Professional Documents

Culture Documents

Process Control Narratives: NEORSD Design Standard

Process Control Narratives: NEORSD Design Standard

Uploaded by

RaviCopyright:

Available Formats

You might also like

- Low-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionFrom EverandLow-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionRating: 5 out of 5 stars5/5 (1)

- Self Reference CriterionDocument2 pagesSelf Reference CriterionJaemarie CamachoNo ratings yet

- Control Systems Engineer at FluorDocument36 pagesControl Systems Engineer at FluorMarvin Garcia Oliva100% (2)

- System Manual, Page 1.1Document8 pagesSystem Manual, Page 1.1Juan FresnedaNo ratings yet

- Process Control NarrativesDocument27 pagesProcess Control Narrativesengr.shahid041No ratings yet

- Process Control NarrativesDocument29 pagesProcess Control NarrativesSergei LisiyNo ratings yet

- Project Planning and Implementation of PLC or DCS Control SystemDocument4 pagesProject Planning and Implementation of PLC or DCS Control SystemVraja KisoriNo ratings yet

- Presentation CompletionsDocument34 pagesPresentation Completionsian84No ratings yet

- Process Control Narratives: Neorsd C S D SDocument1 pageProcess Control Narratives: Neorsd C S D SRaviNo ratings yet

- Engineering Design Verification InspectionsDocument20 pagesEngineering Design Verification InspectionsixoteeNo ratings yet

- Commissioning Documents For Instrumentation EngineersDocument7 pagesCommissioning Documents For Instrumentation EngineersVraja Kisori100% (1)

- Gamp 5: User Requirements Specification PQDocument1 pageGamp 5: User Requirements Specification PQGerald Deva AdhitamaNo ratings yet

- Control Basics: DocumentationDocument19 pagesControl Basics: DocumentationUsman ArshadNo ratings yet

- Process Flow Diagram - Drawing That Shows The General: 7.3 Piping and Instrumentation DiagramDocument1 pageProcess Flow Diagram - Drawing That Shows The General: 7.3 Piping and Instrumentation DiagramAnonymous QucKa3TCBNNo ratings yet

- Process Control NarrativesDocument7 pagesProcess Control NarrativesHenok DireNo ratings yet

- Saep 349 PDFDocument41 pagesSaep 349 PDFRami ElloumiNo ratings yet

- Chapter 13 Instrumentation and Control: 13.1 ScopeDocument14 pagesChapter 13 Instrumentation and Control: 13.1 ScopeBhavanishankar ShettyNo ratings yet

- Coa PresentationDocument8 pagesCoa Presentationnikki123456790No ratings yet

- Algorithms: Performance Assessment of Predictive Control - A SurveyDocument22 pagesAlgorithms: Performance Assessment of Predictive Control - A Surveyali coNo ratings yet

- YCPTI03 Process Control Functional DescriptionDocument48 pagesYCPTI03 Process Control Functional Descriptionarmdsf100% (1)

- Process Control: A Practical Approach: © 2011 John Wiley & Sons Ltd. ISBN: 978-0-470-97587-9Document2 pagesProcess Control: A Practical Approach: © 2011 John Wiley & Sons Ltd. ISBN: 978-0-470-97587-9Trường Đỗ ThếNo ratings yet

- Successfully Designing Integrated Substations: NtroductionDocument12 pagesSuccessfully Designing Integrated Substations: NtroductionHassanNo ratings yet

- MC - Industrial-Automation-Specialist V 5.0Document16 pagesMC - Industrial-Automation-Specialist V 5.0Kano PatelNo ratings yet

- Chapter 4d) HAZOP PDFDocument61 pagesChapter 4d) HAZOP PDFAmritRoshniKaurNo ratings yet

- PCEDO001Document12 pagesPCEDO001Nestor GalianoNo ratings yet

- Design ControlDocument3 pagesDesign ControlMyra AwanNo ratings yet

- Module 5Document73 pagesModule 5Achsah K VijuNo ratings yet

- Short CNCDocument4 pagesShort CNCjithu21No ratings yet

- ME761A - Lecture 1 IntroductionDocument8 pagesME761A - Lecture 1 IntroductionShakira ParveenNo ratings yet

