 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 538.29 mm

Therefore provide Y 12 @ 300 mm C/C

1.0.6 Check for Deflection:

Basic Span/depth Ratio = 20 IS 456:2000 Cl:23.2.1

% of Tension Reinforcement provided ( pt ) = 0.490 %

Service stress of steel (fs) : 0.58fy(Ast_r/Ast_p) = 138.78 N/mm2 IS456:2000 Fig 4

Modification Factor for Tension Reinforcement (F1) = 2.00 Page 38

Allowable Span/Eff Depth Ratio = 40 IS 456:2000 Cl:23.2.1

Actual Span/Eff Depth Ratio = 3.7 x 1000 / 154 = 24.03

Hence O.K

Page 5 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

1.0 Design of two way Slab

1.0.1 Basic Data

Grade of concrete (fck) = M 30 ###

Grade of steel (fy) = Fe 500 ###

Thickness of slab (D) = 175 mm IS 456-2000 ###

Clear cover (cc) = 15 mm Table 16 Cl.26.4.2

###

Effective thickness of slab (deff)= 175 - 15 - 12 /2 = 154 mm ###

Unit weight of concrete = 25 KN/m 3

IS 456-2000 Cl 19.2.1

###

Effective Shorter Span (Lx) = 4.4 m ###

Effective Longer Span (Ly) = 6.4 m ###

Aspect ratio Ly/Lx = 1.45 Two way slab

Edge Condition : Interior panels

1.0.2 Load Data

Dead Load = 0.18 x 25 = 4.375 KN/m2

Floor finish = 0.00 KN/m2 IS 875-1987

Imposed Load = 15.00 KN/m2 (Part 2) Table 1

Total load = 19.38 KN/m 2

IS 456-2000

Design load ( Wu ) = 1.5 x 19.375 = 29.06 KN/m 2

Table 18 Cl 36.4.1

1.0.3 Moment and Shear Calculations ax+

Case No

Short Span Direction ###

ax for positive moment 1.4 → 0.039 IS 456-2000 ###

1.5 → 0.041 Table 26 Cl D-1.1 ###

for 1.45 ax = 0.040 ###

Positive moment Mx 0.040 x 29.06 x 4.4 ^2 = 22.56 KN-m ###

ax for negative moment 1.4 → 0.051 IS 456-2000 ###

1.5 → 0.053 Table 26 Cl D-1.1 ###

for 1.45 ax = 0.052 ###

Negative moment Mx : 0.052 x 29.06 x 4.4 ^2 = 29.31 KN-m ###

Long Span Direction Interior p

Page 6 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

For positive moment ay = 0.024 IS 456-2000

Positive moment My : 0.024 x 29.06 x 4.4 ^2 = 13.50 KN-m Table 26 Cl D-1.1

For negative moment ay = 0.032 IS 456-2000

Negative moment My : 0.032 x 29.06 x 4.4 ^2 = 18.00 KN-m Table 26 Cl D-1.1

Shear force V u = 29.06 x 4.4 x 0.5 = 63.94 KN

1.0.4 Check Effective Depth for Bending

Depth required = (Mx / (0.133x fck x b))1/2 = 85.71 mm SP 16 :1980 Table C

Depth provided = 175 - 15 - 12 /2 = 154 mm Cl 2.3

Hence O.K

1.0.5 Reinforcement calculations

Short Span Direction @ Support

Mu/bd2 = 29.31 x 10 ^ 6 = 1.236

1000 x 154 x ###

Pt = 0.30 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00299 x 1000 x 154 = 460.701 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 175 = 210.00 mm2 Cl:26.5.2.1

Spacing of Y 12 bars 113.10 x 1000 / 460.70 = 245.365 mm

Check for Spacing

Minimum of 1) 3d = 462 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 245.37 mm

