Professional Documents

Culture Documents

Brochure - Modular Mud Tank 500 Bbls

Brochure - Modular Mud Tank 500 Bbls

Uploaded by

Hassan SleemOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure - Modular Mud Tank 500 Bbls

Brochure - Modular Mud Tank 500 Bbls

Uploaded by

Hassan SleemCopyright:

Available Formats

MUD MIXING & STORAGE TANKS

RENTAL / SALES

Modular Mud Storage & Mixing Tank 500 BBLS

40’ ISO Shipping Dimension

T +603 7722 4113 F +603 7722 4115 E enquiries@petrozchem.com W www.petrozchem.com

MUD MIXING & STORAGE TANKS

RENTAL / SALES

Modular Mud Storage & Mixing Tank 500 BBLS

Salient Features:

Brine Density

2.2 SG

Suction Manifold Line

8” SCH 40 API Pipe with Flanges

Filling Line

6” SCH 40 API Pipe

Vent

4” SCH 40 Gooseneck type

Valves

Butterfly Valves ASTM A126

Dimension

Tank Capacity : 500 Barrels

Length : 12,192 mm Petrozchem Mud Tanks are available for storage and mixing of oil and water

Width : 2,438 mm based drilling mud, it comes with epoxy linings and handrail. Each Tank is

Height : 2,895 mm provided with 8” suction line and 6” filling line. Each Tank is provided with isola-

Max Gross wt : 160 Tons tion valves for provision against leaks and contaminations. Corner Fittings are

Tare Weight : 14 Tons Standard Casted Container Corner Fittings for sea / land transportation.

Max Pay Load : 174 Tons

Agitators Mud Guns

Mud Type : WBM, SBM Mud Type : WBM, SBM

Certificates & Standards

Agreements Motor Power : 2.2 kw Length : 254 mm

Speed : 60 rpm Discharge dia : 88.9 mm

Impellor Dia : 610 mm Inlet Dia : 47.6 mm

Shaft Dia : 57 mm Inlet Jet Dia : 12.7 mm

Motor Mounting : Horizontal / Vertical Spiral Jetting Nozzles

Our rental programs offer includes :

Rentals for both short-term and long-term periods.

Daily, monthly and annual rentals with flexible rental terms.

Fast mobilization and demobilization services.

Services to our clients’ facilities located across Southeast Asia region.

T +603 7722 4113 F +603 7722 4115 E enquiries@petrozchem.com W www.petrozchem.com

1 2 3 4 5 6 7 8

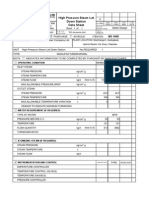

GENERAL NOTES:

ITEM NO. DESCRIPTION QTY. Material Weight (grams) REMARKS

1. ALL DIMENSION ARE IN MILLIMETERS UNLESS NOTED OTEHRWISE.

1 CONTAINER FRAME WITH LADDER & PANEL'S ASSEMBLY 1 see part list 9216556.40

(**) CORNER CASTING SLOT DIMENSION.

2 4" WELD NECK FLANGE, ASME B16.5 CLASS 150 with PIPE FITTING 4 - 9562.68 SEE SEPARATE DWG FOR PIPE FITTING DETAIL

DO NOT SCALE, ASK IF IN DOUBT.

3 6" WELD NECK FLANGE, ASME B16.5 CLASS 150 with PIPE FITTING 4 18640.25 SEE SEPARATE DWG FOR PIPE FITTING DETAIL

A 2. ALL MATERIAL TO BE MILD STEEL A36, UNLESS NOTED OTHERWISE. A

4 8" WELD NECK FLANGE, ASME B16.5 CLASS 150 with PIPE FITTING 2 - 41740.68 SEE SEPARATE DWG FOR PIPE FITTING DETAIL

3. ALL WELDING TO BE FULL PENETRATION WELD, UNLESS NOTED OTHERWISE,

5 BAIER FLUSH HATCH 2 Cast Aluminum Steel (Galvanized) - MODEL NO: BFHSQ24X24A/S

SATISFYING ABS APPROVED WELDING PROCEDURE, SUBMITTED BY FABRICATOR

7 2" PIPE TREADED (VENTILATION PIPE) 2 ASTM A36 Steel 1450.67 TO MASCON PRIOR TO START OF FABRICATION.

