Professional Documents

Culture Documents

32 41 00

32 41 00

Uploaded by

JUAN PABLO VASQUEZ VASQUEZ0 ratings0% found this document useful (0 votes)

40 views29 pagesOriginal Title

32-41-00

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

40 views29 pages32 41 00

32 41 00

Uploaded by

JUAN PABLO VASQUEZ VASQUEZCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 29

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

WHEELS - INSPECTION/CHECK

TASK 32-41-00-210-002

Inspect ion/theck of the Wheels and Tires

1. Reason for the Job

Self Explanatory

2. Job Set-up Information

A. Referenced Information

REFERENCE DESIGNATION

32-41-00-210-003 Inspect ion/Check of the Pressure of Tires

32-41-00-910-001 Tire Mixability Precautions

32-41-11-000-006 Removal of the MLG Wheel

(26496m,2650GM,2651GM,26526M)

32-41-11-400-006 Installation of the MLG Wheel

(26496M,2650GM,2651GM,2652GM)

32-41-12-000-001 Removal of the NLG Wheel (2659GM,2660GM)

32-41-12-400-001 Installation of the NLG Wheel (2659GM,2660GM)

32-41-00-991-001 Fig. 601

32-41-00-991-002 Fig. 602

32-41-00-991-005 Fig. 603

32-41-00-991-006 Fig. 604

32-41-00-991-003 Fig. 605

32-41-00-991-007 Fig. 606

32-41-00-991-004 Fig. 607

32-41-00-991-008 Fig. 608

32-41-00-991-009 Fig. 609

32-41-00-991-036 Fig. 610

32-41-00-991-030 Fig. 611

32-41-00-991-031 Fig. 612

3. Job Set-up

Subtask 32-41-00-860-051

A. Not Applicable

ere AL 32-41-00 ocse co:

May 01/05

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

4. Procedure

(Ref.

Fig. 601/TASK 32-41-00-991-001, 602/TASK 32-41-00-991-002, 603/TASK

32-41-00-991-005, 604/TASK 32-41-00-991-006, 605/TASK 32-41-00-991-003,

606/TASK 32-41-00-991-007, 607/TASK 32-41-00-991-004, 608/TASK 32-41-00-991-

008, 609/TASK 32-41-00-991-009, 610/TASK 32-41-00-991-036)

Subtask 32-41-00-210-070

A. Visual Inspection of the Wheels

NOTE : it is necessary to replace the tires if the speed rating specified

“3

by the tires manufacturer is exceeded .

On each main gear wheel, examine the drive shroud of the tachoneter.

Nake sure that there are no cracks on the wheel rims.

Make sure that there are no Leaks on the valves.

Make sure that the valve thread is not damaged. Fully tighten the

valve cap which seals the valve from dirt and Leaks.

If there are paint marks on the wheel/tire assembly, make sure that

the position of the tire related to the wheel is the same.

Subtask 32-41-00-210-071

B. Visual Inspection of the Tires

a

@

@

Make sure that the aircraft tires are in the correct condition to

continue to operate on the aircraft:

= make sure that there are no air leaks,

- make sure that there is no damage by friction,

- make sure that they are worn equally,

- make sure that there are no cuts and flat spots,

= remove the wheel when the tire is worn to the base of any groove in

ary location or if you can see any reinforcing material (metal or

fabric).

NOTE : Refer to the Limits for the use of the tires. They are related

to the type and make of the tire.

Make sure that the tire pressure is in the specified Limits

(Ref. TASK 32-41-00-210-003).

Obey the tire mixability precautions (Ref. TASK 32-41-00-910-001).

mL 32-41-00 ose soo

May 01/05

Printed in France

Ms 92-41 00 6 AMO 08

EFF

AEF

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

BELT STRUCTURE:

METALLIC PROTECTOR

BINDING LAYER N'9

BINDING LavER N'2

wre SSR en

LIL MI

LLILL ML

FUPPER

PLY CASING N‘3 [BEAD WE

PLY CASING N'2

PLY CASING N"

FLIPPER TURNED UP.