Therefore provide Y 12 @ 240 mm C/C

Short Span Direction @ Mid Span

Mu/bd2 = 22.56 x 10 ^ 6 = 0.951

1000 x 154 x ###

Pt = 0.227 % SP16 :1980 Table 2-4

Page 7 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

Area of steel Ast = 0.00227 x 1000 x 154 = 350.162 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 175 = 210.00 mm 2

Cl:26.5.2.1

Spacing of Y 12 bars 113.10 x 1000 / 350.16 = 322.822 mm

Check for Spacing

Minimum of 1) 3d = 462 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 322.82 mm

Therefore provide Y 12 @ 150 mm C/C 150

Provided % of Tension Reinforcement (pt) = 0.490 %

Long Span Direction @ Support

Mu/bd2 = 18.00 x 10 ^ 6 = 0.759

1000 x 154 x ###

Pt = 0.180 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00180 x 1000 x 154 = 277.22 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 175 = 210.00 mm2 Cl:26.5.2.1

Spacing of Y 12 bars 113.10 x 1000 / 277.22 = 407.763 mm

Check for Spacing

Minimum of 1) 3d = 462 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 407.76 mm

Therefore provide Y 12 @ 300 mm C/C

Long Span Direction @ mid Span

Mu/bd2 = 13.50 x 10 ^ 6 = 0.569

1000 x 154 x ###

Pt = 0.134 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00134 x 1000 x 154 = 206.282 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 175 = 210.00 mm2 Cl:26.5.2.1

Page 8 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

Spacing of Y 12 bars 113.10 x 1000 / 210.00 = 538.286 mm

Check for Spacing

Minimum of 1) 3d = 462 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 538.29 mm

Therefore provide Y 12 @ 300 mm C/C

1.0.6 Check for Deflection:

Basic Span/depth Ratio = 20 IS 456:2000 Cl:23.2.1

% of Tension Reinforcement provided ( pt ) = 0.490 %

Service stress of steel (fs) : 0.58fy(Ast_r/Ast_p) = 134.68 N/mm2 IS456:2000 Fig 4

