Professional Documents

Culture Documents

Practical Considerations For The Installation of Exhaust Gas Cleaning Systems

Practical Considerations For The Installation of Exhaust Gas Cleaning Systems

Uploaded by

Claudio SantellanesCopyright:

Available Formats

You might also like

- MSC AMOS BS - Job DescriptionDocument9 pagesMSC AMOS BS - Job DescriptioncarmaNo ratings yet

- Tech Guidelines Env Management Mining ADocument14 pagesTech Guidelines Env Management Mining AvanpatoNo ratings yet

- Ontario Fish Identification GuideDocument3 pagesOntario Fish Identification GuideT.O. Nature & DevelopmentNo ratings yet

- Armada Hibiscus: 100M Accommodation/ Work BargeDocument2 pagesArmada Hibiscus: 100M Accommodation/ Work BargeClaudio Santellanes100% (2)

- Method Statement For Concrete Foundation WorkDocument21 pagesMethod Statement For Concrete Foundation WorkMihirdutta100% (1)

- Cat Fines Presentation SlidesDocument48 pagesCat Fines Presentation SlidescaptkcNo ratings yet

- S70me-C8 5 PDFDocument397 pagesS70me-C8 5 PDFIgor Tabulynsky100% (1)

- Low Container Ship Speed Facilitated by Versatile ME/ME-C EnginesDocument12 pagesLow Container Ship Speed Facilitated by Versatile ME/ME-C EnginesParthiban NagarajanNo ratings yet

- JKR20710 0001 11Document13 pagesJKR20710 0001 11keesinvong100% (2)

- ABS Practical Considerations For The Installations of Exhaust Gas Cleaning SystemsDocument26 pagesABS Practical Considerations For The Installations of Exhaust Gas Cleaning SystemsJCANo ratings yet

- Exhaust Gas CleaningDocument4 pagesExhaust Gas CleaningSamuel Sneddon-NelmesNo ratings yet

- EgcsDocument21 pagesEgcshein chanNo ratings yet

- Amos Brief Purchasing GuideDocument3 pagesAmos Brief Purchasing GuideAnuj SharmaNo ratings yet

- TIHE20111803 - R02 - Consideration For Ship Energy Saving Method of The Generator Engine Gas EconomizerDocument6 pagesTIHE20111803 - R02 - Consideration For Ship Energy Saving Method of The Generator Engine Gas Economizerajshsu5682No ratings yet

- Brave Royal Ship Management (BD) Limited: Bunkering PlanDocument6 pagesBrave Royal Ship Management (BD) Limited: Bunkering PlanTowfiqNo ratings yet

- MEPC 157 (55) Rate of DischargeDocument3 pagesMEPC 157 (55) Rate of Dischargefineeq100% (3)

- Class 4 2018 Kolkata MMD QuestionsDocument155 pagesClass 4 2018 Kolkata MMD QuestionsAbhinandan ChandraNo ratings yet

- Jai Narain Vyas University Faculty of Law JodhpurDocument12 pagesJai Narain Vyas University Faculty of Law JodhpurDilip JaniNo ratings yet

- Daikin LXE10A PDFDocument162 pagesDaikin LXE10A PDFTama MaliNo ratings yet

- Fuel Test Astm d396Document61 pagesFuel Test Astm d396Muhammad ZainiNo ratings yet

- Damen Container Feeder 800 568309 Johanna Schepersr PDFDocument2 pagesDamen Container Feeder 800 568309 Johanna Schepersr PDFmihai_mitza_2No ratings yet

- Iacs - UrDocument247 pagesIacs - UrDenny AgusNo ratings yet

- Anglo Eastern Gas Carrier Manual Final 2005Document172 pagesAnglo Eastern Gas Carrier Manual Final 2005Joseph AbrahamNo ratings yet

- REEDS - BOILERS - PAGES 01 To 40Document40 pagesREEDS - BOILERS - PAGES 01 To 40Narendra niranjan MathiyarasuNo ratings yet

- DSME VLCC CrosstielessDocument1 pageDSME VLCC Crosstielesssilidiri100% (1)

- 6 Inerting, Nitrogen BlankettingDocument9 pages6 Inerting, Nitrogen BlankettingchNo ratings yet

- 4.3.b - Scr-System-Imo-Tier-IiiDocument22 pages4.3.b - Scr-System-Imo-Tier-IiiRover DmsNo ratings yet

- 2 Stroke Diesel EngineDocument5 pages2 Stroke Diesel EngineJims Cudinyerah100% (1)

- Ekg Class2Document46 pagesEkg Class2Anonymous 4ylE57C6No ratings yet

- General Function Description: Scrubber Exhaust Gas Cleaning SystemDocument26 pagesGeneral Function Description: Scrubber Exhaust Gas Cleaning SystemLi Ann ChungNo ratings yet

- Ekm Motor Class 2Document84 pagesEkm Motor Class 2Anonymous 4ylE57C6100% (1)

- Investigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Document7 pagesInvestigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Darmawan PutrantoNo ratings yet

- Piston - Hce First ReviewDocument23 pagesPiston - Hce First ReviewLAKKANABOINA LAKSHMANARAONo ratings yet

- Unitor Chemical Treatment SummaryDocument7 pagesUnitor Chemical Treatment Summaryamirouche15No ratings yet

- Ae 2 PerformanceDocument4 pagesAe 2 PerformanceankitNo ratings yet

- Attachment For Quick Reference Issues After Starting To Use of VLSFO ClassNKDocument2 pagesAttachment For Quick Reference Issues After Starting To Use of VLSFO ClassNKmarcoNo ratings yet

- MSC 1 Circ 1511 - Unified Interpretations of SOLAS Regulations II-2 - 9 & II-2 - 13Document9 pagesMSC 1 Circ 1511 - Unified Interpretations of SOLAS Regulations II-2 - 9 & II-2 - 13Goh Boon TiongNo ratings yet

- MSC AMOS BS - Counters UpdateDocument6 pagesMSC AMOS BS - Counters UpdatecarmaNo ratings yet

- Mehr OtraDocument13 pagesMehr OtraThomas JoseNo ratings yet

- Airguard 3as 2005.2.15Document35 pagesAirguard 3as 2005.2.15TMZNo ratings yet

- Incinerators On ShipsDocument4 pagesIncinerators On ShipsVishu SharmaNo ratings yet

- Black Smoke From The Funnel What To Do CDocument3 pagesBlack Smoke From The Funnel What To Do CsaraashunNo ratings yet

- Man Diesel 2015Document38 pagesMan Diesel 2015LelosPinelos123No ratings yet

- Piston Cleaning Ring Sl2016-620Document2 pagesPiston Cleaning Ring Sl2016-620Parthiban Nagarajan100% (2)

- Cleaning of Heavy Fuel Oil and Maximum 0.10% Sulphur Fuels: Service Letter SL2017-638/DOJADocument6 pagesCleaning of Heavy Fuel Oil and Maximum 0.10% Sulphur Fuels: Service Letter SL2017-638/DOJAabhijit_11No ratings yet

- Central Cooling System On Ships - Full ExplanationDocument5 pagesCentral Cooling System On Ships - Full ExplanationBrown JohnsonNo ratings yet

