Professional Documents

Culture Documents

Mivan Formwork Technology@ PDF

Mivan Formwork Technology@ PDF

Uploaded by

vishaliCopyright:

Available Formats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mivan 9Document40 pagesMivan 9vishaliNo ratings yet

- Implementation of Value Engineering For Residential and Commercial BuildingsDocument7 pagesImplementation of Value Engineering For Residential and Commercial BuildingsvishaliNo ratings yet

- Exercise: 1: Introduction To Qgis: ObjectiveDocument5 pagesExercise: 1: Introduction To Qgis: ObjectivevishaliNo ratings yet

- Comparison AND Effectiveness OF Mivan Formwork Over THE Conventional FormworkDocument3 pagesComparison AND Effectiveness OF Mivan Formwork Over THE Conventional FormworkvishaliNo ratings yet

- Fast Track ConstructionDocument10 pagesFast Track ConstructionvishaliNo ratings yet

- Exercise 5 & 6Document9 pagesExercise 5 & 6vishaliNo ratings yet

- NEET R.P.T - 2 (26.04.2020) RESULT: Velammal Bodhi Campus - Online ExamDocument2 pagesNEET R.P.T - 2 (26.04.2020) RESULT: Velammal Bodhi Campus - Online ExamvishaliNo ratings yet

- Census 2011 PDFDocument2 pagesCensus 2011 PDFvishaliNo ratings yet

- Contract Administration in Infrastructure Projects: Department of Civil and Environmental EngineeringDocument1 pageContract Administration in Infrastructure Projects: Department of Civil and Environmental EngineeringvishaliNo ratings yet

- Types of Construction Accidents:: Accidents and Their CausesDocument5 pagesTypes of Construction Accidents:: Accidents and Their CausesvishaliNo ratings yet

- ABC AnalysisDocument3 pagesABC AnalysisvishaliNo ratings yet

- Challenges in Maintenance of Infrastructure EngineeringDocument26 pagesChallenges in Maintenance of Infrastructure EngineeringvishaliNo ratings yet

- Sec07 - RacewaysDocument10 pagesSec07 - RacewaysYusufNo ratings yet

- Method Statement For Construction - Designing Buildings Wiki PDFDocument5 pagesMethod Statement For Construction - Designing Buildings Wiki PDFKareemAdelNo ratings yet

- ZP CEA SyllabusDocument4 pagesZP CEA SyllabusAbhijeet ShelkeNo ratings yet

- Flyer of BIS Webinar On Diaster Resilient InfrastructureDocument3 pagesFlyer of BIS Webinar On Diaster Resilient InfrastructurekarthiksampNo ratings yet

- Regie LacernaDocument69 pagesRegie LacernaRvin Jay Cabontocan MarianoNo ratings yet

- Alg 11. WorkDocument3 pagesAlg 11. WorkTrisha AbalosNo ratings yet

- CPM 10-91 Contractor Safety PolicyDocument6 pagesCPM 10-91 Contractor Safety PolicyGilbert GillNo ratings yet

- Bowling Hall Design Standards Bowling SaDocument3 pagesBowling Hall Design Standards Bowling SaRichard ObiriNo ratings yet

- Feb 2017 Buildability SiteDocument21 pagesFeb 2017 Buildability SiteTun Lin OoNo ratings yet

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Document7 pagesMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuNo ratings yet

- Rockwin India Consulting Engineers PVT LTD: Northern RailwayDocument2 pagesRockwin India Consulting Engineers PVT LTD: Northern RailwayNeelesh JadaunNo ratings yet

- DI 17 Tal Chhapar Rajasthan Kamath DesigDocument6 pagesDI 17 Tal Chhapar Rajasthan Kamath DesigShakti SinghNo ratings yet

- Kombolcha Institute of Technology: Building ConstructionDocument41 pagesKombolcha Institute of Technology: Building Constructionbini1221No ratings yet

- General FEEDER InformationDocument16 pagesGeneral FEEDER InformationFacsolNo ratings yet

