Professional Documents

Culture Documents

Module 5 - Stresses in Beams

Module 5 - Stresses in Beams

Uploaded by

wag naOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 5 - Stresses in Beams

Module 5 - Stresses in Beams

Uploaded by

wag naCopyright:

Available Formats

UNIVERSITY OF SANTO TOMAS

FACULTY OF ENGINEERING

CIVIL ENGINEERING DEPARTMENT

1907

ENG 2019

MECHANICS OF DEFORMABLE BODIES

MODULE 5

Stresses in Beams

This module belongs to:

_____________________________________________________

Engr. Jervin Kent C. Nava

FLEXURAL STRESS

In the previous modules, we considered stresses in members caused by axial loading and torsion. Here we

introduce the third fundamental loading: bending. Since the length or span of a beam is comparatively larger than

the depth of the beam, beams tend to experience much significant bending or flexure than any other member.

Stresses caused by bending moments are known as bending / flexural stress (𝑓𝑏 ), and is given by the formula:

where: 𝑀 : bending moment at section being considered

𝑴𝒄 𝑐 : distance from the neutral axis to fiber in question

𝒇𝒃 =

𝑰 𝐼 : moment of inertia about the neutral axis

The maximum flexural stress is also expressed as:

𝑴 where: 𝑆 : Section modulus

𝒇𝒃𝑴𝑨𝑿 =

𝑺

SAMPLE PROBLEMS

Problem 56: Determine the maximum flexural stress (tension and compression) developed in the loaded beam

below. The cross-sectional area of the beam is shown.

Problem 57: A cantilever beam has a hollow shaped cross-sectional area shown. The beam is supporting a

uniform load of 40 kN/m throughout its entire 5-m length. Determine the maximum flexural stress

(tension and compression) developed in the loaded beam.

Look for solutions, not excuses.

Problem 58: A composite section shown consists of a wide

flange and a channel (properties of each

section are shown). The composite section is

used as a simply supported beam 8 m in span

carrying a uniformly distributed load of 20 kN/m

(self-weight included). Determine the maximum

fb in tension and compression.

FLEXURAL SHEARING STRESS

Imbalances due to horizontal stresses due to flexure at adjacent fibers is balanced by resisting horizontal shear

forces acting along the length of the beam. These forces would be causing the flexural shearing stress in the

beam. It is also called as horizontal shearing stress / transverse shearing stress. It is given by the formula:

where: 𝑓𝑣 : flexural shearing stress of the fiber in question

𝑽𝑸 𝑉 : shear at the point being considered

𝒇𝒗 =

𝑰𝒃 𝑄 : statical moment of area about the neutral axis

𝐼 : moment of inertia about the neutral axis

𝑏 : width of the fiber in question

SAMPLE PROBLEMS

Problem 59: A simply-supported beam 150 mm deep, 100 mm wide and 4 m long has a uniformly distributed

load of 5 kN/m throughout its span. Compute for the flexural shear stress developed at horizontal

layers 25 mm apart from top to bottom at the section 1 meter from the left support. Compute also

for the maximum flexural shear stress in the beam.

Problem 60: A rectangular hollow beam as shown is used as a cantilever beam

subjected to a concentrated load at the end of its 5-m length. If the

allowable flexural shearing stress at the neutral axis is 10 MPa, determine

the allowable load P it can carry.

Problem 61: The cross-section of a beam is an isosceles triangle with vertex uppermost, of altitude h and base

b. Locate and derive its maximum flexural shearing stress.

Look for solutions, not excuses.

ECONOMIC SECTIONS

In standard structural steel design, a W-shape beam is commonly used. This shape

is one of the most efficient standard structural shapes manufactured because it |𝑴|𝑴𝑨𝑿

provides great flexural strength with minimum weight of material. Another “slimmer” 𝑺𝑴𝑰𝑵 ≥

version of the W shape is the I-beam (referred to as an S-shape). The I-beam 𝒇𝒃𝒂𝒍𝒍𝒐𝒘𝒂𝒃𝒍𝒆

preceded the wide-flange beam, but because it is not as efficient, it has largely

replaced by the wide-flange beam.

Properties of W- and S-shapes are given in the AISC Manual of Steel Construction. In SI units, a beam of either

type is specified by stating its depth in millimeters and its mass per unit length in kilograms per meter. Is

U.S. Customary units, a structural section is specified by stating its depth in inches followed by its weight per

unit length in pounds per linear foot.

When a structural section is selected to be used as a beam, the section modulus (S) must be equal to or greater

than the section modulus determined by the flexure equation that is:

A design engineer is often required to select the lightest standard structural shape that can carry a given

loading in addition to the weight of the beam.

Procedure for selecting standard shapes:

• Neglect the weight of the beam. Determine the largest bending moment (absolute value).

• Determine the minimum allowable section modulus from SMIN = |M|MAX / fb(allowable)

• Choose the lightest shape from the list of structural shapes for which S ≥ S MIN and note its weight.

• Calculate the maximum bending stress in the selected beam caused by the prescribed loading plus the

weight of the beam. If fb MAX ≤ fb(allowable) the selection is finished. Otherwise, the second lightest shape with

S ≥ SMIN must be considered and the maximum bending stress recalculated. The process must be

repeated until a satisfactory shape is found.

SAMPLE PROBLEMS

Problem 62: What is the lightest W-shape beam that will support the 45-kN load shown? It must not exceed a

bending stress of 120 MPa. Afterwards, determine the actual bending stress in the beam.

Problem 63: A 12-m simple beam carries a uniformly distributed load of 17.5 kN/m over its entire span. Find the

lightest W-shape for which the bending stress does not exceed 120 MPa. What is the actual bending

stress in the beam selected?

Look for solutions, not excuses.

SPACING OF RIVETS

When two or more layers of beams, or built-up sections, are fastened

together with a bolt or a rivet so that they act as a unit to gain more

strength, it is necessary to design the spacing of these bolts or rivets

so that it can carry the shearing force acting between each adjacent

layers.

