Professional Documents

Culture Documents

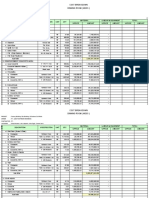

SR - No Item Unit Requirement in Bags Remarks

SR - No Item Unit Requirement in Bags Remarks

Uploaded by

Ravi kumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SR - No Item Unit Requirement in Bags Remarks

SR - No Item Unit Requirement in Bags Remarks

Uploaded by

Ravi kumarCopyright:

Available Formats

ROHAN BUILDERS (I) PVT.

LTD

QUALITY STANDARD

Sr.No Item Unit Requirement in Bags Remarks

A Reinforced Cement Concrete Consumption

1 Cement Concrete M-20 Cum. 6.52

2 Cement Concrete M-25 Cum. 7.0

3 Cement Concrete M-30 Cum. 7.66

Relative Propration

B Concrete Mix Ratio of ingredients by In Genrul we specify it as

Volume

Sr.No Grade of Concrete Cemant Fine Agg. Crush Agg. Ratios

1 M-5 1 5 10 (1:5:10)

2 M-7.5 1 4 8 (1:4:8)

3 M-10 1 3 6 (1:3:6)

4 M-15 1 2 4 (1:2:4)

5 M-20 1 1.5 3 (1:1.5:3)

6 M-25 1 1 2 (1:1:2)

7 M-30 1 0.75 1.5 1:0.75:1.5

C Sample of Concrete Cubes

Number of samples Cube size :

Sr.No Quantity of concrete in the work (m3)

( 3 no. one set ) 150mmx150x150mm

1 0-5 1

2 6_15 2

3 16-30 3

4 31-50 4

5 51 and above 4 plus one additional sample for each additional

D Grade Of Concrete (IS:456 :2000)

Compressive Strength

Sr.No Grade Designe 28 Days in N/mm2 Group

1 M-10 (M=Mixd)10=Compressive Strength 10

2 M-15(M=Mixd)15=Compressive Strength 15 Ordinary Concrete

3 M-20(M=Mixd) 20=Compressive Strength 20

4 M-25(M=Mixd)25=Compressive Strength 25

5 M-30(M=Mixd)30=Compressive Strength 30

6 M-35(M=Mixd)35=Compressive Strength 35

7 M-40(M=Mixd)40=Compressive Strength 40 Stendard Concrete

8 M-45(M=Mixd)45=Compressive Strength 45

9 M-50(M=Mixd)50=Compressive Strength 50

10 M-55(M=Mixd)55=Compressive Strength 55

11 M-60(M=Mixd)60=Compressive Strength 60

12 M-65(M=Mixd)65=Compressive Strength 65

13 M-70(M=Mixd)70=Compressive Strength 70 High Strength Concrete

14 M-75(M=Mixd)75=Compressive Strength 75

15 M-80(M=Mixd)80=Compressive Strength 80

E Our Site Concrete Desgin Mix

Sr.No MIX DESIGNE OF CONCRETE Per/CUM M20 M25 M30

1 Cement 326 350 383

2 Water 163 161 161

3 Admixture Fosroc SP-430 2.93 3.15 3.45

4 Aggregate 20 mm 828 818 804

5 Aggregate 10 mm 455 450 442

6 Crushed Sand 764 762 754

7 Weight per Cum 2538.93 2544.15 2547.45

1 Date of Packing /Date of Manufacture

F Cement Physical Test ( LAB ) Unit 53-Grade(IS:12269:2013)

