Professional Documents

Culture Documents

SeaBoss Pre-Move Survey

SeaBoss Pre-Move Survey

Uploaded by

saeed ghafooriOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SeaBoss Pre-Move Survey

SeaBoss Pre-Move Survey

Uploaded by

saeed ghafooriCopyright:

Available Formats

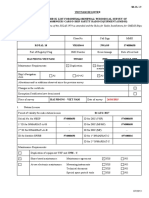

Report No.

:

ACS-TH-302-PGFK-0217

Survey Report Date :

17 Feb. 2020

Asia Classification Society Job No. :

Vessel Particulars

Petro Gohar Farasahel Kish.

Name of Vessel MODU SEA BOSS Owner

PGFK

Petro Gohar Farasahel Kish.

Previous Names --- Operator

PGFK

Self-Elevating Drilling Unit –

Type of vessel Independent Leg Cantilever

LOA 236 ft.

& Construction (Triangular Shaped, Slot Type

Premium Jack-up)

SembCorp Marine Ltd. PPL Breadth 224 ft.

Builder

Shipyard. Depth 27 ft.

Place & Date of

Singapore, 2012 Legs LOA ---

Build

No. /Port of

Kings Town Spud can Dia. ---

registry

Spud Can

Call sign --- ---

Height

IMO & Hull Rig Design &

9655119 Baker Marine – Pacific 400

Number Type

Gross Tonnage Leg Type & Three Independent Three

10501, 3400

& DWT Numbers Sided Lattice Braced Legs

Max Drill

Propulsion Non-Self Propelled Unit 35,000 ft.

Depth

Scope of Survey

Survey type Pre-Move Survey

Survey date January 28 to January 29, 2020

Place of survey Kish Anchorage Area – Persian gulf

Surveyor to ACS Saeed Ghafoori

Report Number: ACS-TH-302-PGFK-0217

Surveyor’s to ACS Offshore Division

Saeed Ghafoori Page 1 of 8

Report No. :

ACS-TH-302-PGFK-0217

Survey Report Date :

17 Feb. 2020

Asia Classification Society Job No. :

1- PART (A) : SURVEY REPORT

ITEM YES NO REMARKS

Communications

A) Is rig intercom system operative? √

8) Is marine radio operative? √

C) Are all remote stations operative? √

1 DSC set of 2 Set is

operational.

Lack of sufficient sets of

D) Describe any communications failures

portable VHF/UHF devices.

Some remote stations is

not operational.

Ballast System

A) Do all gauges operate properly? √

B) Describe any gauge malfunctions - - -

C) Are all sounding lines open? √

D) Were ballast pumps operating satisfactorily? √

E) Were all ballast tanks watertight? √

Master Dump Valve is

F) Were all valves operational? √

under overhaul.

Function test all valves, main/emer power

G) √ Satisfactory

Function ballast pumps sea to sea

H) Function emergency bilge suctions& pumps √ Satisfactory

I) Function bilge alarms √ Satisfactory

J) Function Secondary De Ballast system √ Satisfactory

K) Function auxiliaries √ Satisfactory

Function bilge alarm/pump auto start Power √ Satisfactory

L)

trial test run 80-90% power

Function of deepwell pump. √ a) Exist deepwell pump

type and flow rate is not

SeaBoss main configure.

Should be replace with the

manufacturer

M) recommended deepwell

pump.

b) Need to arrange

minimum 2 set of deepwell

pump for main and

emergency usage.

Surveyor’s to ACS Offshore Division

Saeed Ghafoori Page 2 of 8

Report No. :

ACS-TH-302-PGFK-0217

Survey Report Date :

17 Feb. 2020

Asia Classification Society Job No. :

ITEM YES NO REMARKS

Structural

Were the main vertical and horizontal

A) members inspected at tie in on lower hull, √

columns and main deck?

8) Were cracks in welds or steel noted? √

C) Were corrosion weakened members found? √

D) Was hull maintenance or repair work done? √

When were last potential readings taken on

E) - - -

cathodic protection system?

