Professional Documents

Culture Documents

Bipolar Analog Integrated Circuit: 3-Terminal Positive Adjustable Regulator

Bipolar Analog Integrated Circuit: 3-Terminal Positive Adjustable Regulator

Uploaded by

LeoSilvaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bipolar Analog Integrated Circuit: 3-Terminal Positive Adjustable Regulator

Bipolar Analog Integrated Circuit: 3-Terminal Positive Adjustable Regulator

Uploaded by

LeoSilvaCopyright:

Available Formats

DATA SHEET

DATA SHEET

BIPOLAR ANALOG INTEGRATED CIRCUIT

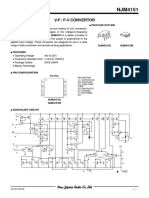

µPC317

3-TERMINAL POSITIVE ADJUSTABLE REGULATOR

DESCRIPTION

The µPC317 is an adjustable 3-terminal positive voltage regulator, which has 1.5 A capable for the output current.

www.DataSheet4U.comThe output voltage can be set any value between 1.3 V and 30 V by two external resistors.

FEATURES PIN CONFIGURATION (Marking Side)

• Output current excess of 1.5 A 3-pin plastic SIP (MP-45G)

• On-chip some protection circuit (over current protec- µPC317HF

tion, SOA protection and thermal shut down).

ORDERING INFORMATION

Part Number Package 1 : ADJ

1 2 3

µPC317HF 3-pin plastic SIP (MP-45G) (isolated TO-220) 2 : OUTPUT

3 : INPUT

EQUIVALENT CIRCUIT

INPUT

R1 R2 R3 R4 R5

Q22

Q10

Q23 R19

R27 Q25

Q4 Q8

Q2 Q14 Q18 R16 R17 D2

Q26

R6 Q16 Q20 R18

Q13 C3 R23

R21

R22

R7 R8 Q15 Q21

Q9 R20

Q17 Q19 Q24 D3

D1 Q7 Q11 Q12

Q6 C1

Q3 Q5 R15

R24

R9 C2

R14

R10 R11 R12 R13

R26 R25

OUTPUT

ADJ

The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

Not all devices/types available in every country. Please check with local NEC representative for

availability and additional information.

Document No. G12826EJ3V0DS00 (3rd edition)

Date Published January 2000 N CP(K) © 2000

Printed in Japan

µPC317

ABSOLUTE MAXIMUM RATINGS (TA = 25°C, unless otherwise specified.)

Parameter Symbol Rating Unit

Input-Output Voltage Differential VIN − VO –0.3 to +40 V

Note

Total Power Dissipation (TC = 25°C) PT 15 W

Operating Ambient Temperature TA –20 to +80 °C

Operating Junction Temperature TJ –20 to +150 °C

Storage Temperature Tstg –65 to +150 °C

Thermal Resistance (junction to case) Rth (J–C) 5 °C/W

Thermal Resistance (junction to ambient) Rth (J–A) 65 °C/W

www.DataSheet4U.com

Note Internally limited.

When operating junction temperature rise up to 150°C (≤200°C), the internal circuit shutdown output

voltage.

Caution Product quality may suffer if the absolute maximum rating is exceeded even momentarily for any

parameter. That is, the absolute maximum ratings are rated values at which the product is on the

verge of suffering physical damage, and therefore the product must be used under conditions

that ensure that the absolute maximum ratings are not exceeded.

RECOMMENDED OPERATING CONDITIONS

Parameter Symbol MIN. TYP. MAX. Unit

Input-Output Voltage Differential VIN – VO 3 38.7 V

Input Voltage VIN 4.3 40 V

Output Voltage VO 1.3 30 V

Output Current IO 0.01 1.5 A

Operating Junction Temperature TJ –20 +125 °C

Caution The recommended operating range may be exceeded without causing any problems provided

that the absolute maximum ratings are not exceeded. However, if the device is operated in a way

that exceeds the recommended operating conditions, the margin between the actual conditions

of use and the absolute maximum ratings is small, and therefore thorough evaluation is

necessary. The recommended operating conditions do not imply that the device can be used

with all values at their maximum values.