The spacing (also called as pitch) is given by the formula:

𝑹𝑰 where: 𝑠 : spacing / pitch of bolts or rivets

𝒔= 𝑅 : total shearing force to be resisted by the bolts

𝑽𝑸

𝐼 : moment of inertia about the neutral axis

𝑉 : maximum shear

𝑄 : statical moment of area about the neutral axis

SAMPLE PROBLEMS

Problem 64: Two wooden planks form a T-section for a beam as shown. If there is a constant vertical shear of

3 kN, find the necessary nail spacing. The allowable shear force per nail is 700 N.

Problem 65: A beam is formed by bolting together two W200 × 100 sections as shown. It is used to support a

uniformly distributed load of 30 kN/m (including the weight of the beam) on a simply supported

span of 10 m. Compute the pitch between bolts that have a shearing strength of 30 kN.

Look for solutions, not excuses.

MOHR’S CIRCLE

The stress transformation equations for plane stress can be represented in graphical form by a plot known as

Mohr’s Circle. This graphical representation is extremely useful because it enables you to visualize the

relationships between the normal and shear stresses acting on various inclined planes at a point in a stressed

body.

Using Mohr’s Circle, you can also calculate principal stresses, maximum shear stresses and stresses on inclined

planes.

PRINCIPAL STRESSES USING MOHR’S CIRCLE

General Notes in using Mohr’s Circle:

1. The planes in the stress element represent the points along the Mohr’s Circle.

2. The stresses in the stress element represent the coordinates of the points along the Mohr’s Circle.

3. For every angle measured in the stress element, the corresponding angle in the Mohr’s Circle is twice

of that angle.

Steps in plotting the Mohr’s Circle:

1. Determine the coordinates of the points to be plotted, according to the value and nature of stresses

on the planes of the stress element. Note that these two points that were previously plotted must be

diametrically opposite each other.

2. Locate the center of the Mohr’s circle and draw the Mohr’s circle.

3. From this circle, you can determine the values of the maximum normal and shear stresses.

SAMPLE PROBLEMS

Problem 66: Draw the Mohr’s Circle of the stress element shown below.

Determine the maximum principal stresses and the maximum

shear stresses. Draw the corresponding stress element that (1) the

principal stresses are maximum, and (2) shear stress is maximum.

Look for solutions, not excuses.

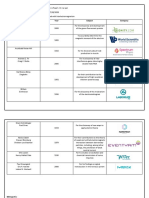

Properties of Wide-Flange Sections (W-Shapes)

(Taken from AISC Manual of Steel Construction, 13th ed., 2005, American Institute of Steel Construction)

Mass A d bf tw tf Ix(cg) Sx rx Iy(cg) Sy ry

Designation

(kg/m) (mm2) (mm) (mm) (mm) (mm) (x106 mm4) (x103 mm3) (mm) (x106 mm4) (x103 mm3) (mm)

W1100 X 499 499 63500 1120 404 26.2 45.0 12900 23100 452 499 2460 88.6

X 433 433 55100 1110 401 22.0 40.1 11200 20300 452 433 2160 88.6

X 390 390 49800 1100 401 19.9 36.1 10000 18200 450 384 1920 88.1

X 343 343 43700 1090 401 18.0 31.0 8660 15900 445 331 1660 87.1

W1000 X 883 883 112000 1090 424 45.5 82.0 21000 38300 432 1050 4950 96.5

X 748 748 95500 1070 417 39.1 70.1 17300 32400 427 849 4080 94.5

X 642 642 81900 1050 411 34.0 59.9 14500 27700 422 703 3410 92.7

X 591 591 75500 1040 409 31.0 55.9 13300 25600 422 641 3130 92.5

X 554 554 71000 1030 409 29.5 52.1 12300 23900 419 591 2900 91.4

X 539 539 68400 1030 406 28.4 51.1 12000 23300 419 574 2830 91.4

X 483 483 61500 1020 404 25.4 46.0 10700 21000 417 508 2510 90.9

X 443 443 56300 1010 401 23.6 41.9 9660 19200 414 454 2260 89.9

X 412 412 52600 1010 401 21.1 40.1 9120 18000 417 433 2160 90.9

X 371 371 47400 1000 401 19.1 36.1 8160 16300 414 385 1930 90.2

X 321 321 41000 991 401 16.5 31.0 6950 14100 411 334 1660 89.9

X 296 296 37900 983 401 16.5 27.2 6200 12600 406 289 1450 87.6

X 584 584 74800 1060 315 36.1 64.0 12400 23600 409 334 2130 67.1

X 494 494 63000 1040 310 31.0 54.1 10300 19800 404 268 1740 65.3

X 486 486 61900 1040 307 30.0 54.1 10200 19700 406 266 1720 65.5

X 438 438 55600 1030 305 26.9 49.0 9120 17700 404 234 1530 64.8

X 415 415 53100 1020 305 26.2 46.0 8530 16700 401 217 1430 64.0

X 393 393 49900 1020 302 24.4 43.9 8070 15900 401 205 1350 64.0

X 350 350 44600 1010 302 21.1 40.1 7240 14300 404 185 1220 64.5

X 314 314 40100 1000 300 19.1 36.1 6450 12900 401 162 1080 63.8

X 272 272 34400 991 300 16.5 30.5 5490 11100 399 138 918 63.2

X 249 249 31800 980 300 16.5 26.2 4830 9830 389 118 785 61.0

X 222 222 28300 970 300 16.0 21.1 4080 8410 381 95.3 636 58.2

W920 X 970 970 124000 1040 447 50.0 89.9 21100 40300 411 1340 6010 104

X 787 787 101000 1010 437 40.9 73.9 16500 32600 406 1040 4740 102

Look for solutions, not excuses.

