Professional Documents

Culture Documents

Wall Pier Design Based On 2016 CBC & 2018 IBC Input Data & Design Summary

Wall Pier Design Based On 2016 CBC & 2018 IBC Input Data & Design Summary

Uploaded by

Cesar Romero VilchezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Wall Pier Design Based On 2016 CBC & 2018 IBC Input Data & Design Summary

Wall Pier Design Based On 2016 CBC & 2018 IBC Input Data & Design Summary

Uploaded by

Cesar Romero VilchezCopyright:

Available Formats

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

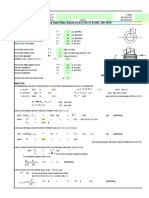

Wall Pier Design Based on 2016 CBC & 2018 IBC

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH

fc' = 3 ksi, (21 MPa)

REBAR YIELD STRESS

fy = 60 ksi, (414 MPa)

WALL PIER LENGTH

L = 5 ft, (1.52 m)

WALL PIER HEIGHT

H = 12 ft, (3.66 m)

WALL PIER THICKNESS

t = 10 in, (254 mm)

VERTICAL EDGE BARS, As

2 # 9

TRANSVERSE REINFORCEMENT, Av THE DESIGN IS ADEQUATE.

2 # 5 @ 6 in. (152 mm), o.c. (at each face.)

FACTORED AXIAL LOAD Pu = 60 kips, (267 kN)

FACTORED SHEAR FORCE Vu = 35 kips, (156 kN), (in plane)

ANALYSIS

CHECK WALL PIER DEFINITION (ACI 318-14 Chapter 2)

L/t= 6.00 within [2.5 , 6] & H/L= 2.40 > 2

[Satisfactory]

CHECK SHEAR STRENGTH (IBC/CBC 1905.1 / ACI 318-14 18.7.6.1.1)

Ve = (Mpr, left, top + Mpr, right,bot) / H + Vu = 149.8 kips

< 8f(fc')0.5bd = 152.6 kips [Satisfactory]

< f[Vc + Avfyd/s ] = 216.0 kips [Satisfactory]

where d= 58.06 in, (ACI 318 25.2, 25.2, & 5.1)

rleft = 0.003 > rmin=MIN[3(fc')0.5/fy, 200/fy ]= 0.003 [Satisfactory]

rright = 0.003 > rmin = 0.003 [Satisfactory]

Mpr, left, top = rleft bd2fy (1.25 - 0.919rleft fy/fc') = 689 ft-kips

Mpr, right ,bot = rright bd2fy (1.25 - 0.919rright fy/fc') = 689 ft-kips

f = 0.6 (ACI 318 21.2)

Av = 0.62 in2

Vc = 2(fc')0.5bd = 0.0 kips, (Per ACI 318-14 18.7.6.2.1, V c = 0, if (Ve -Vu) ≥ 50% Ve AND Pu < Ag fc' / 20 )

Daniel PROJECT : PAGE :

CLIENT : DESIGN BY :

Tian Li JOB NO. : DATE : REVIEW BY :

Concrete Column Design Based on ACI 318-02

INPUT DATA & DESIGN SUMMARY

CONCRETE STRENGTH fc' = #REF! ksi

REBAR YIELD STRESS fy = #REF! ksi

COLUMN DIMENSUINS cx = #REF! in

cy = #REF! in

FACTORED AXIAL LOAD Pu = #REF! k

FACTORED MOMENT LOAD Mu,x = #REF! ft-k

Mu,y = 0.0001 ft-k

FACTORED SHEAR LOAD Vu,x = 0 k

Vu,y = 0 k

COLUMN VERT. REINF. #REF! # #REF! at x dir.

#REF!

#REF! # #REF! at y dir.

SHEAR REINF. ### legs,# #REF! @ 4 in o.c., x dir. #REF!

2 legs,# #REF! @ 4 in o.c., y dir.

ANALYSIS

2 0.85 f

'

C '

o , E c 57 f C

, E s 29000ksi

12 Ec

2

0.85 f

'

C

2 c c , for 0 c o

10 f C o o

'

0.85 f C , for c o

8

f Pn (k) s E s , for s y

f

S

f , for s y

6 y

f Pn (kips) f Mn (ft-kips)

4 AT AXIAL LOAD ONLY #REF! 0

AT MAXIMUM LOAD #REF! #REF!

AT 0 % TENSION #REF! #REF!

2

AT 25 % TENSION #REF! #REF!

AT 50 % TENSION #REF! #REF!

0

0 0 0 1 1 1 1

AT e t = 0.002 #REF! #REF!

