Professional Documents

Culture Documents

Manufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)

Manufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)

Uploaded by

khmortezaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)

Manufacturing Operations Checklist (Readiness Review For Ppap/Run@Rate)

Uploaded by

khmortezaCopyright:

Available Formats

F25(SOP/PM/01)00

00/01.03.10

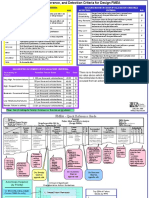

MANUFACTURING OPERATIONS CHECKLIST (READINESS REVIEW FOR PPAP/RUN@RATE)

Target Completion Date:

Checklist Tracking No.:

Date Issued:

REASON FOR CHECKLIST Part Number Part Print

New Operation Part Name Operation No.(Optional)

New Product Plant/Dept./Group Opern Decp. (Optional.)

Revised Operation EN # (optional) Checklist Originator

Revised Process Reason for Checklist:

Product Design Change

Other

NOTE: ALL ELEMENTS WITH A “NO” ANSWER MUST HAVE A COMMENT OR ACTION PLAN COMPLETED.

S.No. FUNCTION RESPONSIBILITY ASSESSMENT ELEMENT YES NO N/A ACTION PLAN / TARGET DATE

HAS THE FLOOR PLAN BEEN REVIEWED &

1

APPROVED?

IS MATERIAL HANDLING INSTALLED AND

2

FUNCTIONAL?

HAVE JOB INSTRUCTION GUIDES

3

WRITTEN/REVISED?

ARE THE VISUAL AIDS/BORDER SAMPLES UP TO

4

DATE?

5 IS THE PROCESS FLOW DIAGRAM COMPLETE?

IS THE PROCESS CONTROL PLAN COMPLETE

6

AND AVAILABLE TO THE OPERATOR (S)?

IS PURCHASED PART PPAP SUBMISSION

7

APPROVED?

HAVE GAGES BEEN ENTERED INTO THE GAGE

8

MAINTENANCE PROGRAM?

9 ARE GAGE R&R’s COMPLETE?

F25(SOP/PM/01)00

00/01.03.10

MANUFACTURING OPERATIONS CHECKLIST (READINESS REVIEW FOR PPAP/RUN@RATE)

Target Completion Date:

Checklist Tracking No.:

Date Issued:

REASON FOR CHECKLIST Part Number Part Print

New Operation Part Name Operation No.(Optional)

New Product Plant/Dept./Group Opern Decp. (Optional.)

Revised Operation EN # (optional) Checklist Originator

Revised Process Reason for Checklist:

Product Design Change

Other

NOTE: ALL ELEMENTS WITH A “NO” ANSWER MUST HAVE A COMMENT OR ACTION PLAN COMPLETED.

S.No. FUNCTION RESPONSIBILITY ASSESSMENT ELEMENT YES NO N/A ACTION PLAN / TARGET DATE

IS FIRST ARTICLE/PPAP OR OTHER CUSTOMER

10

REQUIREMENTS COMPLETE ON THIS PART?

IS GP-12 NOTIFICATION AND CONTAINMENT IN

11

PLACE?

IS THERE ERROR-PROOFING

12

IS THEIR AUDIT PROCEDURE FOR ERROR

PROOFING?

13 HAVE ENGINEERING PERMITS BEEN APPROVED?

IS THERE A MATERIAL IDENTIFICATION SYSTEM

14

IN PLACE TO AVOID PRODUCT MIX?

IS THERE A CLEAR METHOD FOR

15 IDENTIFICATION AND DISPOSAL OF

NONCONFORMING MATERIAL?

16 IS 5“S” PROGRAM IN PLACE?

IS THERE A DOCUMENTED TRAINING PROGRAM

17 FOR ALL OPERATORS, INSPECTORS, AND

COORDINATORS?

F25(SOP/PM/01)00

00/01.03.10

MANUFACTURING OPERATIONS CHECKLIST (READINESS REVIEW FOR PPAP/RUN@RATE)

Target Completion Date:

Checklist Tracking No.:

Date Issued:

REASON FOR CHECKLIST Part Number Part Print

New Operation Part Name Operation No.(Optional)

New Product Plant/Dept./Group Opern Decp. (Optional.)

