Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

78 viewsATI Metal Water Tanks Ecatalogue PDF

ATI Metal Water Tanks Ecatalogue PDF

Uploaded by

Nguyễn LinhCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- UNC25 Sound Curtain Datasheet1 PDFDocument1 pageUNC25 Sound Curtain Datasheet1 PDFNguyễn LinhNo ratings yet

- B Blla Ac CK KD Diia Am Mo On ND DDocument6 pagesB Blla Ac CK KD Diia Am Mo On ND DNguyễn LinhNo ratings yet

- Mobile Jaw Crusher PDFDocument7 pagesMobile Jaw Crusher PDFNguyễn LinhNo ratings yet

- Enoise Control Sound Curtains Brochure PDFDocument6 pagesEnoise Control Sound Curtains Brochure PDFNguyễn LinhNo ratings yet

- Purchase Specification For Sludge DryerDocument84 pagesPurchase Specification For Sludge DryerNguyễn LinhNo ratings yet

- Technical Data Sheet GM24A-SR-TPDocument6 pagesTechnical Data Sheet GM24A-SR-TPNguyễn LinhNo ratings yet

- Sound Curtain Enclosure Windows Datasheet1 PDFDocument1 pageSound Curtain Enclosure Windows Datasheet1 PDFNguyễn LinhNo ratings yet

- 11 CVC 01 INLET VANE CONTROL DAMPER Flamgard Calidair Product Data Sheet1Document2 pages11 CVC 01 INLET VANE CONTROL DAMPER Flamgard Calidair Product Data Sheet1Nguyễn LinhNo ratings yet

- Installation Operation Man GTXDocument20 pagesInstallation Operation Man GTXNguyễn LinhNo ratings yet

- Cone StandardDocument16 pagesCone StandardNguyễn LinhNo ratings yet

- DA102-13 Damper Torque PDFDocument3 pagesDA102-13 Damper Torque PDFNguyễn LinhNo ratings yet

- Conveyor Chain Data SheetDocument24 pagesConveyor Chain Data SheetNguyễn LinhNo ratings yet

- Industrial PDFDocument8 pagesIndustrial PDFNguyễn LinhNo ratings yet

- Techsupport #63: Properties and ProcessingDocument4 pagesTechsupport #63: Properties and ProcessingNguyễn Linh100% (1)

- Technical Data Sheet: Sound Curtain Enclosure UN-10 CV WindowsDocument1 pageTechnical Data Sheet: Sound Curtain Enclosure UN-10 CV WindowsNguyễn LinhNo ratings yet

- Quilted Sound Barrier/Sound Absorber CurtainDocument1 pageQuilted Sound Barrier/Sound Absorber CurtainNguyễn LinhNo ratings yet

- Sound Curtains: Specializing in Acoustics, Noise & Vibration ControlDocument6 pagesSound Curtains: Specializing in Acoustics, Noise & Vibration ControlNguyễn LinhNo ratings yet

- Ash+Extractor - PDD GOC120200 331RA 00 PDFDocument109 pagesAsh+Extractor - PDD GOC120200 331RA 00 PDFNguyễn Linh100% (1)

- FTang - Pitot Type L - 02 04 19Document3 pagesFTang - Pitot Type L - 02 04 19Nguyễn LinhNo ratings yet

- CrushersDocument6 pagesCrushersNguyễn LinhNo ratings yet

- DY Catalogue ENDocument88 pagesDY Catalogue ENNguyễn LinhNo ratings yet

- Damper TorqueDocument3 pagesDamper TorqueNguyễn LinhNo ratings yet

- ACAT Screw Press Brochure Rev001Document4 pagesACAT Screw Press Brochure Rev001Nguyễn LinhNo ratings yet

ATI Metal Water Tanks Ecatalogue PDF

ATI Metal Water Tanks Ecatalogue PDF

Uploaded by

Nguyễn Linh0 ratings0% found this document useful (0 votes)

78 views6 pagesOriginal Title

ATI Metal Water tanks Ecatalogue.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

78 views6 pagesATI Metal Water Tanks Ecatalogue PDF

ATI Metal Water Tanks Ecatalogue PDF

Uploaded by

Nguyễn LinhCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 6

AT

ALAM TIMUR INDUSTRIES SDN. BHD.

