Professional Documents

Culture Documents

conplast-SP 432 BS Datasheet PDF

conplast-SP 432 BS Datasheet PDF

Uploaded by

Varun KediaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

conplast-SP 432 BS Datasheet PDF

conplast-SP 432 BS Datasheet PDF

Uploaded by

Varun KediaCopyright:

Available Formats

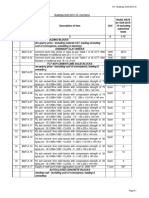

Conplast® SP432BS constructive solutions

Superplasticising admixture for blast furnace slag

cements

Uses Properties

To produce pumpable concrete with replacement of cement

Specific gravity 1.21 to 1.23 at 300C

( upto 70%) with blast furnace slag and Ordinary Portland

cement. Chloride content Nil. as per IS:456 and

BS:5075

To produce high strength, high grade concrete by

substantial reduction in water resulting in low permeability Air entrainment Approx. 1% additional air

and high early strength. is entrained

To produce high workability concrete requiring little or no

vibration during placing. Compatibility : Can be used with all types of cements except

Advantages high alumina cement. Conplast SP432BS is compatible with

other types of Fosroc admixtures when added separately to

Improved workability - Easier, quicker placing and the mix. Site trials should be carried out to optimise dosages.

compaction. Workability : Can be used to produce flowing concrete that

Increased strength - Provides high early requires no compaction. Some minor adjustments may be

strength for precast concrete if water reduction is taken required to produce high workable mix without segregation.

advantage of.

Cohesion : Cohesion is improved due to dispersion of cement

Improved quality - Denser, close textured concrete with particles thus minimising segregation and improving surface

reduced porosity and hence more durable. finish.

Higher cohesion - Risk of segregation and bleeding

Compressive strength : Early strength is increased upto 40

minimised; thus aids pumping of concrete

to 50% if water reduction is taken advantage of. Generally,

Chloride free - Safe in prestressed concrete and with there is improvement in strength upto 20% depending upon

sulphate resisting cements and marine aggregates. W/C ratio and other mix parameters.

Standards Durability : Reduction in W/C ratio enables increase in density

Conplast SP432BS complies with IS:9103:2000 and and impermeability thus enhancing durability of concrete.

BS:5075 Part 3 and ASTM-C-494 Type 'G' as a high range Application instructions

water reducing admixture.

Dosage

Description

The optimum dosage is best determined by site trials with

Conplast SP432BS is based on Sulphonated Napthalene the concrete mix which enables the effects of workability,

Polymers and is supplied as a brown liquid instantly strength gain or cement reduction to be measured. Site trials

dispersible in water. with Conplast SP432BS should always be compared with

Conplast SP432BS has been specially formulated to give mix containing no admixture. As a guide, the rate of addition

high water reductions upto 25% without loss of workability or is generally in the range of 0.6 - 2.0 litres /100 kg cement.

to produce high quality concrete of reduced permeability. Over dosing

An over dose of double the recommended amount of Conplast

SP432BS, will result in very high workability and some

Conplast® SP432(BS)

retardation of setting time will occur. However, the ultimate

compressive strength will not be impaired.

Conplast® SP432BS

Dispensing Precautions

The measured quantity of Conplast SP432BS should be Health & Safety instructions

added along with the gauging water. For best results, add

Conplast SP432BS is nontoxic. Any splashes on the skin

Conplast SP432BS in the last phase after prewetting the mix

should be washed immediately with water. Splashes to the

with 80% of the total water required.

eyes should be washed immediately with water and medical

Mix design advice should be sought.

Fosroc has an advisory service on Concrete Mix Design and Fire

can be contacted if assistance is required.

Conplast SP432BS is non flammable.

Estimating

Packing

Conplast SP432BS is supplied in 5,20,50 and 200 litre

drums.

Storage

Conplast SP432BS has a minimum shelf life of 12 months

when stored under normal temperatures. It should be

protected from extreme temperatures and preferably stored

in shade.

® Denotes the trademark of Fosroc International Limited

Important note :

Fosroc products are guaranteed against defective materials and manufacture and are sold subject

to its standard terms and conditions of sale, copies of which may be obtained on request. Whilst

Fosroc endeavours to ensure that any advice, recommendation specification or information it may

give is accurate and correct, it cannot, because it has no direct or continuous control over where

or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products whether or not in accordance with any advice, specification, recommendation

Fosroc Chemicals (India) Pvt. Ltd. or information given by it.

