Professional Documents

Culture Documents

Sample Wps Carbon Steel GTAW SMAW PDF

Sample Wps Carbon Steel GTAW SMAW PDF

Uploaded by

irwanCopyright:

Available Formats

You might also like

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad Bilal100% (1)

- WPS Reg Rev.0Document3 pagesWPS Reg Rev.0Ed FangNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Calified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Document11 pagesCalified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Costin RotaruNo ratings yet

- QW-483 (Red) PQR No.: Tme 358Document1 pageQW-483 (Red) PQR No.: Tme 358Sudhir KotkarNo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- 610X610X62 MM HSR Formate MasterDocument4 pages610X610X62 MM HSR Formate MasterQUALITYNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessNo ratings yet

- Inspection and Quality Control in ManufacturingDocument598 pagesInspection and Quality Control in Manufacturingsaeed.pdNo ratings yet

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDocument4 pages177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- Book 1Document6 pagesBook 1QUALITYNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- WPS 1.1Document1 pageWPS 1.1Juan Diego Carvajal100% (1)

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Golden Joint ChecklistDocument2 pagesGolden Joint ChecklistMohd Effiezool YaserNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- Weder Qualification Test Certificates-Part 2Document7 pagesWeder Qualification Test Certificates-Part 2Avijit DebnathNo ratings yet

- Alishar SP 2Document84 pagesAlishar SP 2Alam MD SazidNo ratings yet

- WPS - 004Document12 pagesWPS - 004MAT-LIONNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- Editable AWS D1.1 WPSDocument2 pagesEditable AWS D1.1 WPSSheik Mohamed100% (1)

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- List of WeldersDocument3 pagesList of Welderskumaraswamy.kNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pages1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- 316L CRO - SAW Study - Final ReportDocument24 pages316L CRO - SAW Study - Final ReportAshley JacksonNo ratings yet

- Welder I.D CardDocument2 pagesWelder I.D Cardvhung TranNo ratings yet

- UDocument1 pageUmohd as shahiddin jafriNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- OC-1-1-FCAW-1 Rev 0 PDFDocument4 pagesOC-1-1-FCAW-1 Rev 0 PDFDario100% (1)

- 26.WPS Log CoilDocument1 page26.WPS Log CoilAvishek GuptaNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- 4422-VW-SG-001000000001 - B3-Painting & CoatingDocument203 pages4422-VW-SG-001000000001 - B3-Painting & CoatingPaul NieNo ratings yet

- Course Module 4Document6 pagesCourse Module 4Makise AghataNo ratings yet

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- Form - Overtime Work Status and Detail - Rev1Document2 pagesForm - Overtime Work Status and Detail - Rev1irwanNo ratings yet

- Aconex - Document WPSDocument2 pagesAconex - Document WPSirwanNo ratings yet

- Form - Overtime Work Before 23-24 July 2022xDocument2 pagesForm - Overtime Work Before 23-24 July 2022xirwanNo ratings yet

- Aconex NDE Map D 167 01Document2 pagesAconex NDE Map D 167 01irwanNo ratings yet

- Client: Supplier: Location: Sheet: Item: Large Size Gear BoxDocument1 pageClient: Supplier: Location: Sheet: Item: Large Size Gear BoxirwanNo ratings yet

- Black 2.0 Magnetic Particle Testing YokeDocument2 pagesBlack 2.0 Magnetic Particle Testing YokeirwanNo ratings yet

- Form-Und Lagetoleranzen e PDFDocument1 pageForm-Und Lagetoleranzen e PDFirwanNo ratings yet

- Daftar Kode Kesalahan Canon IR5000 IR6000Document26 pagesDaftar Kode Kesalahan Canon IR5000 IR6000desy zulfiarniNo ratings yet

- Wacker g50 Operation Manual 0162089en - 008Document92 pagesWacker g50 Operation Manual 0162089en - 008Carlos Alberto Ramirez ParraNo ratings yet

