Professional Documents

Culture Documents

MS Villagio Polyurea Metalex-SIKA-709

MS Villagio Polyurea Metalex-SIKA-709

Uploaded by

souravrobinCopyright:

Available Formats

You might also like

- MS - Demolition of Concrete SlabDocument7 pagesMS - Demolition of Concrete Slabzizojundi83% (6)

- Method Statement For FormworkDocument8 pagesMethod Statement For FormworkEng hassan hussienNo ratings yet

- Swift TS06E Risk AssessmentDocument9 pagesSwift TS06E Risk AssessmentsouravrobinNo ratings yet

- Method Statement For Erection of PanelDocument13 pagesMethod Statement For Erection of PanelNadeem Afzal100% (1)

- Method Statement Demolison and Site ClearanceDocument7 pagesMethod Statement Demolison and Site ClearanceSasi Kumar100% (3)

- 1.method Statement - Aboveground Drainage PipeDocument11 pages1.method Statement - Aboveground Drainage Pipesarmad spectrumNo ratings yet

- 1.method Statement - INSTALLATION OF WATER SUPPLY PIPES & FITTINGSDocument16 pages1.method Statement - INSTALLATION OF WATER SUPPLY PIPES & FITTINGSsarmad spectrumNo ratings yet

- 05 Method of Statment - Duct Insulation - PSDocument11 pages05 Method of Statment - Duct Insulation - PSUnique PlanningNo ratings yet

- 4293 Dgtyp 1 19 0003 ADocument10 pages4293 Dgtyp 1 19 0003 ARajarajan RajaNo ratings yet

- 1 - Method Statement For Sika WaterproofingDocument6 pages1 - Method Statement For Sika WaterproofingAyda JohariNo ratings yet

- Method Statement For Installation of Electrical DB, SMDB and MDB PanelboardsDocument6 pagesMethod Statement For Installation of Electrical DB, SMDB and MDB Panelboardsnidhinm92No ratings yet

- Method Statement For Installation of Electrical DB, SMDB and MDB PanelboardsDocument6 pagesMethod Statement For Installation of Electrical DB, SMDB and MDB Panelboardsnidhinm92No ratings yet

- Method Statement - Grading WorksDocument14 pagesMethod Statement - Grading Worksrehanapple3863No ratings yet

- Method Statement For Installation of Earthing System: South Plage at The Pearl Qatar InfrastructureDocument23 pagesMethod Statement For Installation of Earthing System: South Plage at The Pearl Qatar InfrastructureMariam Awad100% (2)

- Method of Statement HDDDocument12 pagesMethod of Statement HDDSyed FaizNo ratings yet

- Method Statement and Risk Assessment For Basement Waterproofing WorksDocument30 pagesMethod Statement and Risk Assessment For Basement Waterproofing WorksVishaul RamanNo ratings yet

- MS Field Instrument InstallationDocument11 pagesMS Field Instrument InstallationMohammad Fazal KhanNo ratings yet

- Method Statement For Installation of DBsDocument11 pagesMethod Statement For Installation of DBstristan guarinoNo ratings yet

- MS For Installation of LP System - LatestDocument8 pagesMS For Installation of LP System - Latestمقاول تكييف كهرباء وصحيNo ratings yet

- MS-21 For Fiberglass InsulationDocument9 pagesMS-21 For Fiberglass InsulationAlaa AliNo ratings yet

- Method Statement For LPG DismantlingDocument8 pagesMethod Statement For LPG DismantlingHusain abidiNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Underground Domestic Water Pipe Installation (r.1)Document34 pagesCgk063-Rfa-mos-m-xxx - Underground Domestic Water Pipe Installation (r.1)diki anggriawanNo ratings yet

- Method Statement For Testing of Fire Detection and Alarm SystemDocument17 pagesMethod Statement For Testing of Fire Detection and Alarm Systemjimmuel mendozaNo ratings yet

- 1.method Statement - INSTALLATION OF GRP WATER TANKSDocument11 pages1.method Statement - INSTALLATION OF GRP WATER TANKSsarmad spectrumNo ratings yet

- Lps 01 Hti MST El 005 Point WiringDocument22 pagesLps 01 Hti MST El 005 Point WiringJomy JohnyNo ratings yet

- Method Statement For Installation of Electrical DBDocument6 pagesMethod Statement For Installation of Electrical DBsamsungloverNo ratings yet

- Method Statement For Backfilling and Compaction ProcedureDocument22 pagesMethod Statement For Backfilling and Compaction ProcedureAlbertyNo ratings yet

- Method Statement Anti Termite r2 MRTDocument10 pagesMethod Statement Anti Termite r2 MRTKeristiyantoNo ratings yet

- Method Statement: Underground Waterproofing Using Hdpe Waterproofing System From FosrocDocument10 pagesMethod Statement: Underground Waterproofing Using Hdpe Waterproofing System From Fosrocdindo lauronNo ratings yet

- Bitumen Painting MOSDocument10 pagesBitumen Painting MOSebrahimlinda25619No ratings yet

- Constr-001 Method Statements DATA PANEL INSTALLATIONDocument13 pagesConstr-001 Method Statements DATA PANEL INSTALLATIONprestbussNo ratings yet

- ESP Installation Scheme PLTU Jeranjang 1x25 MWDocument30 pagesESP Installation Scheme PLTU Jeranjang 1x25 MWzaky rahmanNo ratings yet

- Method Statement For Testing of Lighting and Small Power SystemDocument14 pagesMethod Statement For Testing of Lighting and Small Power Systemjimmuel mendozaNo ratings yet

- Method Statement For Pile Head TreatmentDocument7 pagesMethod Statement For Pile Head TreatmentJoe Ps100% (1)

- Method Statement For Chipping Works-CCTV and ACS DevicesDocument4 pagesMethod Statement For Chipping Works-CCTV and ACS DevicesHannah San JuanNo ratings yet