- 7.4 Loop Diagram: C L F: B A C PDocument1 page7.4 Loop Diagram: C L F: B A C PAnonymous QucKa3TCBNNo ratings yet

- SE Management 2015Document31 pagesSE Management 2015GeorgeAruNo ratings yet

- Saep 349Document41 pagesSaep 349Abdul Ahad LoneNo ratings yet

- Criticial Utility Qualification Part-1Document22 pagesCriticial Utility Qualification Part-1Terrence Terry BhengoeNo ratings yet

- UNIT 5Document16 pagesUNIT 5THELLIAN T PNo ratings yet

- Unit-43-CNC Assignment 1Document4 pagesUnit-43-CNC Assignment 1teat46441No ratings yet

- Review Design, Constructions and Testing Commissioning For Operational Facilities 2 - Noviar Arman HarisDocument42 pagesReview Design, Constructions and Testing Commissioning For Operational Facilities 2 - Noviar Arman HarisArief DarmawanNo ratings yet

- EquipmentqualificationDocument40 pagesEquipmentqualificationSSR PRASAD KOVELAMUDI100% (1)

- System Description Design GuideDocument15 pagesSystem Description Design GuideCivil FriendNo ratings yet

- Calibration Master Plan LMDocument45 pagesCalibration Master Plan LMJAGADISH PHARMACEUTICALS50% (2)

- Process Validation of Thermoforming ProcessDocument3 pagesProcess Validation of Thermoforming ProcessumeshNo ratings yet

- Job DescriptionDocument23 pagesJob DescriptionIbrahim ElkhatibNo ratings yet

- MES From WikiDocument11 pagesMES From Wikiashish2718No ratings yet

- OMS OverviewDocument22 pagesOMS OverviewkashinathNo ratings yet

- Control Engineering Design CriteriaDocument34 pagesControl Engineering Design CriteriaTimothy LeonardNo ratings yet

- Define? - Purpose of Using DCS?Document30 pagesDefine? - Purpose of Using DCS?deep_the_creepNo ratings yet

- 3 - Week 3 Lecture Supplementary NotesDocument7 pages3 - Week 3 Lecture Supplementary NotesMeena LochniNo ratings yet

- Calibration of EquipmentDocument80 pagesCalibration of EquipmentVivek Sagar100% (3)

- Industrial Automation and Control Systems - Chapter 1 - Basic Concepts of MeasurementsDocument21 pagesIndustrial Automation and Control Systems - Chapter 1 - Basic Concepts of MeasurementsHasan IsmailNo ratings yet

- Preliminary System DesignDocument44 pagesPreliminary System DesignjohnzellagmayNo ratings yet

- Unit 5 CNC Machines and Tool Handling SystemsDocument22 pagesUnit 5 CNC Machines and Tool Handling SystemssmijusNo ratings yet

- Validation Master Plan ExampleDocument11 pagesValidation Master Plan ExampleAjay GangakhedkarNo ratings yet

- 7376211MC134 - SANJAY KDocument7 pages7376211MC134 - SANJAY KSANJAY KNo ratings yet

- Fundamentals of InstrumenatationDocument12 pagesFundamentals of InstrumenatationNicoleAmparoGarciaNo ratings yet

- Computer System Validation - Definition and Requirements - MustRead PDFDocument3 pagesComputer System Validation - Definition and Requirements - MustRead PDFtraining validNo ratings yet

- Project 40Document35 pagesProject 40mukesh lannaNo ratings yet

- Hvacr Designer Tips: - Commissioning and Project Closeout ChecklistDocument1 pageHvacr Designer Tips: - Commissioning and Project Closeout ChecklistsajuhereNo ratings yet

- Equipment QualificationDocument64 pagesEquipment QualificationbuuNo ratings yet

- Process and Instrumentation DiagramsDocument14 pagesProcess and Instrumentation Diagramsandrie.caquilalaNo ratings yet

- Piping and Instrumentation DiagramDocument2 pagesPiping and Instrumentation DiagramJejomar DantesNo ratings yet

- Good Practices For Computerised Systems - CRAdvisor30Jul2008Document8 pagesGood Practices For Computerised Systems - CRAdvisor30Jul2008FkNo ratings yet

- Application Review Audit ProgramDocument7 pagesApplication Review Audit Programحسين عبدالرحمنNo ratings yet