Mass A d bf tw tf Ix Sx rx Iy Sy ry

Designation

(kg/m) (mm2) (mm) (mm) (mm) (mm) (x106 mm4) (x103 mm3) (mm) (x106 mm4) (x103 mm3) (mm)

W 920 X 725 725 92300 998 434 38.1 68.1 15000 30000 401 937 4310 101

X 656 656 83900 988 432 34.5 62.0 13400 27000 399 828 3850 99.6

X 588 588 74800 975 427 31.0 55.9 11900 24400 399 728 3410 98.6

X 537 537 68400 965 424 28.4 51.1 10700 22100 396 653 3080 97.8

X 491 491 62500 958 422 25.9 47.0 9700 20300 394 591 2800 97.3

X 449 449 57400 947 424 24.0 42.7 8780 18500 391 541 2560 97.0

X 420 420 53500 942 422 22.5 39.9 8160 17200 391 499 2360 96.5

X 390 390 49800 937 422 21.3 36.6 7450 15900 389 454 2160 95.5

X 368 368 46800 932 419 20.3 34.3 6950 15000 386 420 2020 95.0

X 344 344 44000 927 419 19.3 32.0 6490 14000 384 391 1870 94.2

X 381 381 48600 951 310 24.4 43.9 6990 14700 378 220 1420 67.3

X 345 345 43900 943 307 22.1 39.9 6240 13300 376 195 1270 66.5

X 313 313 39900 932 310 21.1 34.5 5490 11800 371 171 1110 65.5

X 289 289 36800 927 307 19.4 32.0 5040 10900 371 156 1010 65.0

X 271 271 34600 922 307 18.4 30.0 4700 10200 368 144 944 64.8

X 253 253 32300 919 305 17.3 27.9 4370 9520 368 133 872 64.3

X 238 238 30300 914 305 16.5 25.9 4060 8880 366 123 805 63.5

X 223 223 28600 912 305 15.9 23.9 3760 8260 363 112 739 62.7

X 201 201 25700 904 305 15.2 20.1 3250 7190 356 93.7 618 60.5

W 840 X 576 576 73500 914 411 32.0 57.9 10100 22100 371 674 3280 95.8

X 527 527 67100 904 409 29.5 53.1 9160 20300 368 608 2970 95.0

X 473 473 60500 894 406 26.4 48.0 8120 18200 368 537 2640 94.2

X 433 433 55200 884 404 24.4 43.9 7370 16700 366 483 2390 93.5

X 392 392 49900 876 401 22.1 39.9 6620 15100 363 433 2150 93.0

X 359 359 45900 869 404 21.1 35.6 5910 13600 358 388 1930 91.9

X 329 329 42100 861 401 19.7 32.5 5370 12400 358 350 1740 91.2

X 299 299 38100 856 399 18.2 29.2 4830 11200 356 312 1560 90.4

X 251 251 31900 859 292 17.0 31.0 3870 9000 348 129 883 63.5

X 226 226 29000 851 295 16.1 26.9 3400 7980 343 114 773 62.7

X 210 210 26800 846 292 15.4 24.4 3100 7340 340 102 700 61.7

X 193 193 24700 841 292 14.7 21.7 2790 6650 335 90.7 621 60.7

X 176 176 22400 836 292 14.0 18.8 2460 5880 330 77.8 534 58.9

W 760 X 582 582 74200 843 396 34.5 62.0 8620 20500 340 645 3240 93.2

X 531 531 67700 833 394 31.5 56.9 7780 18700 338 579 2930 92.5

X 484 484 61900 823 391 29.0 52.1 6990 17000 335 516 2650 91.4

X 434 434 55500 813 389 25.9 47.0 6200 15200 335 458 2360 90.9

X 389 389 49700 803 386 23.6 41.9 5450 13600 333 399 2080 89.7

X 350 350 44700 795 384 21.1 38.1 4870 12300 330 356 1870 89.2

Look for solutions, not excuses.

Mass A d bf tw tf Ix Sx rx Iy Sy ry

Designation

(kg/m) (mm2) (mm) (mm) (mm) (mm) (x106 mm4) (x103 mm3) (mm) (x106 mm4) (x103 mm3) (mm)

W 760 X 314 314 40200 785 384 19.7 33.5 4290 10900 328 315 1640 88.6

X 284 284 36200 780 381 18.0 30.2 3830 9830 325 280 1470 87.9

X 257 257 32800 772 381 16.6 27.2 3430 8870 323 249 1310 86.9

X 220 220 28100 780 267 16.5 30.0 2780 7140 315 94.5 710 57.9

X 196 196 25000 770 267 15.6 25.4 2400 6230 310 81.6 610 57.2

X 185 185 23500 767 267 14.9 23.6 2230 5820 307 75.3 564 56.6

X 173 173 22100 762 267 14.4 21.6 2050 5390 305 68.3 513 55.6

X 161 161 20500 757 267 13.8 19.3 1860 4900 302 60.8 457 54.6

X 147 147 18700 754 267 13.2 17.0 1660 4410 297 53.3 401 53.3

X 134 134 17000 749 264 11.9 15.5 1500 4010 297 47.9 362 53.1

W 690 X 802 802 103000 826 389 50.0 89.9 10700 25700 323 878 4540 92.7

X 548 548 70300 772 373 35.1 63.0 6740 17400 310 545 2930 88.4

X 500 500 64000 762 371 32.0 57.9 6080 15900 307 491 2650 87.6

X 457 457 58200 752 366 29.5 53.1 5450 14500 305 437 2390 86.6

X 419 419 53600 744 366 26.9 49.0 4950 13300 305 397 2180 86.1

X 384 384 49100 737 363 24.9 45.0 4500 12200 302 358 1970 85.3

X 350 350 44800 729 361 23.1 40.9 4040 11100 300 320 1770 84.6

X 323 323 41200 721 358 21.1 38.1 3710 10300 300 293 1640 84.3

X 289 289 36800 714 356 19.1 34.0 3270 9160 297 258 1440 83.6

X 265 265 33900 706 358 18.4 30.2 2920 8280 295 231 1290 82.6

X 240 240 30700 701 356 16.8 27.4 2630 7510 292 207 1160 82.0

X 217 217 27900 696 356 15.4 24.8 2360 6780 292 184 1040 81.3

X 192 192 24400 701 254 15.5 27.9 1980 5650 284 76.6 603 56.1

X 170 170 21700 693 257 14.5 23.6 1700 4900 279 66.2 516 55.4

X 152 152 19400 688 254 13.1 21.1 1510 4380 279 57.9 456 54.6

X 140 140 17800 683 254 12.4 18.9 1360 3980 277 51.6 406 53.8

X 125 125 15900 678 254 11.7 16.3 1190 3490 272 44.1 347 52.6

W 610 X 551 551 70300 711 348 38.6 69.1 5580 15700 282 483 2790 83.1

X 498 498 63400 699 343 35.1 63.0 4950 14200 279 429 2490 82.0

X 455 455 57900 688 340 32.0 57.9 4450 12900 277 383 2250 81.3

X 415 415 52800 678 338 29.5 53.1 4000 11800 274 343 2030 80.5

X 372 372 47400 668 335 26.4 48.0 3530 10600 272 301 1800 79.8

X 341 341 43400 660 333 24.4 43.9 3180 9640 272 271 1630 79.0

X 307 307 39200 653 330 22.1 39.9 2840 8700 269 241 1460 78.2

X 285 285 36500 648 330 20.6 37.1 2610 8050 267 221 1340 78.0

X 262 262 33400 640 328 19.1 34.0 2360 7370 267 199 1220 77.2

X 241 241 30800 635 330 17.9 31.0 2150 6780 264 184 1120 77.5

X 217 217 27700 627 328 16.5 27.7 1910 6080 262 163 991 76.5

Look for solutions, not excuses.