2 Data Sheet G12826EJ3V0DS00

µPC317

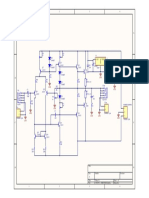

TYPICAL CONNECTION

D2

INPUT OUTPUT

VIN µ PC317 VO

D1

R1

240 Ω

ADJ

CIN +

0.1 µ F CO

1 µF

www.DataSheet4U.com + R2

CADJ

10 µ F

Remark R1, R2 : Resistor to set the output voltage.

R2 . R2

VO = (1 + ) • VREF + IADJ • R2 .= (1 + ) • VREF

R1 R1

VO (V) R2 (Ω : TYP.)

1.25 0

2.5 240

5.0 720

12 2064

24 4368

30 5520

CIN : Need to stop the oscillation for the long input wiring length.

CO : Need to stop the oscillation for the long output wiring length.

Improve the transient stability of the output voltage when the lord current is suddently changed.

CADJ : Improve the ripple rejection and the oscillate rejection.

D1 : Protect against CADJ from output short.

D2 : Need for VIN < VO.

Data Sheet G12826EJ3V0DS00 3

µPC317

ELECTRICAL CHARACTERISTICS

(VIN − VO = 5 V, IO = 0.5 A, 0°°C ≤ TJ ≤ +125°°C, unless otherwise specified.)

Parameter Symbol Conditions MIN. TYP. MAX. Unit

TA = 25°C, 3 V ≤ (VIN – VO) ≤ 40 V, IO = 0.1 A

Note

Line Regulation REGIN 0.01 0.04 %/V

3 V ≤ (VIN – VO) ≤ 40 V, IO = 0.1 A

Note

0.02 0.07 %/V

Load Regulation REGL TJ = 25°C VO ≤ 5 V 5 25 mV

10 mA ≤ lO ≤ 1.5 A VO ≥ 5 V

Note

0.1 0.5 %

10 mA ≤ lO ≤ 1.5 A VO ≤ 5 V

Note

20 70 mV

VO ≥ 5 V 0.3 1.5 %

Thermal Regulation REGTH TA = 25°C, 0.2 ms ≤ t ≤ 20 ms 0.01 0.07 %/W

www.DataSheet4U.com

ADJ pin Output Current IADJ 50 100 µA

IADJ Change ∆IADJ 10 mA ≤ IO ≤ 1.5 A, PT ≤ 15 W 0.4 5 µA

Reference Voltage VREF 10 mA ≤ IO ≤ 1.5 A, PT ≤ 15 W 1.20 1.25 1.30 V

Temperature Stability of VREF ∆VREF/∆T 0.7 %

Minimum Load Current IOMIN. VIN − VO = 40 V 4.7 10 mA

Peak Output Current IOpeak 5 V ≤ (VIN − VO) ≤ 15 V 1.5 2.2 2.9 A

VIN − VO = 40 V 0.15 0.8 A

Output Noise Voltage (RMS) Vn TA = 25°C, 10 Hz ≤ f ≤ 10 kHz 0.001 %

Ripple Rejection R•R TA = 25°C, ∆VIN = 1 Vr.m.s CADJ = 0 48 dB

f = 120 Hz, VO = 10 V CADJ = 10 µF 56 65 dB

Note Measured at constant junction temperature, using pulse testing with a low duty cycle.

PW = 10 ms, Duty Cycle ≤ 2 %

4 Data Sheet G12826EJ3V0DS00

µPC317

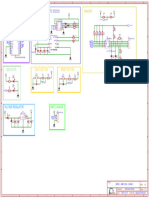

TYPICAL CHARACTERISTICS (TA = 25°°C, unless otherwise specified. Reference Values.)