- Msra For GRP Piping Installtion in Ro Plant: AE004-S3TU-MS-0002Document71 pagesMsra For GRP Piping Installtion in Ro Plant: AE004-S3TU-MS-0002adnan hanifNo ratings yet

- Method Statement For Installation & Testing of Underground Drainage PipingDocument18 pagesMethod Statement For Installation & Testing of Underground Drainage PipingMohammed Mostafa El HaddadNo ratings yet

- Bauer - Method of Statement For Glass Wall PartitionDocument8 pagesBauer - Method of Statement For Glass Wall PartitionGeorge VitacionNo ratings yet

- Method Statement For PCC Pouring, Waterproofing & ScreedDocument9 pagesMethod Statement For PCC Pouring, Waterproofing & ScreedJoe PsNo ratings yet

- Pipes Cladding and Insullations MSDocument8 pagesPipes Cladding and Insullations MSahmadNo ratings yet

- Lps-01-Hti-Mst-Me-024 - Fan Coil UnitDocument12 pagesLps-01-Hti-Mst-Me-024 - Fan Coil UnitJomy JohnyNo ratings yet

- MS-001 - Trial TrenchesDocument5 pagesMS-001 - Trial Trenchesgeriaxavier2022No ratings yet

- Cgk063-Rfa-Mos-M-Xxx - Refrigerant & Condensate Pipe InstallationDocument31 pagesCgk063-Rfa-Mos-M-Xxx - Refrigerant & Condensate Pipe Installationdiki anggriawanNo ratings yet

- Cgk063 Rfa Mos M XXX - Fire Hydrant Underground Pipe InstallationDocument31 pagesCgk063 Rfa Mos M XXX - Fire Hydrant Underground Pipe Installationdiki anggriawanNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)Document39 pagesCgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)diki anggriawanNo ratings yet

- MS 05Document21 pagesMS 05unnicyriacNo ratings yet

- MS For Fabrication of Steel GirderDocument19 pagesMS For Fabrication of Steel GirderAjit Kumar LakshmiNo ratings yet

- Method Statement For Grounding and Lighting Protection.Document11 pagesMethod Statement For Grounding and Lighting Protection.Praveen KumarNo ratings yet

- MP2019 186 Mec 002Document17 pagesMP2019 186 Mec 002puwe qiheNo ratings yet

- Lean Concrete MOSDocument9 pagesLean Concrete MOSebrahimlinda25619No ratings yet

- Mof For Fiber Optic CableDocument14 pagesMof For Fiber Optic Cableabd masoudNo ratings yet

- Mos Concrete Air Viods RepairDocument9 pagesMos Concrete Air Viods RepairKhaledNo ratings yet

- Method Statement For Installation of Cable Tray or TrunkingDocument9 pagesMethod Statement For Installation of Cable Tray or TrunkingEmmanuel TamayoNo ratings yet

- METHOD STATEMENT - Strengthening of Steel Beams of Brood Stock Building B-3 - Copy (AutoRecovered)Document18 pagesMETHOD STATEMENT - Strengthening of Steel Beams of Brood Stock Building B-3 - Copy (AutoRecovered)Nafees AhmadNo ratings yet

- Form J - Item 4 - Quality Control PlanDocument10 pagesForm J - Item 4 - Quality Control PlanBALARISI ENGINEERNo ratings yet

- Pipelayer (R1)Document12 pagesPipelayer (R1)zandro padillaNo ratings yet

- Method Statement For Continuity and Earth Resistance TestDocument10 pagesMethod Statement For Continuity and Earth Resistance Testjimmuel mendozaNo ratings yet

- 4293 Dgtyp 1 19 0012 ADocument12 pages4293 Dgtyp 1 19 0012 ARajarajan RajaNo ratings yet

- 04 Method of Statment - Chilled Water Pipe Insulation - PSDocument12 pages04 Method of Statment - Chilled Water Pipe Insulation - PSUnique PlanningNo ratings yet

- Assurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveFrom EverandAssurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveNo ratings yet

- Guarantee FormatDocument1 pageGuarantee FormatsouravrobinNo ratings yet

- Column DetailsDocument1 pageColumn DetailssouravrobinNo ratings yet

- MTC IMS FO 14A Monthly Safety ReportDocument7 pagesMTC IMS FO 14A Monthly Safety ReportsouravrobinNo ratings yet

- FIS V PlusDocument10 pagesFIS V PlussouravrobinNo ratings yet

- Centre LineDocument1 pageCentre LinesouravrobinNo ratings yet

- Rate and SpecificationDocument7 pagesRate and SpecificationsouravrobinNo ratings yet

- 1799 Construction AgreementDocument13 pages1799 Construction AgreementsouravrobinNo ratings yet

- Soudaflex 40FC - DatasheetDocument2 pagesSoudaflex 40FC - DatasheetsouravrobinNo ratings yet

- SWMS C101 Safe Use of LaddersDocument6 pagesSWMS C101 Safe Use of LadderssouravrobinNo ratings yet

- Checklist1101 - Structural Steelwork - Fabrication - UnlockedDocument2 pagesChecklist1101 - Structural Steelwork - Fabrication - UnlockedsouravrobinNo ratings yet

- MTC-IMS-PR-14-Procedure For HSE Monitoring & MeasurementDocument6 pagesMTC-IMS-PR-14-Procedure For HSE Monitoring & MeasurementsouravrobinNo ratings yet

- MTC Ims Fo 14e Starrt CardDocument1 pageMTC Ims Fo 14e Starrt CardsouravrobinNo ratings yet

- MTC Ims Fo 14d Tool Box TalkDocument2 pagesMTC Ims Fo 14d Tool Box TalksouravrobinNo ratings yet

- MTC IMS FO 15A Purchase Requisition FormDocument2 pagesMTC IMS FO 15A Purchase Requisition FormsouravrobinNo ratings yet

- MTC-IMS-PR-15-Procedure For Externally Provided ProductsDocument5 pagesMTC-IMS-PR-15-Procedure For Externally Provided ProductssouravrobinNo ratings yet