Revised Operation EN # (optional) Checklist Originator

Revised Process Reason for Checklist:

Product Design Change

Other

NOTE: ALL ELEMENTS WITH A “NO” ANSWER MUST HAVE A COMMENT OR ACTION PLAN COMPLETED.

S.No. FUNCTION RESPONSIBILITY ASSESSMENT ELEMENT YES NO N/A ACTION PLAN / TARGET DATE

ARE ALL JOB INSTRUCTIONS/PEOPLE FOCUSED

18 PRACTICE SHEETS POSTED AND REVIEWED

WITH APPROPRIATE PEOPLE?

ARE ALL QUALITY CONTROL DOCUMENTS ON

19

THE JOB?

20 ARE GAGES ON THE JOB?

HAVE PROVISIONS BEEN ESTABLISHED FOR

21 TRACEABILITY (E.G. MACHINE, OPERATION, and

SHIFT)?

HAS A PREVENTIVE MAINTENANCE PROGRAM

22

BEEN ESTABLISHED AND IMPLEMENTED?

23 HAS THE PFMEA BEEN UPDATED?

IS SAFETY & LOCK OUT PROCEDURE AVAILABLE

24

ON LINE?

HAVE CALIBRATION PROCEDURES BEEN

25

DEVELOPED AND PERFORMED ON EQUIPMENT?

HAVE GAGE INSTRUCTIONS BEEN

26

WRITTEN/REVISED?

F25(SOP/PM/01)00

00/01.03.10

MANUFACTURING OPERATIONS CHECKLIST (READINESS REVIEW FOR PPAP/RUN@RATE)

Target Completion Date:

Checklist Tracking No.:

Date Issued:

REASON FOR CHECKLIST Part Number Part Print

New Operation Part Name Operation No.(Optional)

New Product Plant/Dept./Group Opern Decp. (Optional.)

Revised Operation EN # (optional) Checklist Originator

Revised Process Reason for Checklist:

Product Design Change

Other

NOTE: ALL ELEMENTS WITH A “NO” ANSWER MUST HAVE A COMMENT OR ACTION PLAN COMPLETED.

S.No. FUNCTION RESPONSIBILITY ASSESSMENT ELEMENT YES NO N/A ACTION PLAN / TARGET DATE

ARE THE UPDATED SET-UP SHEETS ON THE

27

JOB?

28 IS THE PROCESS STATISTICALLY CAPABLE?

DOES THE PROCESS MEET A MINIMUM OF 1.67

29

Ppk ON KPC’S & KCC’S.

30 IS MACHINE MEETING QUOTED CYCLE TIME?

IS REPLACEMENT TOOLING AND SPARE PARTS

31

SET-UP AND AVAILABLE?

HAS THE MACHINE EQUIPMENT NUMBER TAG

32

BEEN INSTALLED?

33 ARE THEIR REWORK PROCEDURES AVAILABLE?

IS THERE A PROCEDURE TO REQUALIFY

34

REWORKED MATERIAL?

HAS THE PULL SYSTEM BEEN REVIEWED AND

35

CHANGES IMPLEMENTED?

F25(SOP/PM/01)00

00/01.03.10

MANUFACTURING OPERATIONS CHECKLIST (READINESS REVIEW FOR PPAP/RUN@RATE)

Target Completion Date:

Checklist Tracking No.:

Date Issued:

REASON FOR CHECKLIST Part Number Part Print

New Operation Part Name Operation No.(Optional)

New Product Plant/Dept./Group Opern Decp. (Optional.)

Revised Operation EN # (optional) Checklist Originator

Revised Process Reason for Checklist:

Product Design Change

Other

NOTE: ALL ELEMENTS WITH A “NO” ANSWER MUST HAVE A COMMENT OR ACTION PLAN COMPLETED.

S.No. FUNCTION RESPONSIBILITY ASSESSMENT ELEMENT YES NO N/A ACTION PLAN / TARGET DATE

36 ARE ALL CONTAINERS/DUNNAGE AVAILABLE?

HAS PRODUCT ENGINEERING BEEN NOTIFIED OF

37

CHANGES AND/OR NEW OPERATIONS?