- Soot Deposits and Fires in Exhaust Gas BoilersDocument28 pagesSoot Deposits and Fires in Exhaust Gas BoilersFuchsbauNo ratings yet

- MarineDocument21 pagesMarineAsm FaysalNo ratings yet

- HSE-07.24 - Appendix XVI - Exhaust Gas Scrubber Management PlanDocument68 pagesHSE-07.24 - Appendix XVI - Exhaust Gas Scrubber Management PlanAndriy100% (1)

- IM WinGD X92-B 2023-09-01Document990 pagesIM WinGD X92-B 2023-09-01konstantinos.tsitsilonisNo ratings yet

- DieselFacts 2008-1 PDFDocument16 pagesDieselFacts 2008-1 PDFAsh Kai100% (1)

- High Temperature Corrosion Exh ValvesDocument6 pagesHigh Temperature Corrosion Exh ValvesCvita CvitićNo ratings yet

- Relevance of Miller Cycle On Marine Diesel Engines: Ritinkar SenDocument7 pagesRelevance of Miller Cycle On Marine Diesel Engines: Ritinkar SenDhirendra DubeyNo ratings yet

- Procedure For Starting and Stopping of Sewage Treatment Plant On A ShipDocument4 pagesProcedure For Starting and Stopping of Sewage Treatment Plant On A ShipILHAMNo ratings yet

- ORBDocument14 pagesORBRommelNo ratings yet

- Pilot Operated Safety Relief ValvesDocument6 pagesPilot Operated Safety Relief ValvesfabioNo ratings yet

- March 11, 2016 News Hound: Engine Crankshaft Deflection MeasurementDocument11 pagesMarch 11, 2016 News Hound: Engine Crankshaft Deflection Measurementiwan ridwanNo ratings yet

- EKM Dec 2016Document2 pagesEKM Dec 2016Arun SNo ratings yet

- HGS-MAN-SL-20-010 - Top Controlled Exh. Valve (TCEV)Document5 pagesHGS-MAN-SL-20-010 - Top Controlled Exh. Valve (TCEV)ajshsu5682No ratings yet

- Marine TerminologyDocument109 pagesMarine Terminologyadam1950No ratings yet

- BIO-SEA - Technical Sheet BIO SEA L02-0055 - Va02 - 26032020Document2 pagesBIO-SEA - Technical Sheet BIO SEA L02-0055 - Va02 - 26032020Claudio SantellanesNo ratings yet

- Specification D6 Virgin: Method Test Result UnitDocument1 pageSpecification D6 Virgin: Method Test Result UnitClaudio SantellanesNo ratings yet

- Pump Non Return Flaps APRIL 2015Document2 pagesPump Non Return Flaps APRIL 2015Claudio SantellanesNo ratings yet

- UL1057114 - T12253 - Armada Tuah 85 - TT1650 DPN CP - DMN300007719 - D - W...Document4 pagesUL1057114 - T12253 - Armada Tuah 85 - TT1650 DPN CP - DMN300007719 - D - W...Claudio SantellanesNo ratings yet

- Oily Water Separator Inventory APRIL 2015Document4 pagesOily Water Separator Inventory APRIL 2015Claudio SantellanesNo ratings yet

- Sewage April 2015Document2 pagesSewage April 2015Claudio SantellanesNo ratings yet

- Bio Sea Solution BenefitsDocument3 pagesBio Sea Solution BenefitsClaudio Santellanes100% (1)

- OSV Corrosion Management ManualDocument16 pagesOSV Corrosion Management ManualClaudio SantellanesNo ratings yet

- The Case For Standards Management: Cutting Costs, Reducing Risk and Improving Work ProcessesDocument5 pagesThe Case For Standards Management: Cutting Costs, Reducing Risk and Improving Work ProcessesClaudio SantellanesNo ratings yet

- Armada Tuah 83: 65M Anchor Handling / Offshore Support VesselDocument2 pagesArmada Tuah 83: 65M Anchor Handling / Offshore Support VesselClaudio SantellanesNo ratings yet

- Root Cause 102 Transmission DamagesDocument8 pagesRoot Cause 102 Transmission DamagesClaudio SantellanesNo ratings yet

- Intersmooth 7570 SPC: TBT Free, Low Friction, Self Polishing Copolymer AntifoulingDocument2 pagesIntersmooth 7570 SPC: TBT Free, Low Friction, Self Polishing Copolymer AntifoulingClaudio SantellanesNo ratings yet

- Armada Tugas 4: 40M Anchor Handling TugDocument2 pagesArmada Tugas 4: 40M Anchor Handling TugClaudio SantellanesNo ratings yet

- Understanding Your Towing Vessel Inspection Options: Paul HiteDocument8 pagesUnderstanding Your Towing Vessel Inspection Options: Paul HiteClaudio SantellanesNo ratings yet

- ARMADA TUAH 105 - Brief Tech Spec (8-Apr-2019)Document2 pagesARMADA TUAH 105 - Brief Tech Spec (8-Apr-2019)Claudio SantellanesNo ratings yet

- Armada Tuah 101: 65M Dp2 Anchor Handling & Towing/ Offshore Support VesselDocument2 pagesArmada Tuah 101: 65M Dp2 Anchor Handling & Towing/ Offshore Support VesselClaudio SantellanesNo ratings yet

- ABS Matrix of Regulation - Updated May 2019Document37 pagesABS Matrix of Regulation - Updated May 2019Claudio SantellanesNo ratings yet

- MEPC.2-Circ.40 - Issuance - of - BWMCDocument2 pagesMEPC.2-Circ.40 - Issuance - of - BWMCClaudio SantellanesNo ratings yet

- Exhaust Emission Abatement APRIL 2019: Guide ForDocument64 pagesExhaust Emission Abatement APRIL 2019: Guide ForClaudio SantellanesNo ratings yet

- Shoshin Kendo Dojo: Rules and EtiquetteDocument2 pagesShoshin Kendo Dojo: Rules and EtiquetteClaudio SantellanesNo ratings yet

- SP 1275 Civil Design Criteria Manual PDFDocument184 pagesSP 1275 Civil Design Criteria Manual PDFayman ammarNo ratings yet

- Soil Nailing For Slope Strengthening: Liew Shaw-ShongDocument9 pagesSoil Nailing For Slope Strengthening: Liew Shaw-Shongjinwook75No ratings yet

- Intrinsic Extrinsic Parameters of Fish Spoilage PDFDocument19 pagesIntrinsic Extrinsic Parameters of Fish Spoilage PDFAnonymous gWLbtD100% (1)

- Is 9523Document78 pagesIs 9523Anonymous XBq5J840% (1)

- Suunto Zoop UserGuide enDocument108 pagesSuunto Zoop UserGuide enjohanf8041No ratings yet

- ORC和Kalina以及Uehara循环的热力性能分析Document22 pagesORC和Kalina以及Uehara循环的热力性能分析zhyhhNo ratings yet