- MTC-IMS-FO-15F Supplier Re-EvaluationDocument2 pagesMTC-IMS-FO-15F Supplier Re-EvaluationsouravrobinNo ratings yet

- MTC-IMS-FO-15E Supplier Pre-Qualification FormDocument2 pagesMTC-IMS-FO-15E Supplier Pre-Qualification FormsouravrobinNo ratings yet

- MTC-IMS-FO-15G Purchase Order Internal ApprovalDocument2 pagesMTC-IMS-FO-15G Purchase Order Internal ApprovalsouravrobinNo ratings yet

- MTC-IMS-FO-15H Purchase Order Internal ApprovalDocument2 pagesMTC-IMS-FO-15H Purchase Order Internal ApprovalsouravrobinNo ratings yet

- MTC-IMS-FO-15A Purchase Requisition FormDocument2 pagesMTC-IMS-FO-15A Purchase Requisition FormsouravrobinNo ratings yet

- MTC-IMS-FO-15D Approved Suppliers ListDocument1 pageMTC-IMS-FO-15D Approved Suppliers ListsouravrobinNo ratings yet

- GBT 3191-2019Document23 pagesGBT 3191-2019souravrobin0% (1)

- MTC-IMS-FO-15B Request For Quotation ApprovalDocument1 pageMTC-IMS-FO-15B Request For Quotation ApprovalsouravrobinNo ratings yet

- Design No. X790: BXUV.X790 Fire-Resistance Ratings - ANSI/UL 263Document4 pagesDesign No. X790: BXUV.X790 Fire-Resistance Ratings - ANSI/UL 263souravrobinNo ratings yet

- MX3-Safety Plan - DrawingDocument5 pagesMX3-Safety Plan - DrawingsouravrobinNo ratings yet

- GB T 3190-2008Document32 pagesGB T 3190-2008souravrobinNo ratings yet

- Technical Data Sheet For HSC Safety Anchor Technical Information ASSET DOC 2331080Document20 pagesTechnical Data Sheet For HSC Safety Anchor Technical Information ASSET DOC 2331080souravrobinNo ratings yet

- UL Design - S729Document3 pagesUL Design - S729souravrobinNo ratings yet

- Ul 263-Y708Document3 pagesUl 263-Y708souravrobinNo ratings yet

- Module 1 - Computer EthicsDocument19 pagesModule 1 - Computer EthicsJay BagayasNo ratings yet

- Coralia AntenasDocument3 pagesCoralia AntenasALEX_125No ratings yet

- TDS - Emaco R907 PlusDocument2 pagesTDS - Emaco R907 PlusVenkata RaoNo ratings yet

- Second Order Runge-Kutta Method: ExampleDocument9 pagesSecond Order Runge-Kutta Method: ExampleAhmed MobarkiNo ratings yet

- Air Algerie Confirmation Abdelhafid Lahreche N9nqugDocument2 pagesAir Algerie Confirmation Abdelhafid Lahreche N9nqughomeyhomemelyNo ratings yet

- Solutions To Mathematical Statistics With Applications, Pg. 409, Ex. 39Document5 pagesSolutions To Mathematical Statistics With Applications, Pg. 409, Ex. 39Ivi DownhamNo ratings yet

- Carl Størmer's Auroral Discoveries: Alv Egeland and William J. BurkeDocument9 pagesCarl Størmer's Auroral Discoveries: Alv Egeland and William J. BurkesantiagoNo ratings yet

- Metode PengujianDocument17 pagesMetode Pengujianabraham samadNo ratings yet

- FSC International StandardDocument15 pagesFSC International StandardEMINANo ratings yet

- 2018 Resume NVDocument1 page2018 Resume NVcourtney willsonNo ratings yet

- Module 7Document5 pagesModule 7marleteNo ratings yet

- Personal Details: SRM Institute of Science and TechnologyDocument2 pagesPersonal Details: SRM Institute of Science and TechnologyZenelNo ratings yet

- Msds Aceite de Sacha Inchi Indice de RefracciónDocument5 pagesMsds Aceite de Sacha Inchi Indice de Refraccióngabriela_moron_aNo ratings yet

- Al Tronic Ill-Cpu Medium Engines, 2 16 Cylinders Service Instructions FORM Alii-CPU SL 4-91Document8 pagesAl Tronic Ill-Cpu Medium Engines, 2 16 Cylinders Service Instructions FORM Alii-CPU SL 4-91SMcNo ratings yet

- Cost C. Test EM Question 03.03.2023 VI-1, VDI-1Document2 pagesCost C. Test EM Question 03.03.2023 VI-1, VDI-1harish jangidNo ratings yet

- Evolution of Media PPT FinalDocument50 pagesEvolution of Media PPT FinalRoxette SantillanNo ratings yet

- 1-s2.0-S0079670005000122-main.pdf 二氧化碳開環聚合回顧文獻Document33 pages1-s2.0-S0079670005000122-main.pdf 二氧化碳開環聚合回顧文獻hungNo ratings yet

- Sample CodeDocument8 pagesSample CodeDudhipala Deepak ReddyNo ratings yet

- Writing Covered Calls: The Ultimate Guide ToDocument36 pagesWriting Covered Calls: The Ultimate Guide ToRamus PerssonNo ratings yet

- Understanding Computer InvestigationsDocument64 pagesUnderstanding Computer InvestigationsLillian KobusingyeNo ratings yet

- MAin The PEOPLE v. Michael R. TOMANELLIDocument4 pagesMAin The PEOPLE v. Michael R. TOMANELLIcb1998No ratings yet

- Luyện thi vào lớp 6: chuyên Anh, chuyên đề Viết lại câuDocument9 pagesLuyện thi vào lớp 6: chuyên Anh, chuyên đề Viết lại câuLệ NguyễnNo ratings yet

- When Caring Hurts: The Silence Burnout of SonographersDocument5 pagesWhen Caring Hurts: The Silence Burnout of SonographersCarlos BarradasNo ratings yet

