Professional Documents

Culture Documents

4-Proof of Current Competencies

4-Proof of Current Competencies

Uploaded by

Celso Amoto100%(1)100% found this document useful (1 vote)

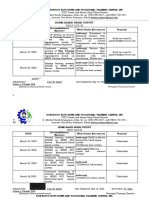

147 views5 pagesThis document outlines the competencies of an individual. It lists 14 basic competencies across areas like communication, teamwork, career development, and safety. It also lists 9 common competencies related to tasks like applying sealants, vehicle movement, measurement, manual use, and maintenance. Finally, it outlines 4 core competencies involving servicing systems of motorcycles and small engines like fuel, electrical, chassis, and overhauling engines. Competencies are validated through methods like direct observation, practical demonstrations, and records.

Original Description:

Original Title

4-Proof of current competencies

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the competencies of an individual. It lists 14 basic competencies across areas like communication, teamwork, career development, and safety. It also lists 9 common competencies related to tasks like applying sealants, vehicle movement, measurement, manual use, and maintenance. Finally, it outlines 4 core competencies involving servicing systems of motorcycles and small engines like fuel, electrical, chassis, and overhauling engines. Competencies are validated through methods like direct observation, practical demonstrations, and records.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

100%(1)100% found this document useful (1 vote)

147 views5 pages4-Proof of Current Competencies

4-Proof of Current Competencies

Uploaded by

Celso AmotoThis document outlines the competencies of an individual. It lists 14 basic competencies across areas like communication, teamwork, career development, and safety. It also lists 9 common competencies related to tasks like applying sealants, vehicle movement, measurement, manual use, and maintenance. Finally, it outlines 4 core competencies involving servicing systems of motorcycles and small engines like fuel, electrical, chassis, and overhauling engines. Competencies are validated through methods like direct observation, practical demonstrations, and records.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 5

Determining the current competency

Name

Qualification:

Current Proof/Evidence Means of validating

competencies

BASIC COMPETENCIES

1. Participate in Workplace Communication

1.1 Obtain and

convey workplace verified the authenticity of

information the documents submitted

1.2 Complete

relevant work related

documents.

1.3 Participate in

workplace meeting

and discussion

2. Work in Team Environment

2.1 Describe team

role and scope

2.2 Identify own role

and responsibility

within team

2.3 Work as a team

member

3. Practice Career Professionalism

3.1 Integrate

personal objectives

with organizational

goals

3.2 Set and meet

work priorities

3.3 Maintain

professional growth

and development

4. Practice Occupational Health and Safety Procedures

4.1 Identify hazards

and risks

4.2 Evaluate hazards

and risks

4.3 Control hazards

and risks

4.4 Maintain

occupational health

and safety

awareness

COMMON COMPETENCIES

1. Apply Appropriate Sealant/Adhesive

1.1 Identify appropriate

sealant/ adhesive Direct Observation /

Practical

1.2 Prepare surface for demonstration/submitte

sealant/ adhesive d transcript of records

1.3 Apply sealant/

adhesive evenly

1.4 Store/Dispose of

sealant/ adhesive

2. Move and Position Vehicle

2.1 Prepare vehicle for

driving

2.2 Move and position

vehicle

2.3 Check the vehicle

3. Perform Mensuration and Calculation

3.1 Select measuring

instruments

3.2 Carry out

measurements and

calculation

3.3 Maintain

measuring instruments

4. Read, Interpret and Apply Specifications and Manuals

4.1 Identify and access

manual/ specification

4.2 Interpret manuals

4.3 Apply information

in manual

4.4 Store manuals

5. Use and Apply Lubricants/Coolants

5.1 Identify types of

lubricants/ coolant

5.2 Use and apply

lubricants/ coolant

5.3 Perform

housekeeping activities

6. Perform Shop Maintenance

6.1 Inspect/clean tools

and work area

6.2 Store/arrange

tools and shop

equipment

6.3 Dispose

wastes/used lubricants

6.4 Report damaged

tools/equipment

7. Prepare Job Estimate/Costing

7.1 Identify

nature/scope of work

7.2 Prepare and

present estimate

8. Observe Quality Systems

8.1. Conduct final

quality check on

completed work /

orders

8.2 Report on the

quality of processes

and work outcomes

8.3 Implement

improvements to work

processes

9. Perform Periodic Maintenance

9.1Confirm and

troubleshoot items

scheduled for

maintenance

9.2 Inspect, clean and

adjust items scheduled

for Maintenance

9.3 Lubricate with oil

or grease items

scheduled for

maintenance

9.4 Replace items

scheduled for

maintenance

9.5 Tighten bolts and

nuts scheduled for

maintenance

9.6 Final inspection of

items scheduled for

maintenance

9.7 Clean-up work area

CORE COMPETENCIES

1. Service motorcycle/small engine system

1.1 Service fuel system

1.2 Service intake and Direct Observation /

exhaust system Practical

1.3 Service lubrication demonstration/submitte

system d transcript of records

1.4 Service cooling

system

1.5 Service

transmission and

clutch system (for

motorcycle only)

