Professional Documents

Culture Documents

Materiales Serie XL PDF

Materiales Serie XL PDF

Uploaded by

carolina PortocarreroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materiales Serie XL PDF

Materiales Serie XL PDF

Uploaded by

carolina PortocarreroCopyright:

Available Formats

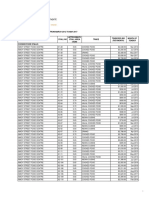

MATERIALS OF CONSTRUCTION

Page Number 107-091

Effective Dec 2009

Models: XRL1.25A, XL1.25A, XL1.5A, Replaces Sept 2007

XRLF1.25B, XLF1.25B, XLF1.5B Section 107

NOTE: Temperature and viscosity ratings given below apply to individual components Only. For actual

maximum temperatures and viscosities for the rated pump, see "Operating Limits" on backside.

PART NAME STANDARD MATERIALS AVAILABLE OPTIONS

Casing, Heads, Relief Valve Cover Ductile Iron: ASTM 536

Discs, Bearing Covers, Liner Cast Iron: ASTM A48

Rotor & Shaft

Rotor Cast Iron: ASTM A48

Shaft High Strength Steel

Bearings Single Ball Bearing; Grease

Lubricated, to 300°F (149°C) Max.

Relief Valve (R/V) Cast Iron Nickel Plated Cast Iron

Relief Valve Spring Plated Steel

R/V Spring Ranges 20-50 psi (138-345 kPa)

51-80 psi (352-552 kPa)

81-150 psi (558-1034 kPa)

O-Rings: Other than Mechanical Seal Fluorocarbon (FKM) to PTFE to 500°F (260°C)

400°F (204°C)

Gaskets Fiber to 300°F (149°C)

Vanes Duravane - Full Size with Stainless EC Laminate - Extra-Clearance to

Steel Wear Plate to 240°F (115°C); 350°F (176°C); 40,000 SSU (8,500 cP)

20,000 SSU (4,250 cP) Maximum. Max.

Push Rods Case Hardened Steel

Mechanical Seals

Stationary O-Ring FKM to 400°F (204°C) PTFE

Stationary Seat Hardened Steel Silicon Carbide

Rotating O-Ring / Seal Ring FKM to 400°F (204°C) PTFE Seal Ring

Rotating Seal Face Carbon - 20,000 SSU (4,250 cP) Max.

Seal Jacket Plated Steel

Seal Spring Stainless Steel

Gage Ports 1/4” NPT

PIPE CONNECTIONS

PUMP SIZE STANDARD

1.25” 1 ¼” NPT Tapped Ports

1.5” 1 ½” NPT Tapped Ports

OPERATING LIMITS

STANDARD MATERIALS OPTIONAL MATERIALS

Maximum Temperature 240°F (115°C) 300°F (149°C): w/ FKM or PTFE O-Rings and

EC-Laminate Vanes. NOTE: Temperature is

limited by ball bearings

Maximum Viscosity 20,000 SSU (4,250 cP)

Maximum Differential Pressure* 150 psi (10.3 Bar)

Maximum Working Pressure 350 psi (24.1 Bar)

Centipoise (cP) = centistokes (cSt) at fluid specific gravity of 1.0.

* Maximum Relief Valve Setting

www.blackmer.com

You might also like

- Concept MapDocument1 pageConcept MapLesley Joy T. BaldonadoNo ratings yet

- Ecoline Est 150-600Document21 pagesEcoline Est 150-600Yosses Sang NahkodaNo ratings yet

- Catalogo ESCODocument29 pagesCatalogo ESCOcarolina Portocarrero100% (1)

- Materiales MLX4B PDFDocument2 pagesMateriales MLX4B PDFcarolina PortocarreroNo ratings yet

- Materiales de Construcción Bomba Blackmer MLXDocument2 pagesMateriales de Construcción Bomba Blackmer MLXgermanpoloramosNo ratings yet

- Alfa Laval M10-BW: Gasketed Plate-And-Frame Heat ExchangerDocument4 pagesAlfa Laval M10-BW: Gasketed Plate-And-Frame Heat Exchangersandor terceroNo ratings yet