1 Standerd Consistancy

2 Fineness by Blaines air permeability

3 Initial setting time Minutes Min-30

4 Final setting time Minutes Max-600

5 Soundness test

6 Comp.strength

G Types of Cement Grade of Cement

1 Ordinary portland cement 33

2 pozzolana portland cement 43

3 Portland blast furnance slag cement 53

4 sulphate resisting portland cement

5 Rapid hardening portland cement

6 oil well cement

7 clinker cement

8 white cement

H Reinforcement steel (As per IS:1786:2008

Sr.No Reinforcement steel(As per IS:1786:2008 Grade of steel

1 Steel-chemical ( Lab test ) Fe-415

2 Carbon Fe-415D

3 sulpher Fe-500

4 phosphorus Fe-500D

5 Steel-Physical ( Lab test ) Fe-550

6 Tensile test Fe-550D

7 Elongation Fe-600

8 Yield strength

9 Bend test

10 weight per mtr (kg/m)

I Steel Covers in strcture wise

1 footing 50mm

2 column 30mm

3 wall 30mm

4 beam 30mm

5 slab 25mm

J General points about steel

1 length of hooks in ring 10D

2 bend Angle in rings and hooks 135 degree

3 lap length 45D

4 Anchorage length 55D

K Steel Bar Weight Calculation

Sr.No Dia of a steel bar formulat of steel Weight Kg/mt

1 8 mm 8x8\162=0.395kg/mt 0.395 Kg/mt

L Plywood Size & Weight

Sr.No Size Weight Kg Area m2

1 12 mm 1220x2440 30 2.97 m2

2 18 mm 1220x2440 54 2.97 m2

M M.S Binding Wire

Sr.No Gauge of Wire Per Ton

1 16 Gauge 12-13 kg

2 18 Gauge 10-12kg

N Shuttering

minimum period before

A Type of formwork

striking formwork

1 Vertical formwork to colum,bem,wall 16-24 h

2 soffit formwork to slab proper to be refixed 3 days

B Props to slab

1 spanning up to 4.5m 7 days

2 spanning over 4.5m 14 days

C Props to beam

1 spinning up to 6.0 m 14 days

2 spinning over 6.0 m 21 days

Equipment fuel Consumption

Equipment Work Description Fuel Ltr Per Hrs Out/ Put

1 Jcb For Mass excavation 5 Ltr/ Hrs 15-18 m3

Soil excavation 13-15 Ltr /Hrs 45-50 m3

2 Poclain

Hard Rock Material 15-17 Ltr/Hrs 15-18 m3

Full Vibration For

3 Vibro Roller 12-14 Ltr/Hrs 800 m2

Compaction Work

Unloading Debris and

4 Dumper 1 Ltr / 3Km 5-6 m3 per Trip

Shifting cons. Material

P Brickwork & Block work Unit Per Cum Curing Period

1 B.B. masonry in C.M. 1 : 6 proportion Cum. 1.44 7 Days

2 B.B. masonry in C.M. 1 : 6 proportion Cum. 1.44 7 Days

3 ACC Block masonry in C.M. 1:4 proportion Cum 0.578 7 Days

Q Plastering Curing Period

1 Providing internal cement plaster 6 mm.thick single coat in C.M. 1 : 4 7 Days

2 Providing internal cement plaster 6 mm.thick single coat in C.M. 1 : 3 8 Days

3 Providing internal cement plaster 12 mm.thick single coat in C.M. 1 : 5 9 Days

(a) -- do -- in C.M. 1 : 4 proportion. 10 Days

(b) -- do -- in C.M. 1 : 3 proportion 11 Days

5 Providing cement plaster 20 mm. thick in single coat in C.M. 1 : 3 12 Days

Density of Grade construction materials below.