PT vs TA REGL vs TJ

25 1.0

VIN = 10 V

VO = 5 V

PT - Total Power Dissipation - W

20

REGL - Load Regulation - %

Infinite heatsink

15

0.5

10

With 10°C/W heatsink

5

www.DataSheet4U.com No heatsink

0

0 25 50 75 100 125 −25 0 25 50 75 100 125

TA - Operating Ambient Temperature - °C TJ - Operating Junction Temperature - °C

IOpeak vs (VIN – VO) VREF vs TJ

3.0 1.27

VIN−VO = 5 V

TJ = −20 °C IO = 0.5 A

IOpeak - Peak Output Current - A

25 °C

VREF - Reference Voltage - V

1.26

2.0 125 °C

1.25

1.0

1.24

1.23

0 10 20 30 40 −25 0 25 50 75 100 125

(VIN – VO) - Input - Output Voltage Differential - V TJ - Operating Junction Temperature - °C

IADJ vs TJ IOMIN. vs VDIF

60 6

VIN−VO = 5 V

IOMIN. - Minimum Load Current - mA

IO = 0.5 A 5

IADJ - ADJ pin Output Current - µA

TJ = −20 °C

4

TJ = 125 °C

50 3

2

TJ = 25 °C

40

−25 0 25 50 75 100 125 0 10 20 30 40

TJ - Operating Junction Temperature - °C VDIF - Minimum Dropout Voltage - V

Data Sheet G12826EJ3V0DS00 5

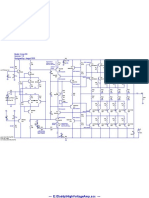

µPC317

VDIF vs TJ R • R vs f

4.0 80

∆VO

=2%

VO 70 CADJ = 10 µ F

VDIF - Minimum Dropout Voltage - V

3.5

R • R - Ripple Rejection - dB

60

3.0 CADJ = 0

50

IO = 1.5 A

2.5 40

IO = 1.0 A

30

2.0 IO = 0.5 A

IO = 0.2 A 20

VIN = 15 V

1.5 VO = 10 V

10 IO = 0.5 A

www.DataSheet4U.com IO = 0.02 A CO = 0

TA = 25 °C

1.0 0

−25 0 25 50 75 100 125 150 10 100 1k 10 k 100 k

TJ - Operating Junction Temperature - °C f - Frequency - Hz

R • R vs VO RO vs f

80 10

VIN = 15 V

70 CADJ = 10 µ F VO = 10 V

IO = 0.5 A

TA = 25 °C

R • R - Ripple Rejection - dB

RO - Output Impedance - Ω

60 1

50

CADJ = 0 µ F

40 0.1 CADJ = 0

30

VIN−VO = 5 V

IO = 0.5 A

20

f = 120 Hz

0.01 CADJ = 10 µ F

TA = 25 °C

10

0.001

0 5 10 15 20 25 30 10 100 1k 10 k 100 k

VO - Output Voltage - V f - Frequency - Hz

LINE TRANSIENT RESPONSE LOAD TRANSIENT RESPONSE

VIN = 15 V, TA = 25 °C VIN = 15 V

VO = 10 V VO = 10 V

∆VO - Output Voltage

∆VO - Output Voltage

IO = 50 mA TA = 25 °C

+1 +2

Deviation - V

Deviation - V

0 0

CADJ = 10 µ F, CO = 10 µ F

−1 −2

CADJ = 10 µ F, CO = 10 µ F 0 µF 1 µF

0 µF 1 µF

IO - Output Current

1.5

∆VIN - Input Voltage

Deviation - V

1.0 1.0

-A

0.5 0.5 IOL = 10 mA

0 0

0 10 20 30 40 0 10 20 30 40

t - Time - µ s t - Time - µ s

6 Data Sheet G12826EJ3V0DS00

µPC317

PACKAGE DRAWING

3PIN PLASTIC SIP (MP-45G)

A N

E

B P

I

L

www.DataSheet4U.com

D M

1 2 3

H J V U

Z

C

F G M

NOTE ITEM MILLIMETERS

Each lead centerline is located within 0.25 mm of A 10.0±0.2

its true position (T.P.) at maximum material condition. B 7.0±0.2

C 1.50±0.2

D 17.0±0.3

E φ 3.3±0.2

F 0.75±0.10

G 0.25

H 2.54 (T.P.)