- NPC v. CADocument2 pagesNPC v. CAEmir MendozaNo ratings yet

- Calc FormulaDocument1 pageCalc FormulaVaibhav PathakNo ratings yet

- China 2Document77 pagesChina 2Feri Rahmat Chandra PiliangNo ratings yet

- Integrated Collector Storage Solar Water HeatersDocument36 pagesIntegrated Collector Storage Solar Water HeatersomidNo ratings yet

- 6" Encapsulated Submersible Motors: Application DataDocument2 pages6" Encapsulated Submersible Motors: Application DataBenicio Joaquín Ferrero BrebesNo ratings yet

- Rainwater Harvesting: FFFFFFFFFFDocument26 pagesRainwater Harvesting: FFFFFFFFFFAmaira SinhaNo ratings yet

- Contoh Packing List EksporDocument1 pageContoh Packing List EksporAugusta Alda P.No ratings yet

- 03.1 Exhibit B - Appendix - Compensation TableDocument12 pages03.1 Exhibit B - Appendix - Compensation TableTikaNo ratings yet

- Proposal VAHP R1-Acrex Thermax ProthermDocument28 pagesProposal VAHP R1-Acrex Thermax ProthermradheNo ratings yet

- Science Fun Facts PDFDocument3 pagesScience Fun Facts PDFHikaru Graal100% (1)

- Characterization of Spray Lubricants For The High Pressure Die Casting Next Term ProcessesDocument8 pagesCharacterization of Spray Lubricants For The High Pressure Die Casting Next Term ProcessessinanaciNo ratings yet

- Petronas Technical Standards: Drainage and Sewer Systems For Onshore FacilitiesDocument23 pagesPetronas Technical Standards: Drainage and Sewer Systems For Onshore FacilitiesMohd Nizamuddin Mohamad NoorNo ratings yet

- Aquatreat® 695Document7 pagesAquatreat® 695GhazanfarNo ratings yet

- Rel Pçs 988B Eixo 06-07-21Document2 pagesRel Pçs 988B Eixo 06-07-21Silvanio Rosa QueirozNo ratings yet

- Climate 02 00242Document30 pagesClimate 02 00242Mohamed ZuhailNo ratings yet

- (POLAR EXPLORATION) The Race To The North Pole PDFDocument32 pages(POLAR EXPLORATION) The Race To The North Pole PDFluccamantiniNo ratings yet

- Underwater Archaeological Project at The Ancient City Akra in 2013 (Eastern Crimea)Document12 pagesUnderwater Archaeological Project at The Ancient City Akra in 2013 (Eastern Crimea)Mirjana PrekovicNo ratings yet

- Hydrology ReviewerDocument3 pagesHydrology ReviewerMisael CamposanoNo ratings yet

- Safety Data Sheet: Emulan® PDocument13 pagesSafety Data Sheet: Emulan® Pjuan carlosNo ratings yet

- Final Mass Transfer - I All Practical WriteupsDocument36 pagesFinal Mass Transfer - I All Practical WriteupsvkpaithankarNo ratings yet

Practical Considerations For The Installation of Exhaust Gas Cleaning Systems

Practical Considerations For The Installation of Exhaust Gas Cleaning Systems

Uploaded by

Claudio SantellanesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Practical Considerations For The Installation of Exhaust Gas Cleaning Systems

Practical Considerations For The Installation of Exhaust Gas Cleaning Systems

Uploaded by

Claudio SantellanesCopyright:

Available Formats

PRACTICAL

CONSIDERATIONS

FOR THE

INSTALLATION

OF EXHAUST

GAS CLEANING

SYSTEMS

1 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

PRACTICAL CONSIDERATIONS FOR THE

INSTALLATION OF EXHAUST GAS CLEANING

SYSTEMS

OVERVIEW

The IMO 2020 global sulfur limit requirements become effective on 01 January 2020. Common

compliance options to address these requirements are the use of compliant fuels, the use of

alternative fuels with a sulfur content less than 0.5% such as LNG, or the installation of an

exhaust gas cleaning system commonly known as a scrubber. This document introduces the

regulatory requirements and outlines items to be considered during the planning, procurement,

engineering, installation, commissioning and operation of scrubbers.

REGULATORY REQUIREMENTS

In designated Emission Control Areas (ECAs), compliance with a sulfur limit of 0.1% has been

in force since January 2015. Beginning 01 January 2020, a global 0.5% sulfur limit will go into

effect. In addition to IMO requirements, there are regional and local requirements that may be

appliable as seen in Figure 1 below.

Figure 1: Examples of Regional and Local Scrubber Related Regulations

2 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

Scrubber as Equivalency

As indicated in Figure 1, an approved scrubber system is commonly accepted as an equivalent

alternative for meeting the fuel sulfur limit requirements.

The most common installation is a wet scrubber system with the following three option types:

open loop, closed loop and hybrid.

The three scrubber types operate on the same principle: the washwater is injected into the

scrubber tower through the spray nozzles arranged in an optimized pattern to create a turbulent

environment to maximize the surface area of sprayed water in contact with the exhaust gas.

Sulfur Oxides (SOx) in the exhaust gas is absorbed in the water and becomes acidic which is

neutralized by the naturally existing or artificially added alkali in the washwater to form sulfites

and is further oxidized to a sulfate.

In an open loop system, seawater with naturally existing alkali is used for scrubbing and

discharged back to sea. Treatment of the washwater effluent is typically optional provided the

effluent meets the criteria, which includes pH, PAH and turbidity, for discharge in the applicable

IMO or regional/national requirements. The system typically incorporates an automated

arragement to adjust the washwater flowrate when operational parameters change such as

increase of engine load which increases the exhaust gas flowrate, making the SOx emission

level and washwater to be within the required limit.

For a closed loop system, fresh water is typically treated by adding sodium hydroxide (NaOH) to

achieve the required alkalinity for scrubbing and neutralization. The washwater effluent will be

treated before being re-circulated to the scrubber and any losses are made up with additional

freshwater. A small quantity of the washwater effluent is bled off to a treatment plant before

discharge to sea,If discharge is prohibited, the effluent is routed to a holding tank. Sludge

removed by the treatment plant will be stored onboard for disposal ashore. For closed loop

systems, the washwater circulation rate typically remains unchanged. When operational

parameters such as engine load changes, the automation system will adjust the dosing amount

to the circulation washwater.

In addition to scrubber and associated auxiliaries, a closed loop system will include equipment

for washwater treatment, sludge handling and chemical dosing (typically Sodium Hydroxide,

NaOH).

Hybrid systems can operate in either open or closed loop mode as needed.

PLANNING

Effective planning for installation of a scrubber onboard a vessel should consider a feasibility

evaluation, lead time for the supply of the scrubber, scope of structure and system modification,

engineering evaluation and class approval, fabrication, installation and integration, and testing,

commissioning and demonstration of compliance.

Scubber installation typically involves the shipowner, scrubber supplier, engineering company

and shipyard. It is important to have defined roles for each party during the various stages of

3 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

installation. As an example, the equipment provider may deliver the basic design and system

material specification, the engineering company or shipyard may develop construction drawings,

while the shipyard carries out equipment installation and system integration.

For existing vessels, the time spent to retrofit a scrubber system depends on several factors

with the equipment supply lead time and the availability of a retrofit yard often being critical.