- Plan of 3.5 KM Flowline ConstructionDocument1 pagePlan of 3.5 KM Flowline ConstructionRohit SharmaNo ratings yet

- Construction Scope - of - WorksDocument55 pagesConstruction Scope - of - WorksFiroj AlamNo ratings yet

- Preston Bus Station MSCP Case StudyDocument4 pagesPreston Bus Station MSCP Case StudysivnarayanNo ratings yet

- General Notes 2Document1 pageGeneral Notes 2Wilbert ReuyanNo ratings yet

- 15 - 1490 GFM SHE 24 Construction Noise and Vibration Management PlanDocument11 pages15 - 1490 GFM SHE 24 Construction Noise and Vibration Management PlanHussein Adnan FneishNo ratings yet

- Ungureanu 2020Document16 pagesUngureanu 2020Zeyad F SaadNo ratings yet

- WBG Presentation DAEPDocument39 pagesWBG Presentation DAEPhrhhamadaNo ratings yet

- PS577000-28769 (General Technical Specific of Steel Construction)Document26 pagesPS577000-28769 (General Technical Specific of Steel Construction)HoangNo ratings yet

- Und - Ar-07.02 - Rencana Fin. Lantai-Ar-07.02Document1 pageUnd - Ar-07.02 - Rencana Fin. Lantai-Ar-07.02Deden NurarifNo ratings yet

- Megha Engineering & Infrastructures LTD: List of Register TechnicalDocument31 pagesMegha Engineering & Infrastructures LTD: List of Register TechnicalLaxmikanta swainNo ratings yet

- RK MallikCVDocument10 pagesRK MallikCVRK MallikNo ratings yet

- Precast SystemsDocument13 pagesPrecast Systemsparamarthasom1974No ratings yet

- Odiong Bridge FinalDocument18 pagesOdiong Bridge Finaljenor delatorreNo ratings yet

- Resultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDocument4 pagesResultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDIEGO FERNANDO CADENA ARANGONo ratings yet

- ICC ES Report ESR 1961: The Dow Chemical CompanyDocument3 pagesICC ES Report ESR 1961: The Dow Chemical CompanymurdicksNo ratings yet

- Cat Hammers C842898Document8 pagesCat Hammers C842898maggioraNo ratings yet

Mivan Formwork Technology@ PDF

Mivan Formwork Technology@ PDF

Uploaded by

vishaliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mivan Formwork Technology@ PDF

Mivan Formwork Technology@ PDF

Uploaded by

vishaliCopyright:

Available Formats

INTERNATIONAL RESEARCH JOURNAL OF MULTIDISCIPLINARY STUDIES & SPPP's,

Karmayogi Engineering College, Pandharpur Organize National Conference

Special Issue March 2016

Vol. 2, Special Issue 1, March, 2016 ISSN (Online): 2454-8499 Impact Factor: 1.3599(GIF),

0.679(IIFS)

MIVAN FORMWORK TECHNOLOGY

Sirse Guruling Ramling 1, Patil Yogendra.Ramesh2.

1

Department of Civil Engineering Karmayogi Engineering College

Shelve, Pandharpur

Assist Prof 2Department of Civil Engineering Karmayogi Engineering College

Shelve, Pandharpur

Abstract- Construction is one of the significant sectors of Indian economy and is an integral part of

the development. Today India’s urban population is the second largest in the world and its future

development leads to increased demand for housing to cope with this problem India should

desperately need to plan for acquisition of land and rapid creation of dwelling units. Construction is a

complex process involving basically the areas of Architectural planning, Engineering & Construction.

