Professional Documents

Culture Documents

CHF101 CHW S16 PDF

CHF101 CHW S16 PDF

Uploaded by

Immalatulhusna0 ratings0% found this document useful (0 votes)

72 views1 pageThis document provides information on flux/wire combination CHF101/CHW-S16 for submerged arc welding. The flux is a fluoride-basic type sintered flux with a basicity of 1.8, used for welding low alloy steels. The welding performance includes good arc stability, slag detachability, and low temperature impact toughness of the weld metal. The wire and flux compositions meet various standards including AWS, ISO, BS, and GB/T for welding structures such as power plants, pressure vessels, and bridges fabricated from equivalent tensile strength low alloy steels.

Original Description:

Original Title

CHF101-CHW-S16.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information on flux/wire combination CHF101/CHW-S16 for submerged arc welding. The flux is a fluoride-basic type sintered flux with a basicity of 1.8, used for welding low alloy steels. The welding performance includes good arc stability, slag detachability, and low temperature impact toughness of the weld metal. The wire and flux compositions meet various standards including AWS, ISO, BS, and GB/T for welding structures such as power plants, pressure vessels, and bridges fabricated from equivalent tensile strength low alloy steels.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

72 views1 pageCHF101 CHW S16 PDF

CHF101 CHW S16 PDF

Uploaded by

ImmalatulhusnaThis document provides information on flux/wire combination CHF101/CHW-S16 for submerged arc welding. The flux is a fluoride-basic type sintered flux with a basicity of 1.8, used for welding low alloy steels. The welding performance includes good arc stability, slag detachability, and low temperature impact toughness of the weld metal. The wire and flux compositions meet various standards including AWS, ISO, BS, and GB/T for welding structures such as power plants, pressure vessels, and bridges fabricated from equivalent tensile strength low alloy steels.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

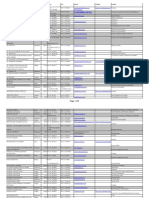

CHF101/CHW-S16

Flux/Wire Combination for Submerged Arc Welding

AWS A5.23M F55P2-EA2-A4

IS0 14171-A-S 46 2 FB S2Mo

IS0 14171-B-S 55P2 FB SU2M3

BS EN 756-S 46 2 FB S2Mo

GB/T 12470 F55P2-H08MnMoA

Type of Flux: Agglomerated (sintered)

Type of Current: DCEP

Features & Applications

CHF101 is a fluoride-basic type sintered flux and its basicity is about 1.8. This combination

is used for welding power plants, petrochemical industrial equipments, pressure vessels,

boilers, hoisting & conveying machineries, engineering & construction machineries, heavy

machineries, bridges, heavy H-beam structures and so on that fabricated by equivalent

tensile strength low alloy steels. The welding performance of it has good arc stability and

good slag detachability and the weld metal has good low temperature impact toughness.

Chemical Composition (%)

C Mn Si S P Mo Cu

CHW-S16 (EA2) Standard 0.05-0.17 0.95-1.35 ≤0.20 ≤0.025 ≤0.025 0.40-0.65 ≤0.3

Typical 0.09 1.10 0.15 0.008 0.011 0.53 0.11

Deposited Metal Standard ≤0.15 ≤1.60 ≤0.80 ≤0.030 ≤0.030 0.40-0.65 ≤0.3

(A4) Typical 0.065 1.31 0.40 0.006 0.017 0.42 0.10

Mechanical Properties of Deposited Metal (PWHT 620℃x1h)

Tensile Strength Yield Strength Elongation Impact Value (J)

Rm (MPa) ReL/RP0.2 (MPa) A4 (%) -20℃

Standard 550-700 ≥470 ≥20 ≥27

Typical 660 560 26 100

X-ray radiographic inspection: Grade Ⅰ

Quality Guarantee of Flux

Moisture Solid Impurities S P Mesh

≤0.10% ≤0.30% ≤0.06% ≤0.08% 10-60

Notice: 1) To avoid rust the wire must be kept in dry condition and keep the package in

good condition also before welding.

2) The flux should be re-baked at 300℃-350℃ for 1-2 hours before use.

3) The surfaces to be welded must be cleaned away impurities of oil

contamination, rust, moisture and so on.

4) The welding conditions mentioned above for reference only and it is better to

do a welding procedure qualification according to project before put it into

formal welding.