I 5.0±0.3

J 2.46±0.2

K 5.0±0.2

L 8.5±0.2

M 8.5±0.2

N 4.5±0.2

P 2.8±0.2

U 2.4±0.5

V 0.65±0.10

Y 8.9±0.7

Z 1.30±0.2

P3HF-254B-4

Data Sheet G12826EJ3V0DS00 7

µPC317

RECOMMENDED SOLDERING CONDITIONS

When soldering these products, it is highly recommended to observe the conditions as shown below. If other

soldering processes are used, or if the soldering is performed under different conditions, please make sure to consult

with our sales offices.

For more details, refer to our document "SEMICONDUCTOR DEVICE MOUNTING TECHNOLOGY MANUAL"

(C10535E).

Type of Through-hole Devices

µPC317HF: 3-pin plastic SIP (MP-45G)(isolated TO-220)

www.DataSheet4U.com

Process Conditions

Wave soldering (only to leads) Solder temperature: 260°C or below,

Flow time: 10 seconds or less.

Partial heating method Pin temperature: 300°C or below,

Heat time: 3 seconds or less (per each lead).

Caution For through-hole device, the wave soldering process must be applied only to leads, and make

sure that the package body does not get jet soldered.

REFERENCE DOCUMENTS

QUALITY GRADES ON NEC SEMICONDUCTOR DEVICES C11531E

SEMICONDUCTOR DEVICE MOUNTING THCHNOLOGY MANUAL C10535E

SEMICONDUCTORS SELECTION GUIDE – Products and Packages – (CD-ROM) X13769X

SEMICONDUCTORS SELECTION GUIDE X10679E

NEC SEMICONDUCTOR DEVICE RELIABILITY/QUALITY CONTROL SYSTEM IEI-1212

-THREE TERMINAL REGULATOR

8 Data Sheet G12826EJ3V0DS00

µPC317

[MEMO]

www.DataSheet4U.com

Data Sheet G12826EJ3V0DS00 9

µPC317

[MEMO]

www.DataSheet4U.com

10 Data Sheet G12826EJ3V0DS00

µPC317

[MEMO]

www.DataSheet4U.com

Data Sheet G12826EJ3V0DS00 11

µPC317

[MEMO]

• The information in this document is subject to change without notice. Before using this document, please

confirm that this is the latest version.

• No part of this document may be copied or reproduced in any form or by any means without the prior written

consent of NEC Corporation. NEC Corporation assumes no responsibility for any errors which may appear in

www.DataSheet4U.com

this document.

• NEC Corporation does not assume any liability for infringement of patents, copyrights or other intellectual property

rights of third parties by or arising from use of a device described herein or any other liability arising from use

of such device. No license, either express, implied or otherwise, is granted under any patents, copyrights or other

intellectual property rights of NEC Corporation or others.

• Descriptions of circuits, software, and other related information in this document are provided for illustrative

purposes in semiconductor product operation and application examples. The incorporation of these circuits,

software, and information in the design of the customer's equipment shall be done under the full responsibility

of the customer. NEC Corporation assumes no responsibility for any losses incurred by the customer or third

parties arising from the use of these circuits, software, and information.

• While NEC Corporation has been making continuous effort to enhance the reliability of its semiconductor devices,

the possibility of defects cannot be eliminated entirely. To minimize risks of damage or injury to persons or

property arising from a defect in an NEC semiconductor device, customers must incorporate sufficient safety

measures in its design, such as redundancy, fire-containment, and anti-failure features.