‘TURN UP OF PLY GASING N2

TURN-UP OF PLY CASING NT

‘THE NUMBER OF PLY CASINGS GAN BE LESS OR MORE THAN 9

THE NUMBER OF BINDING LAYERS CAN BE LESS OR MORE THAN 3

THE METALLIC PROTECTOR IS OPTIONAL AND MAY NOT BE USED

Radial Tire - General Description

Figure 601/TASK 32-41-00-991-001

mL 32-41-00

Printed in France

Page 603

may 01/00

Ms 92-41 09 6 ABM 06

i

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

TREAD AREA,

| MeTauuc «

PROTECTOR

+ THE METALLIC PROTECTOR IS OPTIONAL, AND

DEPENDING ON TIRE MANUFACTURER MAY NOT

BE USED ON A RADIAL AIRCAAFT TRE

Radial Tire - Sectional View

Figure 602/TASK 32-41-00-991-002

mL 32-41-00 rose sos

may 01/00

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

coo BODY

SS

BEAD HEEL

CHARS BEAD TOE

PLY TURNUPS

APEX STRIP

WIRE BEADS

Ms 92-41 99 6 BAMD 00

Bias Tire - General Description

Figure 603/TASK 32-41-00-991-005

ere AL 32-41-00 ose sos

may 01/00

AEF

Printed in France

Ms 92-41 99 6 BBMO 00

EFF

AEF

ALL

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

TAEAD

mRE CROVINy

TREAD RIB =

my

Groove

DEPTH UNDERTREAD

‘BEAD BUNDLES

| BEAD HEEL

Bias Tire - Sectional View

Figure 604/TASK 32-41-00-991-006

32-41-00

Mi

Printed in France

TREAD REINFORCEMENT

(CARCASS PLIES

Page 606

ay 01/00

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

y

a

WORN BEYOND UMITS,

SKID BURN

THROWN TREAD PEELED AB

g

Tire Wear and Deterioration Characteristics

Figure 605/TASK 32-41-00-991-003

ere AL 32-41-00 rece cor

may 01/00

Printed in France

NM 92 41 99 6 BCMO 09

AEF

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

EXCESSIME

(OVERINELATION

UNDERINELATION

Tire Wear and Deterioration Characteristics

Figure 606/TASK 32-41-00-991-007

32-41-00

Printed in France

Page 608

may 01/00

Ms 92-41 99 6 ADMO 04

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

An

OPEN TREAD SPLICE curs

AEF

Tire Deterioration characteristics

gure 6o7/Task 32-e1-00-991-008

mL 32-41-00

Printed in France

Page 609

may 01/00

Ms 92 41 99 6 BEMD 00

AEF

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

BLISTERS AND BULGES

GROOVE CRACKING

CUTS BELOW THE AIB

Tire Deterioration Characteristics

Figure 608/TASK 32-41-00-991-008

32-41-00

Printed in France

Page 610

may 01/00

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

CIRCUMFERENTIAL CRACKS

RADIAL CRACKS

R Tire Deterioration Characteristics

Figure 609/TASK 32-41-00-991-009

ere AL 32-41-00 ose cn

May 01/05

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

CHEVRON CUTTING

2 Tice Deterioration characteristics

: gure e10/Task 32-41-00-991-036

ere AL 32-41-00

Printed in France

Page 612

May 01/05

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

(4) Remove the wheel when the tire shows signs of a tread bulge (make a

mark on the bulge before you deflate the tire) (Ref. TASK 32-41-11-

000-006) (Ref. TASK 32-41-11-400-006) or (Ref. TASK 32-41-12-000-001)

(Ref. TASK 32-41-12-400-001)-

(5) If the tread is not worn equally, make sure that the wheels are

aligned correctly (if it is necessary remove the wheel and put it on

the opposite axle (Ref. TASK 32-41-11-000-006) (Ref. TASK 32-41-11

400-006) or (Ref. TASK 32-41-12-000-001) (Ref. TASK 32-41-12-400-

001)).

If you find tread wear on the shoulder of the tire, inflate the tire

to the nominal inflation pressure plus 10 per cent.

NOTE : This 10 per cent increase gives the new maximum of the Normal

Operating Range (N.O.R.) and not a new Nominal Pressure

(PND

Example: For a Nominal Pressure of 200 PSI, the maximum of the

N.O.R. becomes 220 PSI.

Subtask 32-41-00-210-060

C. Tire Wear Deterioration Characteristics

(Ref. Fig. 605/TASK 32-41-00-991-003, 606/TASK 32-41-00-991-007, 607/TASK

32-41-00-991-004, 608/TASK 32-41-00-991-008, 609/TASK 32-41-00-991-009,

610/TASK 32-41-00-991-036)

(1) Under inflated.