- Laser AttenuationDocument8 pagesLaser AttenuationMARTIN TIRKEYNo ratings yet

- Electrical Resistance Lecture 2Document5 pagesElectrical Resistance Lecture 2bigbang0% (1)

- Logistics Service AgreementDocument1 pageLogistics Service AgreementBong Tolenada Aled ZurcNo ratings yet

- The Causative Fun Activities Games 1086Document2 pagesThe Causative Fun Activities Games 1086lemonbusNo ratings yet

- Lesson 1 - Intro and BIDMASDocument16 pagesLesson 1 - Intro and BIDMASPatrick FitzgibbonNo ratings yet

- Unit Iv Linear Block Codes: Channel EncoderDocument26 pagesUnit Iv Linear Block Codes: Channel EncoderSudhaNo ratings yet

- Mergers Acquisitions and Other Restructuring Activities 7th Edition Depamphilis Test BankDocument19 pagesMergers Acquisitions and Other Restructuring Activities 7th Edition Depamphilis Test Banksinapateprear4k100% (35)

MS Villagio Polyurea Metalex-SIKA-709

MS Villagio Polyurea Metalex-SIKA-709

Uploaded by

souravrobinOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS Villagio Polyurea Metalex-SIKA-709

MS Villagio Polyurea Metalex-SIKA-709

Uploaded by

souravrobinCopyright:

Available Formats

METHOD STATEMENT WATERPROOFING

of CORRUGATED ROOF (REPAIR WORKS)

PROJECT: VILLAGIO MALL

SUMMARY

1 Purpose ................................................................................................................................... 3

2 Definitions and Abbreviations ................................................................................................... 3

3 Key Roles ................................................................................................................................ 3

4 Reference Document, Legislation, and Code of Practice ......................................................... 4

5 Resources ............................................................................................................................... 5

5.1 Equipment and Small Tools ........................................................................................... 5

5.2 Materials ......................................................................................................................... 5

5.3 Human Resources ......................................................................................................... 5

6 Operating Methodologies and Work Phases ............................................................................ 5

6.1 Substrate Preparation – Corrugated Metal Sheet (By Main Contractor)........................... 6

6.2 Preparation & Application of Primer – Sikalastic Primer ................................................. 6

6.3 Application of 2mm Polyurea Membrane – Sikalastic 709 .............................................. 6

6.4 Application of UV Coating- Sikalastic 701 ...................................................................... 6

6.5 Materials Delivery, Storage, and Handling ..................................................................... 7

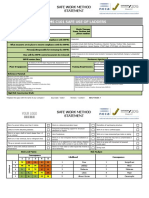

7 HSE Requirements .................................................................................................................. 7

8 QA/QC Requirements .............................................................................................................. 7

6.4 Materials Delivery, Storage, and Handling ..................................................................... 7

7 HSE Requirements .................................................................................................................. 7

8 QA/QC Requirements .............................................................................................................. 7

Roof Waterproofing – Polyurea Membrane Page 2 of 7

1 Purpose

The scope and purpose of this method statement is to provide a minimum guideline or procedure,

to ensure fundamental checks and good working practices during application of Polyurea

waterproofing membrane with respect to project specifications and contract requirements. This

document covers the repair application with Sikalastic 709 Cold Applied Hybird Pulyurea

Membrane to existing metal corrugated roof of Villagio Mall at Al Waab St., Doha, Qatar.

2 Definitions and Abbreviations

Abbreviation Definition

H&S Health and Safety

ITP Inspection and Test Plan

MES Method Statement

PPE Personal Protective Equipment

QA/QC Quality Assurance/ Quality Control

QCS-2014 Qatar Construction Standards-2014

Main Contractor Metalex Trading & Contracting

Sub-Con Specialized El-Salah Contracting Co. WLL

MSDS Material Safety Data Sheets

TDS Technical Data Sheet

MEP Mechanical Electrical Plumbing

MAR Material Approval Request

3 Key Roles

Ref Trade /Discipline No. Responsibility

1 Construction 1 Responsible for implementation of this Method

Manager

Statement and shall ensure that his team is familiar with

quality and safety procedures required as per contract

requirements.

To guarantee that all resources are available to

complete the waterproofing works as planned and

without any delay.

Roof Waterproofing – Polyurea Membrane Page 3 of 7

2 Site Engineer 1 The Site Engineer is responsible for carrying out the

work as per the approved shop drawings, materials and

method statement.

Control the Site Activities.

Monitor health and safety performance of the workers.

Prepare material requirement for day to day allocation.

Ensuring quality of Workmanship.

Coordinating with MEP subcontractor to ensure that all

MEP wall and floor penetrations are in place and pre-

treatment of pipes had been done prior to waterproofing

works.

3 Safety Inspector 1 Identify H&S requirements, non-compliance or by

conducting both formal and informal audits.

Record and advice immediately Project Manager and

H&S Officer on H&S sub standard acts/conditions.

Investigate accidents and complaints; determining if there

has been a breach of health and safety practices.

Monitor workers are provided with suitable PPE.

Report on results of inspections and investigations and

completing detailed paperwork.

4 Quality Engineer/ Responsible for ensuring full compliance with contract

Material Inspector 1

specifications, drawings, and method statement.

Carry out required inspections on all waterproofing

works to ensure compliance with project’s quality

requirements.

Ensures quality inspection carried out as per ITP.

Report on results of inspections and investigations and

completing detailed paperwork.