Modification Factor for Tension Reinforcement (F1) = 2.00 Page 38

Allowable Span/Eff Depth Ratio = 40 IS 456:2000 Cl:23.2.1

Actual Span/Eff Depth Ratio = 4.4 x 1000 / 154 = 28.57

Hence O.K

Page 9 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

1.0 Design of two way Slab

1.0.1 Basic Data

Grade of concrete (fck) = M 30 ###

Grade of steel (fy) = Fe 500 ###

Thickness of slab (D) = 200 mm IS 456-2000 ###

Clear cover (cc) = 15 mm Table 16 Cl.26.4.2

###

Effective thickness of slab (deff)= 200 - 15 - 16 /2 = 177 mm ###

Unit weight of concrete = 25 KN/m 3

IS 456-2000 Cl 19.2.1

###

Effective Shorter Span (Lx) = 6 m ###

Effective Longer Span (Ly) = 6.4 m ###

Aspect ratio Ly/Lx = 1.07 Two way slab

Edge Condition : One Long edge discontinuous

1.0.2 Load Data

Dead Load = 0.20 x 25 = 5 KN/m2

Floor finish = 0.00 KN/m2 IS 875-1987

Imposed Load = 15.00 KN/m2 (Part 2) Table 1

Total load = 20.00 KN/m 2

IS 456-2000

Design load ( Wu ) = 1.5 x 20 = 30.00 KN/m 2

Table 18 Cl 36.4.1

1.0.3 Moment and Shear Calculations ax+

Case No

Short Span Direction ###

ax for positive moment 1 → 0.028 IS 456-2000 ###

1.1 → 0.033 Table 26 Cl D-1.1 ###

for 1.07 ax = 0.03 ###

Positive moment Mx 0.031 x 30.00 x 6 ^2 = 33.84 KN-m ###

ax for negative moment 1 → 0.037 IS 456-2000 ###

1.1 → 0.044 Table 26 Cl D-1.1 ###

for 1.07 ax = 0.04 ###

Negative moment Mx : 0.042 x 30.00 x 6 ^2 = 45.00 KN-m ###

Long Span Direction One Long

Page 10 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

For positive moment ay = 0.028 IS 456-2000

Positive moment My : 0.028 x 30.00 x 6 ^2 = 30.24 KN-m Table 26 Cl D-1.1

For negative moment ay = 0.037 IS 456-2000

Negative moment My : 0.037 x 30.00 x 6 ^2 = 39.96 KN-m Table 26 Cl D-1.1

Shear force V u = 30.00 x 6 x 0.5 = 90.00 KN

1.0.4 Check Effective Depth for Bending

Depth required = (Mx / (0.133x fck x b))1/2 = 106.20 mm SP 16 :1980 Table C

Depth provided = 200 - 15 - 16 /2 = 177 mm Cl 2.3

Hence O.K

1.0.5 Reinforcement calculations

Short Span Direction @ Support

Mu/bd2 = 45.00 x 10 ^ 6 = 1.436

1000 x 177 x ###

Pt = 0.35 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00351 x 1000 x 177 = 621.066 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 200 = 240.00 mm2 Cl:26.5.2.1

Spacing of Y 16 bars 201.06 x 1000 / 621.07 = 323.573 mm

Check for Spacing

Minimum of 1) 3d = 531 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 323.57 mm

Therefore provide Y 16 @ 300 mm C/C

Short Span Direction @ Mid Span

Mu/bd2 = 33.84 x 10 ^ 6 = 1.080

1000 x 177 x ###

Pt = 0.260 % SP16 :1980 Table 2-4

Page 11 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

Area of steel Ast = 0.00260 x 1000 x 177 = 459.621 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 200 = 240.00 mm 2

Cl:26.5.2.1

Spacing of Y 16 bars 201.06 x 1000 / 459.62 = 437.23 mm

Check for Spacing

Minimum of 1) 3d = 531 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 437.23 mm

Therefore provide Y 16 @ 125 mm C/C 125

Provided % of Tension Reinforcement (pt) = 0.909 %

Long Span Direction @ Support

Mu/bd2 = 39.96 x 10 ^ 6 = 1.275

1000 x 177 x ###

Pt = 0.309 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00309 x 1000 x 177 = 547.478 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 200 = 240.00 mm2 Cl:26.5.2.1

Spacing of Y 12 bars 113.10 x 1000 / 547.48 = 206.474 mm

Check for Spacing

Minimum of 1) 3d = 531 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 206.47 mm

Therefore provide Y 12 @ 200 mm C/C

Long Span Direction @ mid Span

Mu/bd2 = 30.24 x 10 ^ 6 = 0.965

1000 x 177 x ###

Pt = 0.231 % SP16 :1980 Table 2-4

Area of steel Ast = 0.00231 x 1000 x 177 = 408.676 mm2 IS 456:2000

Minimum area of steel: 0.0012 x 1000 x 200 = 240.00 mm2 Cl:26.5.2.1

Page 12 .

CLIENT DOCUMENT.NO. DATE DESIGNED DATE

PROJECT REVISION DATE CHECKED DATE

CL. NO. DESIGN CALCULATIONS REFERENCES

Spacing of Y 12 bars 113.10 x 1000 / 408.68 = 276.601 mm

Check for Spacing

Minimum of 1) 3d = 531 mm IS 456:2000

2) = 300 mm Cl:26.3.3.(b).1

3) = 276.60 mm

Therefore provide Y 12 @ 270 mm C/C

1.0.6 Check for Deflection:

Basic Span/depth Ratio = 23 IS 456:2000 Cl:23.2.1

% of Tension Reinforcement provided ( pt ) = 0.909 %

Service stress of steel (fs) : 0.58fy(Ast_r/Ast_p) = 82.87 N/mm2 IS456:2000 Fig 4