There is growing realization today that speed of construction needs to be given greater importance

especially for large housing projects. This is not only essential for the faster turnover of equipment and

investment – leading possible to the reduction in the housing cost but also for achieving the national

objective of creating a large stock to overcome shortest possible time. Fortunately, some of the

advanced technologies catering to faster speed of construction are already available in the country. For

e.g. Prefabrication, autoclaved blocks, tunnel formwork, aluminium formwork (MIVAN Technology)

of construction etc. The aluminium formwork system was developed by Malaysian Company and

that’s why the aluminium formwork technology is named after it. Mivan is an aluminium formwork

system used widely in the construction of residential units and mass housing projects. It is fast, simple,

adaptable, durable and cost effective, produces total quality work which requires minimum

maintenance. This system suitable for Indian condition as a tailor made aluminium formwork for cast-

in-situ fully concrete structure. Mivan is new construction technology upcoming for successful

completion of mass housing project in India. In this project we have discussed about cost comparison

of mivan technology with conventional construction technology. The Mivan technology is absolutely

fine with cost, quality and time saving as compare to conventional.

Keyword: cost effective, adaptable, time saving, & minimum maintenance etc.

1. INTRODUCTION ensured a fast and economical method of

construction. The concrete surface finish

The Mivan Technology System was developed produced with the aluminium forms allows

by Mivan Company Ltd from Malaysia late achievement of a high quality wall finish

1990s as a system for constructing mass without the need for extensive plastering. This

housing project in developing countries. The is one of the systems identified to be very

units were to be of cast-in-place concrete, with much suitable for Indian conditions for mass

load bearing walls using a formwork of construction, where quality and speed can be

aluminium panels. To be erected by the achieved at high level. The speed of

hundreds, of a repetitive design, the system

Web: www.irjms.in Email: irjms2015@gmail.com, irjms.in@gmail.com Page No: 1

INTERNATIONAL RESEARCH JOURNAL OF MULTIDISCIPLINARY STUDIES &

SPPP's, Karmayogi Engineering College, Pandharpur Organize

National Conference Special Issue March 2016

Vol. 2, Special Issue 1, March, 2016 ISSN (Online): 2454-8499 Impact Factor: 1.3599(GIF),

0.679(IIFS)

construction by this system will surpass speed system where in the complete methodology is

of most of the other construction methods / planned to the finest details. In this system the

technologies. Several systems are adopted at walls, columns and slab are casted in one

different places in the world; eventually the continuous pour on concrete. Early removal of

systems which are reasonably economical and forms can be achieved by the air curing/ curing

easy for operation with skilled labor are useful compounds. These forms are made strong and

in India. Certain systems are in vogue and sturdy, fabricated with accuracy and easy to

more and more contractors are trying to bring handle. The components are made out of

in new technologies. aluminium and hence are very light weight.

They afford large number of repetitions

The progress made by the (around 250). The re-propping is simple hence

construction industry of any country could be short cycle time can be achieved.

considered as the index of development of that

country. Further, the number of pucca houses

built in any country could be another index.

While there has been a progressive rise in stock

of housing in India since independence, the

speed thereof has not kept pace with the rapid

growth of population and urbanization. As a

result, the shortage of accommodation is

increasing continuously and the situation has

become acute in urban areas. The traditional

mode of construction for individual houses

comprising load bearing walls with an

appropriate roof above or reinforced concrete

(RC) framed structure construction with infill

masonry walls would be totally inadequate for

mass housing construction industry in view of

the rapid rate of construction. Further, such

constructions are prone to poor quality control

even in case of contractors with substantial

MIVAN formwork can be used for a broad

resources and experience.

range of applications, from straight forward

2. Mivan system wall and slab construction to more complicated

structures involving bay windows, stairs and

It is the most advanced formwork systems. It is A/C hoods. The MIVAN system for forming

fast, simple and adaptable. It produces total concrete structures is probably the most

quality work which requires minimum versatile modern construction system and

maintenance and when durability is the prime unlike other system, it is equally suited to both

consideration. It is a totally pre-engineered high and rise construction. By using specially

Web: www.irjms.in Email: irjms2015@gmail.com, irjms.in@gmail.com Page No: 2

INTERNATIONAL RESEARCH JOURNAL OF MULTIDISCIPLINARY STUDIES &

SPPP's, Karmayogi Engineering College, Pandharpur Organize

National Conference Special Issue March 2016

Vol. 2, Special Issue 1, March, 2016 ISSN (Online): 2454-8499 Impact Factor: 1.3599(GIF),