S.No. Construction Materials Density (Kg/m 3 ) Grade/Unit

1 Water 1000 Ltr.

2 Sandy soil 1800 kg/m3

3 Clay soil 1900 kg/m3

4 Gravel soil 2000 kg/m3

5 Sandstone 2000 kg/m3

6 Silt 2100 kg/m3

7 Cement mortar 2080 kg/m3

8 Lime 640 kg/m3

9 Lime mortar 1760 kg/m3

10 Stainless steel 7480 – 8000 kg/m3

11 Aluminum 2739

12 Cast iron 7208

13 Copper 8940

14 Iron 7850

15 Glass 2580

16 AAC Block 650-750

17 Redimix Plaster 1770

18 Cement 1440 kg/m3

19 Natural Sand 1.540 kg/m3

20 Concrete (P.C.C) 2400 kg/m3

21 Concrete (R.C.C) 2500 kg/m3

22 Steel 7850 kg/m3,Grade- Fe500D

23 Gravel 1750 kg/m3

24 Stone Aggregate 40 mm 1.510 kg/m3

25 Stone Aggregate 10mm 1.330 kg/m3

26 Stone Aggregate 20mm 1.360 kg/m3

27 Crushed Sand 1.640 kg/m3

You might also like

- D.S.R. - 2012-2013finel PDWDocument243 pagesD.S.R. - 2012-2013finel PDWprashantlingayat25% (4)

- Concrete Grades With Their Respective Mi PDFDocument1 pageConcrete Grades With Their Respective Mi PDFOLUWASEUN QUADRINo ratings yet

- Concrete Mix Ratio - Typees, Grades, & Design - CiviconceptsDocument16 pagesConcrete Mix Ratio - Typees, Grades, & Design - CiviconceptsAbraham BirhanNo ratings yet

- Influence of Marble Powder Mortar and Concrete MixDocument5 pagesInfluence of Marble Powder Mortar and Concrete MixAjithNo ratings yet

- Mix DesignDocument6 pagesMix DesignschaktenNo ratings yet

- Different Types of Concrete Grades and Their UsesDocument9 pagesDifferent Types of Concrete Grades and Their UsesTunchiTheBadGuyNo ratings yet

- Designed Concrete MixDocument6 pagesDesigned Concrete MixniceseshaNo ratings yet

- Amendment No. 4 May 2013 TO Is 456: 2000 Plain and Reinforced Concrete - Code of PracticeDocument5 pagesAmendment No. 4 May 2013 TO Is 456: 2000 Plain and Reinforced Concrete - Code of Practiceraviteja036No ratings yet

- 456a4 PDFDocument5 pages456a4 PDFNaveen NunnaNo ratings yet

- Unit 528 Concrete Design Task 3Document4 pagesUnit 528 Concrete Design Task 3Shine AungNo ratings yet

- Concrete GradeDocument3 pagesConcrete GradeAzriNo ratings yet

- Study On Strength Improvement of Pervious Concrete: B.V.R.Murthy, G.RajeswariDocument3 pagesStudy On Strength Improvement of Pervious Concrete: B.V.R.Murthy, G.RajeswariDusmanta Kumar BeheraNo ratings yet

- Mix Design of ConcreteDocument41 pagesMix Design of ConcreteBijay Krishna Das92% (13)

- Strength Behaviour of Varies Grades of ConcreteDocument13 pagesStrength Behaviour of Varies Grades of Concretekanchari naveen kumarNo ratings yet

- Part List Iron Wheel: Kode Part Nama Part Descrition Relation 1 2 3Document3 pagesPart List Iron Wheel: Kode Part Nama Part Descrition Relation 1 2 3Beni hidayatullahNo ratings yet

- Full DCSDocument45 pagesFull DCSStructure EngineerNo ratings yet

- Compressive Strength Test On Brick: ShareDocument5 pagesCompressive Strength Test On Brick: ShareNick GeneseNo ratings yet

- Compressive Strength Test On BrickDocument5 pagesCompressive Strength Test On BrickAnonymous LiddTaTaZTNo ratings yet

- ST2013-120-M15-M25-J K Laxmi-SNDDocument4 pagesST2013-120-M15-M25-J K Laxmi-SNDPrakash MakwanaNo ratings yet

- Mechanics of Masonry in CompressionDocument16 pagesMechanics of Masonry in CompressionPankaj SainiNo ratings yet