Effective planning may allow some of the required steps to be performed concurrently with the

possibility for much of the work to be completed before the ship arrives at the retrofit yardwhich

can significantly reduce time spent in the yard.

Drydocking needs to be taken into consideration if it is necessary to enlarge the existing

seachest, or an additional seachest is needed to meet the demand for washwater for the

scrubber. If feasible, the retrofit activity may be aligned with the statutory renewal survey or

other modification work.

Two major items to be addressed during the initial planned phase are space constraints and

power availability.

Space Constraints

Scrubbers are large pieces of equipment. Space to accommodate a scrubber and its auxiliaries

is one of the challenges of scrubber retrofitting.

Figure 2: Scrubber

Typically, closed loop and hybrid systems are more complicated than open loop systems. More

space is required for the storage of dosing chemicals, circulating water, bleed-off water and

4 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

washwater residues. Additional space is necessary to accommodate equipment such as heat

exchangers and water treatment units. The capacity of a circulating water tank is typically the

volume of water pumped by a circulation pump in 1.5 minutes with 10% margin, plus the pipe

volume of the circulation system. The bleed water holding tank could be a few hundred cubic

meters depending on the duration that the system operates in zero discharge mode when

overboard discharge of washwater is prohibited.

To accommodate the scrubber towers and gas sampling equipment, enlargement of the funnel

is often required.

Power Availability

Power availability onboard an existing vessel is another key factor to be considered. Typical

additional power demand can be around 1.5% of the rating of the engines the scrubber serves.

An electrical load analysis will help to determine if the ship’s existing power plant has adequate

capacity for the additional power demand of the scrubber. The evaluation is to consider various

operation modes of the ship, including normal sea going, maneuvering and cargo

loading/offloading. If it is determined that an additional generator is needed, the installation of a

scrubber may not be a viable compliance option.

PROCUREMENT

Since a scrubber system is a ship-specific solution for sulfur emissions, the procurement

process should ensure the system is suitable for the vessel needs. This should consider the

operating profile of the candidate vessel. Key items to be addressed are:

• Technical limitations and operational restrictions

• Emission monitoring technology

• Footprint and weight

• Power requirement under all operating conditions

• Materials of scrubber chamber and accessory components/systems

• Regulatory approval status

• Redundancy and worldwide service availability

ENGINEERING

Key considerations to be addressed during the Engineering phase include material suitability,

backpressure, system configuration and vessel integration, and sludge handling arrangements.

Materials

The materials used in the construction of the scrubber and the accessory components are

important for the reliability and durability of the system. They should be suitable for the potential

high temperatures and corrosive operational conditions.

5 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

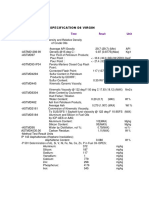

The table below summarizes typical materials for different systems, equipment and

components.

Component Common Material

Scrubber reaction chamber Super austenitic stainless steel - SMO 254 (6 Moly)

GRP (glass reinforced plastic)

Washwater lines (effluent, bleed-off)

Super duplex stainless steel

Water lines GRE (glass reinforced epoxy)

(scrubbing, cooling, reaction, makeup

water) Carbon steel with PE (polyethylene) lining

Alkali (NaOH) supply Stainless steel - SS 316L

Plastic

Sludge tanks

Steel with synthetic coating

Sludge lines GRE, FRP or GRP

Valves (Exhaust, bypass, isolation) Nickel alloys

Table 1: Common Scrubber Materials

Backpressure

The installation of a scrubber may impact the operation of the engine if excessive exhaust

backpressure is generated. It is important to verify during the evaluation of a candidate scrubber

system that the backpressure is within the limits set by the engine manufacturer. Increase of

exhaust backpressure may result in additional fuel consumption due to lower turbocharger

efficiency, increased component temperatures, and cause increased wear. In addition, Nitrogen

Oxides (NOx) emission may be increased. It is to be noted that scrubber systems that cause

diesel engines to operate outside the exhaust backpressure limits detailed in the approved IMO

Annex VI Regulation 13 Technical Files may invalidate the emissions certification and will

require a re-approval of the engine NOx certification by the Flag Administration or Recognized

Oraganization (RO) responsible for the original certification. Exhaust gas fans may be used at

the scrubber outlet to compensate for any additional backpressure, however the addition of

more equipment may increase the required power and maintenance over the life of the system.

6 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

System Configuration and Vessel Integration

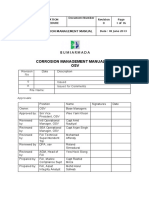

Multi-inlet scrubbers are typically

installed so one scrubber can serve

multiple engines/boilers. Such

integrated systems require isolation

and bypass arrangements so that any

engine not in operation can be

isolated, or in case of scrubber failure,

the scrubber can be bypassed if they

are not designed for operation in a dry

condition. As illustrated in Figure 3, the

isolation valve (tag no. 7) and bypass

valve (tag no. 6) should not both

closed, otherwise, the excessive

backpressure may cause the engine to

stall. A proper control logic and

Figure 3: Bypass and Isolation for Scrubber

interlock arrangement should be

provided.

The scrubber system design is to consider any abnormal condition that may occur during the

operation, for example, excessive high temperature, lack of washwater or potential of scrubber

flooding. Automatic shutdown should be incorporated in the monitoring and control system as a

safety measure.

Sludge Handling

For closed loop or hybrid systems, sludge will be generated from the washwater treatment

system. Under IMO Guidelines for Exhaust Gas Cleaning Systems, MEPC.259(68), such sludge

is not to be discharged to sea or incinerated onboard. Typical tanks of 0.5 – 1 cubic meter per

megawatt (MW) of engine power are specified. A sludge dewatering system may be provided to

dry the sludge and minimize the volume, eliminating the need for a sludge tank on board.

Sludge can be stored in Intermediate Bulk Containers (IBC) or barrels and transferred ashore.

Class and Statutory Approval

A scrubber system requires approval from both a statutory and Class perspective and includes

the review of the equipment as well as the review of the onboard installation.

From a statutory perspective, the IMO Guideline for Exhaust Gas Cleaning Systems, MEPC.

259(68), outlines the process including approval Schemes A and Scheme B as depicted in

Figure 4. Scheme B is typically used for the approval of scrubber installations on both new

construction and retrofit projects.

7 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

Figure 4: Outline of Exhaust Gas Cleaning System Approval Scheme

Compliance with the SOx emission limit is through in-service continuous monitoring of the Sulfur

Dioxide/Carbon Dioxide (SO2/CO2) ratio in the exhaust gas, and the condition of discharged

washwater.

Upon satisfactory initial survey of the installation, and verification of the performance of the

monitoring system, with the concurrence of the Flag Administration, the scrubber will be

annotated in the Supplement to the International Air Pollution Prevention (IAPP) certificate as

the equivalent means for meeting fuel sulfur limit requirements.

The Flag administration is to notify their acceptance to the IMO for inclusion in the IMO GISIS

database for each ship-specific approval.