0.679(IIFS)

designed and manufactured aluminium formwork considering its requirements is an

formwork and effectively managing associated essential part during the construction of the

construction activities, MIVAN has virtually building. The Mivan Formwork should be able

brought ‘assembly line’ productivity to the to take a live load including the impact about

construction site environment, completing 370kg/m². It is however, usual to work with a

projects in record times with four day per floor small factor of safety in the design of

construction work cycle.Using this unique formwork. The surfaces of formwork should

system, all walls, floor slabs, balconies, be dressed in such a manner that after

together with door and window openings are deflection due to weight of concrete and

cast in place in single a site based operation. reinforcement, the surface remains horizontal,

The resulting building structure is very strong, or as desired by the designer. The sheathing

accurate in dimensions and tolerances, with with full live load of 370 kg/m² should not

high quality of finished concrete surface, and deflect more than 0.25 cm and the joists with

yet at the same time, the MIVAN Formwork 200kg/m² of live load should not deflect more

Technology is fast, adaptable and very cost than 0.25cm.Maintaining the Integrity of the

effective.The main characteristics of the specifications. The modular nature of the

MIVAN formwork technology is that it makes mivan formwork should allow easy fixing and

use of concrete as the principle building removal of formwork and the construction can

material for the prime rasons of cost and proceed speedily with very little deviation in

accessibility of cement, sand and stone are dimensional tolerances. Further, it should is

readily available in most countries. Concrete quite flexible and can be easily adapted for any

also brings additional benefits in terms of its variations in the layout.

build quality and strength, it is resistance to 2.2 General specification of Mivan

earthquake tremors, it is resistance to fire, rot Formwork

and vermin attack; it is low noise transmission The basic element of the Mivan

with good thermal capacity and it is proven Formwork is the panel, which is an extruded

durability, giving long life, with little aluminium rail section, welded to an

maintenance. aluminium sheet. This produces a lightweight

panel with an excellent stiffness to weight

ratio, yielding minimal deflection under

2.1 Requirement of Mivan Formwork concrete loading. Panels are manufactured in

The Mivan formwork is made up of of an the size and shape to suit the requirements of

aluminium alloy. While Construction is in specific projects. The panels are made from

process , the formwork is supposed to bear, high strength aluminium alloy with a 4 mm

besides its own weight, the weight of wet thick skin plate and 6mm thick ribbing behind

concrete, the live load due to labor, and the

to stiffen the panels. Earlier the panels were

impact due to pouring concrete and workmen

used to manufacture only in factories in Europe

on it. The vibration caused due to vibrators

and South East Asia but in recent the formwork

used to compact the concrete should also be

components are started manufacturing in india

taken care off. Thus, the design of the

Web: www.irjms.in Email: irjms2015@gmail.com, irjms.in@gmail.com Page No: 3

INTERNATIONAL RESEARCH JOURNAL OF MULTIDISCIPLINARY STUDIES &

SPPP's, Karmayogi Engineering College, Pandharpur Organize

National Conference Special Issue March 2016

Vol. 2, Special Issue 1, March, 2016 ISSN (Online): 2454-8499 Impact Factor: 1.3599(GIF),

0.679(IIFS)

as well e.g. COSMOS Construction The basic element of the formwork is

Machineries And Equipments Pvt. Ltd . Once the panel, which is an extruded aluminium rail

they are assembled they are subjected to a trial section, welded to an aluminium sheet. This

erection in order to eliminate any dimensional produces a lightweight panel with an excellent

or on site problems. The formwork components stiffness to weight ratio, yielding minimal

are durable they can be used repetitively up to deflection under concrete loading. All the

200 times. It is light weighted so heavy lifting formwork components are received at the site

is eliminated, the heaviest components is of 25 within three months after they are ordered.

kg, a labor can easily lift it. Following are the components that are

regularly used in the construction.