Head Office telephone fax e-mail

‘Vishnu Chittam’, No. 10, 2nd Floor

Sirur Park B Street, Seshadripuram ++91 80-2334 3188 ++91 80-2334 3178 india@fosroc.com

Bangalore 560020

www.fosroc.com Regional Offices

Bangalore Mumbai Delhi Kolkata

‘Vishnu Chittam’, No.10, 1stFloor 208/209, Persepolis 109-113, 1st Floor, Vikrant Towers P-569, Lake Terrace Extn.

Sirur Park B Street, Seshadripuram Sector 17, Vashi 4, Rajendra Place First Floor

Bangalore 560 020 Navi Mumbai 400 703 New Delhi 110 008 Kolkata 700 029

Ph:080-2334 3188 Ph:022-2789 6411/12 Ph:011- 45062000-5 Ph: 033 24650917 / 55343188

Fax : 080-23368667 Fax: 022 - 2789 6413 Fax: 011- 45062001 Fax: 033-24650891

email: Bangalore@fosroc.com email:Mumbai@fosroc.com email:Delhi@fosroc.com email:Kolkata@fosroc.com

Ahmedabad : (079) 26762799 Ankleshwar :(02646) 220704/224687 Bellary: 09845891690 Bhubaneshwar : (0674) 2521176

Chennai : (044) 24899949/24853383 Chandigarh : (0172) 2639360 Cochin : (0484) 2347465 Coimbatore : (0422) 2472966

Goa : (0832) 09423058696 Guwahati : (0361) 2462866 Hyderabad : (040) 27662324/27662425 Indore : (0731) 4049339

Jaipur : (0141) 2336103 Lucknow :(0522) 2239044 Nagpur: (0712) 2753510/2563242 Visakhapatnam : (0891) 2564850 / 2707607

INDIA/01-195/B

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Silo Clean Safe CleaningDocument7 pagesSilo Clean Safe CleaningSanjeev GuptaNo ratings yet

- A Literature Review of Use of Recycled Concrete Aggregates PDFDocument61 pagesA Literature Review of Use of Recycled Concrete Aggregates PDFyyanan111875% (4)

- Vacancy Announcement: Heavy Equipment Sales Executive - Cement Industry Consultant - Sales Executive RetailDocument1 pageVacancy Announcement: Heavy Equipment Sales Executive - Cement Industry Consultant - Sales Executive RetailVarun KediaNo ratings yet

- Focus - Area - Shot-Blasting - Cabins - 2009Document16 pagesFocus - Area - Shot-Blasting - Cabins - 2009Varun KediaNo ratings yet

- Vent System SpecksDocument2 pagesVent System SpecksVarun KediaNo ratings yet

- Focus Area Waste Recycling 2009Document26 pagesFocus Area Waste Recycling 2009Varun KediaNo ratings yet

- Focus Area Refuse Trucks 2009Document25 pagesFocus Area Refuse Trucks 2009Varun KediaNo ratings yet

- Focus Area Plastic Recycling 2009Document20 pagesFocus Area Plastic Recycling 2009Varun KediaNo ratings yet

- Auramix 201 TDS PDFDocument2 pagesAuramix 201 TDS PDFVarun KediaNo ratings yet

- conplast-SP 432 BS Datasheet PDFDocument2 pagesconplast-SP 432 BS Datasheet PDFVarun Kedia0% (1)

- Auracast 50 TDS PDFDocument2 pagesAuracast 50 TDS PDFVarun KediaNo ratings yet

- Auramix 201 TDS PDFDocument2 pagesAuramix 201 TDS PDFVarun KediaNo ratings yet

- Conplast NC PDFDocument2 pagesConplast NC PDFVarun KediaNo ratings yet

- Auracast 50 TDS PDFDocument2 pagesAuracast 50 TDS PDFVarun KediaNo ratings yet

- Cement and Steel Rates For The Month of August 2013Document1 pageCement and Steel Rates For The Month of August 2013Guru PrasadNo ratings yet

- CIVILMEET2023 Paulo DE MORAISDocument12 pagesCIVILMEET2023 Paulo DE MORAISPaulo MoraisNo ratings yet