- Bee026 MemsDocument49 pagesBee026 MemsRaviNo ratings yet

- SSRN Id3926709Document13 pagesSSRN Id3926709RaviNo ratings yet

- Icon What Is Displayed: Inputs Adjustments Select/deselects All Adjustments Drivers PlotsDocument3 pagesIcon What Is Displayed: Inputs Adjustments Select/deselects All Adjustments Drivers PlotsRaviNo ratings yet

- About This ManualDocument5 pagesAbout This ManualRaviNo ratings yet

- 2.1.1 Data Display: About 963Document4 pages2.1.1 Data Display: About 963RaviNo ratings yet

- 963 User Guide: Issue 6Document4 pages963 User Guide: Issue 6RaviNo ratings yet

- 3.industrial Engineering and ManagementDocument16 pages3.industrial Engineering and ManagementRaviNo ratings yet

- 4 (A) .Micro Electro Mechanical System (Elective)Document11 pages4 (A) .Micro Electro Mechanical System (Elective)RaviNo ratings yet

- IQ4/IO/..: I/O Expansion ModulesDocument12 pagesIQ4/IO/..: I/O Expansion ModulesRaviNo ratings yet

- 5.programable Logic Controller LabDocument7 pages5.programable Logic Controller LabRaviNo ratings yet

- MC-Scheme of StudyDocument6 pagesMC-Scheme of StudyRaviNo ratings yet

- 3 & 4 Inch Borewell Submersible Installation ProcedureDocument7 pages3 & 4 Inch Borewell Submersible Installation ProcedureRaviNo ratings yet

- 100mm - 4 Inch Borewell - Submersible - Pumpset - TRF552HDocument1 page100mm - 4 Inch Borewell - Submersible - Pumpset - TRF552HRaviNo ratings yet

- 7.professional PracticeDocument8 pages7.professional PracticeRaviNo ratings yet

- Menthya PuDi Menthe Powder Fenugreek PowderDocument1 pageMenthya PuDi Menthe Powder Fenugreek PowderRaviNo ratings yet

- MC-Vision, Mission, PEO's and PO'sDocument7 pagesMC-Vision, Mission, PEO's and PO'sRaviNo ratings yet

- 75 MM & 100 MM Borewell Submersible Pumpset Performance ChartDocument17 pages75 MM & 100 MM Borewell Submersible Pumpset Performance ChartRaviNo ratings yet

- Flaxseeds and Sesame Seeds Chutney Powder Agase Beeja Mattu Ellina Chutney PudiDocument2 pagesFlaxseeds and Sesame Seeds Chutney Powder Agase Beeja Mattu Ellina Chutney PudiRaviNo ratings yet

- CS 436 CS 5310-Computer Vision Fundamentals-Sohaib Ahmad KhanDocument4 pagesCS 436 CS 5310-Computer Vision Fundamentals-Sohaib Ahmad Khansalman_azmat_666No ratings yet

- What Is RC Series Circuit - Phasor Diagram and Power Curve - Circuit GlobeDocument6 pagesWhat Is RC Series Circuit - Phasor Diagram and Power Curve - Circuit GlobeAdrian WongNo ratings yet

- Childhood and Growing UpDocument181 pagesChildhood and Growing UpManichander100% (2)

- Stepper Motor SpecDocument10 pagesStepper Motor SpecyaserNo ratings yet

- HYPERGROWTH by David Cancel PDFDocument76 pagesHYPERGROWTH by David Cancel PDFAde Trisna100% (1)

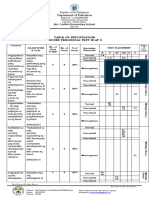

- SECOND Periodic Test in AP 4 With TOS SY 2022 2023Document6 pagesSECOND Periodic Test in AP 4 With TOS SY 2022 2023MICHAEL VERINANo ratings yet

- SMK Bandaraya Kota Kinabalu English Language Lesson Plan: MondayDocument6 pagesSMK Bandaraya Kota Kinabalu English Language Lesson Plan: MondaySITI NORZUANI BINTI BAHARUDDIN MoeNo ratings yet

- Businessstudy Xii DDocument2 pagesBusinessstudy Xii Dvarun ChoudharyNo ratings yet