8 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

From a Classification Society perspective, the requirements in the ABS Guide for Exhaust

Emission Abatement related to the safety aspects of the system include:

• Configuration and vessel integration

• Exhaust by-pass arrangement

• Prevention of flooding

• Vessel Stability

• Electrical load analysis

• Piping system

• NaOH supply system

• Safety Shutdown

In addition, ABS offers an optional class notation, EGC-SOx, which can be assigned if the

applicable requirements in the ABS Guide for Exhaust Emission Abatement are fully complied.

INSTALLATION

For existing vessels, preparation for installation can be completed onboard while the vessel is in

operation, onshore before the vessel arrives at the yard, or when the vessel is in the yard. The

work onboard will typically require modifications to the structure, electrical and piping systems.

Onboard Preparation

Some preparation work onboard may be

carried out while the vessel is in

operation. This includes the installation

of piping, cabling and foundations for

seawater pumps and sealing air fans.

This can help reduce the time required

for retrofitting at the yard.

On Shore Preparation

Typically, when a new funnel block is

required, it is common practice to have

the block constructed with the scrubber

and associated piping and electrical

installed within the new block. Piping for

the engine room can be prefabricated for Figure 5: Seawater Pumps for

installation. Scrubber System in Engine Room

9 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

Work in Dry Dock and at Quayside

The additional water demand for scrubber systems may require the existing sea chest to be

enlarged, or an additional sea chest to be added. In such cases, dry docking may be necessary.

Integration of the scrubber system with the shipboard system include the exhaust piping system

and the control and monitoring system. The control and monitoring panel is typically installed

close to the engine control station. Depending on the scrubber system, an engine load signal

may be needed as input to the scrubber system for adjusting the washwater flowrate through

VFD (variable frequency driving) pump or throttling valve in washwater supply line.

Due to the corrosive nature of washwater effluent, plastic pipe (FRP or other similar material)

are commonly used. Plastic pipe connection work should be in accordance with the

manufacturer’s installation guidelines and carried out onboard by qualified personnel.

Structure

Structural modification associated with scrubber retrofitting is typically related to creating the

space needed for the installation. Commonly, the funnel requires modification to accommodate

the scrubber and the associated exhaust bypass pipes. Equipment, piping and ventilation ducts

may need to be rearranged for the installation of accessory equipment/system. For closed loop

systems, space for storage of processing water and chemicals and accommodation of additioanl

equipment may take up some cargo space.

Electrical

In addition to electric load analysis, an electrical coordination study and short circuit analysis to

verify the integrity of the power supply system may be needed.

Piping and Seachest

Piping modification involves sea chest enlargement or adding additional sea chest if existing

sea chest cannot meet the water demand of the scrubber system. Overboard discharge for

washwater will need to be added. The pipe between overboard discharge valves and the side

shell need to be of metallic material as required by class Rules. This pipe could be subject to

severe corrosive effluent. Carbon steel with plastic lining or high-grade stainless steel should be

considered.

Stability

Stability and lightship weight need to be evaluated due to the additional weight of the scrubber

system. In general, if the change in lightship displacement exceeds 2% of the lightship

displacement from the most recent approved lightship data and/or the change in lightship

Longitudinal Center of Gravity (LCG), relative to the most recent approved lightship data,

exceeds 1.0% of the Length Between Perpendiculars (LBP), a stability test may be required on

the vessel and stability calculations would need to be revised to indicate the changes.

10 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

COMMISSIONING

Commissioning of a scrubber system includes calibration of the monitoring and control system,

functional testing, and performance evaluation of the complete system. Crew training may also

be conducted during the system commissioning phase.

Commissioning can be time consuming. One option is to separate the commissioning and

installation process. Once installation in the yard is completed, the ship may return for service

with commissioning planned in the future. This can help to decrease the off-hire time.

Arrangements would need to be made to ensure the vessel was operated in compliance during

the interim period.

Preparation for commissioning should consider:

• Development and review of a test plan by Class

• Onboard verification of the monitoring and control system sensors. These sensors

should be preset at the manufacturer’s plant; however they may require some calibration

once the system is installed onboard the vessel, such as zero and span calibration to

confirm gas analyzers.

• Availability of fuel with the sulfur content corresponding to the design sulfur limit of the

scrubber system for performance evaluation

• Availability of the sampling kit for the washwater effluent, typically provided by the testing

laboratory

Functional testing is to be carried out to verify the integrity and operability of the system

including the control, monitoring, alarm and safety system. This includes the interlock

arrangement on the exhaust pipes bypassing the scrubber.

Performance testing will involve testing at quay side and during sea trials. Although not required

for the Scheme B approval approach under the IMO Guidelines, many owners/operators have

chosen to carry out testing to evaluate the performance before the scrubber system is put into

operation. This includes the measurement of the SO2 to CO2 ratio, and the properties of

washwater including pH, PAH, turbidity and nitrates.

The test for emission limit verification can be time consuming. IMO Guidelines (Section 4.3.6)

require the test to be done for at least 4 engine load points. At each load point, it may take

proximately 20 to 30 minutes to get the load steady, and an additional 10 to 15 minutes to get

the stabilized reading on the emission monitor. Scrubber system commissioning has taken two

to three days during sea trials for some past projects.

The accuracy of the emission monitor may be validated by testing the exhaust gas sampled at

the exhaust stack with a portable analyzer.

The pH value of washwater could be measured 4 meters from overboard discharge at quay side

when the vessel is stationary with generator engines in operation. The corresponding pH value

11 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

measured at overboard discharge is set as the minimum pH limit. Alternatively, the pH limit

monitored at the overboard may also be determined by calculation method following IMO

Guideline criteria. For U.S. EPA requirements, the pH value needs to be measured at the

overboard discharge.

Lessons Learned

Key lessons learned from completed scrubber installation projects are summarized in Table 2.

Observation Possible Causes Recommendation

Washwater carryover by • Inappropriate exhaust gas • Improve flow path

exhaust gas flow path • Modify demister design

Operation interruption • Clogging of filter in supply • Consider redundancy

(e.g., wash water supply) piping • Complete Failure Modes

and Effects Analysis

(FMEA)

Unexpected high exhaust • Undersized scrubbers • Improve design,

gas backpressure • Sharp bend in piping incorporate design

• Water spray resistance verification and simulation

• Failure of bypass/ isolation for back pressure

interlock evaluation

Out of compliance • Inadequate wash water • Improve design

performance (wash water • Low pH of supply water • Verify through CFD

pH, SO2/CO2 ratio) • Wash water/gas contact simulation

• Verify supply water pH

Reliability of monitoring • Not for marine application • Use approved monitoring

system including • Lack of calibration system

instrument malfunction • Inappropriate installation • Use proven product

• Follow makers instructions

Loose nozzles, water/gas • Poor workmanship • Improve workmanship

leak

Extended test period • Lack of test plan/pre- • Follow approved test plan

commission • Complete

pre- commissioning

Table 2: Key Lessons Learned from Scrubber Installation Projects

12 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

OPERATION

Manning and Crew intervention

In service operation planning should consider manning and crew intervention, demonstration of

compliance, contingency measures, maintenance and repair, and calibration of instrumentation.