ALL STIFFENERS ANGLE BAR AND T-BEAM WELDING TO BE FILLET WITH LEG LENGTH

5mm, UNLESS NOTED OTHERWISE.

12192

PREPARTION EDGES FOR WELDING AS PER STANDARD UNLESS NOTED

CH OTHERWISE.

3390

4. MPI INSPECTION: ALL WELDS TO HAVE 100% MPI PER AWS D1.1.

VISUAL INSPECTION:ALL WELDS TO HAVE 100% VISUAL INSPECTION PER AWS

D1.1.

1365

B 9TYP) ACCEPTANCE CRITERIA: UT INSPECTION, MPI INSPECTION & VISUAL INSPECTION B

TO BE ACCORDANCE WITH ADS D1.1.

2438 2260**

DR

5. ALL FLANGES SPECIFICATION TO BE ASME B16.5 CLASS 150.

19.20°

ALL PIPE TO BE SCH. 40, ASTM 106 GR. B, UNLESS NOTED OTHERWISE.

725 AGITATOR MOUNTING PLATE (2X) BOLTS AND NUT SPECS SIZE, LENGTH AND QUANTITY AS PER FLANGES

(TYP) 666 (TYP) REQUIREMENTS, MATERIAL TO BE EN8.8 OR EQUIVALENT, ZYLAN COATING,

2260** REFER TO DWG NO : S27329089-10-01

PLAN PROVIDED BY FABRICATOR.

784 ALL DRILLED HOLE FOR AGITATOR

11989** MOUNTING TO BE MEASURED AT SITE 6. PAINTING AND SURFACE PREPARATION:

EB BY FABRICATOR.

1173 SAND BLASTING - PRIOR TO PAINTING THE ITEMS SHALL BE SAND BLASTED TO

GRADE SA 21/2 AS DEFINED IN THE SWEDISH CODE OF PRACTICE SIS

055900/1967.

C C

STANDARD MINIMUM MAXIMUM

SA 21/2 40MICROMETERS 100 MICROMETERS

2895

(WATER BASE MUD & STEEL BRINE TANKS ONLY)

COATS - INTERNAL LINING

PRIMER - CEILCOTE 380 PRIMER ( 2-5 MILS ) WET

INTERMEDIATE - 2 COATS CEILCOTE 242HT (APPLY 20-32MILS WFT)

EA

1083

EC FRONT VIEW COATS - PAINT FOR TANK EXTERIOR

SIDE VIEW SCALE 1:60 PRIMER -INTERZINC 52 @ 2-3 MILS (50-75 MICRONS) DFT

INTERMEDIAT - INERGARD 475HS MIO @ 5-7 MILS (125-150 MICRONS) DFT

FINISH - INTERTHANE 990 @ 2-3 MILS (50-75 MICRONS) DFT

275

7. TESTING:

DETAIL DR

2 SCALE 1 : 30 THE SHELL AND ANCILLARY COMPONENTS OF TANK CONTAINERS MUST BE

D INSPECTED AND TESTED AT FIVE-YEAR INTERVALS WITH AN INTERMEDIATE 2.5 YEAR D

INSPECTION.

THE 2.5-YEAR TEST INCLUDES AN INTERNAL INSPECTION OF THE TANK CONTAINER

VESSEL, AN EXTERNAL INSPECTION OF THE ISO FRAME, A LEAKAGE TEST OF THE

7 SHELL AND ALL SERVICE EQUIPMENT INCLUDING ALL VALVES AND FITTINGS.

5 1 THE 5-YEAR TEST INCLUDES A HYDROSTATIC PRESSURE TEST, AN INTERNAL AND

DETAIL EB

SCALE 1 : 15 typ 5

EXTERNAL VISUAL INSPECTION, A LEAKAGE TEST AND A TEST OF THE

5 SATISFACTORY OPERATION OF ALL SERVICE EQUIPMENT INCLUDING ALL VALVES

AND FITTINGS.