4 Reference Document, Legislation, and Code of Practice

This Method Statement shall be read in conjunction with the following documents:

a) Approve Material Submittal for Waterproofing (MAR)

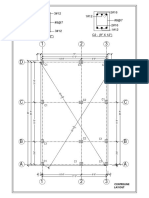

b) Approved Waterproofing Shop Drawings and Architectural IFC Drawings.

c) Material Technical Data Sheet (TDS) of Waterproofing Products

d) Material Safety Data Sheet (MSDS) of Waterproofing Products

e) Project’s Health and Safety Plan

f) Project’s Quality Plan

g) Environnemental Management Plan

Roof Waterproofing – Polyurea Membrane Page 4 of 7

5 Resources

5.1 Equipment and Small Tools

Ref Type Use

1 Coaster Van For transport of personnel

2 Pick-up Vehicle Emergency standby vehicle

3 3 Tonner Pick-up Truck Delivery of materials

4 Angle Grinder For smoothing surfaces

5 Set of basic hand tools Emergency repairs

6 Brush or Roller For the application of Polyurea

7 Safety cones, notice boards For barricades and safety notice

8 PPE – Safety Harness with Lanyards For H & S – Working at Heights

5.2 Materials

Ref Type Use

1 Sikalastic Metal Primer Priming layer

2 Sikalastic 709 Waterproofing membrane

3 Sikalastic 701 UV Coating

The store in-charge shall ensure that all necessary equipment is available as well as fit and

safe prior to the commencement of work.

5.3 Human Resources

Designation Work Scope Total

Number

Foreman Overall Workers Management 1

Applicators Application of waterproofing membrane 2

Skilled workers Assist in waterproofing application 2

warehouseman Issuance of materials 1

Common labours Housekeeping, materials handling 3

Note: The number of manpower and equipment may vary to match work requirements.

6 Operating Methodologies and Work Phases

6.1 Removing the existing Polyurea System

Remove the existing damaged hot applied polyuria system and grinding the surface, the

metal surface must be clean, dry and surface treatment that could impair adhesion.

The metal surfaces must be prepared accordingly and to be treated with suitable primer

as recommended by the polyurea membrane manufacturer.

Roof Waterproofing – Polyurea Membrane Page 5 of 7

6.2 Preparation & Application of Primer – Sika Metal Primer

It shall be ensured prior to application that the surface is dry, clean and smooth.

Sika Metal Primer is a two component epoxy primer for metallic surfaces and shall be

used as prime coat prior to application of the polyurea membrane.

To prepare the product, mix each of the two components for a few minutes and then

pour component B into the container of component A.

Mix the two components together with a slow speed electric mixer for at least 3 to 4

minutes until a homogenous mixture had been achieved.

Apply an even coat of the primer with brush, with a roller or with a suitable airless spray

gun.

The mix must be applied at a temperature of between +10°C and +30°C.

All preparatory works such as installation of vents and pipe fixtures (if any) must be

executed prior to primer installation. (MEP Works)

6.3 Application of 2mm Polyurea Membrane – Sikalastic 709

The application of polyurea membrane will be carried out after the area has been

primed and the primer has dried.

The polyurea membrane must be applied within 6 – 24 hours from the application of the

primer. It shall be ensured prior to application of Polyurea install geotextile on those

joints which shall cause cracks afterward.

Before applying Sikalastic 709 remove all dust from the

surface. To apply the polyurea membrane, use brush or roller.

The membrane must be applied continuously on all horizontal and vertical surfaces. If

the application of the membrane is interrupted, and then taken up again after the

maximum covering time of 2 hours. An overlap of at least 5cm must be made with the

previously hot applied polyurea membrane.

Consumption of Sikalastic 709 depends on the roughness of the substrate. The

theoretical consumption for a smooth surface is average of 2 kg/m² for a 2mm thickness.

Sikalastic 709 may gradually turns to yellow if exposed to UV rays and artificial

atmospheric agents but without affecting the membrane original physical properties. If

change in roof finish color is un-acceptable, a top coat is recommended at an extra cost.

6.4 Termination

Remove the existing GRP using grinder or suitable tools so that metal primer can be in

direct contact with the metal.

Termination of polyurea on GRP can be done by covering the existing GRP joint with

geotextile than apply primer and polyurea membrane with an overlap of 15cm.

6.5 Application of Sika UV Coating 701

Once the polyuria is dry and smooth apply Sika UV coating over the Polyurea as Top

Coat.

Apply 02 Coats of acrylic coating using brush or roller. The coat should have an

average thickness of 0.5mm.

Roof Waterproofing – Polyurea Membrane Page 6 of 7

6.6 Materials Delivery, Storage, and Handling

Storage areas shall comply with the manufacturer’s requirements with regards to

shade, ventilation and temperature limits and shall be located away from sources of

excessive heat, sparks or open flame.

Materials shall be delivered in their original tightly sealed containers or unopened

packages, all clearly labelled with the manufacturer's name, brand name and batch

number of the materials where appropriate.

Packaged materials shall be stored in their original containers.

Containers of liquid materials shall not be left open at any time in the storage area.

All materials shall be stored and piled as per product stacking requirement, and in a

neat and safe manner.

6.7 HSE Requirements

Specific safety measures have to be followed as applicable, and all the safety measures

are covered separately in the Project’s Health & Safety Plan.

Risks and Controls - Site safety control shall be conducted in accordance with the

guidelines stipulated in the Project’s Health & Safety Plan

Emergency Arrangements – Contact numbers of personnel concerned to be posted on

the job site.

6.8 QA/QC Requirements

Quality control shall be conducted in accordance with the guidelines stipulated in the

Project’s Inspection Test Plan (ITP)

Roof Waterproofing – Polyurea Membrane Page 7 of 7

You might also like

- MS - Demolition of Concrete SlabDocument7 pagesMS - Demolition of Concrete Slabzizojundi83% (6)

- Method Statement For FormworkDocument8 pagesMethod Statement For FormworkEng hassan hussienNo ratings yet

- Swift TS06E Risk AssessmentDocument9 pagesSwift TS06E Risk AssessmentsouravrobinNo ratings yet

- Method Statement For Erection of PanelDocument13 pagesMethod Statement For Erection of PanelNadeem Afzal100% (1)

- Method Statement Demolison and Site ClearanceDocument7 pagesMethod Statement Demolison and Site ClearanceSasi Kumar100% (3)

- 1.method Statement - Aboveground Drainage PipeDocument11 pages1.method Statement - Aboveground Drainage Pipesarmad spectrumNo ratings yet