• NEC devices are classified into the following three quality grades:

"Standard", "Special", and "Specific". The Specific quality grade applies only to devices developed based on a

customer designated "quality assurance program" for a specific application. The recommended applications of

a device depend on its quality grade, as indicated below. Customers must check the quality grade of each device

before using it in a particular application.

Standard: Computers, office equipment, communications equipment, test and measurement equipment,

audio and visual equipment, home electronic appliances, machine tools, personal electronic

equipment and industrial robots

Special: Transportation equipment (automobiles, trains, ships, etc.), traffic control systems, anti-disaster

systems, anti-crime systems, safety equipment and medical equipment (not specifically designed

for life support)

Specific: Aircraft, aerospace equipment, submersible repeaters, nuclear reactor control systems, life

support systems or medical equipment for life support, etc.

The quality grade of NEC devices is "Standard" unless otherwise specified in NEC's Data Sheets or Data Books.

If customers intend to use NEC devices for applications other than those specified for Standard quality grade,

they should contact an NEC sales representative in advance.

M7 98. 8

You might also like

- Introduction To Circuits Remote LabDocument6 pagesIntroduction To Circuits Remote LabLeen Haniya50% (2)

- WIPL-D User's ManualDocument476 pagesWIPL-D User's ManualtonyuluckyNo ratings yet

- LTE Drive Test ParametersDocument8 pagesLTE Drive Test ParametersRohan Das100% (1)

- Esquema SamsungDocument60 pagesEsquema SamsungCleumo BarrosNo ratings yet

- 3-Terminal Positive Linear Regulators Az78XxDocument13 pages3-Terminal Positive Linear Regulators Az78XxDiego AzevedoNo ratings yet

- BA6208Document4 pagesBA6208dexkezzNo ratings yet

- 1A 3-Terminal Positive Linear Regulators Az78XxDocument14 pages1A 3-Terminal Positive Linear Regulators Az78XxRuben Dante PachecoNo ratings yet

- Datasheet For Several PartsDocument8 pagesDatasheet For Several PartsMohammed MushtahaNo ratings yet

- TDA8145Document9 pagesTDA8145rosme.gonzalez7No ratings yet

- TV East/West Correction Circuit For Square Tubes: DescriptionDocument5 pagesTV East/West Correction Circuit For Square Tubes: DescriptionAlfian MangadjibNo ratings yet

- Dual Comparator: Features DescriptionDocument9 pagesDual Comparator: Features DescriptionRaviNo ratings yet

- V-F / F-V Convertor: General Description Package OutlineDocument14 pagesV-F / F-V Convertor: General Description Package OutlineIlyes KHOUILDINo ratings yet

- V-F / F-V Convertor: General Description Package OutlineDocument15 pagesV-F / F-V Convertor: General Description Package Outlinejjtrivedi8717No ratings yet

- Negative Voltage Regulators: FeaturesDocument29 pagesNegative Voltage Regulators: Featureszainul mzakariaNo ratings yet

- C4570C Nec 2Document11 pagesC4570C Nec 2cdeeman azdiNo ratings yet

- 79L05A NegativDocument9 pages79L05A NegativTb303No ratings yet

- TV East/West Correction Circuit: Features Summary Figure 1. PackageDocument11 pagesTV East/West Correction Circuit: Features Summary Figure 1. PackageTorikul HabibNo ratings yet

- TV East/West Correction Circuit: Features Summary Figure 1. PackageDocument11 pagesTV East/West Correction Circuit: Features Summary Figure 1. PackageTorikul HabibNo ratings yet

- Tda 8145Document6 pagesTda 8145Milorad PajovicNo ratings yet

- Greenchip Tea1761 Synchronous Rectification and Feedback ControllerDocument11 pagesGreenchip Tea1761 Synchronous Rectification and Feedback Controllerdado0905No ratings yet

- MC3403 Datasheet 4xOV741Document11 pagesMC3403 Datasheet 4xOV741algogeniusNo ratings yet