Mass A d bf tw tf Ix Sx rx Iy Sy ry

Designation

(kg/m) (mm2) (mm) (mm) (mm) (mm) (x106 mm4) (x103 mm3) (mm) (x106 mm4) (x103 mm3) (mm)

W 610 X 195 195 24900 622 328 15.4 24.4 1670 5390 259 142 869 75.4

X 174 174 22200 617 325 14.0 21.6 1470 4770 257 124 762 74.7

X 155 155 19800 612 325 12.7 19.1 1290 4230 257 108 667 73.9

X 153 153 19500 622 229 14.0 24.9 1250 4010 254 49.5 434 50.5

X 140 140 17900 617 230 13.1 22.2 1120 3640 251 45.4 393 50.3

X 125 125 15900 612 229 11.9 19.6 986 3210 249 39.3 342 49.5

X 113 113 14500 607 228 11.2 17.3 874 2880 246 34.3 302 48.8

X 101 101 13000 602 228 10.5 14.9 762 2520 243 29.3 257 47.5

X 92 92 11700 602 179 10.9 15.0 645 2150 234 14.4 161 35.1

X 82 82 10500 599 178 10.0 12.8 562 1870 231 12.1 136 34.0

W 530 X 300 300 38300 584 320 23.1 41.4 2210 7550 241 226 1410 76.7

X 272 272 34600 577 318 21.1 37.6 1970 6830 239 201 1270 76.2

X 248 248 31500 572 315 19.1 34.5 1780 6230 238 181 1150 75.9

X 219 219 27900 561 318 18.3 29.2 1510 5390 233 157 985 74.9

X 196 196 25000 554 315 16.5 26.4 1340 4830 232 139 877 74.4

X 182 182 23200 551 315 15.2 24.4 1230 4470 231 127 806 74.2

X 165 165 21000 546 312 14.0 22.2 1110 4080 230 114 729 73.7

X 150 150 19200 544 312 12.7 20.3 1010 3720 229 103 660 73.4

X 138 138 17600 549 214 14.7 23.6 862 3150 221 38.7 362 46.7

X 123 123 15700 544 212 13.1 21.2 762 2800 220 33.9 320 46.5

X 109 109 13900 538 211 11.6 18.8 666 2470 219 29.4 279 46.0

X 101 101 12900 536 210 10.9 17.4 616 2290 218 26.9 257 45.7

X 92 92 11800 533 209 10.2 15.6 554 2080 217 23.9 229 45.0

X 82 82 10500 528 209 9.53 13.3 475 1800 213 20.1 193 43.9

X 72 72 9100 523 207 8.89 10.9 399 1520 209 16.1 156 42.2

X 85 85 10800 536 167 10.3 16.5 487 1820 212 12.7 153 34.3

X 74 74 9480 528 166 9.65 13.6 410 1550 208 10.4 125 33.0

X 66 66 8390 526 165 8.89 11.4 351 1340 205 8.62 104 32.0

W 460 X 464 464 59100 566 305 38.6 69.6 2900 10200 221 331 2160 74.9

X 421 421 53700 556 302 35.6 63.5 2570 9260 219 293 1930 73.9

X 384 384 49000 546 300 32.5 58.4 2290 8420 217 261 1750 73.2

X 349 349 44300 536 297 29.5 53.6 2040 7640 214 232 1570 72.4

X 315 315 40200 526 295 26.9 48.5 1800 6870 212 205 1400 71.6

X 286 286 36300 518 292 24.4 44.5 1610 6230 210 183 1260 70.9

X 260 260 33200 508 290 22.6 40.4 1440 5640 208 163 1130 70.1

X 235 235 29900 500 287 20.6 36.6 1270 5080 206 144 1010 69.6

X 213 213 27100 495 284 18.5 33.5 1140 4620 205 129 909 69.1

X 193 193 24700 490 284 17.0 30.5 1020 4200 204 116 818 68.6

Look for solutions, not excuses.

Mass A d bf tw tf Ix Sx rx Iy Sy ry

Designation

(kg/m) (mm2) (mm) (mm) (mm) (mm) (x106 mm4) (x103 mm3) (mm) (x106 mm4) (x103 mm3) (mm)