Modification Factor for Tension Reinforcement (F1) = 2.00 Page 38

Allowable Span/Eff Depth Ratio = 46 IS 456:2000 Cl:23.2.1

Actual Span/Eff Depth Ratio = 6 x 1000 / 177 = 33.90

Hence O.K

Contents:

1 IS 456:2000 Codal Provisions for slab.

2 Design template for one-way slab.

3 Design template for two-way slab.

Limitations :-

1 Shear Check not included.

You might also like

- ItilDocument11 pagesItilNarendar P100% (2)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Communication Networks Fundamental Concepts and Key Architectures 2nd PDFDocument2 pagesCommunication Networks Fundamental Concepts and Key Architectures 2nd PDFDustin0% (2)

- Wind Load Calculator For Solar (IS 875 Part 3)Document1 pageWind Load Calculator For Solar (IS 875 Part 3)JaaiBadgujarNo ratings yet

- Design Calculation For Watch Tower - R00 - 20200615Document3 pagesDesign Calculation For Watch Tower - R00 - 20200615Raviraj Thorat100% (1)

- Ia Caterpillar Specifications 3304 VehicularEngine TextDocument100 pagesIa Caterpillar Specifications 3304 VehicularEngine Textkatarkivos94% (16)

- Two Way Slab Design - 2 KN m2Document16 pagesTwo Way Slab Design - 2 KN m2pandianNo ratings yet

- Loads:: Housing Layout-Sd-EastDocument2 pagesLoads:: Housing Layout-Sd-Eastpvrk_78No ratings yet

- Design of Formwork For Column R0 - 3.7 MTRDocument5 pagesDesign of Formwork For Column R0 - 3.7 MTRrahul1433No ratings yet

- New Plan House Epsom Project Job No. Calcs For Start Page No./revision Calcs by Calcs Date Checked by Checked Date Approved by Approved DateDocument4 pagesNew Plan House Epsom Project Job No. Calcs For Start Page No./revision Calcs by Calcs Date Checked by Checked Date Approved by Approved DateGirinathNo ratings yet

- Installation - Typical 3.3m.precast Concrete Beam Design (EN1992)Document5 pagesInstallation - Typical 3.3m.precast Concrete Beam Design (EN1992)zms msswiNo ratings yet

- Aluminium TransomDocument2 pagesAluminium TransomRaju SainiNo ratings yet

- F.1 - Crane Pedestal Fatigue Checks - Rev 2Document20 pagesF.1 - Crane Pedestal Fatigue Checks - Rev 2christi SNo ratings yet

- Purlin and RunnerDocument8 pagesPurlin and RunnerBabu Sundararaman0% (1)

- Reference Output 1.0 Genaral Details CalculationsDocument11 pagesReference Output 1.0 Genaral Details CalculationsUmesgNo ratings yet

- Slab Design (Typical Floor Tower-A)Document72 pagesSlab Design (Typical Floor Tower-A)Prolay MannaNo ratings yet

- Calculations For Design of Slab (Aci Method) : Spread SheetDocument9 pagesCalculations For Design of Slab (Aci Method) : Spread Sheetvenkatesh19701No ratings yet

- Welding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateDocument37 pagesWelding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateMatthew CHANNo ratings yet

- Min AxisDocument3 pagesMin AxisjasekanNo ratings yet

- Code Ref. Calculations Output: Column Size: 254 X 146 X 44.64kg/m UBDocument9 pagesCode Ref. Calculations Output: Column Size: 254 X 146 X 44.64kg/m UBkhewzyNo ratings yet

- Steel Beam DesignDocument4 pagesSteel Beam Designanshutomar7915100% (1)

- Ref. Calculations Output: The Capacity of The Slab Basic MeshDocument3 pagesRef. Calculations Output: The Capacity of The Slab Basic MeshOmar MokhtarNo ratings yet

- Design Sheet: DPWH DesignedDocument5 pagesDesign Sheet: DPWH DesignedEdward Albert Mendoza BañagaNo ratings yet