- Investigation Into Transient SFO FFO VFTDocument7 pagesInvestigation Into Transient SFO FFO VFTJosNo ratings yet

- Capacitor Bank Switching With Vacuum Circuit Breakers - Schneider Electric PDFDocument5 pagesCapacitor Bank Switching With Vacuum Circuit Breakers - Schneider Electric PDFpitambervermaNo ratings yet

- Analog Assignment ADVDDocument24 pagesAnalog Assignment ADVDRajeevDuttNo ratings yet

- ELG3311: Solutions For Assignment 1: Problem 2-6Document14 pagesELG3311: Solutions For Assignment 1: Problem 2-6tesfayregs gebretsadik100% (1)

- Lecture On Scmitt - TriggerDocument17 pagesLecture On Scmitt - TriggerNakib AhsanNo ratings yet

- Sony Fda-Ev1s Ver.1.0 SMDocument8 pagesSony Fda-Ev1s Ver.1.0 SMGiovanni PuperiNo ratings yet

- Service Manual - Compaq, LG Monitor - CQ771G, S7500, MV7500, CV7500 - Chassis CA-110Document34 pagesService Manual - Compaq, LG Monitor - CQ771G, S7500, MV7500, CV7500 - Chassis CA-110Luis TavisNo ratings yet

- MacSpice - User's Guide (TOC)Document5 pagesMacSpice - User's Guide (TOC)Lee RickHunter0% (1)

- DANA ECON.a Error Code List - Production Firmware 4.5Document30 pagesDANA ECON.a Error Code List - Production Firmware 4.5Mustafa Tam100% (3)

- Interfacing 7 Segment Display and LCDDocument35 pagesInterfacing 7 Segment Display and LCDYupniatsNo ratings yet

- On Kron's DiakopticsDocument5 pagesOn Kron's Diakopticsr_berthetNo ratings yet

- Data Sheet 6ES7138-4DA04-0AB0: Supply VoltageDocument3 pagesData Sheet 6ES7138-4DA04-0AB0: Supply VoltageLuis Gustavo FernandesNo ratings yet

- CH 11Document43 pagesCH 11Cumali Türkeri100% (1)

- WAEC PHYSICS SyllabusDocument59 pagesWAEC PHYSICS SyllabusSani MubarakNo ratings yet

- Voltage Dividers and Current DividersDocument24 pagesVoltage Dividers and Current DividersRon Rex100% (1)

- Gpwii - Pii - 160FDocument2 pagesGpwii - Pii - 160FashokghtNo ratings yet

- Antenna Analysis and Design in MATLAB: Koneru Lakshmaiah Education FoundationDocument33 pagesAntenna Analysis and Design in MATLAB: Koneru Lakshmaiah Education FoundationMalli Karjuna Reddy Gongati100% (1)

- Design and Development of Three Phase Shunt Active Filter With Balanced and Unbalanced SupplyDocument18 pagesDesign and Development of Three Phase Shunt Active Filter With Balanced and Unbalanced SupplyKush DewanganNo ratings yet

- Amperes LawDocument59 pagesAmperes LawFrancis FigoNo ratings yet

- Substations-Pdf Parte2 PDFDocument76 pagesSubstations-Pdf Parte2 PDFCopr'esunaestafa EditorialdemierdaNo ratings yet

- Standard Makes For Electrical EquipmentsDocument3 pagesStandard Makes For Electrical EquipmentsJignesh Parmar100% (1)

- PM Recomendation For RepairDocument1 pagePM Recomendation For RepairEriko SepacioNo ratings yet

- Balun InstallationDocument18 pagesBalun Installationdorin serbanNo ratings yet

- 5 Amp Current TransformerDocument1 page5 Amp Current TransformerDarvin VargheseNo ratings yet

- Aselco Itb 2021apr08Document2 pagesAselco Itb 2021apr08Edsel Alfred OtaoNo ratings yet

- Questions and Answers For PSPD (Part 1)Document16 pagesQuestions and Answers For PSPD (Part 1)Electrical EngineersNo ratings yet