527

8. LIFTING PADEYES 4X = WLL 8.5 TONNES EACH, TO SUIT CROSBY SHACKLE

WLL=8.5TONNES, G-2130CT, STOCK NO. 1260586 OR EQUIVALENT. (PROVIDED BY

2 FABRICATOR)

397

REVISIONS

E E

4 ZONE REV. DESCRIPTION DATE APPROVED

3 A ISSUED FOR FABRICATION 30-JAN-15

10mm PETROZCHEM OILFIELD SERVICES SDN BHD

OFFSET FROM OUTER SURFACE

TYPICAL ALL FLANGES ALL INFORMATION AND DATA ON THIS DRAWING ARE THE PROPERTY OF PETROZCHEM

IT IS NOT TO BE COPIED, DISCLOSED, DUPLICATED NOR SHOWN TO A THIRD PARTY WITHOUT PRIOR CONSENT

TITLE:

F DETAIL EA 20

4

DETAIL CH GENERAL ASSEMBLY F

SCALE 1 : 15 SCALE 1 : 75

DETAIL EC PROJECT:

SCALE 1 : 15 40FT MUD CONTAINER

TOTAL WEIGHT: DRAWN: ENGINEER: SCALE:

10.0 TONNES EGL AC/UR/SC 1:100 (UNO)

DWG NO: PROJ NO: SHT NO: REV. UNIT: SHT SIZE:

094.01-DWG-101 094.01 1 OF 1 0 mm A3

1 2 3 4 5 6 7 8

You might also like

- ASME B 31.12 (Hydrogen Piping & Pipeline)Document1 pageASME B 31.12 (Hydrogen Piping & Pipeline)AdanNo ratings yet

- DRS - Operation & Control PhilosophyDocument5 pagesDRS - Operation & Control PhilosophyAnand GNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- COMPASS TrainingDocument383 pagesCOMPASS TrainingNikhil Barshettiwar100% (3)

- Liquid SizingDocument38 pagesLiquid SizingChetan Churi100% (1)

- Using The ASME VIII-1 Nozzle F Factor (UG-37)Document7 pagesUsing The ASME VIII-1 Nozzle F Factor (UG-37)Ricardo Paz SoldanNo ratings yet

- Mi Swaco - Mongoose PT Platform Shale Shaker PDFDocument318 pagesMi Swaco - Mongoose PT Platform Shale Shaker PDFJavier Danilo Aranda Pinzon75% (4)

- FVCDocument0 pagesFVCsmileya_vpNo ratings yet

- Sa-516 70 TDCDocument2 pagesSa-516 70 TDCshazan100% (1)

- Underground Pipe Stress Check - UGP 2: Design CalculationDocument6 pagesUnderground Pipe Stress Check - UGP 2: Design CalculationHeri KurniawanNo ratings yet

- Technical DataDocument48 pagesTechnical Datashekhar2681No ratings yet

- Venting CalculationDocument14 pagesVenting CalculationValen MaselaNo ratings yet

- TES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)Document19 pagesTES-ME-STRTN-GL Design and Fabrication of Butt-Welded Transition Joints Specification (CAN-US-MEX)BetoCostaNo ratings yet

- P01-E28-01 Rev 6 Dec 2021 Qualification of FRP Pipe and ComponentsDocument18 pagesP01-E28-01 Rev 6 Dec 2021 Qualification of FRP Pipe and ComponentsMohamed AdelNo ratings yet

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 pagesFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyNo ratings yet

- PIP-Vessel S and T Heat Exchanger Design Criteria ASME Code Section VIII, Div 1 and 2Document74 pagesPIP-Vessel S and T Heat Exchanger Design Criteria ASME Code Section VIII, Div 1 and 2rizaNo ratings yet

- Mss sp-71 1997 PDFDocument10 pagesMss sp-71 1997 PDFChotiwan RattanasatienNo ratings yet

- Annex V External PressureDocument26 pagesAnnex V External PressureJohnny Villarroel100% (1)

- BS EN 12542 - 2010 LPG Equipment and Accessories. Static Welded Steel Cylindrical Tanks, Serially Produced For The Storage of Liqu - Libgen - LiDocument66 pagesBS EN 12542 - 2010 LPG Equipment and Accessories. Static Welded Steel Cylindrical Tanks, Serially Produced For The Storage of Liqu - Libgen - LiRinnoNo ratings yet

- ANZ Technical Guide Heat Exchanger DesigDocument13 pagesANZ Technical Guide Heat Exchanger DesigvikramNo ratings yet