See Pressure Table : (Ref. TASK 32-41-00-210-003)

If tires are not inflated sufficiently =

= their shoulders wear too much,

= too much flex heating can occur

(2) Worn Beyond Limits

If the tire is worn to the reinforcing material (metal or fabric),

you must remove the tire and the retreader must inspect it.

(3) Tread rubber reversion (usually caused by a wet or icy runway). You

can see this condition when there is an oval area in the tread. It is

almost the same as a skid but the rubber shows signs of burns. You

must remove the tire if damage extends to or into the reinforcing

material, of if the out-of-balance is not satisfactory.

ere AL 32-41-00 rece ois

May 01/05

Printed in France

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

(4) Thrown tread

If a tire loses part or all of its tread to the tread fabric ply

Remove the two wheel assemblies on the same axle, Send them to the

workshop for an inspection or for repairs.

If there is only one replacement tire, you must measure the pressure

of the defective tire. If the pressure decreases less than 20% of the

average pressure of the other tires on the aircraft

= the connected tire on the same axle can stay serviceable

= when the aircraft goes back to base, remove the connected tire.

(5) Peeled rib

This condition usually starts with a cut in the tread. This causes a

circumferential delamination of a tread rib, fully or partially from

the tread fabric ply.

You must remove the tire.

(6) Fabric fraying

The tread frays or breaks on the ply at the base of the tread groove.

You must remove the tire.

(7) Open tread splice

There is an opening in the angle tread splice across one or more

tread ribs.

You must remove the tire.

(8) Cuts

These are cuts which extend across more than 50% of a rib and deeper

than 50% of the remaining groove depth.

You must remove the tire if you can see any reinforcing material.

(9) Tread flaking and chipping

You can see this condition when thin pieces of rubber chip or flake

from the section of tread which wears.

You must remove the tire.

(10) Tread broken away

You can see this condition when there are pock marks in the section

of the treads which wears.

You must remove the tire if you can see any reinforcing material.

(11) Chevron cutting

Cross grooves on runway surfaces can cause a pattern of

chevron=shaped cuts in the center of a tire tread. As long as this

condition does not cause chunking of cuts into the reinforcing

material, the tire is correct for continued service. You must remove

the tire if the chevron cuts extend across more than 50% of a rib and

are deeper than 50% of the remaining groove depth.

DAL 32-41-00 rose cx

May 01/05

Printed in France

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

(12) Blister or bulges

You must remove a tire with a separation of the structure in the

tread or in the sidewall and send it to the retreader.

(13) Groove crak ing

You must remove the tire and send it to the retreader if you can see

the reinforcing material through the crack at the bottom of the tread

groove.

(14) Cuts below the rib

You must remove the tire and send it to the retreader if you can see

cuts that extend below the tread rib.

(15) Circumferential cracks or radial cracks

You must remove the tire and send it to the retreader if you can see

the reinforcing material through cracks in the sidewall of the

shoulder area of the tire.

(16) Ozone and weather checking

You must remove the tire and send it to the retreader if you can see

the reinforcing material through cracks caused by weather

deterioration.

(17) Skid/Flat Spot

This is a flat spot on the tire wear -

You must remove the tire if it is worn to the base of any groove.

Subtask 32-41-00-210-052

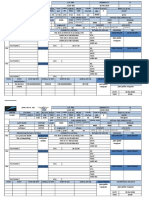

D. Tire Utilization Limits (MICHELIN)

(Ref. Fig. 611/TASK 32-41-00-991-030)

(1) Tread Surface

OBSERVATION/DAMAGE LIMITS CORRECTIVE ACTION

curs

i

Ie

Il

+ Radial tires !