- IC-706MK2G Service ManualDocument85 pagesIC-706MK2G Service Manualtomasbacklund100% (1)

- Variador Carlo GavazziDocument107 pagesVariador Carlo GavazziPepe ChampiiNo ratings yet

Sample Wps Carbon Steel GTAW SMAW PDF

Sample Wps Carbon Steel GTAW SMAW PDF

Uploaded by

irwanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample Wps Carbon Steel GTAW SMAW PDF

Sample Wps Carbon Steel GTAW SMAW PDF

Uploaded by

irwanCopyright:

Available Formats

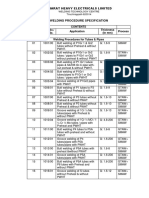

QW-482 WELDING PROCEDURE SPECIFICATION

WPS NO- Sample 02 Date- Supporting PQR No-

Revision-00

Welding Process-SMAW+GTAW Type-Manual

JOINTS (QW-402)

Joint Design : As per apporoved Drawing (groove/fillet) (please refer drawing)

Backing (Yes):for double side and backing strip groove welds

(No) for single side groove welds

Baking Material (Type) : Base metal / Weld Metal

Metal :Yes Non fusing Metal-No

BASE METALS (QW-403)

P.No:1 Group NO 1&2 TO P.No:1 Group NO 1&2

THICKNESS RANGE

Base Metal: Groove: 4.8 mm to 24 mm Fillet : all size

Pipe diameter Range: Groove : all diameter Fillet : all size

OTHERS

Root spacing for backing strip joint :8-10 mm

Root spacing for others:1 to 2 mm

Filler Metal (QW-404)

GTAW SMAW

Spec No.(SFA) 5.18 5.1

AWS NO (CLASS) ER-70S2 E-7018

F.No 6 4

A.No- 1 1

Size of Filler Metals Ø 2.4 Ø 3.15,4.0,5.0

Deposited Weld Metal

Thickness Range:Groove 4mm Max 20 mm Max

:Fillet All size All size

Electrode Flux (Class) NA Basic

Consumable Insert No No

Maximum Bead Thickness 3 mm 5 mm

page :1 of 2

POSITION (QW-405)

Position(s): Groove: All Positions

Welding Progression : for verticle -up hill progression

Position(s): Fillet:All

POST WELD HEAT TREATMENT (QW-407)

NA

PREHEAT (QW-406)

Pre Heat Temp Min : Nil

Interpass Temptrature : 350°C

SHILDING/BACKING GAS (QW-408)

Shielding gas: Argon Trailing : NA Closed Chamber: No

Flow Rate :6 - 10 LPM Backing : NA

TECHNIQUE-(QW-410)

Stringn Or Weave Bead : String & Weave Bead

Intial & interpass Cleaning : chipping:brushing,grinding

Method of Back chipping/gouging: By air arc goging,grinding

Weld Pass: Single Pass/ Multi Pass

Multiple Or single Electrode: Single

Clean weld area to remove oil,rust,grease, etc prior to weld

ELECTRICAL CHARATERISTICS (QW-409)

Current :AC or DC Amps Range-80 to 240 A

Direc Current Voltage Range:12-22 V -GTAW

Polarity :GTAW-DCEN :22-32 V-SMAW

:SMAW-DCEP Tungten Electrode Size & Type :Ø 2.4 mm,2% Thoriated

Pulsing :No

Weld Layer(s) Process Filler Metal Class Current

Root GTAW ER-70S2. Ø2.4 80-120 A DCEN

Subsequent layer SMAW E-7018. Ø 3.15 80-140 A DCEP

Subsequent layer SMAW E-7018. Ø 4.0 140-180 A DCEP

Subsequent layer SMAW E-7018. Ø 5.0 180-240 A DCEP

Subsequent layer SMAW E-7018. Ø 6.3 240-300 A DCEP

Page 2 of 2

You might also like

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- WPS-CS-113 Rev.1Document2 pagesWPS-CS-113 Rev.1Muhammad Bilal100% (1)