- Obsolete Product(s) - Obsolete Product(s) : TV East/West Correction Circuit For Square TubesDocument9 pagesObsolete Product(s) - Obsolete Product(s) : TV East/West Correction Circuit For Square TubesSebastian CorreaNo ratings yet

- 13.8V Reg PSU With Short CKT ProtectionDocument10 pages13.8V Reg PSU With Short CKT ProtectionAdhi WahyuNo ratings yet

- 78DXXL: 3-Terminals0.5Apositive V Olt Age Regu Lat orDocument8 pages78DXXL: 3-Terminals0.5Apositive V Olt Age Regu Lat orAhmad BasirNo ratings yet

- UTC 3414 Linear Integrated Circuit: Single-Supply Dual High Current Operational AmplifierDocument3 pagesUTC 3414 Linear Integrated Circuit: Single-Supply Dual High Current Operational AmplifiermaugrysNo ratings yet

- R6x 100 R8x 1K: 3 4 Out1 IN2 Out2Document1 pageR6x 100 R8x 1K: 3 4 Out1 IN2 Out2Nguyễn Hữu BáchNo ratings yet

- ATtiny-RGB MoodlampDocument1 pageATtiny-RGB MoodlampovidiutacheNo ratings yet

- 78DXXL: Unisonic Technologies Co., LTDDocument8 pages78DXXL: Unisonic Technologies Co., LTDSlava VanatNo ratings yet

- Datasheet PDFDocument10 pagesDatasheet PDFMohammed AliNo ratings yet

- 8 Channel Relay BoardDocument4 pages8 Channel Relay Boardtutajos100% (1)

- Wizfi360: Lqfp48Document1 pageWizfi360: Lqfp48rdsonsantos0No ratings yet

- DatasheetDocument6 pagesDatasheetMuhammad Yasir KhanNo ratings yet

- Airband English VersionDocument4 pagesAirband English VersionGilles FexNo ratings yet

- TDB7910 TDA7910: Medium Power Single Bipolar Operational AmplifierDocument5 pagesTDB7910 TDA7910: Medium Power Single Bipolar Operational AmplifiertommyhghNo ratings yet

- Schematic ESP32 MAX485 DS3231 2022-03-27Document1 pageSchematic ESP32 MAX485 DS3231 2022-03-27Cadis Ekstrama DiraizelNo ratings yet

- Archive: DatasheetDocument11 pagesArchive: DatasheetSo Was RedNo ratings yet

- Lm324 Datasheet (2 - 14 Pages) Stmicroelectronics - Low Power Quad Operational AmplifiersDocument4 pagesLm324 Datasheet (2 - 14 Pages) Stmicroelectronics - Low Power Quad Operational AmplifiersMortal ShooterNo ratings yet

- Laser Driver Circuit: Agnd VDD VDD VDD AgndDocument1 pageLaser Driver Circuit: Agnd VDD VDD VDD AgnddemononesNo ratings yet

- Tda 2320Document13 pagesTda 2320sampedjasNo ratings yet

- LM78XX Linear Integrated Circuit: 3-Terminal 1A Positive Voltage RegulatorDocument7 pagesLM78XX Linear Integrated Circuit: 3-Terminal 1A Positive Voltage Regulatorluis alberto perez monteroNo ratings yet

- Amplificador Atlanta: Title: Rev: Sheet: Drawn By: CompanyDocument1 pageAmplificador Atlanta: Title: Rev: Sheet: Drawn By: CompanyRoberto DiazNo ratings yet

- GC-20 SchematicDocument1 pageGC-20 SchematicPetr BruzaNo ratings yet

- E:/Daddy/Highvoltageamp - Asc - : Model: Amp-230 Designed By: Jaagut 2020Document1 pageE:/Daddy/Highvoltageamp - Asc - : Model: Amp-230 Designed By: Jaagut 2020Mond Timpog LagmanNo ratings yet