F) Was a visual inspection made of anodes? √

Anchor System

Lack of port side anchor.

What is condition of chain, chain chasers and

A) √ Anchor not fitted in

anchors? dedicated designed place.

B) Are chain fairleads operating properly? √

C) Are all windlasses operating properly? √

D) What was condition of buoys? √

E) What was condition of pendant line? √

a) Portside anchor winch

What mooring equipment was lost or wire is disconnected.

F)

replaced? b) Some mooring ropes

need to replace.

System, Legs and LSA FFA Inspections

Test jacking system and panel functions and a) Over temperature alarm

warning lights/alarms. (hull up and hull down on Motor C1.

A) √

test) b) Port leg circuit bracket

defect alarm.

Check lifeboat launch system & activate a) Abandon automatic

lifeboat lunch is not

operational due to free fall

B) √

wire defect.

b) Davits wires should be

change due to SOLAS reg.

C) Check and test lifeboat engines & radios √

D) Test emergency generator under load √

E) Check emergency switchboard √

G) Parallel generators & check main switchb'd √

Test EPIRB & SART EPIRB & SART battery is

H) √ expired, this devices is not

on trusted condition.

Check Life rings, Smokes, Life raft and life a) Almost all life rings have

jackets crack and is out of use.

√

b) Life ring Smokes is out of

use.

Surveyor’s to ACS Offshore Division

Saeed Ghafoori Page 3 of 8

Report No. :

ACS-TH-302-PGFK-0217

Survey Report Date :

17 Feb. 2020

Asia Classification Society Job No. :

ITEM YES NO REMARKS

c) Life raft HRUs are

expired.

d) Life jackets are expired

and life jacket lights need

to replace.

Navigation Equipment

Nav. lights main & stand-by Some lights in not

A) √

operational

N.U.C & towing shapes Some lights in not

B) √

operational

Whistle, fog horns, main & stand-by VHF a) 1 Set of DSC & MF/HF

radios, fixed & portables is not operational

C) √

b) lack of sufficient sets

of portable VHF radios

D) Sat Nav/Astro Nav/Nav System √

E) Nav Text √

F) Direction Finder √

G) Gyro Compass - - -

H) Magnetic Compasses Radar - - -

I) Echo sounder √

Equipment Stowage

A) All loose items an deck stowed & secured √

B) Any items below deck secured properly √

C) All drill pipe & other tubulars secured √

D) Crane booms/flare booms secure in cradles √

E) Blocks laid an drill floor & secured √

G) BOP & subsea equipment stowed & secured √

F) Cellar deck equipment all secure √

Surveyor’s to ACS Offshore Division

Saeed Ghafoori Page 4 of 8

Report No. :

ACS-TH-302-PGFK-0217

Survey Report Date :

17 Feb. 2020

Asia Classification Society Job No. :

2- PART (B) : PRE-MOVE RECOMMENDATION ACTIVITY FOR PREPRATION

A. Barge Engineer's

1) Check operation and hand seat all preload and sump valves.

2) Check Operation of tank gauges and air purge systems.

3) Sound all tanks and void spaces. Strip all preload tanks.

4) Check number and condition of portable radios.

5) Check all tank manholes and sounding caps.

6) Check all watertight doors and hatches for proper sealing and make log entry.

7) Calculate and check the expected "afloat" condition.

8) Check the securing of cargo and equipment.

Review "essential personnel" required to be a board during jacking and towing

9)

operations.

10) Assemble all charts and weather forecasts for move.

Assemble and review all data with regard to the proposed location, including certificate

11)

of approval.

Check all towing brackets are free and greased, locking pins are in place, and that release

12)

equipment is rigged or on hand.

Confirm towing arrangements with Marine Superintendent and Tow Master. Ensure any

13)

pre-rigged towlines are safely secured.

14) Test jacking panel functions and warning lights/alarms.

15) Recover and secure current and wave height meters.

Confirm that the necessary ventilation closures are closed and watertight. Make required

16)

log entry.

17) Assign personnel to work locations and establish reliable communications.