W 460 X 177 177 22600 483 287 16.6 26.9 912 3790 201 105 736 68.3

X 158 158 20100 475 284 15.0 23.9 795 3340 199 91.6 646 67.6

X 144 144 18400 472 282 13.6 22.1 728 3080 199 83.7 592 67.3

X 128 128 16300 467 282 12.2 19.6 637 2720 197 72.8 518 66.8

X 113 113 14400 462 279 10.8 17.3 554 2390 196 63.3 452 66.3

X 106 106 13500 470 194 12.6 20.6 487 2080 191 25.1 259 43.2

X 97 97 12300 467 193 11.4 19.1 445 1920 190 22.8 236 42.9

X 89 89 11400 462 192 10.5 17.7 410 1770 190 20.9 218 42.7

X 82 82 10500 460 191 9.91 16.0 370 1610 188 18.7 195 42.4

X 74 74 9480 457 191 9.02 14.5 333 1460 187 16.7 175 41.9

X 68 68 8710 460 154 9.14 15.4 296 1290 184 9.37 122 32.8

X 60 60 7610 455 153 8.00 13.3 255 1120 183 7.95 104 32.3

X 52 52 6650 450 152 7.62 10.8 212 944 179 6.37 83.9 31.0

W 410 X 149 149 19000 432 264 14.9 25.0 620 2870 180 77.4 585 63.8

X 132 132 16900 427 264 13.3 22.2 541 2540 179 67.8 515 63.2

X 114 114 14600 419 262 11.6 19.3 462 2200 178 57.4 441 62.7

X 100 100 12600 414 259 10.0 16.9 397 1920 177 49.5 380 62.5

X 85 85 10800 417 181 10.9 18.2 316 1510 171 17.9 198 40.6

X 75 75 9480 414 180 9.65 16.0 274 1330 170 15.5 172 40.4

X 67 67 8580 409 179 8.76 14.4 244 1190 169 13.7 153 39.9

X 60 60 7610 406 178 7.75 12.8 216 1060 168 12.0 135 39.9

X 53 53 6840 404 178 7.49 10.9 186 926 165 10.2 115 38.6

X 46.1 46.1 5890 404 140 6.99 11.2 156 773 163 5.16 73.6 29.7

X 38.8 38.8 4950 399 140 6.35 8.76 125 629 159 3.99 57.2 28.4

W 360 X 1086 1090 139000 569 455 78.0 125 5950 21000 208 1960 8640 119

X 990 990 126000 549 450 71.9 115 5160 18800 203 1740 7730 117

X 900 900 115000 531 442 66.0 106 4500 17000 198 1530 6930 116

X 818 818 105000 513 437 60.5 97.0 3930 15300 194 1350 6190 114

X 744 744 94800 498 432 55.6 88.9 3420 13700 190 1200 5560 113

X 677 677 86500 483 427 51.3 81.5 2990 12400 186 1070 4980 111

X 634 634 80600 475 424 47.8 77.2 2750 11600 184 982 4640 110

X 592 592 75500 465 422 45.0 72.4 2500 10700 182 903 4290 109

X 551 551 70300 455 419 42.2 67.6 2260 9950 180 828 3950 108

X 509 509 65200 445 417 39.1 62.7 2040 9140 177 753 3620 108

X 463 463 59000 434 411 35.8 57.4 1800 8290 175 670 3260 107

X 421 421 53700 424 409 32.8 52.6 1600 7520 172 599 2930 106

X 382 382 48800 417 406 30.0 48.0 1420 6800 170 537 2640 105

X 347 347 44200 406 404 27.2 43.7 1250 6150 168 479 2380 104

Look for solutions, not excuses.

Mass A d bf tw tf Ix Sx rx Iy Sy ry

Designation

(kg/m) (mm2) (mm) (mm) (mm) (mm) (x106 mm4) (x103 mm3) (mm) (x106 mm4) (x103 mm3) (mm)

W 360 X 314 314 40000 399 401 24.9 39.6 1110 5540 166 429 2130 103

X 287 287 36600 394 399 22.6 36.6 999 5080 165 388 1950 103

X 262 262 33400 386 399 21.1 33.3 891 4600 163 349 1750 102

X 237 237 30100 381 396 18.9 30.2 791 4160 162 311 1580 102

X 216 216 27500 376 394 17.3 27.7 712 3800 161 282 1430 101

X 196 196 25000 373 373 16.4 26.2 637 3420 160 228 1220 95.5

X 179 179 22800 368 373 15.0 23.9 574 3110 158 206 1110 95.0

X 162 162 20600 363 371 13.3 21.8 516 2830 158 186 1000 94.7

X 147 147 18800 361 371 12.3 19.8 462 2570 157 167 905 94.2

X 134 134 17100 356 368 11.2 18.0 416 2340 156 151 818 94.0

X 122 122 15500 363 257 13.0 21.7 367 2020 154 61.6 480 63.0

X 110 110 14100 361 257 11.4 19.9 331 1840 153 55.8 436 63.0

X 101 101 12900 356 254 10.5 18.3 301 1690 153 50.4 397 62.5

X 91 91 11500 353 254 9.53 16.4 266 1510 152 44.5 352 62.2

X 79 79 10100 353 205 9.40 16.8 225 1270 150 24.0 234 48.8

X 72 72 9100 351 204 8.64 15.1 201 1150 149 21.4 210 48.5

X 64 64 8130 348 203 7.75 13.5 178 1030 148 18.8 185 48.0

X 57.8 57.8 7230 358 172 7.87 13.1 160 895 149 11.1 129 39.4

X 51 51 6450 356 171 7.24 11.6 142 796 148 9.70 113 38.9

X 44 44 5710 351 171 6.86 9.78 121 688 146 8.16 95.4 37.8

X 39 39 4960 353 128 6.48 10.7 102 578 144 3.71 58.2 27.4

X 32.9 32.9 4190 348 127 5.84 8.51 82.8 475 141 2.91 45.9 26.4

W 310 X 500 500 63800 427 340 45.2 75.2 1690 7910 163 495 2900 88.1

X 454 454 57700 414 335 41.4 68.8 1480 7130 160 437 2610 86.9

X 415 415 52800 404 333 38.9 62.7 1290 6440 156 390 2340 85.9

X 375 375 47800 391 330 35.6 57.2 1130 5780 154 345 2080 84.8

X 342 342 43700 384 328 32.8 52.6 1010 5260 152 309 1880 84.1

X 313 313 39900 373 325 30.0 48.3 891 4790 150 276 1700 83.3

X 283 283 36100 366 323 26.9 44.2 787 4310 148 245 1520 82.6

X 253 253 32300 356 320 24.4 39.6 687 3850 146 215 1350 81.8

X 226 226 28800 348 318 22.1 35.6 595 3420 144 189 1190 81.0

X 202 202 25700 340 315 20.1 31.8 516 3050 142 166 1050 80.3

X 179 179 22700 333 312 18.0 28.2 445 2670 140 144 918 79.5

X 158 158 20100 328 310 15.5 25.1 388 2380 139 125 808 79.0

X 143 143 18200 323 310 14.0 22.9 347 2150 138 112 728 78.5

X 129 129 16500 318 307 13.1 20.6 308 1930 137 100 651 78.0

X 117 117 15000 315 307 11.9 18.7 276 1750 136 89.9 587 77.5

X 107 107 13600 312 305 10.9 17.0 248 1600 135 81.2 531 77.2

Look for solutions, not excuses.