= the metallic protector is not damaged (no | Keep the tire on the

Wires are broken) or you cannot see it. | aircraft.

|

I

|

I

Il

I

- the metallic protector is damaged:

if CL or LL or DL is more than the Limits

given on the illustration:

Table for cut and puncture Limits ~ MICHELIN

Remove the tire.

ere AL 32-41-00 rose ors

may 01/05

|

| ace

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

cars,

TRE Sze

é i a

Bansaats | ermiozan | corminen) [lommaarn

ea ‘Srmosen) | amnion | mms)

wei _[lomm(osrar) Pamniiny | Grose)

Tarmoamma] 2am | iammOSin)

Tommoarar] Pamaniny [ammo

(OL: GUT AND PUNCTURE DEPTH LIMITS:

LL: CUT LenoTH

DL: PUNCTURE DIAMETER

cur PUNCTURE

cur or

PUNCTURE

beet

NERSURERENT

DATUM POINT

DEPTH G:

Table for cut and puncture Limits - MICHELIN (radial tires only)

Figure 614/TASK 32-41-00-991-030

ere AL 32-41-00 rece ois

May 01/05

AEF

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

OBSERVATION/DAMAGE LIMITS

= if a cut or injury severs or goes

across a tread rib.

- Bias tires

- if casing belt plies are in view

- if a cut or injury severs or goes

across a tread rib.

BROKEN AWAY

+ Radial tires

= if the protector ply is in view on more than

6 cm2 (1 ina).

+ Bias tires

- if the reinforcing ply is in view on more

than 6 cm2 (1 ind).

CHEVRON CUTTING

+ Radial tires

- if chevron cutting goes to and exposes

the protector ply.

= if chevron cutting causes chunking

which exposes the protector ply more than

6 cm2 (1 ina).

- Bias tires

- if chevron cutting goes to and exposes

the reinforcing ply.

- if chevron cutting causes chunking

which exposes the reinforcing ply more than

6 cm2 (1 ina).

FLAT SPOTS

+ Radial tires

= the flat spot does not go to the protector

ply, the tread depth is more than the

minimum specified for tire removal

(see "WEAR" paragraph) and there is no

start of separation.

= the flat spot goes to the protector ply.

EFF: ALL

Printed in France

Remove the tire

Remove

Remove

Remove

Remove

Keep the tire on the

aircraft (but only if the

crew feel no vibration

when the Landing gear

retracts or during taxi)

Remove the tire.

CORRECTIVE ACTION

the

the

the

the

the

the

the

the

tire

tire.

tire.

tire.

tire

tire

tire

tire

32-41-00 rece oir

May 01/05

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

OBSERVATION/DAMAGE LIMITS

+ Bias tires

= the flat spot does not go to the reinforcing

ply, the tread depth is more than the

minimum specified for tire removal

(see "WEAR" paragraph) and there is no

start of separation.

= the flat spot goes to the reinforcing ply.

WEAR

+ Radial tires

= if wear goes to the bottom of any groove

(outer, inner and central) along more than

4/8 of the circumference at a given

location.

- if the protector ply is in view on more

than 1/8 of the circumference at a given

location.

« Bias tires

= if wear goes to the bottom of any groove

(outer, inner and central) along more than

4/8 of the circumference at a given

location.

= if the reinforcing ply is in view on more

than 1/8 of the circumference at a given

location.

TREAD JOINT IS OPENED

+ Radial and bias tires

= as soon as you can see the opening

GROOVE CRACKING

+ Radial tires

- if the protector ply is in view on more than

6 mm (0.25in.) (continuous).

. Bias tires

- if the reinforcing ply is in view on more

ALL

Printed in France

CORRECTIVE ACTION

Keep the tire on the

aircraft (but only if the

crew feel no vibration

When the Landing gear

retracts or during taxi)

Remove the tire.

Remove the tire

A direct return-to-base

flight is permitted with

tires in this condition.

Remove the tire

A direct return-to-base

flight is permitted with

tires in this condition.

Remove the tire

A direct return-to-base

flight is permitted with

tires in this condition.

Remove the tire

A direct return-to-base

flight is permitted with

tires in this condition.

Remove the tire.

Remove the tire

Remove the tire

32-41-00

Page 618

May 01/05

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

OBSERVATION/DAMAGE LIMITS i CORRECTIVE ACTION

‘than 6 mm (0-25 in) (continuous).

Radial and bias tires

Remove the tire

- if undercutting goes more than 5.5 am

(0.22 in) below the rib.

1

Il

Il Il

I !

| RIB UNDERCUTTING |

I I

| |

I I

(2) Sidewalls

OBSERVATIONS/DAMAGE LIMITS I CORRECTIVE ACTION

!

Il

| RADIAL or INCLINED CUTS, CRACKS OR SPLITS

|. Radial and bias tires

| - if the sidewall cords are in view or damaged| Remove the tire

I

| SEPARATION/BULGES

| . Radial and bias tires

| - separation on the sidewalls :

I!