HAS SPARE PARTS AND TOOLING PLAN BEEN

38

IMPLEMENTED?

HAS ERGONOMIC ASSESSMENT BEEN

39

PERFORMED?

Remarks

(optional)

Reviewed By:

Quality Assurance Manufacturing Engineering

Approved By:

Plant Manager

You might also like

- ANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / VersionDocument1 pageANPQP - Supplier Feasibility Commitment: Renault Project: Document Reference No / Versionjefry sitorusNo ratings yet

- VDA 8D Fehlerursachenkategorien V2.1 en EnglishDocument37 pagesVDA 8D Fehlerursachenkategorien V2.1 en EnglishkhmortezaNo ratings yet

- QAD Procedure - Lab Management P2Document1 pageQAD Procedure - Lab Management P2sumanNo ratings yet

- Describe and Compare Below The Changes Requested To Current Product Features/requirementsDocument1 pageDescribe and Compare Below The Changes Requested To Current Product Features/requirementsdrustagiNo ratings yet

- Product Identification TagDocument3 pagesProduct Identification TagshalinmishraNo ratings yet

- FINETURN Feasibility FormatDocument1 pageFINETURN Feasibility FormatAyush NarangNo ratings yet

- Anexo 05 - PPA Matrix 3.0 Feb2017 NewDocument197 pagesAnexo 05 - PPA Matrix 3.0 Feb2017 NewKim KimNo ratings yet

- Control Plan: 3 1/4" Bore A-Series Side-Lug CapsDocument4 pagesControl Plan: 3 1/4" Bore A-Series Side-Lug CapsRavichandran D100% (1)

- IA Audit Observation ReportDocument12 pagesIA Audit Observation ReportKeval ShethNo ratings yet

- # Chapter 9: Sub-Suppliers Management 3: SupplierDocument1 page# Chapter 9: Sub-Suppliers Management 3: SupplierAnkit SainiNo ratings yet

- TEAM fEASIBILITYDocument2 pagesTEAM fEASIBILITYPk NimiwalNo ratings yet

- PFMEA Review PlanDocument1 pagePFMEA Review PlanKaran Malhi100% (1)

- List of Shelf Life ItemsDocument2 pagesList of Shelf Life ItemsDhinakaranNo ratings yet

- 43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueDocument4 pages43.8D - 20456 - Cyl Bottom - Thread Perpendicular IssueVasanth KumarNo ratings yet

- 8.fixture Inspection ReportDocument1 page8.fixture Inspection ReportBASAVA ENGINEERINGNo ratings yet

- Vda Fmea TemplateDocument54 pagesVda Fmea Templatehmp90No ratings yet

- Sr. No. Date Phenomenon Requirement From RNTBCI (From ASES Report) Actions From Supplier Pilot Target DateDocument4 pagesSr. No. Date Phenomenon Requirement From RNTBCI (From ASES Report) Actions From Supplier Pilot Target DateAnkit SainiNo ratings yet

- Responsibility and Authority - QMSDocument47 pagesResponsibility and Authority - QMSDisha Shah50% (2)

- Draft (Ref - Standard Minimal New Supplier Assesment)Document24 pagesDraft (Ref - Standard Minimal New Supplier Assesment)Asan SusantoNo ratings yet

- PFD and Pqcs of Can Rear BreakDocument16 pagesPFD and Pqcs of Can Rear BreakVikas KashyapNo ratings yet

- 4th Edition PPAPDocument83 pages4th Edition PPAPTerri Paleno Lebow100% (1)

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationDocument36 pagesISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751No ratings yet

- Process Flow For Order ExecutionDocument1 pageProcess Flow For Order ExecutionSathish RNo ratings yet

- Form30TM Advanced Product Quality Planning-APQPDocument1 pageForm30TM Advanced Product Quality Planning-APQPShinichi SuzukiNo ratings yet

- Apqp Advanced Product Quality PlanningDocument27 pagesApqp Advanced Product Quality PlanningRajesh KumarNo ratings yet

- Kunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsDocument2 pagesKunstocom India Pvt. LTD.: Format No: Issue No./Date: Qav-Check Sheet Rev - No/Rev. Date: Control Item Check ItemsSandeep VermaNo ratings yet

- IPV AQEMM 01 11 Turtle Diagram ProductionDocument4 pagesIPV AQEMM 01 11 Turtle Diagram ProductionNurul NatashaNo ratings yet

- Rohtas Fasteners Pvt. LTD.: Defect Matrix-Bolt Cylinder Head SR. Ok Part Defect Reject Part ImageDocument4 pagesRohtas Fasteners Pvt. LTD.: Defect Matrix-Bolt Cylinder Head SR. Ok Part Defect Reject Part ImageVandana MehraNo ratings yet

- P-03 Procedure For Rework 2Document2 pagesP-03 Procedure For Rework 2sharif1974No ratings yet

- FIR-garments PDFDocument4 pagesFIR-garments PDFTarun PariharNo ratings yet

- Efwe 2 e 4 GF 1 W 3Document1 pageEfwe 2 e 4 GF 1 W 3BALACHANDAR SNo ratings yet

- Layout Inspection Plan 2020-2021Document1 pageLayout Inspection Plan 2020-2021rajesh sharmaNo ratings yet

- Deviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReportDocument3 pagesDeviation Request: Deviation Request Is For Temporary Changes Only. Submission Is Only Valid With An 8D ReporttrungNo ratings yet

- Updates Dec09 AIAG FMEA-Ranking-TablesDocument3 pagesUpdates Dec09 AIAG FMEA-Ranking-TablesSuresh Velu100% (1)

- First Article Inspection Report: Purchase Order Number Supplier NameDocument8 pagesFirst Article Inspection Report: Purchase Order Number Supplier NameTuff qualityNo ratings yet

- Layout Inspection Report: MY25 Cummins Filtration Expandable Seal As Per Drawing Spec 0 01 4 5 NosDocument2 pagesLayout Inspection Report: MY25 Cummins Filtration Expandable Seal As Per Drawing Spec 0 01 4 5 NosRohitNo ratings yet

- Quality Evaluation, Problem and Follow Up Results Pdca FormatDocument1 pageQuality Evaluation, Problem and Follow Up Results Pdca FormatPk Nimiwal100% (1)

- CAPA Burr (TSSR)Document3 pagesCAPA Burr (TSSR)Mohit Singh100% (1)

- HR Training Request FormDocument1 pageHR Training Request FormRichard R M ThodéNo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- Control PlanDocument6 pagesControl PlanFahmy Khoerul HudaNo ratings yet

- SRG Global PPAP ChecklistDocument61 pagesSRG Global PPAP Checklistanamika tripathiNo ratings yet

- IPQC General FormatDocument17 pagesIPQC General FormatMohd Isa HarunNo ratings yet

- MACE - Formats - 008 - TGR & TGWDocument2 pagesMACE - Formats - 008 - TGR & TGWMohit KaushikNo ratings yet

- Chintamani Metal Udhoy Pvt. Ltd. 4M Change BoardDocument6 pagesChintamani Metal Udhoy Pvt. Ltd. 4M Change Boardcmu qmsNo ratings yet

- Prepared By:-Sunil Vy. Approved By: - KS NayakDocument4 pagesPrepared By:-Sunil Vy. Approved By: - KS NayakDevaa VyNo ratings yet

- Cubuilt Cepl VC 02 MsaDocument1 pageCubuilt Cepl VC 02 MsaCu Built Engineers Pvt. Ltd.No ratings yet

- Netstal Hourly Production Monitoring Sheet 08-08-2018Document1 pageNetstal Hourly Production Monitoring Sheet 08-08-2018saadbinsadaqat123456No ratings yet

- 14 - P11 Production Scheduling and Planning Process-May'17Document9 pages14 - P11 Production Scheduling and Planning Process-May'17Rohini Gadhawe100% (1)

- Weekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 MarimuthuDocument10 pagesWeekly Employee Shift Schedule Aswini Enterprises: 1 Adalarasu 2 Ajith 3 Marimuthuom cncNo ratings yet

- AQL For SafemateDocument1 pageAQL For SafemateEkklesia Bema PrasyantiNo ratings yet