Mass A d bf tw tf Ix Sx rx Iy Sy ry

Designation

(kg/m) (mm2) (mm) (mm) (mm) (mm) (x106 mm4) (x103 mm3) (mm) (x106 mm4) (x103 mm3) (mm)

W 310 X 97 97 12300 307 305 9.91 15.4 222 1440 134 72.4 477 76.7

X 86 86 11000 310 254 9.14 16.3 198 1280 134 44.5 351 63.8

X 79 79 10100 307 254 8.76 14.6 177 1160 133 39.9 315 63.0

X 74 74 9420 310 205 9.40 16.3 163 1050 132 23.4 228 49.8

X 67 67 8450 307 204 8.51 14.6 145 946 131 20.8 203 49.5

X 60 60 7550 302 203 7.49 13.1 128 844 130 18.4 180 49.3

X 52 52 6650 318 167 7.62 13.2 119 747 133 10.2 122 39.1

X 44.5 44.5 5670 312 166 6.60 11.2 99.1 633 132 8.45 102 38.6

X 38.7 38.7 4940 310 165 5.84 9.65 84.9 547 131 7.20 87.5 38.4

X 32.7 32.7 4180 312 102 6.60 10.8 64.9 416 125 1.94 37.9 21.5

X 28.3 28.3 3590 310 102 5.97 8.89 54.1 349 122 1.57 30.8 20.9

X 23.8 23.8 3040 305 101 5.59 6.73 42.9 280 119 1.17 23.1 19.6

X 21 21 2680 302 101 5.08 5.72 36.9 244 117 0.982 19.5 19.1

W 250 X 167 167 21200 290 264 19.2 31.8 298 2060 118 98.2 742 68.1

X 149 149 18900 282 262 17.3 28.4 259 1840 117 86.2 655 67.3

X 131 131 16800 274 262 15.4 25.1 222 1610 115 74.5 570 66.8

X 115 115 14600 269 259 13.5 22.1 189 1410 114 64.1 493 66.0

X 101 101 12800 264 257 11.9 19.6 164 1240 113 55.8 433 65.8

X 89 89 11400 259 257 10.7 17.3 142 1090 112 48.3 377 65.3

X 80 80 10200 257 254 9.40 15.6 126 983 111 42.9 338 65.0

X 73 73 9290 254 254 8.64 14.2 113 895 110 38.9 306 64.5

X 67 67 8580 257 204 8.89 15.7 103 805 110 22.2 218 51.1

X 58 58 7420 252 203 8.00 13.5 87.0 690 108 18.7 185 50.3

X 49.1 49.1 6260 247 202 7.37 11.0 71.2 574 106 15.2 151 49.3

X 44.8 44.8 5700 267 148 7.62 13.0 70.8 531 111 6.95 94.2 34.8

X 38.5 38.5 4910 262 147 6.60 11.2 59.9 457 110 5.87 80.1 34.5

X 32.7 32.7 4190 259 146 6.10 9.14 49.1 380 108 4.75 65.1 33.8

X 28.4 28.4 3630 259 102 6.35 10.0 40.1 308 105 1.79 35.1 22.2

X 25.3 25.3 3220 257 102 6.10 8.38 34.1 265 103 1.48 29.2 21.5

X 22.3 22.3 2850 254 102 5.84 6.86 28.7 226 100 1.20 23.8 20.6

X 17.9 17.9 2280 251 101 4.83 5.33 22.4 179 99.1 0.907 18.0 19.9

W 200 X 100 100 12700 229 210 14.5 23.7 113 990 94.5 36.9 351 53.8

X 86 86 11000 222 209 13.0 20.6 94.9 852 92.7 31.3 300 53.3

X 71 71 9100 216 206 10.2 17.4 76.6 708 91.7 25.3 246 52.8

X 59 59 7550 210 205 9.14 14.2 60.8 582 89.7 20.4 200 51.8

X 52 52 6650 206 204 7.87 12.6 52.9 511 89.2 17.7 174 51.6

X 46.1 46.1 5890 203 203 7.24 11.0 45.8 451 88.1 15.4 152 51.3

X 41.7 41.7 5320 205 166 7.24 11.8 40.8 398 87.6 9.03 109 41.1

Look for solutions, not excuses.

Mass A d bf tw tf Ix Sx rx Iy Sy ry

Designation

(kg/m) (mm2) (mm) (mm) (mm) (mm) (x106 mm4) (x103 mm3) (mm) (x106 mm4) (x103 mm3) (mm)

W200 X 35.9 35.9 4570 201 165 6.22 10.2 34.4 342 86.9 7.62 92.3 40.9

X 31.3 31.3 3970 210 134 6.35 10.2 31.3 298 88.6 4.07 60.8 32.0

X 26.6 26.6 3390 207 133 5.84 8.38 25.8 249 87.1 3.32 49.8 31.2

X 22.5 22.5 2860 206 102 6.22 8.00 20.0 193 83.6 1.42 27.9 22.3

X 19.3 19.3 2480 203 102 5.84 6.48 16.5 162 81.5 1.14 22.5 21.4

X 15 15 1910 200 100 4.32 5.21 12.8 128 81.8 0.870 17.4 21.4

W150 X 37.1 37.1 4740 162 154 8.13 11.6 22.2 274 68.6 7.12 91.9 38.6

X 29.8 29.8 3790 157 153 6.60 9.27 17.2 220 67.6 5.54 72.3 38.1

X 22.5 22.5 2860 152 152 5.84 6.60 12.1 159 65.0 3.88 51.0 36.8

X 24 24 3060 160 102 6.60 10.3 13.4 167 66.0 1.84 36.1 24.6

X 18 18 2290 153 102 5.84 7.11 9.20 120 63.2 1.24 24.6 23.3

X 13.5 13.5 1730 150 100 4.32 5.46 6.83 91.1 62.7 0.916 18.2 23.0

X 13 13 1630 148 100 4.32 4.95 6.20 83.6 61.7 0.828 16.6 22.6

W130 X 28.1 28.1 3590 131 128 6.86 10.9 10.9 167 55.1 3.80 59.5 32.5

X 23.8 23.8 3040 127 127 6.10 9.14 8.91 140 54.1 3.13 49.2 32.0

W100 X 19.3 19.3 2470 106 103 7.11 8.76 4.70 89.5 43.7 1.61 31.1 25.4

Look for solutions, not excuses.