- An Study On Steel Fiber Reinforced ConcreteDocument26 pagesAn Study On Steel Fiber Reinforced ConcreteVìctòry Vèérá100% (1)

- Different Grade of Concrete Their Uses and ApplicationDocument7 pagesDifferent Grade of Concrete Their Uses and Application丨ㄒ丂ᐯ乇ᗪ卂几ㄒNo ratings yet

- M-15 PCCDocument38 pagesM-15 PCCRaj PandeyNo ratings yet

- BOQ MessDocument10 pagesBOQ Messalfian adriansyahNo ratings yet

- Mix DesignDocument74 pagesMix DesignKarthikeyan m.karthiNo ratings yet

- Pamphlet On Requirements of Manufactured Coarse Aggregate As Per IS 383-2016Document4 pagesPamphlet On Requirements of Manufactured Coarse Aggregate As Per IS 383-2016Umesh ShengalNo ratings yet

- (ABHOG) Material ConsumptionDocument56 pages(ABHOG) Material Consumptionmeerut nazibabad projectNo ratings yet

- CT 3Document14 pagesCT 3B Tupon DuttʌNo ratings yet

- Cement, Sand, Metal Material-1Document9 pagesCement, Sand, Metal Material-1Krishna ChaitanyaNo ratings yet

- Calculate Cement Sand and Aggregate - Nominal Mix Concrete PDFDocument4 pagesCalculate Cement Sand and Aggregate - Nominal Mix Concrete PDFmdaashuNo ratings yet

- Calculate Cement Sand and Aggregate - Nominal Mix Concrete PDFDocument4 pagesCalculate Cement Sand and Aggregate - Nominal Mix Concrete PDFMadhu PaudelNo ratings yet

- Calculate Cement Sand and Aggregate - Nominal Mix Concrete PDFDocument4 pagesCalculate Cement Sand and Aggregate - Nominal Mix Concrete PDFKwasi Bempong100% (1)

- Concrete Calculations PDFDocument4 pagesConcrete Calculations PDFMadhu PaudelNo ratings yet

- Comprehensive Exam Suggetion PDFDocument6 pagesComprehensive Exam Suggetion PDFHasibur RashidNo ratings yet

- Different Grades of ConcreteDocument31 pagesDifferent Grades of ConcreteAlexander MwauraNo ratings yet

- Detailed Plan Database EstimationDocument6 pagesDetailed Plan Database Estimationbelle18 18No ratings yet

- Rab Flying FoxDocument153 pagesRab Flying FoxNovia Delta100% (1)

- Concrete Placing MethodDocument20 pagesConcrete Placing MethodWindiDwiPerkasaNo ratings yet

- Comparision of Concrete Design MixesDocument12 pagesComparision of Concrete Design MixesKuldeep ChakerwartiNo ratings yet

- Quantity of CementDocument19 pagesQuantity of CementAl Patrick Dela CalzadaNo ratings yet

- Concrete Mix DesignDocument101 pagesConcrete Mix DesignAbdul Wali KhanNo ratings yet

- Arulmigu Bavani Amman Thirukoil Periyapalayam EstimatessDocument158 pagesArulmigu Bavani Amman Thirukoil Periyapalayam EstimatessVignesh MNo ratings yet

- Quantity of CementDocument7 pagesQuantity of CementmadangkNo ratings yet

- Mix Design M-40 GradeDocument10 pagesMix Design M-40 GradekilmasterNo ratings yet

- ExperimentsDocument1 pageExperimentsOsamaZaidNo ratings yet

- PT Mos 7Document92 pagesPT Mos 7Richard Widjaja SeputraNo ratings yet

- Presentation On Fly-Ash Paver BlockDocument31 pagesPresentation On Fly-Ash Paver BlockBaharulHussain75% (8)

- Concrete Mix DesignDocument13 pagesConcrete Mix Designpatel2732sNo ratings yet

- Building Material and Construction: Zone TechDocument13 pagesBuilding Material and Construction: Zone TechKshitiz RawatNo ratings yet