- Needle & GaugeDocument10 pagesNeedle & GaugeJandri JacobNo ratings yet

- Antico NJL Series PDFDocument7 pagesAntico NJL Series PDFraajc2No ratings yet

- Plate Heat Exchanger: Applications Standard DesignDocument2 pagesPlate Heat Exchanger: Applications Standard DesignjuguenriNo ratings yet

- BallValve Body Trim MaterialDocument3 pagesBallValve Body Trim Materialsabes26No ratings yet

- Trampas de Vapor FFTDocument5 pagesTrampas de Vapor FFTAndrés ChuquillaNo ratings yet

- Lit RD10 ENDocument6 pagesLit RD10 ENlesonspkNo ratings yet

- ASHCROFT Diaphragm Seal Model 400-401Document2 pagesASHCROFT Diaphragm Seal Model 400-401HanzoNo ratings yet

- VCTDS 02565 enDocument12 pagesVCTDS 02565 enCosmin100% (1)

- Fte S F & T S T: Eries Loat Hermostatic Team RapsDocument4 pagesFte S F & T S T: Eries Loat Hermostatic Team RapsAlvaro Yaciel Rodríguez LagunesNo ratings yet

- FTT FTTS SteamTrapDocument3 pagesFTT FTTS SteamTrapauxiliar.termicaNo ratings yet

- Pipeline Strainer - SpecsDocument6 pagesPipeline Strainer - SpecsCristhian AyanomeNo ratings yet

- Asco Series 290 Angle Body CatalogDocument10 pagesAsco Series 290 Angle Body CatalogcillongNo ratings yet

- Datasheet 1098 1100 Siphon PDFDocument5 pagesDatasheet 1098 1100 Siphon PDFariesefendiNo ratings yet

- Plate Heat Exchanger: ApplicationsDocument2 pagesPlate Heat Exchanger: ApplicationsCelio CostaNo ratings yet

- Dezurik PDFDocument16 pagesDezurik PDFClaudia Pérez Del RíoNo ratings yet

- GasketDocument45 pagesGasketSathish RajanNo ratings yet

- TechnipFMC - Pipeline StrainersDocument6 pagesTechnipFMC - Pipeline StrainersYadir SánchezNo ratings yet

- SC Serie SC 4160Document8 pagesSC Serie SC 4160Anderson QuintãoNo ratings yet

- Nicholson Thermostatic Steam TrapsDocument18 pagesNicholson Thermostatic Steam TrapsAli Fanani100% (1)

- Picture Model: 101-06Document2 pagesPicture Model: 101-06Nilesh MistryNo ratings yet

- Valve Cat-Seats, Offsets Etc..Document12 pagesValve Cat-Seats, Offsets Etc..PRASANTH PRASANTHNo ratings yet

- Gasket Documents PDFDocument66 pagesGasket Documents PDFramnadh803181No ratings yet

- Boiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSDocument2 pagesBoiler Pipe Information List - Avantgarde Shipping & Tuff Offshore - FPSO CYRUSzarni77No ratings yet

- Control Valve Selection and SizingDocument16 pagesControl Valve Selection and SizingSnehashis BoseNo ratings yet

- 400E EngineeringDocument8 pages400E EngineeringDenis Oliveira CostaNo ratings yet

- 4160 SCDocument8 pages4160 SCFERNANDO LARANo ratings yet

- Specification For Fire Pump - Part 10Document5 pagesSpecification For Fire Pump - Part 10Melisa MackNo ratings yet

- Mobin Data Sheet Sample-14000405Document12 pagesMobin Data Sheet Sample-14000405raulNo ratings yet

- Autoclave B.V.Document8 pagesAutoclave B.V.hisaj4uNo ratings yet

- Cashco Back Pressure Relief RegulatorDocument16 pagesCashco Back Pressure Relief RegulatorEduardo RodriguesNo ratings yet

- Ficha Tecnica - Os&y Flanged FivalcoDocument1 pageFicha Tecnica - Os&y Flanged FivalcoDiana C. Parrado MartínezNo ratings yet