18) Maintain good communication with all key personnel throughout operation

Surveyor’s to ACS Offshore Division

Saeed Ghafoori Page 5 of 8

Report No. :

ACS-TH-302-PGFK-0217

Survey Report Date :

17 Feb. 2020

Asia Classification Society Job No. :

B. Drillers

1) Skid derrick to centerline and secure.

2) Stow B.O.P's. and secure top and bottom.

3) Raise cellar deck and secure.

4) Raise conductor platform and secure.

5) Ensure the skimmer tank is drained.

6) Secure rig floor equipment.

7) Disconnect the centrifuge dump line. ·

8) Disconnect mud return line to main deck trough.

9) Disconnect cantilever manifold hoses.

10) Clean and grease cantilever skidding pads.

Release securing clamps a cantilever beams and remove cantilever access ladders.

11)

Rope off openings.

12) Skid cantilever to towing position.

13) Secure cantilever beams with clamps, wedges and pins.

14) Replace the handrails across the aft end of the rig.

15) Reconnect cantilever hoses for fire and deluge lines.

16) Secure top drive and travelling blocks with 50 K. load.

17) Open and inspect master dump non-return valve.

18) Open and inspect pump room drain non-return valves.

19) Close all mud pit valves.

20) Close and padlock the mud pit master dump valve

21) Close and padlock the mud pump room drain valve.

22) Close the mud return to pits isolation valve.

23) Secure the mud pump room.

Driller instructs crew for jacking operations a starboard leg. Assistant driller instructs

24)

crew for jacking operations a port leg.

25) Return completed checklist to barge engineer.

Surveyor’s to ACS Offshore Division

Saeed Ghafoori Page 6 of 8

Report No. :

ACS-TH-302-PGFK-0217

Survey Report Date :

17 Feb. 2020

Asia Classification Society Job No. :

C. Crane Operator's

1) Remove all containers and equipment from bow.

2) Secure flare booms if installed.

Liaise with SR, tool pusher and barge engineer with regard to cargo to stay an board

3) during tow, arrange cargo an deck so that lose items can be boxed in by containers,

tubulars, or other heavy items.

Block stow as much deck load as possible within the central pipe bay. Remove and stow

4)

mooring lines, vent hoses and loading hoses.

5) Make available and prepare jetting hoses for use.

6) Liaise with barge engineer and prepare towing equipment per attached checklist.

7) Check and secure equipment in heavy tool store.

8) Check and secure all equipment in the sack store.

Ensure all lose equipment is secured to decks or to permanent structure (welding in place

9)

if required).

Accompany barge engineer on final inspection and rectify any unsecured cargo or

10)

equipment.

Ensure that there is sufficient grease and brushes available at each leg for rack

11)

lubrication.

12) Close and dog all watertight hatches, dose all watertight doors.

Have electrician isolate and disconnect the deepwell pumps. Disconnect and flexible

13)

hoses and blank-off lines.

14) Lay cranes in rests.

Instruct crews as to duties lobe performed during jacking and towing operations. Pay

15)

particular attention to the safety aspects of forthcoming operations.

16) Close all ventilation closures an main deck and below except for the engine room, SCR

17) Room and accommodations.

NOTE: "Secure" is defined as a means of preventing any horizontal or tipping movement taking into account the weight of the load.

Surveyor’s to ACS Offshore Division

Saeed Ghafoori Page 7 of 8

Report No. :

ACS-TH-302-PGFK-0217

Survey Report Date :

17 Feb. 2020

Asia Classification Society Job No. :

D. Maintenance Department

1) Remove blanks from engine exhausts.

2) Disconnect leg top aircraft lights.

3) Open and inspect sanitary, sewage and galley overboard non-return valves.

Close overboard valves for the sanitary, sewage and galley lines, redirecting the lines to

4)

sewage tank.

5) Remove the leg rack chocks and lock out.

6) Check Operation of sea chest valves and vents.

7) Secure all loose gear in the machinery spaces.

8) Check Operation of mooring winches.

9) Disconnect deepwell pumps.

10) Check all watertight doors to machinery spaces are properly closed.