- Potato ThesisDocument3 pagesPotato ThesisDa VeNo ratings yet

- Strength Development of Soft Clay Stabilized GGSlag and FA GeopolimerDocument15 pagesStrength Development of Soft Clay Stabilized GGSlag and FA GeopolimerBarrita ZonecNo ratings yet

- RF Buildings SOR 2015-16-CIVILDocument122 pagesRF Buildings SOR 2015-16-CIVILMadhu KrishnaNo ratings yet

- Report On FINANCIAL PERFORMANCE ANALYSIS OF CEMENT INDUSTRY AND COMPARISON WITH LAFARGE-HOLCIM BANGLADESH CEMENT LTDDocument34 pagesReport On FINANCIAL PERFORMANCE ANALYSIS OF CEMENT INDUSTRY AND COMPARISON WITH LAFARGE-HOLCIM BANGLADESH CEMENT LTDavishek karmakerNo ratings yet

- B09 Disposal of Solid Waste Reclamation of Contaminated Soil (3,6)Document2 pagesB09 Disposal of Solid Waste Reclamation of Contaminated Soil (3,6)Izut HutaurukNo ratings yet

- Reprint 20 Years of The HoromillDocument6 pagesReprint 20 Years of The HoromillViet Nam M-TechNo ratings yet

- 71 LC3 The Cuban ExperienceDocument38 pages71 LC3 The Cuban ExperienceMirza BasitNo ratings yet

- Low Cost Materials For Building and ConstructionDocument7 pagesLow Cost Materials For Building and ConstructionPraveen SahuNo ratings yet

- Scientific Principles: What Is in This Stuff?Document8 pagesScientific Principles: What Is in This Stuff?hema kumarNo ratings yet

- Preview: Reusing Recycled Aggregates in Structural ConcreteDocument24 pagesPreview: Reusing Recycled Aggregates in Structural ConcretemynameisgunaNo ratings yet

- B034 6 44 0074 PDFDocument14 pagesB034 6 44 0074 PDFShashi RanjanNo ratings yet

- Nagarjuna College of Engineering and TechnologyDocument38 pagesNagarjuna College of Engineering and TechnologySaurav BaranwalNo ratings yet

- ASTM Product ListDocument33 pagesASTM Product ListRudrendu ShekharNo ratings yet

- Factors Affecting Concrete WorkabilityDocument4 pagesFactors Affecting Concrete WorkabilityAli ArsalanNo ratings yet

- Compressive Strength of Concret by Fly AshDocument16 pagesCompressive Strength of Concret by Fly AsheranjanishuklaNo ratings yet

- جهات تقويم المطابقة المقبولة لدى الهيئة على النظام الجديد 1 11 1438Document13 pagesجهات تقويم المطابقة المقبولة لدى الهيئة على النظام الجديد 1 11 1438Wajid KNo ratings yet

- AAC Raw MaterialsDocument7 pagesAAC Raw MaterialsVuk VusovicNo ratings yet

- Familiarization With Apparatus and Equipment Used in Testing of MaterialsDocument5 pagesFamiliarization With Apparatus and Equipment Used in Testing of MaterialsEmanoAce33% (6)

- Fuel Types and Firing SystemsDocument80 pagesFuel Types and Firing SystemsIrshad HussainNo ratings yet

- Managing Quality in Bridge Construction - IABSE Guwahat - V N HeggadeDocument30 pagesManaging Quality in Bridge Construction - IABSE Guwahat - V N HeggadeJaganmohan GuptaNo ratings yet

- Cinar Cement ProjectsDocument2 pagesCinar Cement ProjectsJunaid MazharNo ratings yet

- The Reference For More Than .: Quality 50 YearsDocument6 pagesThe Reference For More Than .: Quality 50 Yearsumuhuza salomonNo ratings yet

- Research CementDocument2 pagesResearch Cementnatarajan_arulNo ratings yet

- Types of Building Materials - Be Assignment-Shreya PDFDocument12 pagesTypes of Building Materials - Be Assignment-Shreya PDFShreya SinghNo ratings yet

- PS1Document25 pagesPS1Edwin PalmaNo ratings yet

- Material Costing: A. Masonry Price: 750psi 500psi 350psi 120psiDocument5 pagesMaterial Costing: A. Masonry Price: 750psi 500psi 350psi 120psiMavelyn TolentinoNo ratings yet