I

I

Il

Il

I!

|

I

I

= blisters or bulges = Remove the tire.

none permitted.

WEATHER/OZONE CRACKING

+ Radial and bias tires

- if weather or ozone checking or cracking

goes to the cords

|

I!

|

I

I

I

I

none permitted. Il

I

i

I!

Il

I!

|

| Remove the tire

I

|

|

|

|

|

|

|

|

Remove the tire. I

I

i

i

|

|

|

|

|

|

(3) Beads

OBSERVATIONS/DAMAGE LIMITS I CORRECTIVE ACTION

Remove the tire.

- The bead wires are in view (radial and

bias tires): none permitted

2. The beads or the bead wires are deformed

(radial and bias tires): none permitted

Remove the tire.

3. The part of the bead that touches the rim

ere AL 32-4100 rece ov

May 01/05

Printed in France

flange is worn (radial only)

make an estimate of the depth of the wear

+ depth > 1 mm (0.0394 in.)

- Blisters on the top of the bead above the

rim flange (radial and bias tires):

i

I!

Il

I!

|

= depth <1 mm (0.0394 in.) | Keep the tire on the

I

I

i

I!

none permitted I

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

OBSERVATIONS/DAMAGE LIMITS CORRECTIVE ACTION

Remove the tire.

aircraft.

Remove the tire

NOTE : - Only one type of repair is permitted:

The filling of cuts with the applicable materials after the

cleaning of the tires and the removal of unwanted objects.

= After the removal of a tire, there are two possible

solutions:

You can retread the tire. Send it to the retreader. He will

examine the tire and make the decision to retread it after a

possible repair, or to reject it.

You cannot retread the tire. Reject the tire.

Subtask 32-41-00-210-055

E. Tire Utilization Limits (DUNLOP)

(1) Permissible damage Limits for tires

Tires damaged within the Limits below can remain in service

(a) Superficial cuts in the tread and/or sidewall rubber that do not

go into the breakers or the cords of the casing plies.

(b) Cracking or splits in the sidewall if you cannot see the cords of

the casing plies.

(c) Unevenly worn tires or tires worn on the shoulder can remain in

service until worn to the base of the tread pattern or to normal

wear Limits whichever occurs the sooner-

(d) Tires which have been subjected to sideways scrubbing can remain

in service until fully worn.

(e) Skid burns or scalds can remain in service if the damage does not

go into the base of the tread pattern or is not Likely to cause

serious out of balance.

mL 32-41-00 ese 20

May 01/05

Printed in France

Subtask 3:

F. Bia

a

a

@

a

3)

«6

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

(f) Rubber blisters in the lower sidewall if:

= The blisters are not more than two and none of them is more

than 25.4 mm (1.0000 in.) in diameter.

= The blisters are not less than 304-8 mm (12-0000 in.) apart

when measured circumferentially.

Within these Limits both blisters can be in the same sidewall.

Puncture any such blisters with an awl held parallel to the

sidewall and be careful not to damage the casing cords or

puncture the tire.

2-4 1-00-2 10-056

s and Radial Tire Utilization Limits (GOODYEAR)

Tread Wear

Make a visual inspection of the treads and do a check of the

remaining tread. You must remove the tires when the tread has worn to

the base of any groove at any spot. You must remove the tires worn to

the fabric in the tread area regardless of the tread remaining.

Uneven Tread Wear

If tread wear is excessive on one side, you can remove the tire and

turn it around, if you cannot see the fabric. Gear misalignment which

causes this condition must be corrected.

Tread Cuts

Make an inspection of the tread for cuts and other foreign object

damage and make a mark with crayon or chalk. Follow the removal

criteria below :

= Any cuts into the reinforcing material.

= Cuts that extend more than half of the width of a rib and deeper

than 50% of the remaining groove depth.

Sidewall/Bead Damage

Remove tire from service if weather checking, cracking, cuts and

snags extend down to a carcass ply in the sidewall and bead areas.

Cuts and cracks into the plies cause the tire to be scrapped.

Bulges

Bulges in a part of tire tread, sidewall or bead areas indicate a

separation or damaged tire. Make a mark with crayon and remove from

service immediately.