11) Check that the emergency escape hatch from the S.C.R. room is closed and watertight.

Prepare generator load to exceed... KW to absorb regenerative power when jacking

12)

down and ensure that.......... KW is available for trial jacking up.

13) Assign power to jacking panel and test all warning devices prior to jacking operations.

14) Shutdown bilge system and operate only when flooding occurs.

15) Line up water supply to sanitary System and fire main from sea chests once rig is in water.

16) Check operation of tow bridle tuggers.

Stop all ventilation fans except those for the engine room, SCR room, paint locker and

17)

accommodations.

Surveyor’s to ACS Offshore Division

Saeed Ghafoori Page 8 of 8

You might also like

- Practical Guide To Draft SurveysDocument64 pagesPractical Guide To Draft SurveysArun Raj95% (58)

- Tanker Operations A Handbook For The Person-In-Charge (PIC) - 5th Ed. 2018 - by MARK E. HUBERDocument629 pagesTanker Operations A Handbook For The Person-In-Charge (PIC) - 5th Ed. 2018 - by MARK E. HUBERAndis Orravs100% (1)

- Drilling Pipe ProcedureDocument20 pagesDrilling Pipe Proceduresaeed ghafoori100% (3)

- Offshore Pipe Line and RisersDocument27 pagesOffshore Pipe Line and Riserssaeed ghafooriNo ratings yet

- Final Report Bulk Carrier SampleDocument54 pagesFinal Report Bulk Carrier SampleNguyễn Văn TrọngNo ratings yet

- Appraisal Report For Seafarers: RD Dd/Mm/Yy Dd/Mm/YyDocument3 pagesAppraisal Report For Seafarers: RD Dd/Mm/Yy Dd/Mm/Yyдима симафоридиNo ratings yet

- Electrical Inspection ChecklistDocument40 pagesElectrical Inspection ChecklistMohamed100% (1)

- Excavation ChecklistDocument1 pageExcavation ChecklistBudoy SmithNo ratings yet

- Standard P&i Condition SurveyDocument31 pagesStandard P&i Condition Surveyluchiappi100% (9)

- DKT0/2020/J5110: Ships in Service Survey ReportDocument26 pagesDKT0/2020/J5110: Ships in Service Survey ReportLeonidas Galanis100% (1)

- 17 - Anita A - Annex 4 To SBMA Ship's Installation ReportDocument2 pages17 - Anita A - Annex 4 To SBMA Ship's Installation ReportahmedNo ratings yet

- Requirement Spare Part: Description / Items Required Part No. Unit Item No. Quantity RequiredDocument2 pagesRequirement Spare Part: Description / Items Required Part No. Unit Item No. Quantity RequiredLinh nguyễnNo ratings yet

- CPP HT Pipeline ReportDocument301 pagesCPP HT Pipeline ReportAbdulkaderNo ratings yet

- Daily Progress Report: Project: Ostt-Ssjetty Submarine Pipeline, Location:Ss Jetty, Salpg, Durga Beach, VisakhapatnamDocument1 pageDaily Progress Report: Project: Ostt-Ssjetty Submarine Pipeline, Location:Ss Jetty, Salpg, Durga Beach, VisakhapatnamNaseer PullatNo ratings yet

- Sl343-Sl343 2021 Advancemdb Survey Cme TSSR Globe-Expansion2020 (Aborox)Document81 pagesSl343-Sl343 2021 Advancemdb Survey Cme TSSR Globe-Expansion2020 (Aborox)Jamil Baraquiel LucenaNo ratings yet

- PASSAGE PLAN Batam To SangattaDocument4 pagesPASSAGE PLAN Batam To SangattaTERAS HYDRA100% (1)

- Materials Transfer Form (MTF) : Logistics Team To Ensure Logistics-RFQ (L-RFQ) Is Properly Filled OutDocument1 pageMaterials Transfer Form (MTF) : Logistics Team To Ensure Logistics-RFQ (L-RFQ) Is Properly Filled OutRCGNo ratings yet