- Tubesheet As Per ASME Sec. VIII-Div.1 UHXDocument1 pageTubesheet As Per ASME Sec. VIII-Div.1 UHXruponline1No ratings yet

- PVM Su 1322 H.1 PDFDocument22 pagesPVM Su 1322 H.1 PDFJEEVITHANo ratings yet

- Piping Stress CriteriaDocument11 pagesPiping Stress Criteriasbrencu100% (1)

- Tema StandardsDocument1 pageTema Standardsjose_alberto2No ratings yet

- CalcvesselDocument11 pagesCalcvesselHami Keserci100% (2)

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- Woc Hse Manual Standards: Woc LP EP DepartmentDocument12 pagesWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- Pages From 6 - 44 - 0005 Piping Material Specification Part1Document200 pagesPages From 6 - 44 - 0005 Piping Material Specification Part1Anonymous EKxXjqyVHNo ratings yet

- Required Dim. & Qty. of Plates For 5000 m3 HFO Storage Tank PDFDocument1 pageRequired Dim. & Qty. of Plates For 5000 m3 HFO Storage Tank PDFJahid Jahidul Islam KhanNo ratings yet

- Brighton Spec ASME 80-10 2017 PDFDocument1 pageBrighton Spec ASME 80-10 2017 PDFSuhas JadhavNo ratings yet

- Astm F436.04 PDFDocument6 pagesAstm F436.04 PDFWelington Volpatto MoraisNo ratings yet

- ASTM B619 B619M 17aDocument6 pagesASTM B619 B619M 17aAbdülHak ÖZkaraNo ratings yet

- Technical Standards For Insulation-Mineral Wool-RockwoolDocument2 pagesTechnical Standards For Insulation-Mineral Wool-RockwooljaganNo ratings yet

- 2632 PL DS 001 Line PipeDocument3 pages2632 PL DS 001 Line PipeAdvisNo ratings yet

- Welding Parameter Sheet - PQR - TemplateDocument1 pageWelding Parameter Sheet - PQR - TemplatevalararumugamsNo ratings yet

- ES 49BranchConnectionsDocument7 pagesES 49BranchConnectionsrodofgodNo ratings yet

- Cone Design ToolDocument1 pageCone Design ToolPramod KumarNo ratings yet

- Improvements in Design and Fitness Evaluation of Above Ground Steel Storage TanksDocument284 pagesImprovements in Design and Fitness Evaluation of Above Ground Steel Storage TanksrodrigoperezsimoneNo ratings yet

- Data Sheet For Barred Tee 010719 PDFDocument1 pageData Sheet For Barred Tee 010719 PDFkandraNo ratings yet

- Asme Sec X 2017Document3 pagesAsme Sec X 2017SARSAN NDTNo ratings yet

- Car Washer CatalogueDocument24 pagesCar Washer Cataloguesra electricalsNo ratings yet

- Caesar Newsletter Timehistory AnalysisDocument16 pagesCaesar Newsletter Timehistory AnalysisNixonNo ratings yet

- 10P87-D0003-046-R0-WHRU by TEPLDocument23 pages10P87-D0003-046-R0-WHRU by TEPLjigarNo ratings yet

- FVC CatalogueDocument80 pagesFVC CatalogueAnonymous qUMJ27ITQs100% (1)

- 각국 재질 비교표 (ASTM)Document2 pages각국 재질 비교표 (ASTM)Tommy Sung100% (1)

- LiquidDocument2 pagesLiquidsiddhesh_guessNo ratings yet

- Thermal Expansion CalculatorDocument5 pagesThermal Expansion Calculatoritshari4uNo ratings yet

- Maximum Allowable Stress: Mechanical Design of Pressure VesselsDocument17 pagesMaximum Allowable Stress: Mechanical Design of Pressure Vesselsfauzi100% (2)

- Pressure Vacuum Relief Valve Flame Arrester 102Document3 pagesPressure Vacuum Relief Valve Flame Arrester 102vikramNo ratings yet

- BS 470 Entry PVDocument8 pagesBS 470 Entry PVbonnicoNo ratings yet

- 03.i. Pipe Data SheetDocument1 page03.i. Pipe Data SheetBalaji NaikNo ratings yet

- Composite Construction Works For CNG Station at Kovvur, West Godavari District, A.PDocument209 pagesComposite Construction Works For CNG Station at Kovvur, West Godavari District, A.Pvinay1999No ratings yet