PRESSED STEEL SECTIONAL RECTANGULAR TANKS:

GENERAL

The pressed steel sectional rectangular tank is @ versatile bulk storage

container of water, ‘The sectional construction concept consists of bolting up

together mass produced tank panels (ether 1.22m or 1.0m square) into tanks

of various sizes and capacities. The tanks manufactured and installed by us

are renowned for their qualty and reliablty. This is brought about by our

relentless effort in the application of the best engineering practices in the

Production processes and the related services offered by us. Our tanks are

\hdely used in Malaysia andthe neighbouring counties of South-east Asia and

have also been exported to many other pats ofthe word

MATERIALS

‘© Mild Stee! Panels : SS 400 or JIS G3101 or BS EN 10025-3 : 2004

‘© Stainless Stee! Panels : AISI Grade 304 and 316

PANEL SIZES

‘© For 1220 x 1220 module : 1220 x 1220, 610 x 1220 and 610 x 610,

‘© For 1000 x 1000 module : 1000 x 1000, 500 x 1000 and 500 x 500

FLANGES OF PLATES

Each individual panel is hydraulically prossad with a combined double flange

tan angle of 45° and 90° tothe face of the panel on all sides,

"ANEL COATING AND LINING

‘© Bitumen painted, hotdipped galvanized, epoxy or polyester, powder

‘coated for mild steel panel

High-density polyethylene (HOPE) intemal lining of completed tank

Fibreglass intoral lining of completed tank.

TANK COVERS

© Pressed steel sectional panel cover,

‘© Pitched roof cover sheets (only upon request).

Each compartment is provided witha hinged manhole and an air vent.

LEVEL INDICATOR

‘© Mechanical of cat-and-mouse type in meric sca

‘© Direct reading acrylic glass tube indicator.

LADDERS

‘© Intemal and extemal ladders of mild steel (bitumen painted, hot dipped

galvanized, epoxy powder coaled, ele), aluminium, PVC and stainless

steel.

© Security cage for extemal ladder also avaiable,

BALL VALVE BOXES AND BOTTOM SUMPS Totnes avenehng hmm

Bal valve boxes and bottom sumps at client's request will provide added

capaci to the storage tank

HOLE OPENING AND PIPE FLANGES

Hole opening and welded pipe sockets and flanges are provided at dent's

request

‘SEALANT

For the joining of panel flanges, we provide high density ulta-volet

resistance PVC foam gaskels (approved to DIN 4102 PUt B2). Specialy

designed butyl rubber mastic comgound provided for the cleats offers

excellent water ight joints

INFORMATION FOR SITE ASSEMBLY

ilustrated erection instructions, drawings and parts lst are issued with

each tank delivery,

STEEL STAND

We also provide fabrication of mild sleel stands for tanks on ground,

buiiding foors and elevations

TANK ERECTION

Erection service for both local and oversea jobs s provided,

QUOTATION

‘To obtain a quotation, the following informations are needed :-

+ Size of tank in terms of length, width and height. Otherwise give

‘apaciy or sketch of tank layout

Stale choice of using 1.0m x 1.0m or 1.22m x 1.22m panels

Number and positions of storage compartments required in each

tank

‘© Type of storage liquid and slorage temperature

‘© Materials and thickness for panels e.g. mild steel, stainless stee!

and grade,

‘© Coatings €.g. painting, hot dipped galvanised, HOPE lining, et.

‘© State if there is any limitation to tank height or tank area.

‘© Sketch and details of pipe connections and other ancilay ings.

‘© Details of ladders and level indicator.

‘© Any grillage or steel stand required?

‘© Isinslallation service required?