- Jack Up Rig Specification For Preparation Inspection Commisioning and TestingDocument82 pagesJack Up Rig Specification For Preparation Inspection Commisioning and Testingcbs9wyyrtyNo ratings yet

- OXIQUIM - Terminals ParticularsDocument18 pagesOXIQUIM - Terminals ParticularsJulio SereyNo ratings yet

- 8 Point Mooring - Attachment XxxiiDocument5 pages8 Point Mooring - Attachment XxxiiFaiqah AzmirNo ratings yet

- G LST 001 Ab Tank Farm in ProgressDocument270 pagesG LST 001 Ab Tank Farm in ProgressPhilippe AlexandreNo ratings yet

- Epirb Report MalvaDocument1 pageEpirb Report Malvamatias dagostoNo ratings yet

- Main Electrical Equipment List1Document4 pagesMain Electrical Equipment List1Qadir MohtashamNo ratings yet

- t0533 - MTN Fy21 Site Survey Report Sde Template LatestDocument65 pagest0533 - MTN Fy21 Site Survey Report Sde Template LatestChika AlbertNo ratings yet

- Wa-10 Pc-Ums Net Tonnage Cert.Document3 pagesWa-10 Pc-Ums Net Tonnage Cert.pawanNo ratings yet

- Technical Data:: Load Center C / SEC TUNNEL-C130/C13O Basement 2 Sec TunnelDocument3 pagesTechnical Data:: Load Center C / SEC TUNNEL-C130/C13O Basement 2 Sec Tunneleswaran005100% (1)

- International LTD: Report of Thorough ExaminationDocument1 pageInternational LTD: Report of Thorough ExaminationChisom IkengwuNo ratings yet

- USV Inspector MKIIDocument6 pagesUSV Inspector MKIIWell100% (1)

- Manifest LCT (Hydrocore)Document1 pageManifest LCT (Hydrocore)zakkir abcNo ratings yet

- DORC Contract No. DORC Project No. Request No. To: ATTACHNENT-5 (For Inspection Management and Coordination Procedure)Document1 pageDORC Contract No. DORC Project No. Request No. To: ATTACHNENT-5 (For Inspection Management and Coordination Procedure)Moorthy NaveenNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- ODU - 38AUD016 SubmittalDocument10 pagesODU - 38AUD016 SubmittalSherman EdgarNo ratings yet

- Checklist SBG TretsleDocument2 pagesChecklist SBG TretsleIzzat IzzuddinNo ratings yet

- Preliminaryu Survey Report NSRDocument1 pagePreliminaryu Survey Report NSRSmita Kumar DiamondNo ratings yet

- American Bureau of Shipping: Check Sheet On Solas Surveys-Slr/GmdssDocument9 pagesAmerican Bureau of Shipping: Check Sheet On Solas Surveys-Slr/GmdssajayiNo ratings yet

- Rail and Wheels: Guide ChannelDocument1 pageRail and Wheels: Guide ChannelnarumenonNo ratings yet

- Classification Characters, NotationsDocument2 pagesClassification Characters, NotationsAhmad FausiNo ratings yet

- 61 AisDocument3 pages61 AisLUU QUANG HOANo ratings yet

- Equipment / System Report: Project: MMTHQ Equipment Type: MDB - Main Distribution Board Panel Tag: Fed FromDocument3 pagesEquipment / System Report: Project: MMTHQ Equipment Type: MDB - Main Distribution Board Panel Tag: Fed FromifranNo ratings yet

- Certificate of Classification InterimDocument2 pagesCertificate of Classification InterimprojectmasternigNo ratings yet

- External Safety Audit Check-List For Onshore Drilling RigsDocument30 pagesExternal Safety Audit Check-List For Onshore Drilling RigsSiddhartha ChakradharNo ratings yet

- ST-6293-02 Mobile Crane 50.5 TonDocument14 pagesST-6293-02 Mobile Crane 50.5 TonMohammed HamzaNo ratings yet

- FAR Transmission PEX 3030 300 766Document4 pagesFAR Transmission PEX 3030 300 766yohanes moningkaNo ratings yet