- Fundamentals of Gas Pipeline Metering StationsDocument5 pagesFundamentals of Gas Pipeline Metering StationsSarah DeanNo ratings yet

- Geoarchaeology, The Geologist and ArchaeologyDocument5 pagesGeoarchaeology, The Geologist and ArchaeologyJohan Sebastian Garcia Zaldua0% (1)

- Indotech Power Transformers BrochureDocument2 pagesIndotech Power Transformers BrochurenmanjNo ratings yet

- Intelligent Urbanism: Convivial Living in Smart Cities: Stephanie Santoso Andreas KuehnDocument5 pagesIntelligent Urbanism: Convivial Living in Smart Cities: Stephanie Santoso Andreas KuehnAdrian VodițăNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet

- Being Aware of Being AwareDocument12 pagesBeing Aware of Being AwareChanchal LNo ratings yet

- BX - Cleansweep Pro ManualDocument10 pagesBX - Cleansweep Pro ManualVICTOR CHRISTIAN VASQUEZ CHAVEZNo ratings yet

- Quality Models CompleteDocument20 pagesQuality Models CompleteUsama AhmedNo ratings yet

- IADC Daily Drilling Report RevADocument4 pagesIADC Daily Drilling Report RevAdullahnurkalimNo ratings yet

- Erection Steel Structure ProcedureDocument15 pagesErection Steel Structure ProcedureOussama Sissaoui100% (2)

- Ventilation Cost CalculationsDocument15 pagesVentilation Cost CalculationsestebanmarinkovicNo ratings yet

- Feasibility Assessment and Financial Projection Results For A Social Health Insurance Scheme in SwazilandDocument96 pagesFeasibility Assessment and Financial Projection Results For A Social Health Insurance Scheme in SwazilandbejarhasanNo ratings yet

- The Simplifiers: Our Pre-Impregnated Materials Made From Carbon, Glass, and Aramid FibersDocument16 pagesThe Simplifiers: Our Pre-Impregnated Materials Made From Carbon, Glass, and Aramid FibersVladimir KunitsaNo ratings yet

- PNR Metro Commuter PDFDocument5 pagesPNR Metro Commuter PDFABCDNo ratings yet

- Cover Letter Sample Interpreter JobDocument5 pagesCover Letter Sample Interpreter Jobqwaskmrmd100% (1)

- 33 Relative and TrueDocument32 pages33 Relative and TrueArun Ketu SethNo ratings yet

- What Is Text, Discourse DefinedDocument2 pagesWhat Is Text, Discourse DefinedChristine BlabagnoNo ratings yet

- JJRM PPT Marxism PSM1Document20 pagesJJRM PPT Marxism PSM1Jeff Rey ColumnaNo ratings yet

- Quick Start PF70Document18 pagesQuick Start PF70selvan_rsk761No ratings yet

- Magazine of Concrete ResearchDocument11 pagesMagazine of Concrete ResearchKathlene Lacosta LastimosaNo ratings yet

- Salleh2021 Article TheEmergenceOfVeryLargeContainDocument21 pagesSalleh2021 Article TheEmergenceOfVeryLargeContainSajid KhanNo ratings yet

Process Control Narratives: NEORSD Design Standard

Process Control Narratives: NEORSD Design Standard

Uploaded by

RaviOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Control Narratives: NEORSD Design Standard

Process Control Narratives: NEORSD Design Standard

Uploaded by

RaviCopyright:

Available Formats

NEORSD Design Standard

Process Control Narratives

I. Introduction

A process control narrative, or PCN, is a functional statement describing how device-mounted

controls, panel mounted controls, PLCs, HMIs, and other processor-based process control system

components should be configured and programmed to control and monitor a particular process,

process area or facility. PCNs are sometimes referred to as control strategies, control narratives,

sequence descriptions, and by other similar names. A PCN is the essential link between process

design and control system design. It also forms an integral part of the final control system

documentation, providing in the most concise but descriptive form, a statement that ties together

process operation, process equipment, instrumentation, control philosophy, available control modes

and control loops, as well as documenting control logic settings such as setpoints, computed values,

alarm limits, normal operating limits, trips, interlocks, and other key parameters.