You might also like

- Bendy Light - The Evidence - The Wild HereticDocument18 pagesBendy Light - The Evidence - The Wild Hereticcarol espartanoNo ratings yet

- Beams: Mu Ø MNDocument12 pagesBeams: Mu Ø MNWalter CatapangNo ratings yet

- Geometrodynamics of Gauge Fields - On The Geometry of Yang-Mills and Gravitational Gauge Theories PDFDocument377 pagesGeometrodynamics of Gauge Fields - On The Geometry of Yang-Mills and Gravitational Gauge Theories PDFDennis Gerken100% (3)

- Strength of Materials-Moving LoadsDocument48 pagesStrength of Materials-Moving Loadscmrayos100% (4)

- Bending and Shear Stresses in BeamsDocument28 pagesBending and Shear Stresses in BeamsJusteen Barrientos Maningo100% (1)

- Aircraft Structural AnalysisDocument65 pagesAircraft Structural AnalysisSebastian CarterNo ratings yet

- Lecture # 6 Stresses in BeamsDocument44 pagesLecture # 6 Stresses in Beamsabcheema112No ratings yet

- Module 4 - BeamsDocument6 pagesModule 4 - Beamswag naNo ratings yet

- Me2003d Solid Mechanics - 16-11Document164 pagesMe2003d Solid Mechanics - 16-11Vidhya NairNo ratings yet

- Civ1501 Engineering Statics Semester 2, 2002: Beam BendingDocument9 pagesCiv1501 Engineering Statics Semester 2, 2002: Beam BendingHundeejireenyaNo ratings yet

- Module 1 StressDocument20 pagesModule 1 StressKylla Shane DuntonNo ratings yet

- Internal II Question Bank SOMDocument7 pagesInternal II Question Bank SOMsathyadallyNo ratings yet

- BCV 108 - Strength of Materials - Lectures 6&7-1Document49 pagesBCV 108 - Strength of Materials - Lectures 6&7-1kelvinkane005No ratings yet

- Bending of Beams SolleroDocument34 pagesBending of Beams SolleroPedroLemosNo ratings yet

- Shear ForceDocument9 pagesShear ForceMuhamed ZaimNo ratings yet

- Stresses in Beams: JU. Dr. Ibrahim Abu-AlshaikhDocument20 pagesStresses in Beams: JU. Dr. Ibrahim Abu-AlshaikhqusayNo ratings yet

- Unit-I Thin Plate Theory, Structural InstabilityDocument78 pagesUnit-I Thin Plate Theory, Structural InstabilityNirav LakhaniNo ratings yet

- 10 Stresses in BeamsDocument32 pages10 Stresses in BeamssephNo ratings yet

- ME1402A QB SomDocument5 pagesME1402A QB Somdeva290605No ratings yet

- Chapter 4-Part I - 2023Document70 pagesChapter 4-Part I - 2023mageba.artworldNo ratings yet

- Who Is Your God NowDocument65 pagesWho Is Your God NowTasos Kontaxoglou100% (1)

- Lecture 6 - Stresses in BeamsDocument57 pagesLecture 6 - Stresses in Beamssounohoney2000No ratings yet

- ES17-Stresses in BeamApril 4-6,2024Document25 pagesES17-Stresses in BeamApril 4-6,2024joseph joseNo ratings yet

- Lesson 3 SoADocument5 pagesLesson 3 SoAJaneccaNo ratings yet

- MOM Module 3Document24 pagesMOM Module 3Ramesh Reddy B TNo ratings yet

- Practise Problems Set06Document3 pagesPractise Problems Set06rohit kumarNo ratings yet

- 6 BeamsDocument116 pages6 BeamsIrish TambisNo ratings yet

- Ae2302 NolDocument42 pagesAe2302 NolShwetha BhatNo ratings yet

- Bending and Shear Stresses in BeamDocument20 pagesBending and Shear Stresses in BeamJiya ShindeNo ratings yet

- Design and Construction of A Structure For A Three Point Bending TestDocument13 pagesDesign and Construction of A Structure For A Three Point Bending TestIñigoNo ratings yet

- SOM Question BankDocument8 pagesSOM Question BankprakashmenmoliNo ratings yet

- Checklist 02 - Unit 02 - Bending StressDocument22 pagesChecklist 02 - Unit 02 - Bending StressRefai SayyadNo ratings yet

- QB114322 2013 RegulationDocument3 pagesQB114322 2013 RegulationiploguNo ratings yet

- Unit-II: Bending and Shear and Torsion of Thin Walled BeamsDocument63 pagesUnit-II: Bending and Shear and Torsion of Thin Walled BeamsSwethaNo ratings yet

- Chapter Three Bending and Shearing StressesDocument70 pagesChapter Three Bending and Shearing StressesYalem MesfinNo ratings yet

- Bsce Ces4 Lecture1-3Document17 pagesBsce Ces4 Lecture1-3Glenn SeoNo ratings yet

- Simple - Stress-Strain and TrussDocument131 pagesSimple - Stress-Strain and Trussdarshan100% (3)

- Diploma Strength of Materials 5th UnitDocument30 pagesDiploma Strength of Materials 5th UnitSuresh BalamNo ratings yet

- Som Unit I 2 & 16 MarksDocument7 pagesSom Unit I 2 & 16 MarksSurjith Bharathi SelvakumarNo ratings yet

- 075 - CE8301, CE6306 Strength of Materials I - Question BankDocument10 pages075 - CE8301, CE6306 Strength of Materials I - Question BankGERARD HAULENo ratings yet

- Limit, Fits and TolerancesDocument85 pagesLimit, Fits and TolerancesdankuNo ratings yet

- Deflection of Beam - 2sDocument19 pagesDeflection of Beam - 2sDave Harrison FloresNo ratings yet

- Aircraft Structure 1Document42 pagesAircraft Structure 1Vishnu Chemmanadu AravindNo ratings yet