Fabric Fraying/Groove Cracking

You must remove the tires from service if groove cracking exposes

fabric or if cracking undercuts tread ribs.

mL 32-41-00 ose ca:

May 01/05

Printed in France

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

(7) Flat Spots

Usually, tires need not be removed because of flat spots due to skid

of hydroplane burns unless you can see the fabric. If this causes a

not satisfactory unbalance, remove the tire from service.

Subtask 32-41-00-210-057

G. Tire Utilization Limit (BRIDGESTONE)

(Ref. Fig. 612/TASK 32-41-00-991-031)

CD Criteria relative to trend wear.

NOTE : for the Bridgestone tires with 6 grooves Airbus recommends,

under normal wear conditions, the center grooves remain the

wear point. The outer groove is not as deep as the other

grooves.

CONDITION Hl LIMITATION i ACTION

Radial tires

1. The groove depth is more than

‘1 mm on the whole tread.

1, Keep the tire on

the aircraft.

NORMAL WEAR 2. The groove depth is less that | 2. Remove the tire.

‘1mm at any point of the

tread surface.

3. The aramid protector is in 3. Remove the tire.

|

|

I

|

i

i

!

!

!

|

|

| Bias tires

| 1. The groove depth is more than

| 1 mm on the whole tread. the aircraft.

I

| 2. The groove depth is less than | 2. Remove the tire.

| 1 mm at any point of the

! tread surface

!

| 3. The reinforced fabric is in | 3. Remove the tire.

! view.

|

|

|

|

|

i

Radial tires

1. The flat spot does not go as

far as the aramid protector

and the tread depth is higher

than the normal specification

1.1. Keep the tire

on the

aircraft.

FLAT SPOT ON 1.2. Remove the

|

|

|

|

I

I

i

i

|

|

|

|

|

|

1. Keep the tire on |

|

I

I

i

|

|

|

|

|

|

|

|

I

i

ere AL 32-41-00 ose 22

May 01/05

AEF

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

Tine Se cUTuMTs

apg Sze PART NUMBER a -

ae PSOE Sonmiozany | sovwnitieny

2601 smmo25m) | semmita

4608 ‘omer in ‘ommil

260 a somni0.28m) | eommnit sti

ani7 APSOS54D Fameno2nn) | sdmmitsiin}

APEOIS AC

ar “OnE Tanmiosiny | aommnsrn

9180 28 Sin Pi eomminszin

oni. 20 Bsmmiosan) | 40mmitsin,

390180 20 APSOO5aT A .omer0 0 Zommit sii

5 CUTUMTS,

ine size Co W0En

ee eee PART NUMBER = =

Te OATS PROS Tammany | _sommitaiay

20 AIS PROS nen in) | ¢Omnth in

aeei7Ra PROBS Somos) | sommit a6

a6R17H20 APROK?S? ‘S.omn(0.35mn | Som. a6

s60i7H00 ‘APROG? amenip'35iny | sommit 96a

T27OstS5RZE__] APROVODD F Tomer Bomm(L 96

27ovssn2e | APROTOO B.omer0 Sin Som a6in

(cu: GUT OFeTH LIMIT

UL GUT LENGTH LnarT

So cr0 ve boron

INFORCED FABRICIARAMIO CORD PROTECTOR

Se states puvintir

Table of cut depth and Length Limits - BRIDGESTONE (bias and radial tires)

R Figure 612/TASK 32-41-00-991-031

ere AL 32-41-00 rece ces

wy 01/05

AEF

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

CONDITION H LIMITATION H ACTION

TREAD SURFACE tire.

for tire removal in the whole

flat spot area and there is

no start of separation and:

|

I

|

I

Caused by too 1.1. You do not find vibration |

much brake during taxi. I

application 1.2. You find vibration during |

I

I

|

I

taxi.

2. The flat spot goes as far as

the aramid cord protector.

Bias tires

1. The flat spot does not go as | 1.1. Keep the tire

far as the reinforced fabric on the

and the tread depth is higher aircraft.

than the normal specification | 1.2. Remove the

for tire removal in the whole

no start of separation and:

!

|

|

|

|

|

I

I

I!

1.1. You do not find vibration |

during taxi. I

1.2. You find vibration during |

taxi. Il

Il

2. The flat spot goes as far as |

the reinforced fabric. I

I

I

I

I

I!