- WPS Reg Rev.0Document3 pagesWPS Reg Rev.0Ed FangNo ratings yet

- JTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackDocument19 pagesJTS Series High Speed Bevel Gear Screw Jack, Bevel Gear Driven Screw Jack, Bevel Gearbox Jack, Bevel Screw Jack Travel Speed, Screw Jack Bevel, Jack Screw Bevel Gearbox, Quick Lifting Screw JackWarren LeeNo ratings yet

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium WeldingMohammed MusaNo ratings yet

- WPS GTAW-SMAW h1Document1 pageWPS GTAW-SMAW h1Jesus Gabrielw Blanco GhostbustersIzNo ratings yet

- Template BUTTDocument1 pageTemplate BUTTDylan TriggNo ratings yet

- Calified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Document11 pagesCalified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Costin RotaruNo ratings yet

- QW-483 (Red) PQR No.: Tme 358Document1 pageQW-483 (Red) PQR No.: Tme 358Sudhir KotkarNo ratings yet

- Sa 516 WPQDocument1 pageSa 516 WPQElgen IgloriaNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- 610X610X62 MM HSR Formate MasterDocument4 pages610X610X62 MM HSR Formate MasterQUALITYNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- Welding SAF2205 Tubes To CS TubesheetDocument2 pagesWelding SAF2205 Tubes To CS Tubesheetmasterdol1983No ratings yet

- SMAW DuniDocument4 pagesSMAW DuniMuhammad Fitransyah Syamsuar PutraNo ratings yet

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessNo ratings yet

- Inspection and Quality Control in ManufacturingDocument598 pagesInspection and Quality Control in Manufacturingsaeed.pdNo ratings yet

- 177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQDocument4 pages177-Gmaw-Zug-Asme (Asep Wahyudi-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 pagesCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONNo ratings yet

- TopCoreBelco 101 FCDocument9 pagesTopCoreBelco 101 FCCesar ArellanoNo ratings yet

- Book 1Document6 pagesBook 1QUALITYNo ratings yet

- Supercito (E 42 5 B 32 h5)Document1 pageSupercito (E 42 5 B 32 h5)brunizzaNo ratings yet

- WPS 1.1Document1 pageWPS 1.1Juan Diego Carvajal100% (1)

- WPS PQR 12 PDFDocument9 pagesWPS PQR 12 PDFVinay YadavNo ratings yet

- CSM-QR-02-2, Medical Gas BPS TablesDocument8 pagesCSM-QR-02-2, Medical Gas BPS TablesaadmaadmNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- Manual Joints (QW - 402) : Page 1 of 12Document12 pagesManual Joints (QW - 402) : Page 1 of 12miteshpatel191No ratings yet

- Golden Joint ChecklistDocument2 pagesGolden Joint ChecklistMohd Effiezool YaserNo ratings yet

- Indt QCP RT HJ 05NDocument14 pagesIndt QCP RT HJ 05NAsad Bin Ala QatariNo ratings yet

- Weder Qualification Test Certificates-Part 2Document7 pagesWeder Qualification Test Certificates-Part 2Avijit DebnathNo ratings yet

- Alishar SP 2Document84 pagesAlishar SP 2Alam MD SazidNo ratings yet

- WPS - 004Document12 pagesWPS - 004MAT-LIONNo ratings yet

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- Editable AWS D1.1 WPSDocument2 pagesEditable AWS D1.1 WPSSheik Mohamed100% (1)

- Wps Mma PipeDocument2 pagesWps Mma PipeDimitris NikouNo ratings yet

- List of WeldersDocument3 pagesList of Welderskumaraswamy.kNo ratings yet

- WPS Qualify To DNV-OS-C401 - SampleDocument12 pagesWPS Qualify To DNV-OS-C401 - SampleBien NguyenDuyNo ratings yet