- MODULE 1 Introduction and Simple Stresses 2Document10 pagesMODULE 1 Introduction and Simple Stresses 2Geri LazaroNo ratings yet

- Shear and Bending 23 - 08 - 2021Document9 pagesShear and Bending 23 - 08 - 2021cos thetaNo ratings yet

- QB114462Document8 pagesQB114462ILAYAPERUMAL KNo ratings yet

- Aircraft Structures - 2 Basic FieldDocument42 pagesAircraft Structures - 2 Basic FieldVenkat Athmanathan100% (1)

- Loadings and Concept of Normal StressDocument12 pagesLoadings and Concept of Normal StressG. Dancer Gh100% (1)

- Combined Stress Gate Notes 55Document6 pagesCombined Stress Gate Notes 55amosomwega21No ratings yet

- RC Design - ACIDocument41 pagesRC Design - ACIAbebe WoldeNo ratings yet

- Solid and Structural Mechanics Iv (Mechanical Engineering)Document34 pagesSolid and Structural Mechanics Iv (Mechanical Engineering)Vasda VinciNo ratings yet

- Questionbank SOM RejinpaulDocument13 pagesQuestionbank SOM Rejinpaularunmct04No ratings yet

- Unit 1Document8 pagesUnit 1harinathNo ratings yet

- Practise Problems Set05Document8 pagesPractise Problems Set05rohit kumarNo ratings yet

- DefinationDocument9 pagesDefinationvaradkadam1901No ratings yet

- Mech206 - 2014-15 Spring - l04 - Pure BendingDocument28 pagesMech206 - 2014-15 Spring - l04 - Pure BendingYazan HarbNo ratings yet

- Mos QBDocument15 pagesMos QBKarnalPreethNo ratings yet

- Instructions on Modern American Bridge BuildingFrom EverandInstructions on Modern American Bridge BuildingNo ratings yet

- Syllabus Content 2020-2021 (Term3) : Learning OutcomesDocument6 pagesSyllabus Content 2020-2021 (Term3) : Learning OutcomesЕлнур ИкимбаевNo ratings yet

- Polarization Tutorial SheetDocument1 pagePolarization Tutorial SheetalokguptamnnitNo ratings yet

- 02 Crystallography Problems and Question BankDocument7 pages02 Crystallography Problems and Question BankBhavesh Mhatre100% (2)

- DPP - Keam Crash Physics Electric Charges and Fields: N/C, F and E Are Along The Same Di-FDocument10 pagesDPP - Keam Crash Physics Electric Charges and Fields: N/C, F and E Are Along The Same Di-FZeroNo ratings yet

- Dual Nature of Radiation and Matter Classwork 2021Document4 pagesDual Nature of Radiation and Matter Classwork 2021Siddhesh KultheNo ratings yet

- Dr. Hazem Falah Sakeek: Modern Physics Is 20th Century PhysicsDocument12 pagesDr. Hazem Falah Sakeek: Modern Physics Is 20th Century PhysicsMohamed shabanaNo ratings yet

- Jitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetDocument25 pagesJitendra Hirwani: Problem Solving Techniques of Physical Chemistry For NeetabhishekNo ratings yet

- Physical Science Week 3Document9 pagesPhysical Science Week 3Rona Grace MartinezNo ratings yet

- Electromagnetic Signals: Engr. Mark Jefferson A. Arellano, Ect, VCP, RtaDocument52 pagesElectromagnetic Signals: Engr. Mark Jefferson A. Arellano, Ect, VCP, RtaMark ArrelanoNo ratings yet

- Lecture On Holography Method of CondmatphyDocument86 pagesLecture On Holography Method of Condmatphyatticus peinNo ratings yet

- Acoustic Metasurface With Hybrid ResonancesDocument6 pagesAcoustic Metasurface With Hybrid Resonancessriky19958084No ratings yet

- Yurth Y BiasandAngularity4Document11 pagesYurth Y BiasandAngularity4Lili BaloghNo ratings yet

- Free Vibration Part-A: Dynamics of MachineryDocument3 pagesFree Vibration Part-A: Dynamics of MachineryMonojit KonarNo ratings yet

- Introductory Functional Analysis With ApplicationsDocument14 pagesIntroductory Functional Analysis With ApplicationsAmir NazirNo ratings yet

- Fitjee Math 23Document14 pagesFitjee Math 23Aryan SoniNo ratings yet

- Lecture 1. Introduction To Various Analytical TechniquesDocument22 pagesLecture 1. Introduction To Various Analytical TechniquesMoiz AhmedNo ratings yet

- Velocity Kinematics PDFDocument24 pagesVelocity Kinematics PDFfayyaz khanNo ratings yet

- Conservation of Linear Momentum Online PHETDocument7 pagesConservation of Linear Momentum Online PHETArlene PenaNo ratings yet

- Annual Xi Sample Paper 22-23Document6 pagesAnnual Xi Sample Paper 22-23Cat ChanNo ratings yet

- 1-Concept of Stress and Strain PDFDocument29 pages1-Concept of Stress and Strain PDFMohamad Zaid83% (6)

- Premios NobelDocument3 pagesPremios NobelDanna Valentina Medina SanchezNo ratings yet

- CH 351 F07 SylDocument4 pagesCH 351 F07 SylLisaSeptianaNo ratings yet

- Question Bank For Advanced Mechanisms, I Sem, M.Tech, M.E.DDocument4 pagesQuestion Bank For Advanced Mechanisms, I Sem, M.Tech, M.E.Dvivek dongareNo ratings yet

- Path Integrals, Density Matrices, and Information Flow With Closed Timelike CurvesDocument25 pagesPath Integrals, Density Matrices, and Information Flow With Closed Timelike CurvesChandra PrakashNo ratings yet

- DR SH GR 12 Chapter 1 To PrintDocument9 pagesDR SH GR 12 Chapter 1 To PrintEvelyn Kate MCANo ratings yet

- Module 2 Unit 4 EnggchemDocument8 pagesModule 2 Unit 4 EnggchemKazuto KirigayaNo ratings yet

- Met Glossary 1963 PDFDocument327 pagesMet Glossary 1963 PDFjavier albaNo ratings yet

- Adobe Scan Dec 19, 2022Document1 pageAdobe Scan Dec 19, 2022Vicky VickyNo ratings yet