3. Components Of Mivan Formwork

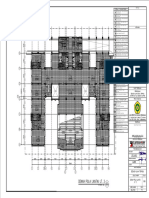

Fig:3.1 Wall panel.

Sr. Paramet Cost By Cost Cost

No er Conventio by Savin

. nal Mivan g

Technolo Techno

gy logy

1. Shutterin Wooden Rs. Rs.

g after Materials 83.8/ 104.6

repetitio =Rs. 88.50 sq.m 3/sq.m

ns /sq.m

M. S.

Material =

Rs.

100.00/sq

m Panels are manufactured in the size and

2. Concreti Rs. 1400 / Rs. Rs. - shape to suit the requirements of specific

ng sq.m 1505/sq 105/sq projects. The panels are made from high

.m .m strength aluminium alloy with a 4 mm thick

3. Reinforc 1,480.00 2,115.2 Rs- skin plate and 6mm thick ribbing behind to

ement 0 635.2/ stiffen the panels. The panels are manufactured

sq.m in MIVAN’S dedicated factories in Europe and

South East Asia. Once they are assembled they

4 Brickwor 484.00 0.00 Rs

are subjected to a trial erection in order to

k 480/sq

eliminate any dimensional or on site problems.

.m

5 Plaster 700.00 0.00 Rs700 Table 1: cost comparison between

/sq.m construction by conventional and mivan

6 Total Rs. technology.

cost 548.4

saving 3/sq.m

Web: www.irjms.in Email: irjms2015@gmail.com, irjms.in@gmail.com Page No: 4

INTERNATIONAL RESEARCH JOURNAL OF MULTIDISCIPLINARY STUDIES &

SPPP's, Karmayogi Engineering College, Pandharpur Organize

National Conference Special Issue March 2016

Vol. 2, Special Issue 1, March, 2016 ISSN (Online): 2454-8499 Impact Factor: 1.3599(GIF),

0.679(IIFS)

1. Grade of M 35

Concrete

2. Slump 180 – 200

mm

3. Wall Thickness External :

200 mm

Internal :

100 mm

4. Steel Partition

wall: 10 mm

Fig 3.2 Beam component dia.

Structural:

12 mm dia.

Shear Wall :

16 mm dia.

5. Slab Thickness Hall : 175

mm

Bedroom :

150 mm

Fig 3.3 Deck component

4. COST COMPARISON

By adopting Mivan technology in the project

not only it gives the better quality of 5 HONEYCOMBING AND CRACKS IN

construction and but also increases the speed of SHEAR WALL

construction and reduces the cost since some of The mivan technology follows monolithic

the construction activities are completely construction i.e. all the structural member viz.

eliminated and others are reduced to a extent . beam, shear wall, slab are casted at same time.

This project includes the cost comparison of In conventional construction the concrete is

conventional construction with Mivan placed from height of 0.6 to 1 meter, and that is

Technology of construction. The following what recommended height to place the

comparison is from the data acquired at concrete. In Mivan Technology of construction

Paranjpe scheme’s “Blue Ridge” a 138 acre the concrete is placed from height of 3 meter in

integrated township Hinjewadi , Pune. shear wall and compacted using vibrator, now

4.1 Details about the structure as height of placing concrete is more there are

It is a part of Paranjpe schemes’s “Blue Ridge” chances of segregation in concrete resulting in

a 138 acre integrated township Hinjewadi , honeycombing and cracks in wall. In mivan

Pune. We have acquired the data of Tower HA- construction it is generally happened that after

1 (25 Floors). removing formwork there is honeycombing in

Web: www.irjms.in Email: irjms2015@gmail.com, irjms.in@gmail.com Page No: 5

INTERNATIONAL RESEARCH JOURNAL OF MULTIDISCIPLINARY STUDIES &

SPPP's, Karmayogi Engineering College, Pandharpur Organize

National Conference Special Issue March 2016

Vol. 2, Special Issue 1, March, 2016 ISSN (Online): 2454-8499 Impact Factor: 1.3599(GIF),