- QW-484A (WPQ) GTAW 4MM FilletDocument2 pagesQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 pagesSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieNo ratings yet

- WPS SampleDocument182 pagesWPS Sampleaymenfr23No ratings yet

- Hust WPS Gtaw - Smaw 6GDocument4 pagesHust WPS Gtaw - Smaw 6GtruongtrungplhdNo ratings yet

- 1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Document2 pages1036330-23-350 Al 465 BX Nam Smaw+fcaw Iso 9606 CS 6G (H-L045)Nguyen Thanh Binh0% (1)

- 316L CRO - SAW Study - Final ReportDocument24 pages316L CRO - SAW Study - Final ReportAshley JacksonNo ratings yet

- Welder I.D CardDocument2 pagesWelder I.D Cardvhung TranNo ratings yet

- UDocument1 pageUmohd as shahiddin jafriNo ratings yet

- Graycor WPS 19 SampleDocument5 pagesGraycor WPS 19 SampleRaul SebastiamNo ratings yet

- P. WpsDocument14 pagesP. WpsIsmiArdyNo ratings yet

- OC-1-1-FCAW-1 Rev 0 PDFDocument4 pagesOC-1-1-FCAW-1 Rev 0 PDFDario100% (1)

- 26.WPS Log CoilDocument1 page26.WPS Log CoilAvishek GuptaNo ratings yet

- Gta+sma PQRDocument3 pagesGta+sma PQRRahul MoottolikandyNo ratings yet

- Welding Procedure Welding Procedure Specification SpecificationDocument2 pagesWelding Procedure Welding Procedure Specification SpecificationHamid MansouriNo ratings yet

- 4422-VW-SG-001000000001 - B3-Painting & CoatingDocument203 pages4422-VW-SG-001000000001 - B3-Painting & CoatingPaul NieNo ratings yet

- Course Module 4Document6 pagesCourse Module 4Makise AghataNo ratings yet

- 121 T BW FPDocument4 pages121 T BW FPA. ΒρατσισταNo ratings yet

- Qw-482 Welding Procedure SpecificationDocument2 pagesQw-482 Welding Procedure SpecificationAmanSharmaNo ratings yet

- Nit 2019 20 56 Wps 1569579575Document16 pagesNit 2019 20 56 Wps 1569579575vijayachiduNo ratings yet

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- Form - Overtime Work Status and Detail - Rev1Document2 pagesForm - Overtime Work Status and Detail - Rev1irwanNo ratings yet

- Aconex - Document WPSDocument2 pagesAconex - Document WPSirwanNo ratings yet

- Form - Overtime Work Before 23-24 July 2022xDocument2 pagesForm - Overtime Work Before 23-24 July 2022xirwanNo ratings yet

- Aconex NDE Map D 167 01Document2 pagesAconex NDE Map D 167 01irwanNo ratings yet

- Client: Supplier: Location: Sheet: Item: Large Size Gear BoxDocument1 pageClient: Supplier: Location: Sheet: Item: Large Size Gear BoxirwanNo ratings yet

- Black 2.0 Magnetic Particle Testing YokeDocument2 pagesBlack 2.0 Magnetic Particle Testing YokeirwanNo ratings yet

- Form-Und Lagetoleranzen e PDFDocument1 pageForm-Und Lagetoleranzen e PDFirwanNo ratings yet

- Daftar Kode Kesalahan Canon IR5000 IR6000Document26 pagesDaftar Kode Kesalahan Canon IR5000 IR6000desy zulfiarniNo ratings yet

- Wacker g50 Operation Manual 0162089en - 008Document92 pagesWacker g50 Operation Manual 0162089en - 008Carlos Alberto Ramirez ParraNo ratings yet

- Investigation Into Transient SFO FFO VFTDocument7 pagesInvestigation Into Transient SFO FFO VFTJosNo ratings yet

- Capacitor Bank Switching With Vacuum Circuit Breakers - Schneider Electric PDFDocument5 pagesCapacitor Bank Switching With Vacuum Circuit Breakers - Schneider Electric PDFpitambervermaNo ratings yet