‘© Location for tank’ to be delvered. For orders that required

shipment, state port of ety

Hotipped galvanised

Sbiniess steel panel

Polyester powder

coated pane!

Hot-ioped galvanised

roof panel

Hydrauc press machine

Bitumen painted pane!

Roller painted pane!

Hol-dipped gahanised

hal pane!

Hot-dipped galvanised

‘manhole panel

SUPPORT STRUCTURES

TANK ON DWARF WALLS

‘A clearance of 600mm is required around, above and below the tank for assembly and maintenance.

‘© The walls must be 150mm longer than the width of the tank

Dwarf walls with steel skid beams-this is by far the best and cost effective way for tank to be sited on ground or building

floor. The dwarf walls are usually built al spacing of either 2.0m or 2.44m depending on the types of plates used.

beams at 1.0m or 1.22m spacing are then placed at right angle across the top of the dwarf walls, See diagram A.

Dwarf walls without steel skid beams - the dwarf walls are built al a spacing of 1.0m or 1.2m. A mild steel capping

flat of 9.01 is recommended to ensure evenness and protection for the dwar wall, See diagram B,

«

Ms,

LAK]

42am 4.1.22 ,, 122m , 122m

(2.0m) zon) (4.0m) (1.0m) (1.0m) (1.0%)

Diagram A, Diagram B

ad

‘Tank on dwarf walls with steel skid beam ‘Tank on dwarf walls without steel skid beam

TANK ON STEEL STAND

‘1.0m width walkway with protective rail aroune tank perimeter be provided,

‘+ Preferably horizontal crass beams about 760mm below tank base be availabe for staging a temporary working platform to fcitate assembly

‘and maintenance, See diagram C.

009

ia

Z2NSI4

aT a aT

Diagram C

>”

5

B

i]

a

ia

=

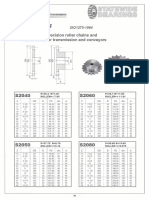

DIMENSION AND NOMINAL THICKNESS.

Weise | Winns | TauHOD | TarkPane Tce mn] Foshan | Noaie | — Maiwal | Taw Woot | Tk Panel Treinen mm | RetPaw)

om [Sime] vat | Taree rn | Boe Wat | Te

fron 1006|riztea | 1000 | 30 [30 (Ter) 15

12201220 mistes! | 1220 | 50 |50(Ter1) 15 2000 | 30 [3.01.2 15

240 | 50|so(tort,2) | 15 3000 | 40 |4oqrert,2.3) | 15

seco | 50 /S0(Tort,2,.9)) 15 4000 | 40 |40(rert.2.3,4) | 15

480 | 60 |. (Ter) 15 sooo | 50 [50 (tert, 2) 15

50 (Ter2, 3,4) 0 ier3, 4,5)

e000 | 50 |s0(mert,2) 15

40 (ier, 4, 5.6)

12201220 |stinless steel] 1220 | 25 |2(Ter1) 15 ||Toopxt000 startess scot] 1000 [25 ]25 (hort) 1

240 | 30|aocnert.2) | 15 2000 | 25 |25ctert,2) 15

sa80 | 40 |<0(Ter 15 son | 25 |ascmeriz3) | 15

3.0 (er2, 3} 4000 | 30 |3.0cmert} 15

4860 | 50 |5.0 (Ter 15 25 er2, 3,4)

4.0 (ier2) sono | 40 |40 (tert) 15

3.0 (her3, 4 30 ier2, 3, 4,5)

7 e000 | s0 [so cnet) 15

40 er2)

30 ier3. 4.5.6)

thickness in compliance wth BS 1564 : 1975

‘CONFIGURATIONS

TYPES OF TANK PANELS ‘The following configurations are possible:

ul Size Fat Panel

Ful Size Tank Panel

Base, Wal Poin (Lge Dia)

Ful Sze Roof Pant antole

[

l

Hall Sze Flat Pane

Base, Wel, Roof

‘Quater Size Flat Pane!