AT BALANCED CONDITION #REF! #REF!

f Mn (ft-k) AT e t = 0.005 #REF! #REF!

AT FLEXURE ONLY 0 #REF!

CHECK FLEXURAL & AXIAL CAPACITY

Mu = ( Mu,x2 + Mu,y2 )0.5 = #REF! ft-k, (combined bending load.) q = #REF! o

, (the direction of combined load.)

f Pmax =0.80 f [ 0.85 fc' (Ag - Ast) + fy Ast] = #REF! kips., (at max axial load, ACI 318-02, Sec. 10.3.6.2)

where f = 0.65 (ACI 318-02, Sec.9.3.2.2) #REF! Pu ###

Ag = #REF! in2. Ast = #REF! in . 2

a = Cbb1 = ### in (at balanced strain condition, ACI 10.3.2)

f = 0.48 + 83 et = 0.652 (ACI 318-02, Fig. R9.3.2)

where Cb = d ec / (ec + es) = #REF! in et = 0.002069 ec = 0.003

d = #REF! in, (ACI 7.7.1) b1 = #REF! ( ACI 318-02, Sec. 10.2.7.3 )

f Mn = 0.9 Mn = #REF! ft-kips @ Pn = 0, (ACI 318-02, Sec. 9.3.2)

f Mn = #REF! ft-kips @ Pu = #REF! kips #REF! Mu #REF!

r max = 0.08 (ACI 318-02, Section 10.9) rprovd = #REF!

rmin = 0.01 (ACI 318-02, Section 10.9) #REF!

CHECK SHEAR CAPACITY (ACI 318-02 Sec. 11.1.1, 11.3.1, & 11.5.6.2)

f Vn = f (Vs + Vc) (ACI 318-02 Sec. 11.1.1)

#REF! Vu #REF!

where f = 0.75 (ACI 318-02 Sec. 9.3.2.3) fy = #REF! ksi

d A0 Av Vc = 2 (fc') A0

0.5

Vs = MIN (d fy Av / s , 4Vc) f Vn

x #REF! #REF! #REF! #REF! #REF! #REF!

y #REF! #REF! #REF! #REF! #REF! #REF!

smax = #REF! (ACI 318-02, Section 10.16.8.5) sprovd = 4 in

smin = 1 (ACI 318-02, Section 7.10.4.3) #REF!

You might also like

- Peter Murray - The Architecture of The Italian Renaissance.-Schocken (May 20, 1997)Document258 pagesPeter Murray - The Architecture of The Italian Renaissance.-Schocken (May 20, 1997)Lara Taborda Ojea100% (2)

- Rate Analysis of PQCDocument6 pagesRate Analysis of PQCAmit Singh83% (6)

- T ShapeCapacityDocument1 pageT ShapeCapacityAmey GudigarNo ratings yet

- Sleeve Joint Connection Design, For Steel Cell Tower / Sign, Based On AISC 360-10 Input Data & Design SummaryDocument2 pagesSleeve Joint Connection Design, For Steel Cell Tower / Sign, Based On AISC 360-10 Input Data & Design SummaryAmey GudigarNo ratings yet

- Steel ColumnDocument8 pagesSteel ColumnLeeCH LeeCHNo ratings yet

- Retaining Wall CRP PLN PSS 01 01Document103 pagesRetaining Wall CRP PLN PSS 01 01Asela UdayangaNo ratings yet

- CHS-rounded Hollow Section DesignDocument2 pagesCHS-rounded Hollow Section DesigntamerragaaNo ratings yet

- ACI-350 P-M Interaction 2.1Document33 pagesACI-350 P-M Interaction 2.1corneliortizNo ratings yet

- Wildlife Crossing Design Based On AASHTO-17th & ACI 318-14Document1 pageWildlife Crossing Design Based On AASHTO-17th & ACI 318-14jklo12No ratings yet

- Under Pass Wing Wall (4.1m)Document12 pagesUnder Pass Wing Wall (4.1m)Naveed NazNo ratings yet

- Column Interaction DiagramDocument4 pagesColumn Interaction DiagramankitNo ratings yet

- Steel Connection DesignDocument81 pagesSteel Connection DesignAnkan SarkarNo ratings yet

- Design of Single Angle Subjected To Compressive Force (LSM)Document4 pagesDesign of Single Angle Subjected To Compressive Force (LSM)mithranNo ratings yet

- WALLPRES ExcavationDocument11 pagesWALLPRES ExcavationShekh Muhsen Uddin AhmedNo ratings yet

- Shear Wall Design, Using Laminated Bamboo, Based On NDS 2018 Design CriteriaDocument1 pageShear Wall Design, Using Laminated Bamboo, Based On NDS 2018 Design Criteriaridho ziskaNo ratings yet