- HFX-FI2021-6428 DT 24-05-21 LPI of 8 NMDC # SBMH 0510Document1 pageHFX-FI2021-6428 DT 24-05-21 LPI of 8 NMDC # SBMH 0510fast fastNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Barrier Cable Glands CMP PX2KX InstructionsDocument2 pagesBarrier Cable Glands CMP PX2KX InstructionsMohammed MustafaNo ratings yet

- XyzDocument32 pagesXyzomprakashom63No ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Cable Gland Types Px2Krex, Px2Kwrex, Px2Kxrex & PB VariantsDocument2 pagesCable Gland Types Px2Krex, Px2Kwrex, Px2Kxrex & PB VariantsNikhil E ANo ratings yet

- 4Tt Avotr/Government Of: No.:04NLO694Document2 pages4Tt Avotr/Government Of: No.:04NLO694Amar ChoudharyNo ratings yet

- Metrosil Test Report: Site Test Report Date: 29/07/2020 Customer: Sec-Eoa Name of SubstationDocument2 pagesMetrosil Test Report: Site Test Report Date: 29/07/2020 Customer: Sec-Eoa Name of Substationمحمد عادلNo ratings yet

- DPR - 18-06-2023Document1 pageDPR - 18-06-2023Muhammad AftabNo ratings yet

- SARTDocument1 pageSARTmatias dagostoNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Under The Provisions of The SOLAS 1974 As Amended and The Rules For Radio Installations For GMDSS ShipsDocument10 pagesUnder The Provisions of The SOLAS 1974 As Amended and The Rules For Radio Installations For GMDSS ShipsthỏaNo ratings yet

- 9-26-2020 DfirDocument2 pages9-26-2020 DfirJulius GatchalianNo ratings yet

- 18.03 Java Imperia SpecificationDocument3 pages18.03 Java Imperia Specificationalex kingNo ratings yet

- Switchgear Installation ChecklistDocument1 pageSwitchgear Installation ChecklistMohamed60% (5)

- Sample OP-01 Singapore To KamsarDocument72 pagesSample OP-01 Singapore To KamsarOgie Piano100% (3)

- Notice To Mariner No. 265: SubjectDocument1 pageNotice To Mariner No. 265: SubjectKaushik SamantaNo ratings yet

- Draft Spec RDSO-CG-18003 For AMDBS 200kmphDocument37 pagesDraft Spec RDSO-CG-18003 For AMDBS 200kmphMS kunalNo ratings yet

- WMS 04 Lifting Works & PositioningDocument18 pagesWMS 04 Lifting Works & PositioningDarren LiewNo ratings yet

- Inspection Report: General InformationDocument22 pagesInspection Report: General InformationShamsul AffendiNo ratings yet

- Checklist For Rock Bolts PDFDocument4 pagesChecklist For Rock Bolts PDFImran FarooqNo ratings yet

- 62 EpirbDocument3 pages62 EpirbLUU QUANG HOANo ratings yet

- Installation Instructions For CMP Cable Gland Types T3Cds & T3CdspbDocument2 pagesInstallation Instructions For CMP Cable Gland Types T3Cds & T3CdspbLailyMLNo ratings yet

- WiMedia UWB: Technology of Choice for Wireless USB and BluetoothFrom EverandWiMedia UWB: Technology of Choice for Wireless USB and BluetoothNo ratings yet

- High Impact Risk Management Plan TemplateDocument11 pagesHigh Impact Risk Management Plan Templatesaeed ghafoori100% (1)

- IOGP423 ScopeSpecificQuestionnaires032021Document23 pagesIOGP423 ScopeSpecificQuestionnaires032021saeed ghafooriNo ratings yet

- ACS Rules For Offshore Fixed Platform InstallationDocument31 pagesACS Rules For Offshore Fixed Platform Installationsaeed ghafooriNo ratings yet

- Jackup DRILLING Rig Data Requirments & Recommendation For LocationbapproachDocument4 pagesJackup DRILLING Rig Data Requirments & Recommendation For Locationbapproachsaeed ghafooriNo ratings yet