You might also like

- Copper and Copper AlloysDocument869 pagesCopper and Copper Alloysrei92% (13)

- LAB 10 CHEM GravimetricDocument5 pagesLAB 10 CHEM Gravimetrictashy richards100% (2)

- CHF101 CHW S12Document1 pageCHF101 CHW S12ImmalatulhusnaNo ratings yet

- AWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Document2 pagesAWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Andre Brama AlvariNo ratings yet

- CHT81 Ni 1Document1 pageCHT81 Ni 1ImmalatulhusnaNo ratings yet

- CHW 50C6Document1 pageCHW 50C6scribdsonbaNo ratings yet

- SmawDocument56 pagesSmawFakhar WindratamaNo ratings yet

- Standar Elektroda PDFDocument182 pagesStandar Elektroda PDFFakhar WindratamaNo ratings yet

- Flux Cored Wires PDFDocument71 pagesFlux Cored Wires PDFCristian Camilo QuirogaNo ratings yet

- CHH517Document1 pageCHH517KureiNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- Che43 PDFDocument1 pageChe43 PDFImmalatulhusnaNo ratings yet

- Che506 PDFDocument1 pageChe506 PDFImmalatulhusnaNo ratings yet

- Che507r PDFDocument1 pageChe507r PDFAnonymous AkzeMHNTUyNo ratings yet

- M El p0.2 2Document3 pagesM El p0.2 2Gopal RamalingamNo ratings yet

- TDS ATLANTIC CHT81Ni1Document1 pageTDS ATLANTIC CHT81Ni1Andi Baso Temalala STNo ratings yet

- CSF-81T en 2014Document1 pageCSF-81T en 2014NGUYEN VINHNo ratings yet

- Bohler Ti 52Document1 pageBohler Ti 52Anonymous nKOyHbNo ratings yet

- CHM 316LDocument1 pageCHM 316LImmalatulhusnaNo ratings yet

- Select Arc Catalogue Part 2Document10 pagesSelect Arc Catalogue Part 2lionheartedNo ratings yet

- CHS29 9Document1 pageCHS29 9sulis setiawanNo ratings yet

- S-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDDocument6 pagesS-777Q X M-12K H-14 L-8: Hyundai Welding Co., LTDSergio AlejandroNo ratings yet

- L1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENDocument1 pageL1 - 12937 - en - Thermanit 25 22 H - Marathon 104 - ENkamals55No ratings yet

- Metrode ER110S-G FillerDocument6 pagesMetrode ER110S-G FillerBernie SimcsNo ratings yet

- Böhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileDocument1 pageBöhler Q 71 RC (C1) : Flux-Cored Wire, Mild Steel, RutileRaviTeja BhamidiNo ratings yet

- CHG 56Document2 pagesCHG 56ImmalatulhusnaNo ratings yet

- E 7016 Spezial electrode-oerlikon-en-TN110089Document2 pagesE 7016 Spezial electrode-oerlikon-en-TN110089Khhg AgddsNo ratings yet

- AWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiDocument1 pageAWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiImmalatulhusnaNo ratings yet

- Supratherm E7018Document1 pageSupratherm E7018yskushwah16No ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- CHE421Document1 pageCHE421Eko SuherNo ratings yet

- CHG 55B2Document1 pageCHG 55B2Nhien ManNo ratings yet

- Hobart Hachene-590Document1 pageHobart Hachene-590Felipe montanaNo ratings yet

- 01112015000000B - Boehler EMK 8 - Solid WireDocument2 pages01112015000000B - Boehler EMK 8 - Solid WirePopa RobertNo ratings yet

- Boehler HL 75 T-MCDocument1 pageBoehler HL 75 T-MCBruno SantosNo ratings yet

- 2 Fcaw-AllDocument51 pages2 Fcaw-AllAhmad ShaheenNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014HoangNo ratings yet

- CSF-71T en 2014Document1 pageCSF-71T en 2014Yousab CreatorNo ratings yet

- Alumina-Silicate Type Agglomerated Submerged Arc Welding FluxDocument1 pageAlumina-Silicate Type Agglomerated Submerged Arc Welding FluxthindmanmohanNo ratings yet

- Boehler CN 23 12 PW-FDDocument1 pageBoehler CN 23 12 PW-FDbrayanNo ratings yet

- E 6013 Fincord M electrode-oerlikon-en-TN110429Document1 pageE 6013 Fincord M electrode-oerlikon-en-TN110429Khhg AgddsNo ratings yet

- Böhler Eas 2 PW-FDDocument1 pageBöhler Eas 2 PW-FDHAKANNo ratings yet

- Low Alloy WiresDocument10 pagesLow Alloy WiresRyan KimNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- L1 8581 en Diamondspark 44 BC CU03100F 3379759 ENDocument1 pageL1 8581 en Diamondspark 44 BC CU03100F 3379759 ENRaviTeja BhamidiNo ratings yet

- Böhler KW 10-Ig: Classifi CationsDocument1 pageBöhler KW 10-Ig: Classifi CationsBranko FerenčakNo ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- Hobart 9LDocument1 pageHobart 9LFelipe montanaNo ratings yet