- Saes L 131Document10 pagesSaes L 131samsurendran_mech4020No ratings yet

- Rock Shield Material Data SheetDocument1 pageRock Shield Material Data SheetR.S.No ratings yet

- Let Down StationDocument5 pagesLet Down StationSabeeh AhmedNo ratings yet

- Gate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDocument1 pageGate Valve Specification Manuf'S Offer: Signature & Seal of ManufacturerDIPANKAR LALANo ratings yet

- Gecpl Boq -Asarma-21_03Document20 pagesGecpl Boq -Asarma-21_03RAJNo ratings yet

- Specification For Jackets of Pipe: Rev. Date Revision Description Issued by Checked by Approved byDocument10 pagesSpecification For Jackets of Pipe: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreNo ratings yet

- Vicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesDocument20 pagesVicflex Sprinkler Fittings Series Ah2-300 and Ah2-Cc-300 Braided Flexible Hose AssembliesbalaasenthilNo ratings yet

- Specification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byDocument13 pagesSpecification For Core & Jacket: Rev. Date Revision Description Issued by Checked by Approved byvishal bhamreNo ratings yet

- Man Power RateDocument2 pagesMan Power RateHassan SleemNo ratings yet

- Beverwijk: Directional Drilling With Ductile Iron Pipes Underneath A MotorwayDocument1 pageBeverwijk: Directional Drilling With Ductile Iron Pipes Underneath A MotorwayHassan SleemNo ratings yet

- Duct Calculation SheetDocument1 pageDuct Calculation SheetHassan SleemNo ratings yet

- Pump PowerDocument1 pagePump PowerHassan SleemNo ratings yet

- Pipe & Fittings Water & Sewer: Installation GuideDocument87 pagesPipe & Fittings Water & Sewer: Installation GuideHassan SleemNo ratings yet

- The Hard Way: Advanced Engineering Anchorage SolutionsDocument6 pagesThe Hard Way: Advanced Engineering Anchorage SolutionsHassan SleemNo ratings yet

- Fire Pump SummaryDocument1 pageFire Pump SummaryHassan SleemNo ratings yet

- Design Scheme Presentation For Swtc285 Lifting FrameDocument47 pagesDesign Scheme Presentation For Swtc285 Lifting FrameHassan SleemNo ratings yet

- D2086 - RFQ - MS Office 2007 Software Skills Program (Port Elizabeth - Not CT)Document33 pagesD2086 - RFQ - MS Office 2007 Software Skills Program (Port Elizabeth - Not CT)Hassan SleemNo ratings yet

- Heat Treatment Procedure: Tebbin Plant Quality ControlDocument5 pagesHeat Treatment Procedure: Tebbin Plant Quality ControlHassan SleemNo ratings yet

- Heat Treatment Procedure: Tebbin Plant Quality ControlDocument5 pagesHeat Treatment Procedure: Tebbin Plant Quality ControlHassan SleemNo ratings yet

- Heat Treatment Procedure2Document2 pagesHeat Treatment Procedure2Hassan SleemNo ratings yet

- Handling of Welding Consumables Procedure: Tebbin Plant Quality ControlDocument3 pagesHandling of Welding Consumables Procedure: Tebbin Plant Quality ControlHassan SleemNo ratings yet

- Calibration Procedure: 1-PurposeDocument5 pagesCalibration Procedure: 1-PurposeHassan SleemNo ratings yet

- Hydrostatic Test Procedure: 1. ScopeDocument5 pagesHydrostatic Test Procedure: 1. ScopeHassan Sleem100% (1)

- BD 3101Document52 pagesBD 3101wanrazzaq29950% (1)

- Heat Treatment Procedure: Tebbin Plant Quality ControlDocument5 pagesHeat Treatment Procedure: Tebbin Plant Quality ControlHassan SleemNo ratings yet

- Oil Fired Boiler UB-Erection SequenceDocument93 pagesOil Fired Boiler UB-Erection SequenceHassan SleemNo ratings yet