- ACS-DCI-2-Location-Assessment v1Document42 pagesACS-DCI-2-Location-Assessment v1saeed ghafooriNo ratings yet

- ACS Offshore Upstream Construction CoP SoW CoADocument32 pagesACS Offshore Upstream Construction CoP SoW CoAsaeed ghafooriNo ratings yet

- ACS-SP-MODU Special Survey of Hull & StructureDocument19 pagesACS-SP-MODU Special Survey of Hull & Structuresaeed ghafoori100% (1)

- ACS Service Specification of Marine Warranty SurveyDocument11 pagesACS Service Specification of Marine Warranty Surveysaeed ghafooriNo ratings yet

- LNAS Marine Manual - Rev 04 - FinalDocument41 pagesLNAS Marine Manual - Rev 04 - Finalsaeed ghafooriNo ratings yet

- 5 ACS SPM Rules - 2017Document92 pages5 ACS SPM Rules - 2017saeed ghafoori100% (1)

- ACS-RIG MOVE-MWS-TECHNICAL v1.0Document6 pagesACS-RIG MOVE-MWS-TECHNICAL v1.0saeed ghafooriNo ratings yet

- ACS-RIG MOVE-MWS-TECHNICAL v1.0Document6 pagesACS-RIG MOVE-MWS-TECHNICAL v1.0saeed ghafooriNo ratings yet

- SL-ELT-PR-WPS1-4105-C1-S1 Topside Load Out ProcedureDocument142 pagesSL-ELT-PR-WPS1-4105-C1-S1 Topside Load Out Proceduresaeed ghafooriNo ratings yet

- Rig Manager Pre-Rig-Move Check List Sea Boss Move No:: Task To Be Performed: InitialsDocument1 pageRig Manager Pre-Rig-Move Check List Sea Boss Move No:: Task To Be Performed: Initialssaeed ghafooriNo ratings yet

- Marshall Island - Annex 02Document16 pagesMarshall Island - Annex 02saeed ghafooriNo ratings yet

- Sail Out Cert - Pasargad 100Document1 pageSail Out Cert - Pasargad 100saeed ghafooriNo ratings yet

- Interim Garbage Pollution Prevention Certificate: DP Hoormand 5IM 873 Zanzibar 474 45Document2 pagesInterim Garbage Pollution Prevention Certificate: DP Hoormand 5IM 873 Zanzibar 474 45saeed ghafooriNo ratings yet

- Rig Move Completion Approval: Offshore Services DivisionDocument1 pageRig Move Completion Approval: Offshore Services Divisionsaeed ghafooriNo ratings yet

- Panama Marine Authority Administration Fees: Seafarers' LicencesDocument5 pagesPanama Marine Authority Administration Fees: Seafarers' Licencessaeed ghafooriNo ratings yet

- Sl-Elt-Pr-Wps1-4107-C2-S1-Welder QualificationDocument15 pagesSl-Elt-Pr-Wps1-4107-C2-S1-Welder Qualificationsaeed ghafooriNo ratings yet

- AMIR KABIR SSDU IWS Report Rev01Document6 pagesAMIR KABIR SSDU IWS Report Rev01saeed ghafoori0% (1)

- READY TO LIFT S1 Top SideDocument1 pageREADY TO LIFT S1 Top Sidesaeed ghafooriNo ratings yet

- EM 385-1-1 2014 Section 16Document89 pagesEM 385-1-1 2014 Section 16saeed ghafooriNo ratings yet

- 2009 Crane Start Up Inspection FormDocument3 pages2009 Crane Start Up Inspection Formsaeed ghafooriNo ratings yet

- SL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFDocument633 pagesSL-ELT-AN-WPS1-4114-C2-S1 Topside Lift Analysis & Report PDFsaeed ghafoori100% (1)

- SL-ELT-AN-WPS1-4115-C2-S1 Topside Lift Analysis & Report For Load Out PDFDocument633 pagesSL-ELT-AN-WPS1-4115-C2-S1 Topside Lift Analysis & Report For Load Out PDFsaeed ghafoori100% (1)