- Boehler CM2-UPDocument1 pageBoehler CM2-UPdiahNo ratings yet

- Metrode 410NiMo B-11Document4 pagesMetrode 410NiMo B-11Claudia MmsNo ratings yet

- B - Boehler EMK 6 - de - en - 5 PDFDocument1 pageB - Boehler EMK 6 - de - en - 5 PDFburakNo ratings yet

- Bohler Subarc t85 - Uv 421 TT en 1Document1 pageBohler Subarc t85 - Uv 421 TT en 1Dragan JerčićNo ratings yet

- F7az Em12kDocument1 pageF7az Em12kKara WhiteNo ratings yet

- S-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDDocument12 pagesS-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDamir bizhehNo ratings yet

- E71T-GS Gasless Flux Cored Welding WireDocument1 pageE71T-GS Gasless Flux Cored Welding WireMarius BarNo ratings yet

- B - Boehler NiMo 1-IG - de - en - 5Document1 pageB - Boehler NiMo 1-IG - de - en - 5cristian popescuNo ratings yet

- Maxfil 42BDocument1 pageMaxfil 42BMurali YNo ratings yet

- YAWATA 7018: Classification Applications Characteristics ApprovalsDocument1 pageYAWATA 7018: Classification Applications Characteristics ApprovalsDenny AgusNo ratings yet

- 02112015000000B - Boehler FOX EASN 25 M - CeDocument1 page02112015000000B - Boehler FOX EASN 25 M - CeABNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Uniform CorrosionDocument33 pagesUniform CorrosionImmalatulhusnaNo ratings yet

- MTC Jfe Eh500Document2 pagesMTC Jfe Eh500ImmalatulhusnaNo ratings yet

- Your Event Guide To TAYLOR SWIFT THE ERAS TOURDocument9 pagesYour Event Guide To TAYLOR SWIFT THE ERAS TOURImmalatulhusnaNo ratings yet

- Welding Materials: Ultra-Precision Mold Padding WelderDocument4 pagesWelding Materials: Ultra-Precision Mold Padding WelderImmalatulhusnaNo ratings yet

- SMI - BBSR - OPN - WI 03.00, Cleaning of Cold Face of Copper PlateDocument1 pageSMI - BBSR - OPN - WI 03.00, Cleaning of Cold Face of Copper PlateImmalatulhusnaNo ratings yet

- SMI - BBSR - OPN - F - 34A-F Roll Assembly Checklist (Internal)Document4 pagesSMI - BBSR - OPN - F - 34A-F Roll Assembly Checklist (Internal)ImmalatulhusnaNo ratings yet

- Duaplate D80 Weld Overlay: ManufactureDocument1 pageDuaplate D80 Weld Overlay: ManufactureImmalatulhusnaNo ratings yet

- Ultrasonic Flaw Detector: Sonocon ВlDocument32 pagesUltrasonic Flaw Detector: Sonocon ВlImmalatulhusnaNo ratings yet

- Sistim Tegangan &: Residual StressDocument52 pagesSistim Tegangan &: Residual StressImmalatulhusnaNo ratings yet

- CHG 308LDocument1 pageCHG 308LImmalatulhusnaNo ratings yet

- Hydrogen Damage and EmbrittlementDocument9 pagesHydrogen Damage and EmbrittlementImmalatulhusnaNo ratings yet

- Copper Alloys in Ingot Form: Standard Specification ForDocument12 pagesCopper Alloys in Ingot Form: Standard Specification ForImmalatulhusnaNo ratings yet

- Introduksi Analisa Kerusakan: (Introduction To Failure Analyses)Document13 pagesIntroduksi Analisa Kerusakan: (Introduction To Failure Analyses)ImmalatulhusnaNo ratings yet

- CHM 316LDocument1 pageCHM 316LImmalatulhusnaNo ratings yet

- Che506 PDFDocument1 pageChe506 PDFImmalatulhusnaNo ratings yet

- ZG42Cr1MoZG42CrMo Datasheet PDFDocument2 pagesZG42Cr1MoZG42CrMo Datasheet PDFImmalatulhusnaNo ratings yet

- AWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiDocument1 pageAWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiImmalatulhusnaNo ratings yet

- CHF101 CHW S12Document1 pageCHF101 CHW S12ImmalatulhusnaNo ratings yet

- Flux 15WDocument2 pagesFlux 15WImmalatulhusnaNo ratings yet

- CHT81 Ni 1Document1 pageCHT81 Ni 1ImmalatulhusnaNo ratings yet

- Che43 PDFDocument1 pageChe43 PDFImmalatulhusnaNo ratings yet

- CHG 56Document2 pagesCHG 56ImmalatulhusnaNo ratings yet

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaNo ratings yet

- Abrasion and Corrosion: GB/T 984 Edzcr-B-08Document1 pageAbrasion and Corrosion: GB/T 984 Edzcr-B-08ImmalatulhusnaNo ratings yet