- By: Engr Ata Ullah Shah Yousafzai: Data InputDocument5 pagesBy: Engr Ata Ullah Shah Yousafzai: Data InputEngr AtaUllahNo ratings yet

- CV DM 001 100dpiDocument58 pagesCV DM 001 100dpighazi andonoNo ratings yet

- Exce-Anclaje Al Concreto - Rosales Mendoza WaldoDocument5 pagesExce-Anclaje Al Concreto - Rosales Mendoza WaldoGabbo pnukNo ratings yet

- Enhanced Steel BeamDocument4 pagesEnhanced Steel BeamBang SutresNo ratings yet

- MC ASD Prying Ref 0Document2 pagesMC ASD Prying Ref 0Roberto Ramirez AlcantarNo ratings yet

- Connection v1.3Document14 pagesConnection v1.3Trần Minh ChiếnNo ratings yet

- Column Design-Unaixial BendingDocument5 pagesColumn Design-Unaixial Bendingruchita jadhav100% (1)

- Moment To Column WebDocument905 pagesMoment To Column WebAmanpreet SinghNo ratings yet

- LRFD Composite Beam DesignDocument261 pagesLRFD Composite Beam DesignJuan Carlos Flores100% (1)

- I Shaped Plate Girder AISC LRFD Design V2.0Document2 pagesI Shaped Plate Girder AISC LRFD Design V2.0Dipak BorsaikiaNo ratings yet

- AnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTDocument3 pagesAnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTRobert Díaz CornejoNo ratings yet

- B1 Beam 2 Required As Drawn MKD' No: List of MaterialsDocument1 pageB1 Beam 2 Required As Drawn MKD' No: List of MaterialsTitus PraveenNo ratings yet

- Solid MOdel - Beam DesignDocument31 pagesSolid MOdel - Beam Designblisscutest beagleNo ratings yet

- Rectangular Combined Footing: Input DataDocument2 pagesRectangular Combined Footing: Input DataAnonymous 5pQf43AJwNo ratings yet

- 14 M Steel Bridge - AnalysisDocument5 pages14 M Steel Bridge - AnalysisvibishnanNo ratings yet

- Larsen & Toubro Limited: ECC Division - EDRCDocument1 pageLarsen & Toubro Limited: ECC Division - EDRCGanesh PrabuNo ratings yet

- BMREACT13Document3 pagesBMREACT13NEONo ratings yet

- Hinge Connection Design: A Reference CodeDocument3 pagesHinge Connection Design: A Reference CodeGaurav BhabadNo ratings yet

- Restrained Retaining WallDocument20 pagesRestrained Retaining WallIbrahim MeharoofNo ratings yet

- Sheet Pile Compound WallDocument13 pagesSheet Pile Compound WallNilay GandhiNo ratings yet

- Spliced ColumnsDocument10 pagesSpliced ColumnsgvlanushaNo ratings yet

- Section Properties and General Stress AnalysisDocument7 pagesSection Properties and General Stress AnalysiscengizNo ratings yet

- Input Data & Design Summary: Project: Client: Job No.: DateDocument6 pagesInput Data & Design Summary: Project: Client: Job No.: DateAnu PathakNo ratings yet

- One - Way Slab: Design SpecificationsDocument4 pagesOne - Way Slab: Design Specificationssetiawan hendroNo ratings yet

- English Metric: Column Interaction Diagram Units: KG, KG-MDocument4 pagesEnglish Metric: Column Interaction Diagram Units: KG, KG-MHans OlmosNo ratings yet

- Multi-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byDocument2 pagesMulti-Tiered Braced Frame Design Based On AISC 341-16: Project: Client: Design By: Job No.: Date: Review byRidho ZiskaNo ratings yet

- Synthetic Unit Hydrograph Method For Catchments More Than 25 SQ - KMDocument7 pagesSynthetic Unit Hydrograph Method For Catchments More Than 25 SQ - KMManojPatneNo ratings yet

- RT Wall Drawing FinalDocument604 pagesRT Wall Drawing FinalYazer ArafathNo ratings yet

- Clipconn All Bolt 13Document22 pagesClipconn All Bolt 13NEONo ratings yet

- Orignal Beam Flexural + Shear DesignDocument3 pagesOrignal Beam Flexural + Shear DesignEngr AtaUllahNo ratings yet

- TCS R0-TCS-3 PDFDocument1 pageTCS R0-TCS-3 PDFLaxmipriya SahooNo ratings yet

- Wind Load Calculations As Per ASCE 7-10:: Z Z ZT D 2Document10 pagesWind Load Calculations As Per ASCE 7-10:: Z Z ZT D 2MayurNo ratings yet