Il

I!

|

I

Radial and bias tires

1. The wear Limit is not reached.

1, Keep the tire on

the aircraft.

(Do the check of the

wheel alignment).

ASYMMETRICAL

TREAD WEAR

2. Remove the tire.

2. The wear Limit is reached or

WiLL soon be reached.

i

|

| |

! |

| |

| |

| |

| |

I i

| I

I I

I i

! |

| |

! |

| |

! |

| |

| |

| tire. |

| flat spot area and there is |

I I

I I

I i

I i

! |

! |

! |

| |

| |

| |

| |

| |

I I

I I

I i

! |

! |

! |

ALL

32-41-00 ose cx

Printed in France

May 01/05

@A320/A321

AIRCRAFT MAINTENANCE MANUAL

(2) Tread surface

DAMAGE Hl LIMITATION Hl ACTION

Radial tires

1. The aramid cord protector is

not in view.

Keep the tire on the

aircraft and remove

imbedded unwanted

object if present.

2. The aramid cord protector is

in view but not damaged.

|

|

I

I

Il

I!

| Keep the tire on the

| aircraft and remove

| imbedded unwanted

| object if present.

Il

curs 3. The aramid protector is damaged |

and: I!

|

|

I

I

Il

I

Il

Il

|

|

|

|

cut depth more than CL (Cut Limit)| Remove the tire.

cut depth less than or equal to

CL (Cut Limit) and cut Length

more than LL (Limit Length)

Remove the tire.

Keep the tire on the

aircraft and remove

imbedded unwanted

object if present.

cut depth less than or equal to

CL (Cut Limit) and cut Length

less than or equal to LL

(Limit Length)

Bias tires

1. The reinforced fabric is not Keep the tire on the

aircraft and remove

imbedded unwanted

object if present.

I!

|

I

I

I!

Il

2. The reinforced fabric is | Keep the tire on the

in view but not damaged. | aircraft and remove

| imbedded unwanted

| object if present.

|

I

I

I

i

Il

3. The reinforced fabric is

damaged and:

cut depth more than CL (Cut Limit)| Remove the tire.

ere AL 32-41-00 rose cas

May 01/05

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

DAMAGE H LIMITATION Il ACTION

cut depth less than or equal to

CL (Cut Limit) and cut Length

more than LL (Limit Length)

Remove the tire.

Keep the tire on the

aircraft and remove

imbedded unwanted

object if present.

cut depth less than or equal to

CL (Cut Limit) and cut Length

less than or equal to LL

(Limit Length)

Radial tires

1. The aramid cord protector is

not in view.

!

I!

|

I

I

|

i

i

i

Il

!

| Keep the tire on the

| aircraft and remove

| imbedded unwanted

| object if present.

|

2. The aramid cord protector is |

in view but not damaged and: |

I

BROKEN AWAY I

Il

I

i

|

Il

I!

|

|

I

chunked area more than 1 square | Remove the tire.

inch (approx.)

Keep the tire on the

aircraft and remove

imbedded unwanted

object if present.

chunked area less than or equal

to 1 square inch (approx.)

Remove the tire.

3. The aramid cord protector is

damaged.

Bias tires

1. The reinforced fabric is not Keep the tire on the

aircraft and remove

imbedded unwanted

object if present.

I!

I

Il

Il

Il

Il

2. The reinforced fabric is Il

in view but not damaged and: |

|

chunked area more than 1 square | Remove the tire.

inch Capprox.) I

I

i

I

Keep the tire on the

aircraft and remove

chunked area less than or equal

to 1 square inch (approx. )

ere AL 32-41-00 rece ozs

May 01/05

Printed in France

DAMAGE H

GROOVE

CRACKING

RIB

UNDER-

CUTTING

OPENED

TREAD

JOINT

EFF: ALL

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

LIMITATION Il ACTION

i

|

‘imbedded unwanted |

object if present. |

|

|

|

3. The reinforced fabric is

damaged.

Remove the tire.

Radial tires

1. The aramid cord protector is

not in view.

Keep the tire on the

aircraft.

2. The aramid cord protector is

in view and:

crack Length more than LL = Remove the tire.

(Limit Length)

crack Length Less than or equal

to LL (Limit Length)

- Keep the tire on the

aircraft.

Bias tires

1. The reinforced fabric is not

Keep the tire on the

aircraft.