- Analog Assignment ADVDDocument24 pagesAnalog Assignment ADVDRajeevDuttNo ratings yet

- ELG3311: Solutions For Assignment 1: Problem 2-6Document14 pagesELG3311: Solutions For Assignment 1: Problem 2-6tesfayregs gebretsadik100% (1)

- Lecture On Scmitt - TriggerDocument17 pagesLecture On Scmitt - TriggerNakib AhsanNo ratings yet

- Sony Fda-Ev1s Ver.1.0 SMDocument8 pagesSony Fda-Ev1s Ver.1.0 SMGiovanni PuperiNo ratings yet

- Service Manual - Compaq, LG Monitor - CQ771G, S7500, MV7500, CV7500 - Chassis CA-110Document34 pagesService Manual - Compaq, LG Monitor - CQ771G, S7500, MV7500, CV7500 - Chassis CA-110Luis TavisNo ratings yet

- MacSpice - User's Guide (TOC)Document5 pagesMacSpice - User's Guide (TOC)Lee RickHunter0% (1)

- DANA ECON.a Error Code List - Production Firmware 4.5Document30 pagesDANA ECON.a Error Code List - Production Firmware 4.5Mustafa Tam100% (3)

- Interfacing 7 Segment Display and LCDDocument35 pagesInterfacing 7 Segment Display and LCDYupniatsNo ratings yet

- On Kron's DiakopticsDocument5 pagesOn Kron's Diakopticsr_berthetNo ratings yet

- Data Sheet 6ES7138-4DA04-0AB0: Supply VoltageDocument3 pagesData Sheet 6ES7138-4DA04-0AB0: Supply VoltageLuis Gustavo FernandesNo ratings yet

- CH 11Document43 pagesCH 11Cumali Türkeri100% (1)

- WAEC PHYSICS SyllabusDocument59 pagesWAEC PHYSICS SyllabusSani MubarakNo ratings yet

- Voltage Dividers and Current DividersDocument24 pagesVoltage Dividers and Current DividersRon Rex100% (1)

- Gpwii - Pii - 160FDocument2 pagesGpwii - Pii - 160FashokghtNo ratings yet

- Antenna Analysis and Design in MATLAB: Koneru Lakshmaiah Education FoundationDocument33 pagesAntenna Analysis and Design in MATLAB: Koneru Lakshmaiah Education FoundationMalli Karjuna Reddy Gongati100% (1)

- Design and Development of Three Phase Shunt Active Filter With Balanced and Unbalanced SupplyDocument18 pagesDesign and Development of Three Phase Shunt Active Filter With Balanced and Unbalanced SupplyKush DewanganNo ratings yet

- Amperes LawDocument59 pagesAmperes LawFrancis FigoNo ratings yet

- Substations-Pdf Parte2 PDFDocument76 pagesSubstations-Pdf Parte2 PDFCopr'esunaestafa EditorialdemierdaNo ratings yet

- Standard Makes For Electrical EquipmentsDocument3 pagesStandard Makes For Electrical EquipmentsJignesh Parmar100% (1)

- PM Recomendation For RepairDocument1 pagePM Recomendation For RepairEriko SepacioNo ratings yet

- Balun InstallationDocument18 pagesBalun Installationdorin serbanNo ratings yet

- 5 Amp Current TransformerDocument1 page5 Amp Current TransformerDarvin VargheseNo ratings yet

- Aselco Itb 2021apr08Document2 pagesAselco Itb 2021apr08Edsel Alfred OtaoNo ratings yet

- Questions and Answers For PSPD (Part 1)Document16 pagesQuestions and Answers For PSPD (Part 1)Electrical EngineersNo ratings yet

- IC-706MK2G Service ManualDocument85 pagesIC-706MK2G Service Manualtomasbacklund100% (1)

- Variador Carlo GavazziDocument107 pagesVariador Carlo GavazziPepe ChampiiNo ratings yet