- 1.method Statement - INSTALLATION OF WATER SUPPLY PIPES & FITTINGSDocument16 pages1.method Statement - INSTALLATION OF WATER SUPPLY PIPES & FITTINGSsarmad spectrumNo ratings yet

- 05 Method of Statment - Duct Insulation - PSDocument11 pages05 Method of Statment - Duct Insulation - PSUnique PlanningNo ratings yet

- 4293 Dgtyp 1 19 0003 ADocument10 pages4293 Dgtyp 1 19 0003 ARajarajan RajaNo ratings yet

- 1 - Method Statement For Sika WaterproofingDocument6 pages1 - Method Statement For Sika WaterproofingAyda JohariNo ratings yet

- Method Statement For Installation of Electrical DB, SMDB and MDB PanelboardsDocument6 pagesMethod Statement For Installation of Electrical DB, SMDB and MDB Panelboardsnidhinm92No ratings yet

- Method Statement For Installation of Electrical DB, SMDB and MDB PanelboardsDocument6 pagesMethod Statement For Installation of Electrical DB, SMDB and MDB Panelboardsnidhinm92No ratings yet

- Method Statement - Grading WorksDocument14 pagesMethod Statement - Grading Worksrehanapple3863No ratings yet

- Method Statement For Installation of Earthing System: South Plage at The Pearl Qatar InfrastructureDocument23 pagesMethod Statement For Installation of Earthing System: South Plage at The Pearl Qatar InfrastructureMariam Awad100% (2)

- Method of Statement HDDDocument12 pagesMethod of Statement HDDSyed FaizNo ratings yet

- Method Statement and Risk Assessment For Basement Waterproofing WorksDocument30 pagesMethod Statement and Risk Assessment For Basement Waterproofing WorksVishaul RamanNo ratings yet

- MS Field Instrument InstallationDocument11 pagesMS Field Instrument InstallationMohammad Fazal KhanNo ratings yet

- Method Statement For Installation of DBsDocument11 pagesMethod Statement For Installation of DBstristan guarinoNo ratings yet

- MS For Installation of LP System - LatestDocument8 pagesMS For Installation of LP System - Latestمقاول تكييف كهرباء وصحيNo ratings yet

- MS-21 For Fiberglass InsulationDocument9 pagesMS-21 For Fiberglass InsulationAlaa AliNo ratings yet

- Method Statement For LPG DismantlingDocument8 pagesMethod Statement For LPG DismantlingHusain abidiNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Underground Domestic Water Pipe Installation (r.1)Document34 pagesCgk063-Rfa-mos-m-xxx - Underground Domestic Water Pipe Installation (r.1)diki anggriawanNo ratings yet

- Method Statement For Testing of Fire Detection and Alarm SystemDocument17 pagesMethod Statement For Testing of Fire Detection and Alarm Systemjimmuel mendozaNo ratings yet

- 1.method Statement - INSTALLATION OF GRP WATER TANKSDocument11 pages1.method Statement - INSTALLATION OF GRP WATER TANKSsarmad spectrumNo ratings yet

- Lps 01 Hti MST El 005 Point WiringDocument22 pagesLps 01 Hti MST El 005 Point WiringJomy JohnyNo ratings yet

- Method Statement For Installation of Electrical DBDocument6 pagesMethod Statement For Installation of Electrical DBsamsungloverNo ratings yet

- Method Statement For Backfilling and Compaction ProcedureDocument22 pagesMethod Statement For Backfilling and Compaction ProcedureAlbertyNo ratings yet

- Method Statement Anti Termite r2 MRTDocument10 pagesMethod Statement Anti Termite r2 MRTKeristiyantoNo ratings yet

- Method Statement: Underground Waterproofing Using Hdpe Waterproofing System From FosrocDocument10 pagesMethod Statement: Underground Waterproofing Using Hdpe Waterproofing System From Fosrocdindo lauronNo ratings yet

- Bitumen Painting MOSDocument10 pagesBitumen Painting MOSebrahimlinda25619No ratings yet

- Constr-001 Method Statements DATA PANEL INSTALLATIONDocument13 pagesConstr-001 Method Statements DATA PANEL INSTALLATIONprestbussNo ratings yet

- ESP Installation Scheme PLTU Jeranjang 1x25 MWDocument30 pagesESP Installation Scheme PLTU Jeranjang 1x25 MWzaky rahmanNo ratings yet

- Method Statement For Testing of Lighting and Small Power SystemDocument14 pagesMethod Statement For Testing of Lighting and Small Power Systemjimmuel mendozaNo ratings yet

- Method Statement For Pile Head TreatmentDocument7 pagesMethod Statement For Pile Head TreatmentJoe Ps100% (1)

- Method Statement For Chipping Works-CCTV and ACS DevicesDocument4 pagesMethod Statement For Chipping Works-CCTV and ACS DevicesHannah San JuanNo ratings yet

- Msra For GRP Piping Installtion in Ro Plant: AE004-S3TU-MS-0002Document71 pagesMsra For GRP Piping Installtion in Ro Plant: AE004-S3TU-MS-0002adnan hanifNo ratings yet

- Method Statement For Installation & Testing of Underground Drainage PipingDocument18 pagesMethod Statement For Installation & Testing of Underground Drainage PipingMohammed Mostafa El HaddadNo ratings yet

- Bauer - Method of Statement For Glass Wall PartitionDocument8 pagesBauer - Method of Statement For Glass Wall PartitionGeorge VitacionNo ratings yet

- Method Statement For PCC Pouring, Waterproofing & ScreedDocument9 pagesMethod Statement For PCC Pouring, Waterproofing & ScreedJoe PsNo ratings yet

- Pipes Cladding and Insullations MSDocument8 pagesPipes Cladding and Insullations MSahmadNo ratings yet

- Lps-01-Hti-Mst-Me-024 - Fan Coil UnitDocument12 pagesLps-01-Hti-Mst-Me-024 - Fan Coil UnitJomy JohnyNo ratings yet

- MS-001 - Trial TrenchesDocument5 pagesMS-001 - Trial Trenchesgeriaxavier2022No ratings yet