Process Control Narratives serve several purposes:

• During the Preliminary Design phase of a project PCNs are used to describe the process

control and monitoring concepts based on the conceptual process design. The PCNs

document preliminary equipment and operational requirements. At the start of this stage the

document may be a Process Narrative or Process Description. At the completion of the

Preliminary Design phase the document should be a well-developed Process Control

Narrative (PCN) that is about 90% complete.

• During the Detailed Design phase, PCNs are used to refine process control design

requirements such as:

o Selection and location of instrumentation and control devices

o Hardwired interlocks and permissives

o Data archiving and reporting requirements

o Trend parameters

o Alarm settings

o Operator prompts and messages

o Other functions and parameters associated with the process.

A PCN provides the instrumentation and control system engineer with a guideline for

development of the overall design.

• During construction and start-up, the PCNs, in conjunction with supporting drawings, control

system lists, equipment specifications and instrumenttion information, must be the controlling

documents used by integrators and programmers for developing the process control logic and

system configuration. The PCNs describe the system functionality that must be installed and

tested. Site and Factory Aceptance Test checklists can, in part, be developed from the

descriptive material in the PCNs.

• Following the construction testing phase, the as-built PCNs become key reference documents,

operation and maintenance manual components, and training materials to provide current,

updatable documentation for the technical and operations personnel at the facilities. The

design documents should require contractors and integrators to submit as-built documents in

You might also like

- Low-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionFrom EverandLow-Current Systems Engineer’S Technical Handbook: A Guide to Design and SupervisionRating: 5 out of 5 stars5/5 (1)

- Self Reference CriterionDocument2 pagesSelf Reference CriterionJaemarie CamachoNo ratings yet

- Control Systems Engineer at FluorDocument36 pagesControl Systems Engineer at FluorMarvin Garcia Oliva100% (2)

- System Manual, Page 1.1Document8 pagesSystem Manual, Page 1.1Juan FresnedaNo ratings yet

- Process Control NarrativesDocument27 pagesProcess Control Narrativesengr.shahid041No ratings yet

- Process Control NarrativesDocument29 pagesProcess Control NarrativesSergei LisiyNo ratings yet

- Project Planning and Implementation of PLC or DCS Control SystemDocument4 pagesProject Planning and Implementation of PLC or DCS Control SystemVraja KisoriNo ratings yet

- Presentation CompletionsDocument34 pagesPresentation Completionsian84No ratings yet

- Process Control Narratives: Neorsd C S D SDocument1 pageProcess Control Narratives: Neorsd C S D SRaviNo ratings yet

- Engineering Design Verification InspectionsDocument20 pagesEngineering Design Verification InspectionsixoteeNo ratings yet

- Commissioning Documents For Instrumentation EngineersDocument7 pagesCommissioning Documents For Instrumentation EngineersVraja Kisori100% (1)

- Gamp 5: User Requirements Specification PQDocument1 pageGamp 5: User Requirements Specification PQGerald Deva AdhitamaNo ratings yet

- Control Basics: DocumentationDocument19 pagesControl Basics: DocumentationUsman ArshadNo ratings yet

- Process Flow Diagram - Drawing That Shows The General: 7.3 Piping and Instrumentation DiagramDocument1 pageProcess Flow Diagram - Drawing That Shows The General: 7.3 Piping and Instrumentation DiagramAnonymous QucKa3TCBNNo ratings yet

- Process Control NarrativesDocument7 pagesProcess Control NarrativesHenok DireNo ratings yet

- Saep 349 PDFDocument41 pagesSaep 349 PDFRami ElloumiNo ratings yet

- Chapter 13 Instrumentation and Control: 13.1 ScopeDocument14 pagesChapter 13 Instrumentation and Control: 13.1 ScopeBhavanishankar ShettyNo ratings yet

- Coa PresentationDocument8 pagesCoa Presentationnikki123456790No ratings yet

- Algorithms: Performance Assessment of Predictive Control - A SurveyDocument22 pagesAlgorithms: Performance Assessment of Predictive Control - A Surveyali coNo ratings yet

- YCPTI03 Process Control Functional DescriptionDocument48 pagesYCPTI03 Process Control Functional Descriptionarmdsf100% (1)