0.679(IIFS)

shear wall, in this project we had tried to fix the

problem of honeycombing in shear wall. We

had gone to BASF The chemical company

pertaining this problem; they suggested us to

use the MasterGlenium ACE 30JP as

admixture to concrete so as to increase the

workability of concrete to reduce

honeycombing

and increase the strength of concrete. One of

the measures to check the workability of

concrete is its slump and to check the strength

is compressive strength. In this project we have

compared the slump and strength of concrete

using admixture and no admixture by slump

cone test and compressive testing machine

respectively. Following are the details .

A. Specification of MasterGlenium ACE

30JP

Appearance : Brownish Liquid

Specific Gravity: 1.00-1.02 g/cm3

PH Value : 6-9

B. Concrete mix design

Grade Designation: M35

Type of Cement: OPC 53 Grades

Reduced water content for admixture: 20 %

6. Advantages of Mivan formwork over

Mix design

conventional construction

Conventional concrete: 1:1.4:2.2

1. More seismic resistance: - The box type

construction provides more seismic resistance

to the structure.

2. Increased durability: - The durability of a

complete concrete structure is more than

conventional brick bat masonry.

3. Lesser number of joints thereby reducing the

leakages and enhancing the durability.

4. Higher carpet area- Due to shear walls the

walls are thin thus increasing area.

Web: www.irjms.in Email: irjms2015@gmail.com, irjms.in@gmail.com Page No: 6

INTERNATIONAL RESEARCH JOURNAL OF MULTIDISCIPLINARY STUDIES &

SPPP's, Karmayogi Engineering College, Pandharpur Organize

National Conference Special Issue March 2016

Vol. 2, Special Issue 1, March, 2016 ISSN (Online): 2454-8499 Impact Factor: 1.3599(GIF),

0.679(IIFS)

5. Integral and smooth finishing of wall and 4. Modifications are not possible as all

slab- Smooth finish of aluminium can be seen members are caste in RCC.

vividly on walls.

6. Uniform quality of construction – Uniform 9.CONCLUSION

grade of concrete is used.

The task of housing due to the rising

7. Negligible maintenance – Strong built up of

population of the country is becoming

concrete needs no maintenance.

increasingly monumental. In terms of technical

8. Faster completion – Unsurpassed

capabilities to face this challenge, the potential

construction speed can be achieved due to light

is enormous; it only needs to be judiciously

weight of forms.

exploited.

9. Lesser manual labour- Less labour is

required for carrying formworks. Traditionally, construction firms all

10. Simplified foundation design due to over the world have been slow to adopt the

consistent load distribution. innovation and changes. Contractors are a

11. The natural density of concrete wall result conservative lot. It is the need of time to

in better sound transmission coefficient. analyze the depth of the problem and find

effective solutions. Our aim is to serves as a

7.Advantages Of Mivan cost effective and efficient tool to solve the

1. High quality formwork ensures consistence problems of the mega housing project all over

of dimensions. the world. Our aim is to maximize the use of

2. On removal of mould a high quality concrete modern construction techniques and

finish is produced to accurate tolerances and equipments on its entire project.

verticality.

We have tried to cover each and

3. Total system forms the complete concrete

every aspect related to conventional and

structures.

aluminium form construction. We thus infer

4. Custom designed to suit project

that aluminium form construction is able to

requirements.

provide high quality construction at

5. Unsurpassed construction speed. unbelievable speed and at reasonable cost. This

6. Panels can be reused up to 250 time technology has great potential for application

7. Can be erected using unskilled labour. in India to provide affordable housing to its

rising population.