- Process Capability Plan FormDocument4 pagesProcess Capability Plan FormMani Rathinam RajamaniNo ratings yet

- PPAPDocument4 pagesPPAPMattNo ratings yet

- Pre and Post Shutdown Activity Forms and ChecklistsDocument44 pagesPre and Post Shutdown Activity Forms and ChecklistsDhanraj PatilNo ratings yet

- PSIPL-PUR-06Supplier Evaluation - FormatDocument6 pagesPSIPL-PUR-06Supplier Evaluation - Formatcghodake1No ratings yet

- Form 1315 Preliminary EvaluationDocument27 pagesForm 1315 Preliminary EvaluationMakeshNo ratings yet

- 195 CasingDocument14 pages195 Casingsasi10000No ratings yet

- Avance EppapDocument5 pagesAvance EppapZael ZaelNo ratings yet

- Apqp FormsDocument67 pagesApqp FormsNeumar NeumannNo ratings yet

- 14 Dimensions and Measures of Manufacturing PerformanceDocument6 pages14 Dimensions and Measures of Manufacturing PerformancekhmortezaNo ratings yet

- List of GaugesDocument1 pageList of GaugeskhmortezaNo ratings yet

- Explaining The Relationships of Knowledge Management Processes With Organizational Performance Through The Mediator Organizational LearningDocument8 pagesExplaining The Relationships of Knowledge Management Processes With Organizational Performance Through The Mediator Organizational LearningkhmortezaNo ratings yet

- 8 Knowledge Management and Organizational Performance - A Decomposed View Mills 2011Document18 pages8 Knowledge Management and Organizational Performance - A Decomposed View Mills 2011khmortezaNo ratings yet

- 7 Knowledge Management and Organizational Performance An Exploratory Zack 2009Document23 pages7 Knowledge Management and Organizational Performance An Exploratory Zack 2009khmortezaNo ratings yet

- 3 7-4 BSCDocument22 pages3 7-4 BSCkhmortezaNo ratings yet

- 10 Knowledge Management An Organizational Capabilities Perspective Gold & Malhotra 2001Document30 pages10 Knowledge Management An Organizational Capabilities Perspective Gold & Malhotra 2001khmortezaNo ratings yet

- Gauge Development Plan: Part Name Part NoDocument1 pageGauge Development Plan: Part Name Part NokhmortezaNo ratings yet

- Initial Feasibility Study For Quotation: Company NameDocument2 pagesInitial Feasibility Study For Quotation: Company NamekhmortezaNo ratings yet

- QSYS Professional - APQP: Advanced Product Quality PlanningDocument2 pagesQSYS Professional - APQP: Advanced Product Quality PlanningkhmortezaNo ratings yet

- Type 1: Technology Council Management ReviewDocument1 pageType 1: Technology Council Management ReviewkhmortezaNo ratings yet

- Planning For FMEA Gather: FMEA Development: MediumDocument2 pagesPlanning For FMEA Gather: FMEA Development: MediumkhmortezaNo ratings yet

- APQP Procedure From Elsmar - 2020-05Document6 pagesAPQP Procedure From Elsmar - 2020-05khmortezaNo ratings yet

- A-Systems-Approach-to-Failure-Modes-v1 Paper Good For Functions and Failure MechanismDocument19 pagesA-Systems-Approach-to-Failure-Modes-v1 Paper Good For Functions and Failure Mechanismkhmorteza100% (1)

- Severity Evaluation CriteriaDocument2 pagesSeverity Evaluation CriteriakhmortezaNo ratings yet

- Planning For FMEA Gather: FMEA Development: Page 1 ©2000Document2 pagesPlanning For FMEA Gather: FMEA Development: Page 1 ©2000khmorteza100% (1)

- Severity Evaluation CriteriaDocument2 pagesSeverity Evaluation CriteriakhmortezaNo ratings yet

- VDA Volume 8D V1.0 EN English PDFDocument18 pagesVDA Volume 8D V1.0 EN English PDFSaravanan SNo ratings yet

- Jayvee Dime,,,,project in Physics Light and SoundDocument25 pagesJayvee Dime,,,,project in Physics Light and SoundJayvee DimeNo ratings yet