- PDS Bioguard PlusDocument3 pagesPDS Bioguard PlusKL PetrachkovNo ratings yet

- Venting System For TankerDocument4 pagesVenting System For TankeribnuharyNo ratings yet

- Intact Damage Stability Booklet PreliminaryDocument241 pagesIntact Damage Stability Booklet PreliminaryNisha SirohiNo ratings yet

- Doc. No. 01 S.D. 04 - 42 21 SP070 - MachDocument65 pagesDoc. No. 01 S.D. 04 - 42 21 SP070 - MachGanantaEgas Wahyu EndriantoNo ratings yet

- Mem-001Document25 pagesMem-001Cees van ZandvlietNo ratings yet

- Topic 6 Tanker Pollution PreventionDocument7 pagesTopic 6 Tanker Pollution PreventionJOSHUA GUIMBANGUNANNo ratings yet

- Anglo Eastern Gas Carrier Manual Final 2005Document172 pagesAnglo Eastern Gas Carrier Manual Final 2005Joseph AbrahamNo ratings yet

- Chapter 1. General InformationDocument33 pagesChapter 1. General InformationaliNo ratings yet

- Seam 3 Group 7Document4 pagesSeam 3 Group 7Hope Earl Ropia BoronganNo ratings yet

- ABS Part5 - C1aC6-Specific Vessel Types - 2001Document952 pagesABS Part5 - C1aC6-Specific Vessel Types - 2001Timothy JonesNo ratings yet

- PVT NEPTUNE Vessel Status ReportDocument28 pagesPVT NEPTUNE Vessel Status ReportNamNo ratings yet

- 1995-Microbes Onboard ShipsDocument43 pages1995-Microbes Onboard ShipsAnakin SkywalkerNo ratings yet

- 33 CFR Part 151 Subpart C (Up To Date As of 6-15-2022)Document8 pages33 CFR Part 151 Subpart C (Up To Date As of 6-15-2022)Alex TanaseNo ratings yet

- Samsung Heavy IndustriesDocument4 pagesSamsung Heavy IndustriesHtun Minn OoNo ratings yet

- Understanding Heavy Lift Vessels (HLVS) Design, Operation and TypesDocument10 pagesUnderstanding Heavy Lift Vessels (HLVS) Design, Operation and TypesGiorgi KandelakiNo ratings yet

- Nace SP0111 2019Document16 pagesNace SP0111 2019Agustín Resio100% (2)

- LNGC Q-Max Lijmiliya - Imo 9388819 - Cargo Operating ManualDocument547 pagesLNGC Q-Max Lijmiliya - Imo 9388819 - Cargo Operating Manualseawolf50No ratings yet

- Ballast Water Treatment PDFDocument33 pagesBallast Water Treatment PDFTagore Pavan KumarNo ratings yet

- Pump Room SystemsDocument8 pagesPump Room SystemsArdyas Wisnu Baskoro100% (1)

- Loadometer BrochureDocument5 pagesLoadometer BrochureTapan KhandelwalNo ratings yet

- Albaño - Final Quiz 1 2 SEAM 213 Capt. Floro R. Pusta JR QuestionaireDocument3 pagesAlbaño - Final Quiz 1 2 SEAM 213 Capt. Floro R. Pusta JR QuestionaireWindy ManayonNo ratings yet

- Ballast Water Exchange: Guide ForDocument84 pagesBallast Water Exchange: Guide Forvsorin83No ratings yet

- Calculation and Specification of Ballast System: Design Iv Machinery System Departement of Marine EngineeringDocument13 pagesCalculation and Specification of Ballast System: Design Iv Machinery System Departement of Marine EngineeringSean Chen GyarinoNo ratings yet

- Hull Surveys of Double Hull Oil TankersDocument132 pagesHull Surveys of Double Hull Oil TankersKatsaras SotirisNo ratings yet

- Deme Qhses CHL 062 eDocument2 pagesDeme Qhses CHL 062 eAndrei SavuNo ratings yet