- WTX264Document1 pageWTX264MUSISAT MADRID 2100% (1)

- Schematic JBL+MAX12 2023-10-04+Document1 pageSchematic JBL+MAX12 2023-10-04+Claudean SoaresNo ratings yet

- Schematic - DIY Battery (Li-Ion) Capacity Tester - 2020-04-21 - 16-58-56Document1 pageSchematic - DIY Battery (Li-Ion) Capacity Tester - 2020-04-21 - 16-58-56Kien TrungNo ratings yet

- LM2903 LM393 LM393A LM293A - FairchildDocument9 pagesLM2903 LM393 LM393A LM293A - FairchildElectronicos CaldasNo ratings yet

- Operational AmplifierDocument46 pagesOperational AmplifierhajjkaNo ratings yet

- LED - DA - Isis - InstramedDocument3 pagesLED - DA - Isis - Instramedtalita severinoNo ratings yet

- Alimentare Sursa Astabil: VCC 9V 9VDocument1 pageAlimentare Sursa Astabil: VCC 9V 9VMares DanielNo ratings yet

- Circuit Diagram of DC Motor Control Using A Single SwitchDocument1 pageCircuit Diagram of DC Motor Control Using A Single Switchravirajsinhvaja100% (1)

- Schematic - RF Transmitter and Reciver - 2022!08!05Document1 pageSchematic - RF Transmitter and Reciver - 2022!08!05Soheil Alizadeh100% (1)

- 78DXX Linear Integrated Circuit: 3-Terminal 0.5A Positive Voltage RegulatorDocument6 pages78DXX Linear Integrated Circuit: 3-Terminal 0.5A Positive Voltage RegulatorNardy HepyNo ratings yet

- Inverter+Philco+T871029 14Document1 pageInverter+Philco+T871029 14peres.gabriel.gabrielNo ratings yet

- Inverter TV Philco Ph32M (Cmo T871029.14) : T1 T8 N-Driver 1Document1 pageInverter TV Philco Ph32M (Cmo T871029.14) : T1 T8 N-Driver 1VictorManuelBernalBlancoNo ratings yet

- BigmufpiDocument4 pagesBigmufpinene_guitarNo ratings yet

- LM324/LM324A, LM2902/LM2902A: Quad Operational AmplifierDocument12 pagesLM324/LM324A, LM2902/LM2902A: Quad Operational AmplifierShabnam EsfandyariNo ratings yet

- LM324/LM324A, LM2902/LM2902A: Quad Operational AmplifierDocument13 pagesLM324/LM324A, LM2902/LM2902A: Quad Operational AmplifierElectronicos CaldasNo ratings yet

- To9 TTCNDocument2 pagesTo9 TTCNPhước Phan VănNo ratings yet

- Mag Pi 64Document1 pageMag Pi 64Adam MikitzelNo ratings yet

- 2x Gain BTL With 2 Pcs Transistor: Main Supply 1x GAIN R13 18K 2x GAIN R13 4K7Document2 pages2x Gain BTL With 2 Pcs Transistor: Main Supply 1x GAIN R13 18K 2x GAIN R13 4K7mdeky20No ratings yet

- Fuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachFrom EverandFuzzy Control Systems Design and Analysis: A Linear Matrix Inequality ApproachNo ratings yet

- SigmaWin+5.72 Release NotesDocument6 pagesSigmaWin+5.72 Release NotesLeoSilvaNo ratings yet

- Uni SP Servo BrochureDocument20 pagesUni SP Servo BrochureLeoSilvaNo ratings yet

- Uni SP Servo BrochureDocument20 pagesUni SP Servo BrochureLeoSilvaNo ratings yet

- Gruner Ul-721q-R1a RelayDocument7 pagesGruner Ul-721q-R1a RelayLeoSilvaNo ratings yet