Crew need to be assigned responsibility for the operation of the scrubber system, however they

do not need to be dedicated. Crew intervention will typically only be required during the start-up

and shutdown of the scrubber system, or, in the case of a hybrid system, when switching

between open and closed loop. This is generally a one-push button task. Crew intervention will

also be necessary whenever an alarm condition occurs. It is important that the responsible crew

is aware of the operation limitations and able to interpret the alarm conditions, such as out of

tolerance sulfur limit, water level, pressure or temperature.

The crew’s intervention may also be required in case operational limits are exceeded, e.g.,

sulfur content of fuel used exceeds the design limit.

Demonstration of Compliance

For systems under the Scheme B approval approach, demonstration of compliance is through

the continuous monitoring of emission level SO2 (ppm) to CO2 (% v/v) ratio, and the monitoring

of washwater discharge properties.

The SOx Emission Compliance Plan (SECP), EGC Technical Manual Scheme B (ETM-B) and

Onboard Monitoring Manual (OMM) are to be used as guidance documents for the operation of

the system.

Daily spot checks of the operational parameters are to be recorded in the EGC Record Book or

Electronic Logging System.

Whenever the scrubber system is in operation, the emission level and washwater properties are

to be automatically monitored and recorded by the continuous emission monitoring system. The

recorded data needs to be retained for at least 18 months from the date of recording and be

made available as required.

Contingency Measures

MARPOL Annex VI Regulation 3.1.2 provides criteria for exemptions and exceptions for vessels

that experience noncompliance with the emission standards set forth in MARPOL Annex VI

Regulation 14 as a result of damage to a ship or its equipment.

Under that criteria, a shipowner needs to follow regulation 5.6 and notify their flag Administration

for guidance as to necessary measures to be taken. In the case of SOx scrubber breakdown ,

switching to compliant fuel is typically expected until scrubber repairs are completed. For the

exemption to be granted by the Flag Administration, the owner would need to demonstrate that

due diligence had been exercised in both design and operation. In addition, national/regional

13 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

guidance has also been issued on the topic. For example, the UK has issued Marine Guidance

Note MGN 510 addressing potential non-compliance of scrubber systems.

Maintenance and Repair

To operate properly, the sensors for a scrubber monitoring and recording system need to be

calibrated periodically in accordance with manufacturer’s guidelines. Since these sensors can

be expected to fail at times, maintaining adequate spares and having a resupply arrangement in

place is important.

Commonly identified failures/malfunctions with scrubbers include:

• Clogging of the sampling tubing with soot, which prevents proper SO2/CO2 analyzer

readings

• Clogging of the pressure transducers at the bottom of the pipe run with debris due to the

inappropriate location of the sensors

• Malfunction of the demister in the scrubber chamber due to the build-up of deposits.

Periodic steam cleaning of the system following the maker’s recommendations will help

to prevent the deposits.

Operational experience indicates that low grade stainless steel, e.g. SS316, will not withstand

the corrosive operational environment within the scrubber chamber. Fittings of such material

installed inside the chamber readily corrode and could require replacement within 3 years.

Service restrictions include wash water discharge prohibition, and low wash water alkalinity in

certain trade routes / or areas. In such case, the system will need to operate as a closed loop

system. The following need to be taken into consideration:

• Handling and disposal of sludge

• Storage of bleed-off water

• Handling and storage of chemical dosing (typically caustic soda)

Other operational issues include possible noise caused by sealing fans. Appropriate location of

the fans may help to reduce the noise affecting the crew.

ABS SUPPORT

ABS can assist owners and operators with reviewing the appropriate compliance options given

the specific operating profile for each of their vessels. With regard to scrubbers, ABS can

support owners and operators with understanding the available technology, life-cycle costs and

operational impact

14 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

ABS Scrubber-related Publications

• ABS Advisory on Exhaust Gas Scrubber Systems (July 2018): This Advisory

summarizes the regulatory requirements applicable to scrubbers and provides an

overview of available technologies.

• ABS Exhaust Emission Abatement Guide (September 2017): This Guide outlines the

requirements to be applied to exhaust emission abatement systems fitted to ABS

classed vessels primarily covering SOx scrubbers, Selective Catalytic Reduction (SCR)

systems, Exhaust Gas Recirculation (EGR) arrangements, and Exhaust Emissions

Monitoring Systems (EEMS) associated with the aforementioned emission abatement

systems.

15 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

16 | PRACTICAL CONSIDERATIONS FOR THE INSTALLATION OF EXHAUST GAS CLEANING SYSTEMS

You might also like

- MSC AMOS BS - Job DescriptionDocument9 pagesMSC AMOS BS - Job DescriptioncarmaNo ratings yet

- Tech Guidelines Env Management Mining ADocument14 pagesTech Guidelines Env Management Mining AvanpatoNo ratings yet

- Ontario Fish Identification GuideDocument3 pagesOntario Fish Identification GuideT.O. Nature & DevelopmentNo ratings yet

- Armada Hibiscus: 100M Accommodation/ Work BargeDocument2 pagesArmada Hibiscus: 100M Accommodation/ Work BargeClaudio Santellanes100% (2)

- Method Statement For Concrete Foundation WorkDocument21 pagesMethod Statement For Concrete Foundation WorkMihirdutta100% (1)

- Cat Fines Presentation SlidesDocument48 pagesCat Fines Presentation SlidescaptkcNo ratings yet

- S70me-C8 5 PDFDocument397 pagesS70me-C8 5 PDFIgor Tabulynsky100% (1)

- Low Container Ship Speed Facilitated by Versatile ME/ME-C EnginesDocument12 pagesLow Container Ship Speed Facilitated by Versatile ME/ME-C EnginesParthiban NagarajanNo ratings yet

- JKR20710 0001 11Document13 pagesJKR20710 0001 11keesinvong100% (2)

- ABS Practical Considerations For The Installations of Exhaust Gas Cleaning SystemsDocument26 pagesABS Practical Considerations For The Installations of Exhaust Gas Cleaning SystemsJCANo ratings yet

- Exhaust Gas CleaningDocument4 pagesExhaust Gas CleaningSamuel Sneddon-NelmesNo ratings yet

- EgcsDocument21 pagesEgcshein chanNo ratings yet

- Amos Brief Purchasing GuideDocument3 pagesAmos Brief Purchasing GuideAnuj SharmaNo ratings yet

- TIHE20111803 - R02 - Consideration For Ship Energy Saving Method of The Generator Engine Gas EconomizerDocument6 pagesTIHE20111803 - R02 - Consideration For Ship Energy Saving Method of The Generator Engine Gas Economizerajshsu5682No ratings yet

- Brave Royal Ship Management (BD) Limited: Bunkering PlanDocument6 pagesBrave Royal Ship Management (BD) Limited: Bunkering PlanTowfiqNo ratings yet

- MEPC 157 (55) Rate of DischargeDocument3 pagesMEPC 157 (55) Rate of Dischargefineeq100% (3)

- Class 4 2018 Kolkata MMD QuestionsDocument155 pagesClass 4 2018 Kolkata MMD QuestionsAbhinandan ChandraNo ratings yet