- 86-Giaflex ts20 SLDocument2 pages86-Giaflex ts20 SLb1badasNo ratings yet

- T4E Brochure PDFDocument6 pagesT4E Brochure PDFgullenariNo ratings yet

- Datasheet 1803 enDocument2 pagesDatasheet 1803 enPhan Việt AnhNo ratings yet

- Flow ServeDocument8 pagesFlow ServeSagarKBLNo ratings yet

- ICO4S 1-4in 5-2way PBMRDocument4 pagesICO4S 1-4in 5-2way PBMRmaqbool1No ratings yet

- 200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationDocument2 pages200 Series Inverted Bucket Steam Traps: Cast Iron For Vertical InstallationbhaskarbabaiNo ratings yet

- Widegap 350Document2 pagesWidegap 350Nguyễn HưngNo ratings yet

- Keystone K-Lok 360-370 Data SheetDocument12 pagesKeystone K-Lok 360-370 Data SheetMnttoMecNo ratings yet

- WAGP-1-PAR-9A-M-SAS-99-0014 Valve SpecificationDocument11 pagesWAGP-1-PAR-9A-M-SAS-99-0014 Valve Specificationtope odumboniNo ratings yet

- m10 BWDocument2 pagesm10 BWMiguel CallataNo ratings yet

- OneSteel Valve Product CatalogueDocument40 pagesOneSteel Valve Product CatalogueEr Pupone de Naza100% (1)

- 409 Data SheetDocument2 pages409 Data SheetMatthieuNo ratings yet

- Keystone 362 K Lok Bfy Valv SSDocument12 pagesKeystone 362 K Lok Bfy Valv SSariel.h.s.tech.docNo ratings yet

- VTV Butterfly ValveDocument1 pageVTV Butterfly Valveryando fernandaNo ratings yet

- Plate Heat Exchanger: T20-BFGDocument2 pagesPlate Heat Exchanger: T20-BFGDaveNo ratings yet

- Aq4 Ahri Certified Plate Heat Exchanger PDFDocument2 pagesAq4 Ahri Certified Plate Heat Exchanger PDFmarko absNo ratings yet

- Ds HG en 1Document9 pagesDs HG en 1Deivid MiquelinoNo ratings yet

- UCM Ball ValvesDocument22 pagesUCM Ball ValvesBalakrishna BisoyiNo ratings yet

- Dezurik Tail Gas High Performance Butterfly Valve BTG Dezurik BTG Tail Gas Butterfly Valves 45-00-3Document3 pagesDezurik Tail Gas High Performance Butterfly Valve BTG Dezurik BTG Tail Gas Butterfly Valves 45-00-3Vettie van LoggerenbergNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- BARS BrochureDocument4 pagesBARS Brochurecarolina PortocarreroNo ratings yet

- Viking Pumps PDFDocument8 pagesViking Pumps PDFcarolina PortocarreroNo ratings yet

- Epsilon DimensionsDocument1 pageEpsilon Dimensionscarolina PortocarreroNo ratings yet

- Service: ManualDocument46 pagesService: Manualcarolina PortocarreroNo ratings yet

- 2008-07 Release Magnum - Vertical PDFDocument1 page2008-07 Release Magnum - Vertical PDFcarolina PortocarreroNo ratings yet

- Blackmer Parts List Pump Models: Mlx4B, Mlxw4B, Mrlx4B, Mrlxw4BDocument2 pagesBlackmer Parts List Pump Models: Mlx4B, Mlxw4B, Mrlx4B, Mrlxw4Bcarolina PortocarreroNo ratings yet

- S1-101 Construction and Features - PpsDocument29 pagesS1-101 Construction and Features - Ppscarolina PortocarreroNo ratings yet

- A-Hydraulics 2 7-12-05 (Rev 2-06) .PpsDocument138 pagesA-Hydraulics 2 7-12-05 (Rev 2-06) .Ppscarolina Portocarrero100% (1)

- Materiales MLX4B PDFDocument2 pagesMateriales MLX4B PDFcarolina PortocarreroNo ratings yet

- AL34 Curves PDFDocument1 pageAL34 Curves PDFcarolina PortocarreroNo ratings yet