1.6 Clean-up work area

2. Service Electrical System

2.1 Confirm and

troubleshoot

electrical system

2.2 Disassemble/

Assemble Electrical

components

2.3 Final inspection of

electrical system

2.4 Clean-up work area

3. Service Chassis

3.1 Service steering

and suspension

system

3.2 Service final drive

system

3.3 Service brake

system

3.4 Service wheels and

tires

3.5 Clean-up work area

4. Overhaul Motorcycle/Small Engine

4.1 Remove engine

from the unit

4.2 Disassemble engine

4.3 Assemble Engine

(Parts and

Components)

4.4 Re-install engine to

frame

4.5 Test engine

performance

4.6 Clean-up work area

You might also like

- Emergency Action PlanDocument2 pagesEmergency Action PlanJose E RafolsNo ratings yet

- DRIVING NC II CBC - 21st IntegratedDocument57 pagesDRIVING NC II CBC - 21st IntegratedClarissa Albor100% (1)

- SMAW NC I (Module 4 Basic) Practice Housekeeping ProcedureDocument18 pagesSMAW NC I (Module 4 Basic) Practice Housekeeping ProcedureCelso Amoto88% (8)

- Safety Data Sheet Acc. To OSHA HCSDocument11 pagesSafety Data Sheet Acc. To OSHA HCSTim BrownNo ratings yet

- Qualification: Driving NC II Unit of Competency: Drive Light VehicleDocument6 pagesQualification: Driving NC II Unit of Competency: Drive Light VehicleByron Abelita100% (1)

- CBC-Driving NC IIDocument68 pagesCBC-Driving NC IISSVTC LRCNo ratings yet

- OHS-PR-02-22 Procurement Contractor ManagementDocument25 pagesOHS-PR-02-22 Procurement Contractor ManagementSn Ahsan100% (3)

- CBC Driving NC II EditedDocument63 pagesCBC Driving NC II Editedgil abanador100% (1)

- SMAW NC I (Module 3 Basic) Demonstrate Work ValuesDocument14 pagesSMAW NC I (Module 3 Basic) Demonstrate Work ValuesCelso Amoto100% (1)

- SMAW NC I (Module 1 Common) Apply Safety PracticesDocument30 pagesSMAW NC I (Module 1 Common) Apply Safety PracticesCelso Amoto100% (1)

- 11 Demonstration With Oral Questioning ChecklistDocument4 pages11 Demonstration With Oral Questioning ChecklistCelso Amoto0% (2)

- DRIVING NC II-KristenDocument16 pagesDRIVING NC II-Kristenkristen caalimNo ratings yet

- Driving NC IiDocument8 pagesDriving NC IiMiko Salvacion BrazaNo ratings yet

- CBC Driving NCIIDocument51 pagesCBC Driving NCIIMga Brad100% (1)

- Can I ?: Local Government Unit of New BataanDocument3 pagesCan I ?: Local Government Unit of New BataanByron AbelitaNo ratings yet

- Job Sheet 1.1-6 SELF-ASSESSMENT-CHECKLIST-FORM-1.1-1.4Document6 pagesJob Sheet 1.1-6 SELF-ASSESSMENT-CHECKLIST-FORM-1.1-1.4Cres SumaldeNo ratings yet

- Cbt-Driving NC IiDocument28 pagesCbt-Driving NC Iimary jane garcines100% (1)

- Competency Based Learning Material: Performing Shop MaintenanceDocument64 pagesCompetency Based Learning Material: Performing Shop Maintenancegillian marbebeNo ratings yet

- CBC Driving NC II New NormalDocument80 pagesCBC Driving NC II New NormalTHE CUTE GURL SUANNo ratings yet

- Module of InstructionDocument4 pagesModule of InstructionDaniel ReyesNo ratings yet

- CBC-RAC (PDF - Io) PDFDocument91 pagesCBC-RAC (PDF - Io) PDFMark MarasiganNo ratings yet

- Evidence Plan DrivingDocument5 pagesEvidence Plan DrivingFrancis Junifer ManiegoNo ratings yet

- CBLMDocument118 pagesCBLMjoannamariecollantesNo ratings yet

- Obey and Observe RpasirhoviaDocument53 pagesObey and Observe Rpasirhoviastoney1986100% (1)