- Cgk063-Rfa-Mos-M-Xxx - Refrigerant & Condensate Pipe InstallationDocument31 pagesCgk063-Rfa-Mos-M-Xxx - Refrigerant & Condensate Pipe Installationdiki anggriawanNo ratings yet

- Cgk063 Rfa Mos M XXX - Fire Hydrant Underground Pipe InstallationDocument31 pagesCgk063 Rfa Mos M XXX - Fire Hydrant Underground Pipe Installationdiki anggriawanNo ratings yet

- Cgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)Document39 pagesCgk063-Rfa-mos-m-xxx - Soil & Waste Water Underground Pipe Installation (r.1)diki anggriawanNo ratings yet

- MS 05Document21 pagesMS 05unnicyriacNo ratings yet

- MS For Fabrication of Steel GirderDocument19 pagesMS For Fabrication of Steel GirderAjit Kumar LakshmiNo ratings yet

- Method Statement For Grounding and Lighting Protection.Document11 pagesMethod Statement For Grounding and Lighting Protection.Praveen KumarNo ratings yet

- MP2019 186 Mec 002Document17 pagesMP2019 186 Mec 002puwe qiheNo ratings yet

- Lean Concrete MOSDocument9 pagesLean Concrete MOSebrahimlinda25619No ratings yet

- Mof For Fiber Optic CableDocument14 pagesMof For Fiber Optic Cableabd masoudNo ratings yet

- Mos Concrete Air Viods RepairDocument9 pagesMos Concrete Air Viods RepairKhaledNo ratings yet

- Method Statement For Installation of Cable Tray or TrunkingDocument9 pagesMethod Statement For Installation of Cable Tray or TrunkingEmmanuel TamayoNo ratings yet

- METHOD STATEMENT - Strengthening of Steel Beams of Brood Stock Building B-3 - Copy (AutoRecovered)Document18 pagesMETHOD STATEMENT - Strengthening of Steel Beams of Brood Stock Building B-3 - Copy (AutoRecovered)Nafees AhmadNo ratings yet

- Form J - Item 4 - Quality Control PlanDocument10 pagesForm J - Item 4 - Quality Control PlanBALARISI ENGINEERNo ratings yet

- Pipelayer (R1)Document12 pagesPipelayer (R1)zandro padillaNo ratings yet

- Method Statement For Continuity and Earth Resistance TestDocument10 pagesMethod Statement For Continuity and Earth Resistance Testjimmuel mendozaNo ratings yet

- 4293 Dgtyp 1 19 0012 ADocument12 pages4293 Dgtyp 1 19 0012 ARajarajan RajaNo ratings yet

- 04 Method of Statment - Chilled Water Pipe Insulation - PSDocument12 pages04 Method of Statment - Chilled Water Pipe Insulation - PSUnique PlanningNo ratings yet

- Assurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveFrom EverandAssurance Technologies Principles and Practices: A Product, Process, and System Safety PerspectiveNo ratings yet

- Guarantee FormatDocument1 pageGuarantee FormatsouravrobinNo ratings yet

- Column DetailsDocument1 pageColumn DetailssouravrobinNo ratings yet

- MTC IMS FO 14A Monthly Safety ReportDocument7 pagesMTC IMS FO 14A Monthly Safety ReportsouravrobinNo ratings yet

- FIS V PlusDocument10 pagesFIS V PlussouravrobinNo ratings yet

- Centre LineDocument1 pageCentre LinesouravrobinNo ratings yet

- Rate and SpecificationDocument7 pagesRate and SpecificationsouravrobinNo ratings yet

- 1799 Construction AgreementDocument13 pages1799 Construction AgreementsouravrobinNo ratings yet

- Soudaflex 40FC - DatasheetDocument2 pagesSoudaflex 40FC - DatasheetsouravrobinNo ratings yet

- SWMS C101 Safe Use of LaddersDocument6 pagesSWMS C101 Safe Use of LadderssouravrobinNo ratings yet

- Checklist1101 - Structural Steelwork - Fabrication - UnlockedDocument2 pagesChecklist1101 - Structural Steelwork - Fabrication - UnlockedsouravrobinNo ratings yet

- MTC-IMS-PR-14-Procedure For HSE Monitoring & MeasurementDocument6 pagesMTC-IMS-PR-14-Procedure For HSE Monitoring & MeasurementsouravrobinNo ratings yet

- MTC Ims Fo 14e Starrt CardDocument1 pageMTC Ims Fo 14e Starrt CardsouravrobinNo ratings yet

- MTC Ims Fo 14d Tool Box TalkDocument2 pagesMTC Ims Fo 14d Tool Box TalksouravrobinNo ratings yet

- MTC IMS FO 15A Purchase Requisition FormDocument2 pagesMTC IMS FO 15A Purchase Requisition FormsouravrobinNo ratings yet

- MTC-IMS-PR-15-Procedure For Externally Provided ProductsDocument5 pagesMTC-IMS-PR-15-Procedure For Externally Provided ProductssouravrobinNo ratings yet

- MTC-IMS-FO-15F Supplier Re-EvaluationDocument2 pagesMTC-IMS-FO-15F Supplier Re-EvaluationsouravrobinNo ratings yet

- MTC-IMS-FO-15E Supplier Pre-Qualification FormDocument2 pagesMTC-IMS-FO-15E Supplier Pre-Qualification FormsouravrobinNo ratings yet

- MTC-IMS-FO-15G Purchase Order Internal ApprovalDocument2 pagesMTC-IMS-FO-15G Purchase Order Internal ApprovalsouravrobinNo ratings yet

- MTC-IMS-FO-15H Purchase Order Internal ApprovalDocument2 pagesMTC-IMS-FO-15H Purchase Order Internal ApprovalsouravrobinNo ratings yet

- MTC-IMS-FO-15A Purchase Requisition FormDocument2 pagesMTC-IMS-FO-15A Purchase Requisition FormsouravrobinNo ratings yet