- Cooling Tower AshraeDocument18 pagesCooling Tower AshraeMAITREE JHANo ratings yet

- Tender Bids From March 2012 To April 2017Document62 pagesTender Bids From March 2012 To April 2017scribd_109097762No ratings yet

- Cosmetics Case ProjectDocument16 pagesCosmetics Case ProjectLaura NardiNo ratings yet

- GenEd - Lumabas Jan 2022Document4 pagesGenEd - Lumabas Jan 2022angelo mabulaNo ratings yet

- KS2 How Do We See ThingsDocument6 pagesKS2 How Do We See ThingsMekala WithanaNo ratings yet

- Ordi 16 2014 Maternal Neonatal PublishedDocument15 pagesOrdi 16 2014 Maternal Neonatal PublishedAbraham AstoNo ratings yet

- Municipality of San Fernando vs. Judge FirmeDocument15 pagesMunicipality of San Fernando vs. Judge FirmeConcerned Former EmployeeNo ratings yet

- Philo ExamDocument2 pagesPhilo ExamJohn Albert100% (1)

- EPM-1183 Ethics, Code of Conduct & Professional PracticeDocument41 pagesEPM-1183 Ethics, Code of Conduct & Professional PracticeDev ThackerNo ratings yet

- En 12245 (2022) (E)Document9 pagesEn 12245 (2022) (E)David Chirinos100% (1)

- Fundamental Principles of AyurvedaDocument2 pagesFundamental Principles of Ayurvedaravisha7kNo ratings yet

- El Ensayo Del Gato NegroDocument4 pagesEl Ensayo Del Gato Negroafefhrxqv100% (1)

- Calculation Sheet1Document1 pageCalculation Sheet1Anneswan ChakrabortyNo ratings yet

- TELECONFERENCINGDocument5 pagesTELECONFERENCINGAbhinav SharmaNo ratings yet

- Anatomy GuDocument13 pagesAnatomy Gujefel umarNo ratings yet

- Gomez V MontalbanDocument1 pageGomez V MontalbanShariefaAichaseAsaliNo ratings yet

- Kinds of Sentences and Their Punctuation: Coordinating Conjunction Conjunctive Adverb SemicolonDocument41 pagesKinds of Sentences and Their Punctuation: Coordinating Conjunction Conjunctive Adverb SemicolonMarwaNo ratings yet

- Roman AchievementsDocument22 pagesRoman Achievementsapi-294843376No ratings yet

- Sailing With Paul - IronsideDocument3 pagesSailing With Paul - IronsideLawrence GarnerNo ratings yet

- Position Paper: Mark David S. Francisco 11 - ServiceDocument2 pagesPosition Paper: Mark David S. Francisco 11 - ServiceMark David FranciscoNo ratings yet

- Software EngeeringDocument120 pagesSoftware EngeeringSanjana SharmaNo ratings yet

- The Literary Comparison Contrast EssayDocument7 pagesThe Literary Comparison Contrast EssayThapelo SebolaiNo ratings yet

- InglesDocument5 pagesInglesJessi mondragonNo ratings yet

- (GUARANTEED RATE AFFINITY) & (8905 BEAVER FALLS) - UCC1 Financial Statement LIENDocument9 pages(GUARANTEED RATE AFFINITY) & (8905 BEAVER FALLS) - UCC1 Financial Statement LIENHakim-Aarifah BeyNo ratings yet

- Glossary of Professional Wrestling TermsDocument14 pagesGlossary of Professional Wrestling TermsMaría GoldsteinNo ratings yet

- Adavantages of Historical ResearchDocument2 pagesAdavantages of Historical ResearchClemence JeniferNo ratings yet

- ICH Quality Guidelines - AnuragDocument4 pagesICH Quality Guidelines - AnuragAnurag BhardwajNo ratings yet

- Third Party Logistics: A Literature Review and Research AgendaDocument26 pagesThird Party Logistics: A Literature Review and Research AgendaRuxandra Radus100% (1)

- (GOLD) The Examples of Final Semester TestDocument8 pages(GOLD) The Examples of Final Semester TestMetiska MunzilaNo ratings yet