- Economize RDocument12 pagesEconomize RHassan SleemNo ratings yet

- BenzoinDocument7 pagesBenzoinLeah ThomasNo ratings yet

- The Cut Off List of Allotment in Round 03 For Programme B.Tech (CET Code-131) For Academic Session 2023-24Document42 pagesThe Cut Off List of Allotment in Round 03 For Programme B.Tech (CET Code-131) For Academic Session 2023-24addisarbaNo ratings yet

- 고압세척기 메뉴얼Document51 pages고압세척기 메뉴얼박일호No ratings yet

- 8 Sem Report 190060106004 Mehul Chauhan Final Report Last SemDocument53 pages8 Sem Report 190060106004 Mehul Chauhan Final Report Last SemLalji AhirNo ratings yet

- A6211 Datasheet PDFDocument18 pagesA6211 Datasheet PDFNestor GlezNo ratings yet

- Wireless Room Freshener Spraying Robot With Video VisionDocument5 pagesWireless Room Freshener Spraying Robot With Video Visionsai thesisNo ratings yet

- Hzt. Ammar e Yaser (R.a.)Document88 pagesHzt. Ammar e Yaser (R.a.)naqvi202No ratings yet

- The Integration of Core and BHI and Resulting Depo Model - Moreni Field Central Romania, EAGE, 2012Document4 pagesThe Integration of Core and BHI and Resulting Depo Model - Moreni Field Central Romania, EAGE, 2012Paul V GrechNo ratings yet

- Persamaan Konduksi & Kasus - Bag 1Document25 pagesPersamaan Konduksi & Kasus - Bag 1ArdanNo ratings yet

- Chapter 12 - LCD and KeyboardDocument27 pagesChapter 12 - LCD and KeyboardAnkit KumarNo ratings yet

- MAD Lab SyllabusDocument2 pagesMAD Lab SyllabusPhani KumarNo ratings yet

- Poka Yoke & Mistake ProofingDocument26 pagesPoka Yoke & Mistake ProofingSarath Babu100% (1)

- Tda8929t PDFDocument36 pagesTda8929t PDFtecniloco80No ratings yet

- Information Gain CalculatorDocument16 pagesInformation Gain CalculatorShashiBhushanSahani0% (1)

- Colfax Product CatalogDocument36 pagesColfax Product CatalogPrasanna BalrajNo ratings yet

- Diagram SankeyDocument5 pagesDiagram SankeyNur WidyaNo ratings yet

- PGN Case StudyDocument3 pagesPGN Case StudyFarizAgustyoNo ratings yet

- Study On Concrete With Partial Replacement of Cement by Rice Husk AshDocument12 pagesStudy On Concrete With Partial Replacement of Cement by Rice Husk AshDorothy Yen EscalañaNo ratings yet

- Stryker Adel 4700,512 Maternity Bed - Service ManualDocument153 pagesStryker Adel 4700,512 Maternity Bed - Service ManualVicTor MiKeNo ratings yet

- Innova Touring SportDocument2 pagesInnova Touring SportcolourhutNo ratings yet

- Panoramic Power Wireless Sensors Bridge DatasheetDocument1 pagePanoramic Power Wireless Sensors Bridge DatasheettiagoorgadoNo ratings yet

- Service Manual: Chassis, Mast & OptionsDocument37 pagesService Manual: Chassis, Mast & OptionsIsos Cell0% (1)

- Development and Testing of Sugarcane Juice Extractor: Agidi GbaboDocument5 pagesDevelopment and Testing of Sugarcane Juice Extractor: Agidi Gbabomekanic24100% (1)

- 6292A: Installing and Configuring Windows® 7 Client Microsoft® Hyper-V Classroom Setup GuideDocument14 pages6292A: Installing and Configuring Windows® 7 Client Microsoft® Hyper-V Classroom Setup GuideMichael DavisNo ratings yet

- 00-Saip-06 Pressure TestDocument4 pages00-Saip-06 Pressure TestUzair AhmadNo ratings yet

- 6016 ManualDocument9 pages6016 ManualDoceigenNo ratings yet

- D+ 2018 Service CatalogDocument2 pagesD+ 2018 Service CatalogAri SaniNo ratings yet

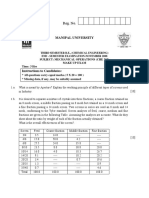

- Mechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Document3 pagesMechanical Operations (CHE-205) (Makeup) (EngineeringDuniya - Com)Cester Avila Ducusin100% (1)