- Process Control: A Practical Approach: © 2011 John Wiley & Sons Ltd. ISBN: 978-0-470-97587-9Document2 pagesProcess Control: A Practical Approach: © 2011 John Wiley & Sons Ltd. ISBN: 978-0-470-97587-9Trường Đỗ ThếNo ratings yet

- Successfully Designing Integrated Substations: NtroductionDocument12 pagesSuccessfully Designing Integrated Substations: NtroductionHassanNo ratings yet

- MC - Industrial-Automation-Specialist V 5.0Document16 pagesMC - Industrial-Automation-Specialist V 5.0Kano PatelNo ratings yet

- Chapter 4d) HAZOP PDFDocument61 pagesChapter 4d) HAZOP PDFAmritRoshniKaurNo ratings yet

- PCEDO001Document12 pagesPCEDO001Nestor GalianoNo ratings yet

- Design ControlDocument3 pagesDesign ControlMyra AwanNo ratings yet

- Module 5Document73 pagesModule 5Achsah K VijuNo ratings yet

- Short CNCDocument4 pagesShort CNCjithu21No ratings yet

- ME761A - Lecture 1 IntroductionDocument8 pagesME761A - Lecture 1 IntroductionShakira ParveenNo ratings yet

- 7.4 Loop Diagram: C L F: B A C PDocument1 page7.4 Loop Diagram: C L F: B A C PAnonymous QucKa3TCBNNo ratings yet

- SE Management 2015Document31 pagesSE Management 2015GeorgeAruNo ratings yet

- Saep 349Document41 pagesSaep 349Abdul Ahad LoneNo ratings yet

- Criticial Utility Qualification Part-1Document22 pagesCriticial Utility Qualification Part-1Terrence Terry BhengoeNo ratings yet

- UNIT 5Document16 pagesUNIT 5THELLIAN T PNo ratings yet

- Unit-43-CNC Assignment 1Document4 pagesUnit-43-CNC Assignment 1teat46441No ratings yet

- Review Design, Constructions and Testing Commissioning For Operational Facilities 2 - Noviar Arman HarisDocument42 pagesReview Design, Constructions and Testing Commissioning For Operational Facilities 2 - Noviar Arman HarisArief DarmawanNo ratings yet

- EquipmentqualificationDocument40 pagesEquipmentqualificationSSR PRASAD KOVELAMUDI100% (1)

- System Description Design GuideDocument15 pagesSystem Description Design GuideCivil FriendNo ratings yet

- Calibration Master Plan LMDocument45 pagesCalibration Master Plan LMJAGADISH PHARMACEUTICALS50% (2)

- Process Validation of Thermoforming ProcessDocument3 pagesProcess Validation of Thermoforming ProcessumeshNo ratings yet

- Job DescriptionDocument23 pagesJob DescriptionIbrahim ElkhatibNo ratings yet

- MES From WikiDocument11 pagesMES From Wikiashish2718No ratings yet

- OMS OverviewDocument22 pagesOMS OverviewkashinathNo ratings yet

- Control Engineering Design CriteriaDocument34 pagesControl Engineering Design CriteriaTimothy LeonardNo ratings yet

- Define? - Purpose of Using DCS?Document30 pagesDefine? - Purpose of Using DCS?deep_the_creepNo ratings yet

- 3 - Week 3 Lecture Supplementary NotesDocument7 pages3 - Week 3 Lecture Supplementary NotesMeena LochniNo ratings yet

- Calibration of EquipmentDocument80 pagesCalibration of EquipmentVivek Sagar100% (3)

- Industrial Automation and Control Systems - Chapter 1 - Basic Concepts of MeasurementsDocument21 pagesIndustrial Automation and Control Systems - Chapter 1 - Basic Concepts of MeasurementsHasan IsmailNo ratings yet

- Preliminary System DesignDocument44 pagesPreliminary System DesignjohnzellagmayNo ratings yet

- Unit 5 CNC Machines and Tool Handling SystemsDocument22 pagesUnit 5 CNC Machines and Tool Handling SystemssmijusNo ratings yet

- Validation Master Plan ExampleDocument11 pagesValidation Master Plan ExampleAjay GangakhedkarNo ratings yet

- 7376211MC134 - SANJAY KDocument7 pages7376211MC134 - SANJAY KSANJAY KNo ratings yet

- Fundamentals of InstrumenatationDocument12 pagesFundamentals of InstrumenatationNicoleAmparoGarciaNo ratings yet