- Session Plan: Performing Vehicle Inspection As Per Manufacturer's Specification Light Vehicle 1 HourDocument3 pagesSession Plan: Performing Vehicle Inspection As Per Manufacturer's Specification Light Vehicle 1 HourJude PellerinNo ratings yet

- 5 Institutional Assessment Instruments 2Document9 pages5 Institutional Assessment Instruments 2Annelyn AqueNo ratings yet

- 4 Implement and Coordinate Accident Driving NC II P UnlockedDocument53 pages4 Implement and Coordinate Accident Driving NC II P UnlockedJosieca Bitancor SandovalNo ratings yet

- List of Tools, Equipment, and Materials Driving NC IIDocument8 pagesList of Tools, Equipment, and Materials Driving NC IIClarissa Albor100% (1)

- Final PortfolioDocument95 pagesFinal Portfolioverneiza balbastroNo ratings yet

- CBC DrivingDocument41 pagesCBC DrivingJames Inigo0% (1)

- Training Regulation DrivingDocument3 pagesTraining Regulation DrivingBernardo John JambalosNo ratings yet

- UC 1 Apply Appropriate Sealant or Adhesive Session PlanDocument3 pagesUC 1 Apply Appropriate Sealant or Adhesive Session PlanAlran Eric Cifra100% (2)

- CD Automotive Servicing NC IDocument9 pagesCD Automotive Servicing NC IAit BiñanNo ratings yet

- CBLM Uc1 - NewDocument104 pagesCBLM Uc1 - NewRomally Antonette TagnipezNo ratings yet

- Session Plan: Drive Light Vehicle Driving Light VehicleDocument8 pagesSession Plan: Drive Light Vehicle Driving Light VehicleEsthad Madah LolimaNo ratings yet

- Surigao State College of Technology: Commission On Higher Education Surigao CityDocument4 pagesSurigao State College of Technology: Commission On Higher Education Surigao Cityian dave semacioNo ratings yet

- Organizational Structure For Assessment CenterDocument1 pageOrganizational Structure For Assessment CenterEm Boquiren CarreonNo ratings yet

- SCAFFOLDING WORKS - (Supported Type Scaffold) NIIDocument82 pagesSCAFFOLDING WORKS - (Supported Type Scaffold) NIInanie1986No ratings yet

- Driving Evidence PlanDocument11 pagesDriving Evidence PlanJanine Anne PeridaNo ratings yet

- Competency Based Learning MaterialsDocument37 pagesCompetency Based Learning Materialsflorence baliwangNo ratings yet

- Plan Training SessionDocument65 pagesPlan Training SessionJohn Michael GalleneroNo ratings yet

- Institutional Assessment Tools Driving NC IIDocument13 pagesInstitutional Assessment Tools Driving NC IIDeovir TesdaNo ratings yet

- Driving Core CBLM UC1 - NEW FinalDocument104 pagesDriving Core CBLM UC1 - NEW FinalRomally Antonette Tagnipez100% (1)

- Form 1.2 Evidences/Proof of Current CompetenciesDocument2 pagesForm 1.2 Evidences/Proof of Current CompetenciesJay Reposo100% (1)

- Revised Driving NC III New 2022 AmendedDocument132 pagesRevised Driving NC III New 2022 AmendedZAIRON DELA BAJAN100% (1)

- Overview of The Fels TrainingDocument14 pagesOverview of The Fels TrainingDlanor Avadec100% (1)

- Presentation Coc1Document22 pagesPresentation Coc1johnnycollideNo ratings yet

- FLS Powerpoint FinalDocument17 pagesFLS Powerpoint FinalkevinNo ratings yet

- Supervise Work-Based Learning by MiaiDocument35 pagesSupervise Work-Based Learning by MiaiSitai CalatravaNo ratings yet

- FLS Demo ScriptDocument6 pagesFLS Demo ScriptRhey Cariño100% (1)

- Self - Assessment Guide - Driving NC IIDocument3 pagesSelf - Assessment Guide - Driving NC IIMichael V. Magallano100% (2)

- UTPRAS Format New Forms As of APRIL 1, 2017Document79 pagesUTPRAS Format New Forms As of APRIL 1, 2017Mommy ShashaNo ratings yet

- CBC NC II Chassis RepairDocument120 pagesCBC NC II Chassis RepairJoseph Rosario100% (2)

- CBLM Apply Appropriate Sealant or AdhesiveDocument33 pagesCBLM Apply Appropriate Sealant or AdhesiveMark Kevin DaitolNo ratings yet