8.Limitations Of Mivan Thus it can be concluded that

1. Because of small sizes finishing lines are quality and speed must be given due

seen on the concrete surfaces. consideration with regards to economy. Good

2. Concealed services become difficult due to quality construction will never deter to projects

small thickness of components. speed nor will it be uneconomical. In fact time

3. It requires uniform planning as well as consuming repairs and modification due to

uniform elevations to be cost effective. poor quality work generally delay the job and

Web: www.irjms.in Email: irjms2015@gmail.com, irjms.in@gmail.com Page No: 7

INTERNATIONAL RESEARCH JOURNAL OF MULTIDISCIPLINARY STUDIES &

SPPP's, Karmayogi Engineering College, Pandharpur Organize

National Conference Special Issue March 2016

Vol. 2, Special Issue 1, March, 2016 ISSN (Online): 2454-8499 Impact Factor: 1.3599(GIF),

0.679(IIFS)

cause additional financial impact on the

project. Some experts feel that housing

alternatives with low maintenance

requirements may be preferred even if at the

slightly may preferred even if at the higher

initial cost.

10. FUTURE SCOPES

This thesis work is restricted to

only Mivan formwork and not other type of

aluminium formworks. The future researchers

can continue by working over other type of

formworks construction by analyzing activities

like brickwork, plastering, painting and many

more. Furthermore interviews of different

people from construction industry can be taken

based on questionnaire prepared and analysis

can be done.

11 References:

[1]http://www.avighnagroup.com/downloads/a

vighna_press_archi_july11. pdf

[2] http://www.replify.com/wp-

content/uploads/2010/07/Construction-Case -

Study-Mivan.pdf

[3]http://www.mivan.com/modular/Mivan_Mo

dular.pdf

[4] http://www.iosrjournals.org/iosr-

jmce/papers/sicete%28civil%29-volum

e3/30.pdf

Web: www.irjms.in Email: irjms2015@gmail.com, irjms.in@gmail.com Page No: 8

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5834)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (903)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (541)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (350)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (824)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (405)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mivan 9Document40 pagesMivan 9vishaliNo ratings yet

- Implementation of Value Engineering For Residential and Commercial BuildingsDocument7 pagesImplementation of Value Engineering For Residential and Commercial BuildingsvishaliNo ratings yet

- Exercise: 1: Introduction To Qgis: ObjectiveDocument5 pagesExercise: 1: Introduction To Qgis: ObjectivevishaliNo ratings yet

- Comparison AND Effectiveness OF Mivan Formwork Over THE Conventional FormworkDocument3 pagesComparison AND Effectiveness OF Mivan Formwork Over THE Conventional FormworkvishaliNo ratings yet

- Fast Track ConstructionDocument10 pagesFast Track ConstructionvishaliNo ratings yet

- Exercise 5 & 6Document9 pagesExercise 5 & 6vishaliNo ratings yet

- NEET R.P.T - 2 (26.04.2020) RESULT: Velammal Bodhi Campus - Online ExamDocument2 pagesNEET R.P.T - 2 (26.04.2020) RESULT: Velammal Bodhi Campus - Online ExamvishaliNo ratings yet

- Census 2011 PDFDocument2 pagesCensus 2011 PDFvishaliNo ratings yet

- Contract Administration in Infrastructure Projects: Department of Civil and Environmental EngineeringDocument1 pageContract Administration in Infrastructure Projects: Department of Civil and Environmental EngineeringvishaliNo ratings yet

- Types of Construction Accidents:: Accidents and Their CausesDocument5 pagesTypes of Construction Accidents:: Accidents and Their CausesvishaliNo ratings yet

- ABC AnalysisDocument3 pagesABC AnalysisvishaliNo ratings yet

- Challenges in Maintenance of Infrastructure EngineeringDocument26 pagesChallenges in Maintenance of Infrastructure EngineeringvishaliNo ratings yet

- Sec07 - RacewaysDocument10 pagesSec07 - RacewaysYusufNo ratings yet

- Method Statement For Construction - Designing Buildings Wiki PDFDocument5 pagesMethod Statement For Construction - Designing Buildings Wiki PDFKareemAdelNo ratings yet