- MTC-IMS-FO-15D Approved Suppliers ListDocument1 pageMTC-IMS-FO-15D Approved Suppliers ListsouravrobinNo ratings yet

- GBT 3191-2019Document23 pagesGBT 3191-2019souravrobin0% (1)

- MTC-IMS-FO-15B Request For Quotation ApprovalDocument1 pageMTC-IMS-FO-15B Request For Quotation ApprovalsouravrobinNo ratings yet

- Design No. X790: BXUV.X790 Fire-Resistance Ratings - ANSI/UL 263Document4 pagesDesign No. X790: BXUV.X790 Fire-Resistance Ratings - ANSI/UL 263souravrobinNo ratings yet

- MX3-Safety Plan - DrawingDocument5 pagesMX3-Safety Plan - DrawingsouravrobinNo ratings yet

- GB T 3190-2008Document32 pagesGB T 3190-2008souravrobinNo ratings yet

- Technical Data Sheet For HSC Safety Anchor Technical Information ASSET DOC 2331080Document20 pagesTechnical Data Sheet For HSC Safety Anchor Technical Information ASSET DOC 2331080souravrobinNo ratings yet

- UL Design - S729Document3 pagesUL Design - S729souravrobinNo ratings yet

- Ul 263-Y708Document3 pagesUl 263-Y708souravrobinNo ratings yet

- Module 1 - Computer EthicsDocument19 pagesModule 1 - Computer EthicsJay BagayasNo ratings yet

- Coralia AntenasDocument3 pagesCoralia AntenasALEX_125No ratings yet

- TDS - Emaco R907 PlusDocument2 pagesTDS - Emaco R907 PlusVenkata RaoNo ratings yet

- Second Order Runge-Kutta Method: ExampleDocument9 pagesSecond Order Runge-Kutta Method: ExampleAhmed MobarkiNo ratings yet

- Air Algerie Confirmation Abdelhafid Lahreche N9nqugDocument2 pagesAir Algerie Confirmation Abdelhafid Lahreche N9nqughomeyhomemelyNo ratings yet

- Solutions To Mathematical Statistics With Applications, Pg. 409, Ex. 39Document5 pagesSolutions To Mathematical Statistics With Applications, Pg. 409, Ex. 39Ivi DownhamNo ratings yet

- Carl Størmer's Auroral Discoveries: Alv Egeland and William J. BurkeDocument9 pagesCarl Størmer's Auroral Discoveries: Alv Egeland and William J. BurkesantiagoNo ratings yet

- Metode PengujianDocument17 pagesMetode Pengujianabraham samadNo ratings yet

- FSC International StandardDocument15 pagesFSC International StandardEMINANo ratings yet

- 2018 Resume NVDocument1 page2018 Resume NVcourtney willsonNo ratings yet

- Module 7Document5 pagesModule 7marleteNo ratings yet

- Personal Details: SRM Institute of Science and TechnologyDocument2 pagesPersonal Details: SRM Institute of Science and TechnologyZenelNo ratings yet

- Msds Aceite de Sacha Inchi Indice de RefracciónDocument5 pagesMsds Aceite de Sacha Inchi Indice de Refraccióngabriela_moron_aNo ratings yet

- Al Tronic Ill-Cpu Medium Engines, 2 16 Cylinders Service Instructions FORM Alii-CPU SL 4-91Document8 pagesAl Tronic Ill-Cpu Medium Engines, 2 16 Cylinders Service Instructions FORM Alii-CPU SL 4-91SMcNo ratings yet

- Cost C. Test EM Question 03.03.2023 VI-1, VDI-1Document2 pagesCost C. Test EM Question 03.03.2023 VI-1, VDI-1harish jangidNo ratings yet

- Evolution of Media PPT FinalDocument50 pagesEvolution of Media PPT FinalRoxette SantillanNo ratings yet

- 1-s2.0-S0079670005000122-main.pdf 二氧化碳開環聚合回顧文獻Document33 pages1-s2.0-S0079670005000122-main.pdf 二氧化碳開環聚合回顧文獻hungNo ratings yet

- Sample CodeDocument8 pagesSample CodeDudhipala Deepak ReddyNo ratings yet

- Writing Covered Calls: The Ultimate Guide ToDocument36 pagesWriting Covered Calls: The Ultimate Guide ToRamus PerssonNo ratings yet

- Understanding Computer InvestigationsDocument64 pagesUnderstanding Computer InvestigationsLillian KobusingyeNo ratings yet

- MAin The PEOPLE v. Michael R. TOMANELLIDocument4 pagesMAin The PEOPLE v. Michael R. TOMANELLIcb1998No ratings yet

- Luyện thi vào lớp 6: chuyên Anh, chuyên đề Viết lại câuDocument9 pagesLuyện thi vào lớp 6: chuyên Anh, chuyên đề Viết lại câuLệ NguyễnNo ratings yet

- When Caring Hurts: The Silence Burnout of SonographersDocument5 pagesWhen Caring Hurts: The Silence Burnout of SonographersCarlos BarradasNo ratings yet

- Laser AttenuationDocument8 pagesLaser AttenuationMARTIN TIRKEYNo ratings yet

- Electrical Resistance Lecture 2Document5 pagesElectrical Resistance Lecture 2bigbang0% (1)

- Logistics Service AgreementDocument1 pageLogistics Service AgreementBong Tolenada Aled ZurcNo ratings yet

- The Causative Fun Activities Games 1086Document2 pagesThe Causative Fun Activities Games 1086lemonbusNo ratings yet

- Lesson 1 - Intro and BIDMASDocument16 pagesLesson 1 - Intro and BIDMASPatrick FitzgibbonNo ratings yet

- Unit Iv Linear Block Codes: Channel EncoderDocument26 pagesUnit Iv Linear Block Codes: Channel EncoderSudhaNo ratings yet

- Mergers Acquisitions and Other Restructuring Activities 7th Edition Depamphilis Test BankDocument19 pagesMergers Acquisitions and Other Restructuring Activities 7th Edition Depamphilis Test Banksinapateprear4k100% (35)