- CHR707Document1 pageCHR707ImmalatulhusnaNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- Igcse Chemistry Notes (Except Unit 1)Document104 pagesIgcse Chemistry Notes (Except Unit 1)michaela menzelNo ratings yet

- 7 Storage 2Document16 pages7 Storage 2ZdSentono ChannelNo ratings yet

- MSDS Co2Document2 pagesMSDS Co2Summer SunNo ratings yet

- Recycling of Aluminium Scrap For Secondary Al-Si AlloysDocument8 pagesRecycling of Aluminium Scrap For Secondary Al-Si AlloyssinrNo ratings yet

- TPP Excel BaruDocument7 pagesTPP Excel BaruAtika HapsatiNo ratings yet

- 10.1 Physical Properties and Uses of Metals + AlloysDocument19 pages10.1 Physical Properties and Uses of Metals + AlloysUmida ZaylobiddinovaNo ratings yet

- Inflatable TentDocument13 pagesInflatable TentDSDSDNo ratings yet

- API 526 6th Edition Errata 2 2009Document1 pageAPI 526 6th Edition Errata 2 2009Noralia Amanina Osman0% (1)

- Chemistry Cambridge Grade 10Document15 pagesChemistry Cambridge Grade 10priyanto laksonoNo ratings yet

- HydrogenDocument18 pagesHydrogenJack LupinoNo ratings yet

- History of PlasticDocument3 pagesHistory of PlasticVikneshwaran BalakrishnanNo ratings yet

- User Guide Cross Reference Atc 5 1Document8 pagesUser Guide Cross Reference Atc 5 1Dabin LeeNo ratings yet

- Presentation: Cahya Mohamad Rizki 2B D3 Chemical Engineering 121411037Document11 pagesPresentation: Cahya Mohamad Rizki 2B D3 Chemical Engineering 121411037Cahya Mohamad RizkiNo ratings yet

- wch11 01 Que 20221012Document28 pageswch11 01 Que 20221012AthenaNo ratings yet

- Measure Measure Pour Measure Set Up: Efficiency of Alkanols As FuelsDocument2 pagesMeasure Measure Pour Measure Set Up: Efficiency of Alkanols As FuelsSara LeeNo ratings yet

- Refining Gas Processing Petrochemicals: Petroleum Technology QuarterlyDocument108 pagesRefining Gas Processing Petrochemicals: Petroleum Technology QuarterlyTruth SeekerNo ratings yet

- Company City Phone Fax Email Website Product P.O. Box: Page 1 of 8Document8 pagesCompany City Phone Fax Email Website Product P.O. Box: Page 1 of 8venkwok_sghcableNo ratings yet

- Kyhieu Vat Lieu Ky ThuatDocument30 pagesKyhieu Vat Lieu Ky ThuattranconglyNo ratings yet

- OTC Ingredient List (Alphabetical by Ingredient) 9-21-10aDocument88 pagesOTC Ingredient List (Alphabetical by Ingredient) 9-21-10awindeleta0% (1)

- Direct Chill Billet Casting of Al AlloysDocument24 pagesDirect Chill Billet Casting of Al AlloysOsman Halil Çelik100% (1)

- Chapter 4 - TreybalDocument2 pagesChapter 4 - TreybalMohamed-DeqSabriyeNo ratings yet

- Cls Jeead-16-17 Xi Che Target-1 Set-1 Chapter-4Document20 pagesCls Jeead-16-17 Xi Che Target-1 Set-1 Chapter-4Ankit GargNo ratings yet

- Solubility EnhancementDocument65 pagesSolubility EnhancementJaspreet GurayaNo ratings yet

- Preliminary Idea of Reaction MechanismDocument15 pagesPreliminary Idea of Reaction MechanismSiddhant SahNo ratings yet

- Is Matter Around Us Pure 2023 2024Document5 pagesIs Matter Around Us Pure 2023 2024armhs schoolNo ratings yet

- 257 - Basic Manufacturing Processes-Ilovepdf-Compressed PDFDocument112 pages257 - Basic Manufacturing Processes-Ilovepdf-Compressed PDFsoul tunesNo ratings yet

- Bap - Bwro SystemDocument55 pagesBap - Bwro SystemGloria HamiltonNo ratings yet

- Complete Immersion Phosphating LineDocument8 pagesComplete Immersion Phosphating LineStay AwayNo ratings yet