2. The reinforced fabric is in

view and:

crack Length more than LL = Remove the tire.

(Limit Length)

crack Length Less than or equal

to LL (Limit Length)

- Keep the tire on the

aircraft.

Radial and bias tires

cut depth more than 1/4 inch Remove the tire.

Keep the tire on the

aircraft.

cut depth less than or equal to

174 inch

Remove the tire.

Radial and bias tires

Radial and bias tires

1. Undulation of grooves

1, Keep the tire on

32-41-00 rece car

May 01/05

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

DAMAGE H LIMITATION Il ACTION

the aircraft.

(e-g- zigzag fashion)

DEFORMATION | 2. Undulation of the tread surface | 2

| |

| |

| |

| (e.g. waved surface) | the aircraft.

| |

| |

I I

I I

3. Blisters 3,

i

|

|

|

Keep the tire on |

|

|

Remove the tire. |

i

I

Bulges 4. Remove the tire

(3) Sidewalls

DAMAGE Hl LIMITATION Hl ACTION

| Radial and bias tires

1. Radial cuts

@eviation from radial direction

is less than 30 deg.)

depth Less than 2 mm and do not

go as far as the carcass and:

Length less than 150 am

|

I

I

I

I

I!

I

| Keep the tire on the

I!

!

aircraft.

OR |

depth more than or equal to 2mm | Remove the tire.

or go as far as the carcass.

|

|

|

I

I

I

I

|

|

CRACKS, | Length more than or equal to 150 mm| Remove the tire.

|

|

| |

| |

| 2. Inclined cuts | Keep the tire on the

I (Deviation from radial | aircraft.

I direction is more than 30 deg.)|

I Il

| Do not go as far as the carcass |

| and : |

Length Less than 150 mm | Keep the tire on the

| aircraft.

Length more than or equal to 150 mm| Remove the tire.

I

!

|

|

|

| Go as far as the carcass | Remove the tire

|

i

i

|

I-

|

I

I

I

I

I!

I

I

Il

Il

I!

|

| spurts

I

I

I

I

I!

Il

Il

Il

Il

I!

|

I

I

I+

Il

FABRIC

| SEPARATION

Radial and bias tires | Remove the tire.

ere AL 32-41-00 rece ozs

May 01/05

Printed in France

GA320/A321

AIRCRAFT MAINTENANCE MANUAL

| DAMAGE H LIMITATION Il ACTION

a -|-

| BLISTERS OR | Radial and bias tires | Remove the tire.

| BULGES I I

(4) Beads

| DAMAGE H LIMITATION Il ACTION

Ie

| EXPOSURE | Radial and bias tires

| OF BEAD |

| WIRES

I+

Remove the tire.

Radial and bias tires

|

|.

|

| DEFORMATION | Deformation of beads or bead wires Remove the tire.

|

|

|

Radial and bias tires

| CRACKS | Cracks in upper part of bead zone Remove the tire.

! | depth of the crack more than

| Radial and bias tire:

WEAR | The wear of the tire surface near

Remove the tire.

| the upper edge of the rim

| depth of the worn area more than

I

I

Il

Il

I!

|

I | 2 mm

I

I

I

I

I

| Radial and bias tires

!

Il

Il

-|-

Il

|

I

-|-.

I

I

Il

14 mm I

-|-.

!

|

I!

|

I

-|-:

I

|

I

I

BLISTER | Blister in upper part of bead zone | Remove the tire.

| Length or diameter more than

110 mm

ere AL 32-41-00 rece cas

May 01/05

Printed in France

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Listas de Chequeo de Motor Io 540 Operating InstructionsDocument4 pagesListas de Chequeo de Motor Io 540 Operating InstructionsJUAN PABLO VASQUEZ VASQUEZNo ratings yet

- Log BookDocument3 pagesLog BookJUAN PABLO VASQUEZ VASQUEZNo ratings yet

- Depart URE: Landi NGDocument3 pagesDepart URE: Landi NGJUAN PABLO VASQUEZ VASQUEZNo ratings yet

- DC-9 Classic - ATA 26 - ATA 35Document10 pagesDC-9 Classic - ATA 26 - ATA 35JUAN PABLO VASQUEZ VASQUEZNo ratings yet

- ATA 26 Fire Protection PDFDocument415 pagesATA 26 Fire Protection PDFDaniel Santiago Montaño Suarez0% (1)