- Final PPT An Experimental Study On Mechanical PropertiesDocument31 pagesFinal PPT An Experimental Study On Mechanical PropertiesMohd JunaidNo ratings yet

- Pamphlet On Requirements of Manufactured Fine Aggregate As Per IS 383-2016Document4 pagesPamphlet On Requirements of Manufactured Fine Aggregate As Per IS 383-2016SP NiralaNo ratings yet

- Michalis 2017Document12 pagesMichalis 2017Paloma CortizoNo ratings yet

- Progress Claim 06 Tridorn Construction SasDocument5 pagesProgress Claim 06 Tridorn Construction SasSHARVINDRANADAN A/L SATHANANDHAN A18KA0153No ratings yet

- Concrete StructuresDocument45 pagesConcrete StructuresDavid Moreno SanchezNo ratings yet

- Concrete Mix Design-M25 Garde IS-456:2000 & IS-10262:2019 Concrete Mix Design-M25Document15 pagesConcrete Mix Design-M25 Garde IS-456:2000 & IS-10262:2019 Concrete Mix Design-M25patel2732sNo ratings yet

- Concrete Mix DesignDocument20 pagesConcrete Mix DesignM Pabire AllanNo ratings yet

- IRC-58 2015 Excel Sheet - Rev (D-E) - Rev 1Document21 pagesIRC-58 2015 Excel Sheet - Rev (D-E) - Rev 1Anonymous D2kuE4oNo ratings yet

- Offsets From Long ChordDocument6 pagesOffsets From Long ChordXyz AvmcNo ratings yet

- Cover Block Method StaDocument1 pageCover Block Method StaRavi kumarNo ratings yet

- JK 43 Opc Test CertificateDocument1 pageJK 43 Opc Test CertificateRavi kumar100% (1)

- Masteremaco S 650: Fast Setting High Strength Thixotropic Roadway Patching MortarDocument2 pagesMasteremaco S 650: Fast Setting High Strength Thixotropic Roadway Patching MortarRavi kumarNo ratings yet

- Initial Vertical Static Load Test: AgencyDocument5 pagesInitial Vertical Static Load Test: AgencyRavi kumarNo ratings yet

- Dye Penetrant TestDocument4 pagesDye Penetrant TestRavi kumarNo ratings yet

- ConcreteDocument1 pageConcreteRavi kumarNo ratings yet

- Aggregate SizeDocument1 pageAggregate SizeRavi kumarNo ratings yet

- ConcreteDocument1 pageConcreteRavi kumarNo ratings yet

- 1 Container No. 1 2 20.12 3 44.12 4 41.18 Mass of Empty Container (M) Mass of Container + Soil (M) Mass of Container + Dry Soil (M)Document2 pages1 Container No. 1 2 20.12 3 44.12 4 41.18 Mass of Empty Container (M) Mass of Container + Soil (M) Mass of Container + Dry Soil (M)Ravi kumarNo ratings yet

- Density ChartDocument1 pageDensity ChartRavi kumarNo ratings yet

- Aplast Rp2640: Retarding Water Reducing AdmixtureDocument4 pagesAplast Rp2640: Retarding Water Reducing Admixturemazen jamalNo ratings yet

- ACCDocument23 pagesACCyaduvansi,rajesh100% (2)

- Design of Automatic Fly Ash Brick Manufacturing Machine ComponentsDocument5 pagesDesign of Automatic Fly Ash Brick Manufacturing Machine ComponentsMuhammad HammadNo ratings yet

- Acc LTD Cement IndustryDocument13 pagesAcc LTD Cement Industryshreeya salunke100% (1)

- Evolution of Advanced Geopolymeric Cementitious Material Via A Novel ProcessDocument10 pagesEvolution of Advanced Geopolymeric Cementitious Material Via A Novel ProcessharveykwanNo ratings yet