- SSP 604 - Audi 30l v6 Tdi Biturbo Engine EngDocument23 pagesSSP 604 - Audi 30l v6 Tdi Biturbo Engine Engfrancois.garcia31100% (1)

- NASA NOAA Earth Sciences Letter To TrumpDocument6 pagesNASA NOAA Earth Sciences Letter To TrumpMelissa Meehan BaldwinNo ratings yet

- Sample Ale ExamDocument37 pagesSample Ale ExamMarian Lim100% (1)

- SONTU Flat Panel Dectector CatalogDocument6 pagesSONTU Flat Panel Dectector CatalogWajahat SheikhNo ratings yet

- Veins and Hydrothermal DepositsDocument2 pagesVeins and Hydrothermal Depositsalimurtadha100% (1)

- Bata Shoe Company (Bangladesh) Ltd.Document6 pagesBata Shoe Company (Bangladesh) Ltd.Vurdalack666No ratings yet

- Data Transformation by Andy FieldDocument1 pageData Transformation by Andy FieldGon MartNo ratings yet

- EVM TechmaxDocument96 pagesEVM Techmaxnikhileshdhuri97No ratings yet

- Amina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionDocument1 pageAmina Ahmed Benchmark Solution Oet Writing Task Practice With CorretionFïzã PäthäñNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

- Fetomaternal Hemorrhage (FMH), An Update Review of LiteratureDocument35 pagesFetomaternal Hemorrhage (FMH), An Update Review of LiteratureEugenia Jeniffer JNo ratings yet

- BDA 542 V3 - powerCON TRUE 1 TOP - NAC3MX-W-TOPDocument2 pagesBDA 542 V3 - powerCON TRUE 1 TOP - NAC3MX-W-TOPluis manuelNo ratings yet

- (2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Document367 pages(2001) (Sun) (Two-Group Interfacial Area Transport Equation For A Confined Test Section)Erol BicerNo ratings yet

- Federal MogulDocument277 pagesFederal Mogulعبدالغني القباطي100% (1)

- Urinalysis - Fatin AinaDocument14 pagesUrinalysis - Fatin AinaAl- ImanuddinNo ratings yet

- NT Seq DatabaseDocument4 pagesNT Seq DatabaseDevinder KaurNo ratings yet

- Straumann Product Catalogue 2018 2019Document260 pagesStraumann Product Catalogue 2018 2019kllasikalleNo ratings yet

- Soal PAS K13 Kelas 9 Ganjil Tp. 2019-2020Document5 pagesSoal PAS K13 Kelas 9 Ganjil Tp. 2019-2020Fairuz AbadiNo ratings yet

- An Overview of Discourse AnalysisDocument26 pagesAn Overview of Discourse Analysisjamogi2943No ratings yet

- Louis I KahnDocument27 pagesLouis I KahnKiran BasuNo ratings yet

- The Fruit Garden CAL: Columbine & AcanthusDocument7 pagesThe Fruit Garden CAL: Columbine & AcanthusMiraNo ratings yet

- Solution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Document16 pagesSolution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797warepneumomxkhf100% (17)

- PQR As Run SheetDocument2 pagesPQR As Run SheetAhmed ElsharkawNo ratings yet

- LECLANCHE Cell Datasheet GL60 GNMC 60ahDocument2 pagesLECLANCHE Cell Datasheet GL60 GNMC 60ahChaitanyaNo ratings yet

- SCM and TQM: by Junaid ShaheedDocument8 pagesSCM and TQM: by Junaid ShaheedjunaidsNo ratings yet

- HT Billing System - May'2022Document2 pagesHT Billing System - May'2022V.Sampath RaoNo ratings yet

- Arthur Lumley Davi̇ds-Sultan Ii. Mahmuta-1832Document318 pagesArthur Lumley Davi̇ds-Sultan Ii. Mahmuta-1832cengizozakinciNo ratings yet

- The Normal DistributionDocument30 pagesThe Normal DistributionJohn Rich CaidicNo ratings yet

- Coal Ash Dewatering SolutionDocument23 pagesCoal Ash Dewatering Solution류태하No ratings yet