Base, Wel, Root

FullSie = 1220 1220nd 1000 x 1000

Half Size

1220x 610and 1000 600

Querier Size = 10x 610.and 500x500

—_—S

S53

pie

rt

=i)

TANK DIVISIONS

“The folowing dhisions within tank are possible -

om

mol

TLT

(Cireuaton)

JOB REFERENCES

2

$

é

Ne

Perak (Malaysia)

Johor (Malaysia)

Singapore

Negeri Sembilan (Malaysia)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- UNC25 Sound Curtain Datasheet1 PDFDocument1 pageUNC25 Sound Curtain Datasheet1 PDFNguyễn LinhNo ratings yet

- B Blla Ac CK KD Diia Am Mo On ND DDocument6 pagesB Blla Ac CK KD Diia Am Mo On ND DNguyễn LinhNo ratings yet

- Mobile Jaw Crusher PDFDocument7 pagesMobile Jaw Crusher PDFNguyễn LinhNo ratings yet

- Enoise Control Sound Curtains Brochure PDFDocument6 pagesEnoise Control Sound Curtains Brochure PDFNguyễn LinhNo ratings yet

- Purchase Specification For Sludge DryerDocument84 pagesPurchase Specification For Sludge DryerNguyễn LinhNo ratings yet

- Technical Data Sheet GM24A-SR-TPDocument6 pagesTechnical Data Sheet GM24A-SR-TPNguyễn LinhNo ratings yet

- Sound Curtain Enclosure Windows Datasheet1 PDFDocument1 pageSound Curtain Enclosure Windows Datasheet1 PDFNguyễn LinhNo ratings yet

- 11 CVC 01 INLET VANE CONTROL DAMPER Flamgard Calidair Product Data Sheet1Document2 pages11 CVC 01 INLET VANE CONTROL DAMPER Flamgard Calidair Product Data Sheet1Nguyễn LinhNo ratings yet

- Installation Operation Man GTXDocument20 pagesInstallation Operation Man GTXNguyễn LinhNo ratings yet

- Cone StandardDocument16 pagesCone StandardNguyễn LinhNo ratings yet

- DA102-13 Damper Torque PDFDocument3 pagesDA102-13 Damper Torque PDFNguyễn LinhNo ratings yet

- Conveyor Chain Data SheetDocument24 pagesConveyor Chain Data SheetNguyễn LinhNo ratings yet

- Industrial PDFDocument8 pagesIndustrial PDFNguyễn LinhNo ratings yet

- Techsupport #63: Properties and ProcessingDocument4 pagesTechsupport #63: Properties and ProcessingNguyễn Linh100% (1)

- Technical Data Sheet: Sound Curtain Enclosure UN-10 CV WindowsDocument1 pageTechnical Data Sheet: Sound Curtain Enclosure UN-10 CV WindowsNguyễn LinhNo ratings yet

- Quilted Sound Barrier/Sound Absorber CurtainDocument1 pageQuilted Sound Barrier/Sound Absorber CurtainNguyễn LinhNo ratings yet

- Sound Curtains: Specializing in Acoustics, Noise & Vibration ControlDocument6 pagesSound Curtains: Specializing in Acoustics, Noise & Vibration ControlNguyễn LinhNo ratings yet

- Ash+Extractor - PDD GOC120200 331RA 00 PDFDocument109 pagesAsh+Extractor - PDD GOC120200 331RA 00 PDFNguyễn Linh100% (1)

- FTang - Pitot Type L - 02 04 19Document3 pagesFTang - Pitot Type L - 02 04 19Nguyễn LinhNo ratings yet

- CrushersDocument6 pagesCrushersNguyễn LinhNo ratings yet

- DY Catalogue ENDocument88 pagesDY Catalogue ENNguyễn LinhNo ratings yet

- Damper TorqueDocument3 pagesDamper TorqueNguyễn LinhNo ratings yet

- ACAT Screw Press Brochure Rev001Document4 pagesACAT Screw Press Brochure Rev001Nguyễn LinhNo ratings yet