- Jai Narain Vyas University Faculty of Law JodhpurDocument12 pagesJai Narain Vyas University Faculty of Law JodhpurDilip JaniNo ratings yet

- Daikin LXE10A PDFDocument162 pagesDaikin LXE10A PDFTama MaliNo ratings yet

- Fuel Test Astm d396Document61 pagesFuel Test Astm d396Muhammad ZainiNo ratings yet

- Damen Container Feeder 800 568309 Johanna Schepersr PDFDocument2 pagesDamen Container Feeder 800 568309 Johanna Schepersr PDFmihai_mitza_2No ratings yet

- Iacs - UrDocument247 pagesIacs - UrDenny AgusNo ratings yet

- Anglo Eastern Gas Carrier Manual Final 2005Document172 pagesAnglo Eastern Gas Carrier Manual Final 2005Joseph AbrahamNo ratings yet

- REEDS - BOILERS - PAGES 01 To 40Document40 pagesREEDS - BOILERS - PAGES 01 To 40Narendra niranjan MathiyarasuNo ratings yet

- DSME VLCC CrosstielessDocument1 pageDSME VLCC Crosstielesssilidiri100% (1)

- 6 Inerting, Nitrogen BlankettingDocument9 pages6 Inerting, Nitrogen BlankettingchNo ratings yet

- 4.3.b - Scr-System-Imo-Tier-IiiDocument22 pages4.3.b - Scr-System-Imo-Tier-IiiRover DmsNo ratings yet

- 2 Stroke Diesel EngineDocument5 pages2 Stroke Diesel EngineJims Cudinyerah100% (1)

- Ekg Class2Document46 pagesEkg Class2Anonymous 4ylE57C6No ratings yet

- General Function Description: Scrubber Exhaust Gas Cleaning SystemDocument26 pagesGeneral Function Description: Scrubber Exhaust Gas Cleaning SystemLi Ann ChungNo ratings yet

- Ekm Motor Class 2Document84 pagesEkm Motor Class 2Anonymous 4ylE57C6100% (1)

- Investigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Document7 pagesInvestigation of Exhaust Valve Failure in Heavy - Duty Diesel Engine (#97238) - 83408Darmawan PutrantoNo ratings yet

- Piston - Hce First ReviewDocument23 pagesPiston - Hce First ReviewLAKKANABOINA LAKSHMANARAONo ratings yet

- Unitor Chemical Treatment SummaryDocument7 pagesUnitor Chemical Treatment Summaryamirouche15No ratings yet

- Ae 2 PerformanceDocument4 pagesAe 2 PerformanceankitNo ratings yet

- Attachment For Quick Reference Issues After Starting To Use of VLSFO ClassNKDocument2 pagesAttachment For Quick Reference Issues After Starting To Use of VLSFO ClassNKmarcoNo ratings yet

- MSC 1 Circ 1511 - Unified Interpretations of SOLAS Regulations II-2 - 9 & II-2 - 13Document9 pagesMSC 1 Circ 1511 - Unified Interpretations of SOLAS Regulations II-2 - 9 & II-2 - 13Goh Boon TiongNo ratings yet

- MSC AMOS BS - Counters UpdateDocument6 pagesMSC AMOS BS - Counters UpdatecarmaNo ratings yet

- Mehr OtraDocument13 pagesMehr OtraThomas JoseNo ratings yet

- Airguard 3as 2005.2.15Document35 pagesAirguard 3as 2005.2.15TMZNo ratings yet

- Incinerators On ShipsDocument4 pagesIncinerators On ShipsVishu SharmaNo ratings yet

- Black Smoke From The Funnel What To Do CDocument3 pagesBlack Smoke From The Funnel What To Do CsaraashunNo ratings yet

- Man Diesel 2015Document38 pagesMan Diesel 2015LelosPinelos123No ratings yet

- Piston Cleaning Ring Sl2016-620Document2 pagesPiston Cleaning Ring Sl2016-620Parthiban Nagarajan100% (2)

- Cleaning of Heavy Fuel Oil and Maximum 0.10% Sulphur Fuels: Service Letter SL2017-638/DOJADocument6 pagesCleaning of Heavy Fuel Oil and Maximum 0.10% Sulphur Fuels: Service Letter SL2017-638/DOJAabhijit_11No ratings yet

- Central Cooling System On Ships - Full ExplanationDocument5 pagesCentral Cooling System On Ships - Full ExplanationBrown JohnsonNo ratings yet

- Soot Deposits and Fires in Exhaust Gas BoilersDocument28 pagesSoot Deposits and Fires in Exhaust Gas BoilersFuchsbauNo ratings yet

- MarineDocument21 pagesMarineAsm FaysalNo ratings yet

- HSE-07.24 - Appendix XVI - Exhaust Gas Scrubber Management PlanDocument68 pagesHSE-07.24 - Appendix XVI - Exhaust Gas Scrubber Management PlanAndriy100% (1)

- IM WinGD X92-B 2023-09-01Document990 pagesIM WinGD X92-B 2023-09-01konstantinos.tsitsilonisNo ratings yet

- DieselFacts 2008-1 PDFDocument16 pagesDieselFacts 2008-1 PDFAsh Kai100% (1)

- High Temperature Corrosion Exh ValvesDocument6 pagesHigh Temperature Corrosion Exh ValvesCvita CvitićNo ratings yet

- Relevance of Miller Cycle On Marine Diesel Engines: Ritinkar SenDocument7 pagesRelevance of Miller Cycle On Marine Diesel Engines: Ritinkar SenDhirendra DubeyNo ratings yet

- Procedure For Starting and Stopping of Sewage Treatment Plant On A ShipDocument4 pagesProcedure For Starting and Stopping of Sewage Treatment Plant On A ShipILHAMNo ratings yet

- ORBDocument14 pagesORBRommelNo ratings yet

- Pilot Operated Safety Relief ValvesDocument6 pagesPilot Operated Safety Relief ValvesfabioNo ratings yet

- March 11, 2016 News Hound: Engine Crankshaft Deflection MeasurementDocument11 pagesMarch 11, 2016 News Hound: Engine Crankshaft Deflection Measurementiwan ridwanNo ratings yet

- EKM Dec 2016Document2 pagesEKM Dec 2016Arun SNo ratings yet

- HGS-MAN-SL-20-010 - Top Controlled Exh. Valve (TCEV)Document5 pagesHGS-MAN-SL-20-010 - Top Controlled Exh. Valve (TCEV)ajshsu5682No ratings yet

- Marine TerminologyDocument109 pagesMarine Terminologyadam1950No ratings yet

- BIO-SEA - Technical Sheet BIO SEA L02-0055 - Va02 - 26032020Document2 pagesBIO-SEA - Technical Sheet BIO SEA L02-0055 - Va02 - 26032020Claudio SantellanesNo ratings yet

- Specification D6 Virgin: Method Test Result UnitDocument1 pageSpecification D6 Virgin: Method Test Result UnitClaudio SantellanesNo ratings yet

- Pump Non Return Flaps APRIL 2015Document2 pagesPump Non Return Flaps APRIL 2015Claudio SantellanesNo ratings yet