- 8.0 Design of Top Slab: 8.1 Simply Supported Slab at El 3.99Document7 pages8.0 Design of Top Slab: 8.1 Simply Supported Slab at El 3.99farhan yazdaniNo ratings yet

- Load CalculationDocument7 pagesLoad Calculationyaro oruvanNo ratings yet

- Slab Design 2 Way IsDocument3 pagesSlab Design 2 Way IsRam LangheNo ratings yet

- BS 8110 Data Given: Calculation SheetDocument10 pagesBS 8110 Data Given: Calculation SheetLee See VoonNo ratings yet

- Sds Screw DesignDocument3 pagesSds Screw DesignvtalexNo ratings yet

- Strctural Calculation For Canopy-R-2Document32 pagesStrctural Calculation For Canopy-R-2Abdul khaliquNo ratings yet

- Tedds RC Beam DesignDocument5 pagesTedds RC Beam DesignHor Ka WaiNo ratings yet

- CK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3: Project Job NoDocument3 pagesCK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3: Project Job NorameshkaaNo ratings yet

- Design of One-Way Slab: LoadsDocument49 pagesDesign of One-Way Slab: LoadsRassal KarimNo ratings yet

- Stair Case One Way SlabDocument3 pagesStair Case One Way SlabPiyush Machhi0% (1)

- Project Job Ref.: CK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3Document4 pagesProject Job Ref.: CK 2 CM CK 2 2 CTM 2 CK 2 2/3 2 CM 2 CM 2 0.3 2 Cu2 Cu3Buvanendran SanjeevanNo ratings yet

- Slab-Design-2 Way - ISDocument5 pagesSlab-Design-2 Way - ISKamran AliNo ratings yet

- Slab Design 2 Way IsDocument5 pagesSlab Design 2 Way IsPirpasha UjedeNo ratings yet

- Slab CrackwidthDocument15 pagesSlab CrackwidthMohammed Saleem Syed KhaderNo ratings yet

- N111 - Outrigger Parking - FinalDocument5 pagesN111 - Outrigger Parking - FinalcheeseonglawNo ratings yet

- Isolated Footing DesignDocument5 pagesIsolated Footing DesignTONY BOULOSNo ratings yet

- RC Column Design (BS8110) - Part2Document1 pageRC Column Design (BS8110) - Part2Himura_No ratings yet

- Bellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004Document4 pagesBellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004himsdNo ratings yet

- EA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Document2 pagesEA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Imaduddin KhajaNo ratings yet

- Design For Steel Circular Columns (R1)Document8 pagesDesign For Steel Circular Columns (R1)rahul1433No ratings yet

- Rafters British Standards 06-02-2023 0931Document4 pagesRafters British Standards 06-02-2023 0931João SidônioNo ratings yet

- Pile CapDocument400 pagesPile CapMITHUN BDML100% (1)

- 2.1 COLUMN DESIGN ETABS VS MANUALDocument23 pages2.1 COLUMN DESIGN ETABS VS MANUALChirag MehtaNo ratings yet

- Calculation Sheet: Test Job Member Design For SB2Document2 pagesCalculation Sheet: Test Job Member Design For SB2bungykitNo ratings yet

- Design of Two Way Slabs Location Reference: Slab-4: B/W Grid 11 To 13 & A To BDocument13 pagesDesign of Two Way Slabs Location Reference: Slab-4: B/W Grid 11 To 13 & A To BAwais HameedNo ratings yet

- Example 5.1Document6 pagesExample 5.1Aisyah JamalNo ratings yet

- Design of Inlet ChamberDocument2 pagesDesign of Inlet ChamberRaju SainiNo ratings yet

- Valve Pit Wall DesignDocument3 pagesValve Pit Wall DesignersivarajNo ratings yet

- Busugan Part 2 Design BSDSDocument257 pagesBusugan Part 2 Design BSDSmarco miguelNo ratings yet