- Computer System Validation - Definition and Requirements - MustRead PDFDocument3 pagesComputer System Validation - Definition and Requirements - MustRead PDFtraining validNo ratings yet

- Project 40Document35 pagesProject 40mukesh lannaNo ratings yet

- Hvacr Designer Tips: - Commissioning and Project Closeout ChecklistDocument1 pageHvacr Designer Tips: - Commissioning and Project Closeout ChecklistsajuhereNo ratings yet

- Equipment QualificationDocument64 pagesEquipment QualificationbuuNo ratings yet

- Process and Instrumentation DiagramsDocument14 pagesProcess and Instrumentation Diagramsandrie.caquilalaNo ratings yet

- Piping and Instrumentation DiagramDocument2 pagesPiping and Instrumentation DiagramJejomar DantesNo ratings yet

- Good Practices For Computerised Systems - CRAdvisor30Jul2008Document8 pagesGood Practices For Computerised Systems - CRAdvisor30Jul2008FkNo ratings yet

- Application Review Audit ProgramDocument7 pagesApplication Review Audit Programحسين عبدالرحمنNo ratings yet

- Bee026 MemsDocument49 pagesBee026 MemsRaviNo ratings yet

- SSRN Id3926709Document13 pagesSSRN Id3926709RaviNo ratings yet

- Icon What Is Displayed: Inputs Adjustments Select/deselects All Adjustments Drivers PlotsDocument3 pagesIcon What Is Displayed: Inputs Adjustments Select/deselects All Adjustments Drivers PlotsRaviNo ratings yet

- About This ManualDocument5 pagesAbout This ManualRaviNo ratings yet

- 2.1.1 Data Display: About 963Document4 pages2.1.1 Data Display: About 963RaviNo ratings yet

- 963 User Guide: Issue 6Document4 pages963 User Guide: Issue 6RaviNo ratings yet

- 3.industrial Engineering and ManagementDocument16 pages3.industrial Engineering and ManagementRaviNo ratings yet

- 4 (A) .Micro Electro Mechanical System (Elective)Document11 pages4 (A) .Micro Electro Mechanical System (Elective)RaviNo ratings yet

- IQ4/IO/..: I/O Expansion ModulesDocument12 pagesIQ4/IO/..: I/O Expansion ModulesRaviNo ratings yet

- 5.programable Logic Controller LabDocument7 pages5.programable Logic Controller LabRaviNo ratings yet

- MC-Scheme of StudyDocument6 pagesMC-Scheme of StudyRaviNo ratings yet

- 3 & 4 Inch Borewell Submersible Installation ProcedureDocument7 pages3 & 4 Inch Borewell Submersible Installation ProcedureRaviNo ratings yet

- 100mm - 4 Inch Borewell - Submersible - Pumpset - TRF552HDocument1 page100mm - 4 Inch Borewell - Submersible - Pumpset - TRF552HRaviNo ratings yet

- 7.professional PracticeDocument8 pages7.professional PracticeRaviNo ratings yet

- Menthya PuDi Menthe Powder Fenugreek PowderDocument1 pageMenthya PuDi Menthe Powder Fenugreek PowderRaviNo ratings yet

- MC-Vision, Mission, PEO's and PO'sDocument7 pagesMC-Vision, Mission, PEO's and PO'sRaviNo ratings yet

- 75 MM & 100 MM Borewell Submersible Pumpset Performance ChartDocument17 pages75 MM & 100 MM Borewell Submersible Pumpset Performance ChartRaviNo ratings yet

- Flaxseeds and Sesame Seeds Chutney Powder Agase Beeja Mattu Ellina Chutney PudiDocument2 pagesFlaxseeds and Sesame Seeds Chutney Powder Agase Beeja Mattu Ellina Chutney PudiRaviNo ratings yet

- CS 436 CS 5310-Computer Vision Fundamentals-Sohaib Ahmad KhanDocument4 pagesCS 436 CS 5310-Computer Vision Fundamentals-Sohaib Ahmad Khansalman_azmat_666No ratings yet

- What Is RC Series Circuit - Phasor Diagram and Power Curve - Circuit GlobeDocument6 pagesWhat Is RC Series Circuit - Phasor Diagram and Power Curve - Circuit GlobeAdrian WongNo ratings yet