- ZP CEA SyllabusDocument4 pagesZP CEA SyllabusAbhijeet ShelkeNo ratings yet

- Flyer of BIS Webinar On Diaster Resilient InfrastructureDocument3 pagesFlyer of BIS Webinar On Diaster Resilient InfrastructurekarthiksampNo ratings yet

- Regie LacernaDocument69 pagesRegie LacernaRvin Jay Cabontocan MarianoNo ratings yet

- Alg 11. WorkDocument3 pagesAlg 11. WorkTrisha AbalosNo ratings yet

- CPM 10-91 Contractor Safety PolicyDocument6 pagesCPM 10-91 Contractor Safety PolicyGilbert GillNo ratings yet

- Bowling Hall Design Standards Bowling SaDocument3 pagesBowling Hall Design Standards Bowling SaRichard ObiriNo ratings yet

- Feb 2017 Buildability SiteDocument21 pagesFeb 2017 Buildability SiteTun Lin OoNo ratings yet

- Mix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Document7 pagesMix Design - New Code Format 2019 - M-20 - JSW - 15.05.2020Snehashish BasuNo ratings yet

- Rockwin India Consulting Engineers PVT LTD: Northern RailwayDocument2 pagesRockwin India Consulting Engineers PVT LTD: Northern RailwayNeelesh JadaunNo ratings yet

- DI 17 Tal Chhapar Rajasthan Kamath DesigDocument6 pagesDI 17 Tal Chhapar Rajasthan Kamath DesigShakti SinghNo ratings yet

- Kombolcha Institute of Technology: Building ConstructionDocument41 pagesKombolcha Institute of Technology: Building Constructionbini1221No ratings yet

- General FEEDER InformationDocument16 pagesGeneral FEEDER InformationFacsolNo ratings yet

- Plan of 3.5 KM Flowline ConstructionDocument1 pagePlan of 3.5 KM Flowline ConstructionRohit SharmaNo ratings yet

- Construction Scope - of - WorksDocument55 pagesConstruction Scope - of - WorksFiroj AlamNo ratings yet

- Preston Bus Station MSCP Case StudyDocument4 pagesPreston Bus Station MSCP Case StudysivnarayanNo ratings yet

- General Notes 2Document1 pageGeneral Notes 2Wilbert ReuyanNo ratings yet

- 15 - 1490 GFM SHE 24 Construction Noise and Vibration Management PlanDocument11 pages15 - 1490 GFM SHE 24 Construction Noise and Vibration Management PlanHussein Adnan FneishNo ratings yet

- Ungureanu 2020Document16 pagesUngureanu 2020Zeyad F SaadNo ratings yet

- WBG Presentation DAEPDocument39 pagesWBG Presentation DAEPhrhhamadaNo ratings yet

- PS577000-28769 (General Technical Specific of Steel Construction)Document26 pagesPS577000-28769 (General Technical Specific of Steel Construction)HoangNo ratings yet

- Und - Ar-07.02 - Rencana Fin. Lantai-Ar-07.02Document1 pageUnd - Ar-07.02 - Rencana Fin. Lantai-Ar-07.02Deden NurarifNo ratings yet

- Megha Engineering & Infrastructures LTD: List of Register TechnicalDocument31 pagesMegha Engineering & Infrastructures LTD: List of Register TechnicalLaxmikanta swainNo ratings yet

- RK MallikCVDocument10 pagesRK MallikCVRK MallikNo ratings yet

- Precast SystemsDocument13 pagesPrecast Systemsparamarthasom1974No ratings yet

- Odiong Bridge FinalDocument18 pagesOdiong Bridge Finaljenor delatorreNo ratings yet

- Resultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDocument4 pagesResultados de La Web: Conveyors For Bulk Materials 6th Ed - CMEDIEGO FERNANDO CADENA ARANGONo ratings yet

- ICC ES Report ESR 1961: The Dow Chemical CompanyDocument3 pagesICC ES Report ESR 1961: The Dow Chemical CompanymurdicksNo ratings yet

- Cat Hammers C842898Document8 pagesCat Hammers C842898maggioraNo ratings yet