- UL1057114 - T12253 - Armada Tuah 85 - TT1650 DPN CP - DMN300007719 - D - W...Document4 pagesUL1057114 - T12253 - Armada Tuah 85 - TT1650 DPN CP - DMN300007719 - D - W...Claudio SantellanesNo ratings yet

- Oily Water Separator Inventory APRIL 2015Document4 pagesOily Water Separator Inventory APRIL 2015Claudio SantellanesNo ratings yet

- Sewage April 2015Document2 pagesSewage April 2015Claudio SantellanesNo ratings yet

- Bio Sea Solution BenefitsDocument3 pagesBio Sea Solution BenefitsClaudio Santellanes100% (1)

- OSV Corrosion Management ManualDocument16 pagesOSV Corrosion Management ManualClaudio SantellanesNo ratings yet

- The Case For Standards Management: Cutting Costs, Reducing Risk and Improving Work ProcessesDocument5 pagesThe Case For Standards Management: Cutting Costs, Reducing Risk and Improving Work ProcessesClaudio SantellanesNo ratings yet

- Armada Tuah 83: 65M Anchor Handling / Offshore Support VesselDocument2 pagesArmada Tuah 83: 65M Anchor Handling / Offshore Support VesselClaudio SantellanesNo ratings yet

- Root Cause 102 Transmission DamagesDocument8 pagesRoot Cause 102 Transmission DamagesClaudio SantellanesNo ratings yet

- Intersmooth 7570 SPC: TBT Free, Low Friction, Self Polishing Copolymer AntifoulingDocument2 pagesIntersmooth 7570 SPC: TBT Free, Low Friction, Self Polishing Copolymer AntifoulingClaudio SantellanesNo ratings yet

- Armada Tugas 4: 40M Anchor Handling TugDocument2 pagesArmada Tugas 4: 40M Anchor Handling TugClaudio SantellanesNo ratings yet

- Understanding Your Towing Vessel Inspection Options: Paul HiteDocument8 pagesUnderstanding Your Towing Vessel Inspection Options: Paul HiteClaudio SantellanesNo ratings yet

- ARMADA TUAH 105 - Brief Tech Spec (8-Apr-2019)Document2 pagesARMADA TUAH 105 - Brief Tech Spec (8-Apr-2019)Claudio SantellanesNo ratings yet

- Armada Tuah 101: 65M Dp2 Anchor Handling & Towing/ Offshore Support VesselDocument2 pagesArmada Tuah 101: 65M Dp2 Anchor Handling & Towing/ Offshore Support VesselClaudio SantellanesNo ratings yet

- ABS Matrix of Regulation - Updated May 2019Document37 pagesABS Matrix of Regulation - Updated May 2019Claudio SantellanesNo ratings yet

- MEPC.2-Circ.40 - Issuance - of - BWMCDocument2 pagesMEPC.2-Circ.40 - Issuance - of - BWMCClaudio SantellanesNo ratings yet

- Exhaust Emission Abatement APRIL 2019: Guide ForDocument64 pagesExhaust Emission Abatement APRIL 2019: Guide ForClaudio SantellanesNo ratings yet

- Shoshin Kendo Dojo: Rules and EtiquetteDocument2 pagesShoshin Kendo Dojo: Rules and EtiquetteClaudio SantellanesNo ratings yet

- SP 1275 Civil Design Criteria Manual PDFDocument184 pagesSP 1275 Civil Design Criteria Manual PDFayman ammarNo ratings yet

- Soil Nailing For Slope Strengthening: Liew Shaw-ShongDocument9 pagesSoil Nailing For Slope Strengthening: Liew Shaw-Shongjinwook75No ratings yet

- Intrinsic Extrinsic Parameters of Fish Spoilage PDFDocument19 pagesIntrinsic Extrinsic Parameters of Fish Spoilage PDFAnonymous gWLbtD100% (1)

- Is 9523Document78 pagesIs 9523Anonymous XBq5J840% (1)

- Suunto Zoop UserGuide enDocument108 pagesSuunto Zoop UserGuide enjohanf8041No ratings yet

- ORC和Kalina以及Uehara循环的热力性能分析Document22 pagesORC和Kalina以及Uehara循环的热力性能分析zhyhhNo ratings yet

- NPC v. CADocument2 pagesNPC v. CAEmir MendozaNo ratings yet

- Calc FormulaDocument1 pageCalc FormulaVaibhav PathakNo ratings yet

- China 2Document77 pagesChina 2Feri Rahmat Chandra PiliangNo ratings yet

- Integrated Collector Storage Solar Water HeatersDocument36 pagesIntegrated Collector Storage Solar Water HeatersomidNo ratings yet

- 6" Encapsulated Submersible Motors: Application DataDocument2 pages6" Encapsulated Submersible Motors: Application DataBenicio Joaquín Ferrero BrebesNo ratings yet

- Rainwater Harvesting: FFFFFFFFFFDocument26 pagesRainwater Harvesting: FFFFFFFFFFAmaira SinhaNo ratings yet

- Contoh Packing List EksporDocument1 pageContoh Packing List EksporAugusta Alda P.No ratings yet

- 03.1 Exhibit B - Appendix - Compensation TableDocument12 pages03.1 Exhibit B - Appendix - Compensation TableTikaNo ratings yet

- Proposal VAHP R1-Acrex Thermax ProthermDocument28 pagesProposal VAHP R1-Acrex Thermax ProthermradheNo ratings yet

- Science Fun Facts PDFDocument3 pagesScience Fun Facts PDFHikaru Graal100% (1)

- Characterization of Spray Lubricants For The High Pressure Die Casting Next Term ProcessesDocument8 pagesCharacterization of Spray Lubricants For The High Pressure Die Casting Next Term ProcessessinanaciNo ratings yet

- Petronas Technical Standards: Drainage and Sewer Systems For Onshore FacilitiesDocument23 pagesPetronas Technical Standards: Drainage and Sewer Systems For Onshore FacilitiesMohd Nizamuddin Mohamad NoorNo ratings yet

- Aquatreat® 695Document7 pagesAquatreat® 695GhazanfarNo ratings yet

- Rel Pçs 988B Eixo 06-07-21Document2 pagesRel Pçs 988B Eixo 06-07-21Silvanio Rosa QueirozNo ratings yet

- Climate 02 00242Document30 pagesClimate 02 00242Mohamed ZuhailNo ratings yet

- (POLAR EXPLORATION) The Race To The North Pole PDFDocument32 pages(POLAR EXPLORATION) The Race To The North Pole PDFluccamantiniNo ratings yet

- Underwater Archaeological Project at The Ancient City Akra in 2013 (Eastern Crimea)Document12 pagesUnderwater Archaeological Project at The Ancient City Akra in 2013 (Eastern Crimea)Mirjana PrekovicNo ratings yet

- Hydrology ReviewerDocument3 pagesHydrology ReviewerMisael CamposanoNo ratings yet

- Safety Data Sheet: Emulan® PDocument13 pagesSafety Data Sheet: Emulan® Pjuan carlosNo ratings yet

- Final Mass Transfer - I All Practical WriteupsDocument36 pagesFinal Mass Transfer - I All Practical WriteupsvkpaithankarNo ratings yet