- Childhood and Growing UpDocument181 pagesChildhood and Growing UpManichander100% (2)

- Stepper Motor SpecDocument10 pagesStepper Motor SpecyaserNo ratings yet

- HYPERGROWTH by David Cancel PDFDocument76 pagesHYPERGROWTH by David Cancel PDFAde Trisna100% (1)

- SECOND Periodic Test in AP 4 With TOS SY 2022 2023Document6 pagesSECOND Periodic Test in AP 4 With TOS SY 2022 2023MICHAEL VERINANo ratings yet

- SMK Bandaraya Kota Kinabalu English Language Lesson Plan: MondayDocument6 pagesSMK Bandaraya Kota Kinabalu English Language Lesson Plan: MondaySITI NORZUANI BINTI BAHARUDDIN MoeNo ratings yet

- Businessstudy Xii DDocument2 pagesBusinessstudy Xii Dvarun ChoudharyNo ratings yet

- Fundamentals of Gas Pipeline Metering StationsDocument5 pagesFundamentals of Gas Pipeline Metering StationsSarah DeanNo ratings yet

- Geoarchaeology, The Geologist and ArchaeologyDocument5 pagesGeoarchaeology, The Geologist and ArchaeologyJohan Sebastian Garcia Zaldua0% (1)

- Indotech Power Transformers BrochureDocument2 pagesIndotech Power Transformers BrochurenmanjNo ratings yet

- Intelligent Urbanism: Convivial Living in Smart Cities: Stephanie Santoso Andreas KuehnDocument5 pagesIntelligent Urbanism: Convivial Living in Smart Cities: Stephanie Santoso Andreas KuehnAdrian VodițăNo ratings yet

- QuestionsDocument20 pagesQuestionsmaheshNo ratings yet

- Being Aware of Being AwareDocument12 pagesBeing Aware of Being AwareChanchal LNo ratings yet

- BX - Cleansweep Pro ManualDocument10 pagesBX - Cleansweep Pro ManualVICTOR CHRISTIAN VASQUEZ CHAVEZNo ratings yet

- Quality Models CompleteDocument20 pagesQuality Models CompleteUsama AhmedNo ratings yet

- IADC Daily Drilling Report RevADocument4 pagesIADC Daily Drilling Report RevAdullahnurkalimNo ratings yet

- Erection Steel Structure ProcedureDocument15 pagesErection Steel Structure ProcedureOussama Sissaoui100% (2)

- Ventilation Cost CalculationsDocument15 pagesVentilation Cost CalculationsestebanmarinkovicNo ratings yet

- Feasibility Assessment and Financial Projection Results For A Social Health Insurance Scheme in SwazilandDocument96 pagesFeasibility Assessment and Financial Projection Results For A Social Health Insurance Scheme in SwazilandbejarhasanNo ratings yet

- The Simplifiers: Our Pre-Impregnated Materials Made From Carbon, Glass, and Aramid FibersDocument16 pagesThe Simplifiers: Our Pre-Impregnated Materials Made From Carbon, Glass, and Aramid FibersVladimir KunitsaNo ratings yet

- PNR Metro Commuter PDFDocument5 pagesPNR Metro Commuter PDFABCDNo ratings yet

- Cover Letter Sample Interpreter JobDocument5 pagesCover Letter Sample Interpreter Jobqwaskmrmd100% (1)

- 33 Relative and TrueDocument32 pages33 Relative and TrueArun Ketu SethNo ratings yet

- What Is Text, Discourse DefinedDocument2 pagesWhat Is Text, Discourse DefinedChristine BlabagnoNo ratings yet

- JJRM PPT Marxism PSM1Document20 pagesJJRM PPT Marxism PSM1Jeff Rey ColumnaNo ratings yet

- Quick Start PF70Document18 pagesQuick Start PF70selvan_rsk761No ratings yet

- Magazine of Concrete ResearchDocument11 pagesMagazine of Concrete ResearchKathlene Lacosta LastimosaNo ratings yet

- Salleh2021 Article TheEmergenceOfVeryLargeContainDocument21 pagesSalleh2021 Article TheEmergenceOfVeryLargeContainSajid KhanNo ratings yet