- SVP010053 - Bih-C-Des - 131Document56 pagesSVP010053 - Bih-C-Des - 131AJAY SHINDENo ratings yet

- 3.000 X 1200m Flag Type (7+965)Document13 pages3.000 X 1200m Flag Type (7+965)UmesgNo ratings yet

- Fea 35mm End Clamp r0Document2 pagesFea 35mm End Clamp r0Prince MittalNo ratings yet

- Z-Purlin DesignDocument6 pagesZ-Purlin DesignrammohanNo ratings yet

- Tedds RC Beam Design 2Document3 pagesTedds RC Beam Design 2Hor Ka WaiNo ratings yet

- Design of MACH Deck Panel - Slab (300mm THK)Document7 pagesDesign of MACH Deck Panel - Slab (300mm THK)Sankar AnandNo ratings yet

- Fea Report - Mini Rail SystemDocument14 pagesFea Report - Mini Rail SystemPrince MittalNo ratings yet

- 2.45M High Rubble Wall: Mila Feb-22Document4 pages2.45M High Rubble Wall: Mila Feb-22Nezza AriffNo ratings yet

- Circular Foundation Design For PoleDocument2 pagesCircular Foundation Design For PoleJayNo ratings yet

- SLABDocument6 pagesSLABLagnajit DasNo ratings yet

- Seminar-I: Structural Behaviour of High Strength Concrete Columns Exposed To FireDocument61 pagesSeminar-I: Structural Behaviour of High Strength Concrete Columns Exposed To FireGovendan GopalakrishnanNo ratings yet

- Underground Construction: by Abhijitsinh A. Parmar Code:-SD1010Document56 pagesUnderground Construction: by Abhijitsinh A. Parmar Code:-SD1010Govendan GopalakrishnanNo ratings yet

- Geosynthetics: Prepared By: Saurabh Shah Code: 1710Document58 pagesGeosynthetics: Prepared By: Saurabh Shah Code: 1710Govendan GopalakrishnanNo ratings yet

- Isolated FootingsDocument12 pagesIsolated FootingsGovendan GopalakrishnanNo ratings yet

- 02.01.05 - UH000 - 01863 - Rev - 02 - Stability Check (8.7m)Document8 pages02.01.05 - UH000 - 01863 - Rev - 02 - Stability Check (8.7m)Govendan GopalakrishnanNo ratings yet

- Corbel RecDocument3 pagesCorbel RecGovendan GopalakrishnanNo ratings yet

- B150 - Lift Roof Slab DesignDocument2 pagesB150 - Lift Roof Slab DesignGovendan GopalakrishnanNo ratings yet

- 02.01.03 - UH000 - 01863 - Rev - 02 - Stability Check (6.75m)Document9 pages02.01.03 - UH000 - 01863 - Rev - 02 - Stability Check (6.75m)Govendan GopalakrishnanNo ratings yet

- Design of Sidewalls For Rain Water Tank-Case-1Document4 pagesDesign of Sidewalls For Rain Water Tank-Case-1Govendan GopalakrishnanNo ratings yet

- 02.02.02 - UH000 - 01863 - Rev - 02 - Stability CheckDocument6 pages02.02.02 - UH000 - 01863 - Rev - 02 - Stability CheckGovendan GopalakrishnanNo ratings yet

- Machine FoundationDocument4 pagesMachine FoundationGovendan GopalakrishnanNo ratings yet

- Project Doc. No. Prepared Date Title Design of Rectangular Beams Revision Checked DateDocument1 pageProject Doc. No. Prepared Date Title Design of Rectangular Beams Revision Checked DateGovendan GopalakrishnanNo ratings yet

- 694/E Steel Column Supporting Structure P1 (KN) 15Document9 pages694/E Steel Column Supporting Structure P1 (KN) 15Govendan GopalakrishnanNo ratings yet

- General: Title Design of Corbel Cl. No. Design Calculations ReferencesDocument15 pagesGeneral: Title Design of Corbel Cl. No. Design Calculations ReferencesGovendan GopalakrishnanNo ratings yet