- PTS Job1.3-6Document6 pagesPTS Job1.3-6Almina BernadetteNo ratings yet

- CBC For BPPDocument107 pagesCBC For BPPFARASAN INSTITUTENo ratings yet

- Welcome To General Trainees' Orientation: Technical Education and Skills Development Authority Tesda 7Document18 pagesWelcome To General Trainees' Orientation: Technical Education and Skills Development Authority Tesda 7Oliver CalledoNo ratings yet

- FLS Demo FlowDocument1 pageFLS Demo FlowReignz Giangan MosquedaNo ratings yet

- Light Vehicle DriDocument1 pageLight Vehicle DriDhena H Rasul Sabdula100% (1)

- EIM NC II - Self Assessment ChecklistDocument3 pagesEIM NC II - Self Assessment ChecklistMary Grace Aboque-Tan Sangcom100% (1)

- Training Activity Matrix MauDocument4 pagesTraining Activity Matrix MauCupido Jr. Sabatin100% (1)

- Facilitate Learning Session ScriptDocument6 pagesFacilitate Learning Session ScriptJm Gaje100% (1)

- TM1 - FLS - CBT - PresentationDocument25 pagesTM1 - FLS - CBT - PresentationRyan MontillaNo ratings yet

- 2019-05-13 (PTS) Form 1.3 Summary of Current Competencies Versus Required CompetenciesDocument1 page2019-05-13 (PTS) Form 1.3 Summary of Current Competencies Versus Required CompetenciesMich Alto50% (2)

- Progress Chart SMAW NC IIDocument11 pagesProgress Chart SMAW NC IIpauline nuegaNo ratings yet

- Self-Assessment Checklist: Can I ?Document2 pagesSelf-Assessment Checklist: Can I ?Jazmine Monique Iledan100% (1)

- Required Units of Competency/Learning Outcomes Based On CBC Current Competencies Training Gaps/RequirementsDocument5 pagesRequired Units of Competency/Learning Outcomes Based On CBC Current Competencies Training Gaps/RequirementsRhendel SanchezNo ratings yet

- SMAW NC I (Module 3 Common) Perform Industry CalculationDocument10 pagesSMAW NC I (Module 3 Common) Perform Industry CalculationCelso Amoto100% (1)

- Carburetor Parts and Their Function (With Diagram)Document6 pagesCarburetor Parts and Their Function (With Diagram)Celso Amoto50% (2)

- SMAW NC I (Module 2 Common) Interpret Drawing and SketchesDocument22 pagesSMAW NC I (Module 2 Common) Interpret Drawing and SketchesCelso Amoto100% (1)

- Basic Motorcycle Maintenance Checklist: Nine Simple Steps For A Worry-Free Riding SeasonDocument20 pagesBasic Motorcycle Maintenance Checklist: Nine Simple Steps For A Worry-Free Riding SeasonCelso AmotoNo ratings yet

- Back To Basics. Nine Fundamentals Every Rider Needs To Know To Push and Manoeuvre Your MotorcycleDocument11 pagesBack To Basics. Nine Fundamentals Every Rider Needs To Know To Push and Manoeuvre Your MotorcycleCelso AmotoNo ratings yet

- The Motorcycle Brake System: How It Works: Cool Stuff Shari Ives 1 Like ShareDocument3 pagesThe Motorcycle Brake System: How It Works: Cool Stuff Shari Ives 1 Like ShareCelso AmotoNo ratings yet

- 1 Home Base Work March 19-MRCH 31Document3 pages1 Home Base Work March 19-MRCH 31Celso AmotoNo ratings yet

- 2 Home Base Work March 31 - Apr 15Document4 pages2 Home Base Work March 31 - Apr 15Celso AmotoNo ratings yet

- 4 Home Base Work May 4-15Document3 pages4 Home Base Work May 4-15Celso AmotoNo ratings yet

- Don Bosco Staff and Educators Association - Dumangas: Sustainable Livelihood ProgramDocument2 pagesDon Bosco Staff and Educators Association - Dumangas: Sustainable Livelihood ProgramCelso AmotoNo ratings yet

- 3 Home Base Work April 16-May 1Document3 pages3 Home Base Work April 16-May 1Celso AmotoNo ratings yet

- Motorcycle: Single-Track Motor Vehicle Long Distance Congested Urban Traffic Cruising Sport RacingDocument11 pagesMotorcycle: Single-Track Motor Vehicle Long Distance Congested Urban Traffic Cruising Sport RacingCelso AmotoNo ratings yet

- 1 Home Base Work March 19-MRCH 31Document3 pages1 Home Base Work March 19-MRCH 31Celso AmotoNo ratings yet