- Casio CTK 650Document22 pagesCasio CTK 650Danilo FernandesNo ratings yet

- PIC24FJ32GB002Document2 pagesPIC24FJ32GB002Claudio EcheverriaNo ratings yet

- Enabling The Shore-To-Ship Power ConnectionDocument5 pagesEnabling The Shore-To-Ship Power ConnectionMark WoodNo ratings yet

- Tutorial On Cadence Virtuoso - IISCDocument8 pagesTutorial On Cadence Virtuoso - IISCK Sri KarthikNo ratings yet

- Application Note TI SoC Estimation Using Smart Battery ChargerDocument7 pagesApplication Note TI SoC Estimation Using Smart Battery Chargera_mullaNo ratings yet

- Mid-Position: Binary Sensor Boxes SRBP For Semi-Rotary ActuatorsDocument2 pagesMid-Position: Binary Sensor Boxes SRBP For Semi-Rotary ActuatorsSayed Ibrahim GhanemNo ratings yet

- Arduino - Voice - Control - Robot CodeDocument6 pagesArduino - Voice - Control - Robot CodePraveen B2LSOLUTIONNo ratings yet

- AIRLINX GigaLink 6221 Data Sheet 1005 PDFDocument4 pagesAIRLINX GigaLink 6221 Data Sheet 1005 PDFDavidRodriguezRojoNo ratings yet

- MikroTik AP SetupDocument23 pagesMikroTik AP SetupuntungpriyantoNo ratings yet

- WM - Cisco Nexus 3548 X 3524 X 3548 XL and 3524 XL SwitchesDocument24 pagesWM - Cisco Nexus 3548 X 3524 X 3548 XL and 3524 XL Switchesfantast.bensonNo ratings yet

- Adv 7202Document28 pagesAdv 7202Atif IlyasNo ratings yet

- HP ELITEBOOK 8840 8840W - COMPAL LA-4902P - REV 1.0sec PDFDocument47 pagesHP ELITEBOOK 8840 8840W - COMPAL LA-4902P - REV 1.0sec PDFابراهيم السعيديNo ratings yet

- 30 KVA Isolation Transformer, 3 Phase, 480 Volt To 415 VoltDocument12 pages30 KVA Isolation Transformer, 3 Phase, 480 Volt To 415 VoltsaravananNo ratings yet

- 1798 FlexArmorDocument10 pages1798 FlexArmorAnderson MaiaNo ratings yet

- Introduction To Compters-COM 1Document52 pagesIntroduction To Compters-COM 1Anas Hussain KhanNo ratings yet

- COMMTECH Module 1 - Overview of CommunicationDocument17 pagesCOMMTECH Module 1 - Overview of CommunicationCHEEZER NICE BERMEJONo ratings yet

- GDPHM 505Document19 pagesGDPHM 505s.uttam.kr40No ratings yet

- Gain Staging - The Bank Account of Your Mix PDFDocument15 pagesGain Staging - The Bank Account of Your Mix PDFSteveJonesNo ratings yet

- Abit AX78 Motherboard ManualDocument80 pagesAbit AX78 Motherboard ManualDuckyLuckyNo ratings yet

- Em10 Ivr PDFDocument5 pagesEm10 Ivr PDFIBRAHIM AL-SURAIHI100% (1)

- Cdma 450Document31 pagesCdma 450Arsalan Badar Wasti100% (1)

- Jack Cat 6a - Exp-Lg-033775 - 0Document2 pagesJack Cat 6a - Exp-Lg-033775 - 0Vincent Conco VegaNo ratings yet

- Kush Eq Controller SmallDocument23 pagesKush Eq Controller Smallkhat johnsonNo ratings yet

- Management Information System Quiz 4Document2 pagesManagement Information System Quiz 4Mara Shaira SiegaNo ratings yet

- PTG5Document2 pagesPTG5Vedant PatelNo ratings yet

- LG 43lj617t Led TV With Webos & Magic Remote - LG In2Document19 pagesLG 43lj617t Led TV With Webos & Magic Remote - LG In2gmurali2kNo ratings yet