- Pre Stress BeamsDocument3 pagesPre Stress BeamsGovendan GopalakrishnanNo ratings yet

- Cinnetic 2014 PDFDocument60 pagesCinnetic 2014 PDFOscar SpinningaliciaNo ratings yet

- A02 Inspection Certificate Voestalpine Grobblech GMBH: Detail of SupplyDocument4 pagesA02 Inspection Certificate Voestalpine Grobblech GMBH: Detail of SupplyPeter TvardzíkNo ratings yet

- Notes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationDocument6 pagesNotes: General Steel Fabrication Notes: Carbon Steel Fabrication Notes: Stainless Steel FabricationAquiles MartinezNo ratings yet

- Alternative Binder Phases For WC Cemented Carbides: April 2014Document122 pagesAlternative Binder Phases For WC Cemented Carbides: April 2014Joao NovaisNo ratings yet

- Airnet Catalog enDocument54 pagesAirnet Catalog enJoseNo ratings yet

- Complaint Management SystemDocument69 pagesComplaint Management SystemChaithra kNo ratings yet

- CobolDocument17 pagesCobolSharathRajNo ratings yet

- 746 1805 1 SM PDFDocument9 pages746 1805 1 SM PDFRahul YaduwanciNo ratings yet

- Atoms and MoleculesDocument12 pagesAtoms and MoleculesKshithij R KikkeriNo ratings yet

- NICA DITTE Application Form 2024-2025Document3 pagesNICA DITTE Application Form 2024-2025magemesojamil126100% (1)

- Map UgDocument1,856 pagesMap Ughanif0404100% (1)

- Mid YearDocument7 pagesMid YearMelvinder KaurNo ratings yet

- HELMKE Plus: Three-Phase Low Voltage Squirrel Cage MotorsDocument28 pagesHELMKE Plus: Three-Phase Low Voltage Squirrel Cage MotorsFernando SchneckenburgerNo ratings yet

- VSL Primary Gas StandardsDocument59 pagesVSL Primary Gas Standards分析室信箱No ratings yet

- Complete Catalogues - 160613-2 PDFDocument63 pagesComplete Catalogues - 160613-2 PDFGabriel Barriga JaqueNo ratings yet

- Aqap2120 Ed 1 PDFDocument18 pagesAqap2120 Ed 1 PDFmaccione4311No ratings yet

- WSTP 112ME: Metrology and Benchwork: Learning ModuleDocument54 pagesWSTP 112ME: Metrology and Benchwork: Learning ModulesheeellyyyNo ratings yet

- Auto NetDocument40 pagesAuto NetsdthrtshrsNo ratings yet

- Duty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerDocument3 pagesDuty Cycle of Circuit Breaker - Operating Sequence of Circuit BreakerHawaz BeyeneNo ratings yet

- Niigata Earthquake Case StudyDocument9 pagesNiigata Earthquake Case StudyJems MansuetoNo ratings yet

- Elektor Electronics 2016-03,04Document132 pagesElektor Electronics 2016-03,04Adrian_Andrei_443388% (8)

- Dom MP 2Document2 pagesDom MP 2darlingprabhas95709No ratings yet

- Material Selection Criteria For Floor Finishing: Requirements For Hospital Lobby FlooringDocument12 pagesMaterial Selection Criteria For Floor Finishing: Requirements For Hospital Lobby FlooringAmna KhanNo ratings yet

- Nug Roho 2010Document22 pagesNug Roho 2010mukhammad nurdiansyahNo ratings yet

- The Demise of The Philippine Aerospace Development CorporationDocument4 pagesThe Demise of The Philippine Aerospace Development CorporationJojo Banzon100% (2)

- Hart ProtocolDocument13 pagesHart ProtocolRey-an A. MorenoNo ratings yet

- Perspective and SpaceDocument4 pagesPerspective and SpaceHazel E. AbantoNo ratings yet