- 2 Home Base Work March 31 - Apr 15Document3 pages2 Home Base Work March 31 - Apr 15Celso AmotoNo ratings yet

- Confirm and Troubleshoot Electrical SystemDocument1 pageConfirm and Troubleshoot Electrical SystemCelso AmotoNo ratings yet

- Motorcycle Brake System.: Sri Lanka PricesDocument9 pagesMotorcycle Brake System.: Sri Lanka PricesCelso AmotoNo ratings yet

- Service Motorcycle/small Engine SystemDocument21 pagesService Motorcycle/small Engine SystemCelso Amoto100% (1)

- 2-Data Gathering Instrument For TraineeDocument2 pages2-Data Gathering Instrument For TraineeCelso AmotoNo ratings yet

- 6 Training NeedsDocument2 pages6 Training NeedsCelso AmotoNo ratings yet

- NSW Safe Design Buildings Structures 2088Document44 pagesNSW Safe Design Buildings Structures 2088asantha5No ratings yet

- 2013 Oa CleaningDocument324 pages2013 Oa CleaningzaiazwaNo ratings yet

- THINK SAFE-Online BOSH D3 FinalDocument22 pagesTHINK SAFE-Online BOSH D3 FinalEarvin Dayle RamosNo ratings yet

- CHNDocument42 pagesCHNvinwaleed50% (2)

- Day 1 Fundamentals of Safety ManagementDocument20 pagesDay 1 Fundamentals of Safety Managementmike cams100% (2)

- Revised Bookkeeping NCIIIDocument62 pagesRevised Bookkeeping NCIIIZAIRON DELA BAJAN100% (1)

- Sds - FLUIDERM GZ PDFDocument8 pagesSds - FLUIDERM GZ PDFmanzar masoodNo ratings yet

- List of U.S. Federal Employment and Labor LawsDocument12 pagesList of U.S. Federal Employment and Labor LawsGoran SigerovNo ratings yet

- Esia Proect Stephen Njuguna T056 01 2149 2019Document21 pagesEsia Proect Stephen Njuguna T056 01 2149 2019steve njugunaNo ratings yet

- ISHO Lofstedt SurveyDocument31 pagesISHO Lofstedt SurveyManjul TakleNo ratings yet

- Sag - Trainers Methodology I PDFDocument9 pagesSag - Trainers Methodology I PDFSarah BaylonNo ratings yet

- Material Safety Data Sheet: Section 1. Chemical Product and Company IdentificationDocument6 pagesMaterial Safety Data Sheet: Section 1. Chemical Product and Company IdentificationMarco CulquiNo ratings yet

- MSDS - Spectrus Bd1551eDocument8 pagesMSDS - Spectrus Bd1551eLee ColeNo ratings yet

- mgt340 ReportDocument11 pagesmgt340 Reportnurul shafifah bt ismailNo ratings yet

- BOSH Training BackgroundDocument1 pageBOSH Training BackgroundJeanne Pabellena DayawonNo ratings yet

- Fly Ash SDSDocument12 pagesFly Ash SDSsanjeevNo ratings yet

- 6.1 Baseline Risk Assessment - PARLIAMENTDocument39 pages6.1 Baseline Risk Assessment - PARLIAMENTjoanne dehalooNo ratings yet

- Nebosh TemplateDocument14 pagesNebosh Templatesandeep KumarNo ratings yet

- Global Asset Protection Services: Bamburi Cement Limited - Mombasa Plant Loss Prevention SurveyDocument4 pagesGlobal Asset Protection Services: Bamburi Cement Limited - Mombasa Plant Loss Prevention SurveyfebousNo ratings yet

- Bbhi4103 Bi PDFDocument170 pagesBbhi4103 Bi PDFPAPPASSININo ratings yet

- JSA Rebar Cutting & BendingDocument2 pagesJSA Rebar Cutting & BendingGunjan Sinha AdityaNo ratings yet

- Community Health NursingDocument42 pagesCommunity Health NursingChucky VergaraNo ratings yet

- Sector: Agri-Fishery: Qualification Title: Organic Agriculture Production NC IiDocument13 pagesSector: Agri-Fishery: Qualification Title: Organic Agriculture Production NC IiaaronjulesNo ratings yet

- Msds Fumicool Sm-20Document2 pagesMsds Fumicool Sm-20arief kuncoroNo ratings yet

- Mod11 Lockout-TagoutDocument15 pagesMod11 Lockout-TagoutMhanna AYNo ratings yet

- Annual Report PUMADocument223 pagesAnnual Report PUMAiamtung100% (1)

- 2 Fall ProtectionDocument9 pages2 Fall ProtectionGu YunruiNo ratings yet