- Standard Norms and Specification PDFDocument16 pagesStandard Norms and Specification PDFKhalid Sherbini100% (1)

- Group01 - End Term ProjectDocument35 pagesGroup01 - End Term ProjectSiddharth GuptaNo ratings yet

- Long-Term Durability Properties of Geopolymer Concrete An in Depth ReviewDocument26 pagesLong-Term Durability Properties of Geopolymer Concrete An in Depth ReviewHazen MasrafatNo ratings yet

- Investigation Into The Effects of Egg Shells Powder (Esp) and Groundnut Husk Ash (Gha) On The Properties of Concrete-2Document12 pagesInvestigation Into The Effects of Egg Shells Powder (Esp) and Groundnut Husk Ash (Gha) On The Properties of Concrete-2USMAN MOHAMMED LIKPATANo ratings yet

- Sikadecor®-803 Nature: Product Data SheetDocument3 pagesSikadecor®-803 Nature: Product Data SheetAJ SamsonNo ratings yet

- A Project Report On ACC GOLDDocument43 pagesA Project Report On ACC GOLDPiYush SharmaNo ratings yet

- For Plastering, 260.00Document15 pagesFor Plastering, 260.00Hayeon KimNo ratings yet

- FLS OM KPI Handbook Work 2012 Version 7 PDFDocument37 pagesFLS OM KPI Handbook Work 2012 Version 7 PDFTARNo ratings yet

- Cement Aggregate Test FrequencyDocument2 pagesCement Aggregate Test Frequencycarol santosNo ratings yet

- Design and Control of Concrete Mixtures (1929)Document80 pagesDesign and Control of Concrete Mixtures (1929)flukemonsterNo ratings yet

- 8 Revised1 - Brgy. PanlautanDocument19 pages8 Revised1 - Brgy. PanlautanJoem'z Burlasa-Amoto Esler-DionaldoNo ratings yet

- Cement ManufacturingDocument25 pagesCement ManufacturingHimanshu PalNo ratings yet

- Chapter 2 - Conceptual Framework Review of Related Literature and StudiesDocument8 pagesChapter 2 - Conceptual Framework Review of Related Literature and StudiesraifelNo ratings yet

- Masterpel 725 TdsDocument2 pagesMasterpel 725 TdsZulkhairi MatoriNo ratings yet

- Aspen Plus-Based Simulation of A Cement Calciner and Optimization Analysis of Air Pollutants EmissionDocument11 pagesAspen Plus-Based Simulation of A Cement Calciner and Optimization Analysis of Air Pollutants EmissionJ OHN BOSCONo ratings yet

- Is 10262 2019Document44 pagesIs 10262 2019Alok0% (1)

- MCQ ShrinkageDocument3 pagesMCQ ShrinkageRavi AyyavuNo ratings yet

- Bala Et Al. 2020 ACI Structural JournalDocument13 pagesBala Et Al. 2020 ACI Structural Journalvooyenlei vooyenlei100% (1)

- GM - Materials Science and TechnologyDocument334 pagesGM - Materials Science and TechnologyPredrag ZivkovicNo ratings yet

- Types of Bedding-Pipe-Excavation-And-Backfill PDFDocument11 pagesTypes of Bedding-Pipe-Excavation-And-Backfill PDFNgoni Mafondokoto100% (1)

- Morflor 160 165x 170 Low Cement-NewDocument3 pagesMorflor 160 165x 170 Low Cement-NewLucas de Brito NascimentoNo ratings yet

- MS - Sikalastic-1 KMY For Swimming PoolDocument6 pagesMS - Sikalastic-1 KMY For Swimming PoolXuân Nam NguyễnNo ratings yet

- B.O.Q Girls HostelDocument54 pagesB.O.Q Girls HosteljerryNo ratings yet

- FHWA Partial-DepthDocument14 pagesFHWA Partial-DepthIndra Ndara TruebluesNo ratings yet