- Aisc 34Document3 pagesAisc 34Stephanie ScottNo ratings yet

- Compression Design Section2Document10 pagesCompression Design Section2Anonymous sfkedkymNo ratings yet

- Spectra CalculationDocument1 pageSpectra CalculationDarshan PanchalNo ratings yet

- Beam Reinforcement Design by Finite Element Method: Input Data & Design SummaryDocument1 pageBeam Reinforcement Design by Finite Element Method: Input Data & Design SummaryRidho ZiskaNo ratings yet

- Design of Rectangular ColumnDocument7 pagesDesign of Rectangular ColumnAmit Kumar Paul100% (1)

- Design of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)Document4 pagesDesign of Lacing: 2.5% of Axial Load Force in Each Lacing Bar (Flac)Prasad SamantNo ratings yet

- Design of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007Document3 pagesDesign of Fin Plate Connection - (Beam To Column) : DT12007-SS-C8831 DT12007sundarNo ratings yet

- 16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor BoltsDocument30 pages16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor Boltsafzal samaNo ratings yet

- Foundation LoadDocument2 pagesFoundation LoadmathuNo ratings yet

- Section Propeties To Staad Parametric FormationDocument160 pagesSection Propeties To Staad Parametric FormationVignesh VenkatasubramanianNo ratings yet

- LVL 2 - 2way - R01Document17 pagesLVL 2 - 2way - R01Abilaash VNo ratings yet

- Wall PierDocument2 pagesWall PierUsman JavedNo ratings yet

- Project: Client: Design By: Job No.: Date: Review By:: Input Data & Design SummaryDocument2 pagesProject: Client: Design By: Job No.: Date: Review By:: Input Data & Design Summaryjubin funterNo ratings yet

- CorbelDocument2 pagesCorbelAbdullah Al MamunNo ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Itinerary of Travel and Fare MatrixDocument2 pagesItinerary of Travel and Fare MatrixTindusNiobetoNo ratings yet

- Invoice: Al Fateh Skills and Training CentreDocument1 pageInvoice: Al Fateh Skills and Training CentreHelmi HashimNo ratings yet

- C H S U D M: Ourtyard Ousing As A Ubtropical Rban Esign OdelDocument444 pagesC H S U D M: Ourtyard Ousing As A Ubtropical Rban Esign OdelTejaswiniNo ratings yet

- Reinforcement - Cross Section 2 Reinforcement - Cross Section 1Document3 pagesReinforcement - Cross Section 2 Reinforcement - Cross Section 1Gerard Vallespí CatalàNo ratings yet

- Loadings - NSCP 2015 - 2 Storey Residential Concrete StructureDocument32 pagesLoadings - NSCP 2015 - 2 Storey Residential Concrete StructureChristian HindangNo ratings yet

- Optimal Deign of Pile FoundationDocument13 pagesOptimal Deign of Pile FoundationJustin Johnson100% (1)

- Hoa Fuckinggg!Document6 pagesHoa Fuckinggg!Jan Ryan FernandezNo ratings yet

- Worksheet - Descriptive TextDocument2 pagesWorksheet - Descriptive TextGhiz VguyNo ratings yet

- CASA15Document19 pagesCASA15Maria BNo ratings yet

- Types of DomesDocument6 pagesTypes of DomesanonymousNo ratings yet

- Tuf Strand SF Polipropileno PDFDocument2 pagesTuf Strand SF Polipropileno PDFChikyNo ratings yet

- Snag ListDocument9 pagesSnag ListJeanfrancois Laurette100% (1)

- Nashik Sinnar Drawing by SP 7 Aug 21Document1 pageNashik Sinnar Drawing by SP 7 Aug 21Suresh patilNo ratings yet

- Architectural Culture in The Fifties: Louis Kahn and The National Assembly Complex in DhakaDocument20 pagesArchitectural Culture in The Fifties: Louis Kahn and The National Assembly Complex in DhakaSomya InaniNo ratings yet

- MH - 3034 Electrobar Elite Brochure FinalDocument12 pagesMH - 3034 Electrobar Elite Brochure FinalcoehlNo ratings yet

- KKP Marine Inspectur SDPDocument9 pagesKKP Marine Inspectur SDPMONDE ASUSNo ratings yet

- IFR Mechanical Shoe Seal Scissor H Spring TypeDocument1 pageIFR Mechanical Shoe Seal Scissor H Spring Typebldp03No ratings yet

- Toaz - Info Traditional Houses PRDocument35 pagesToaz - Info Traditional Houses PRAmaranthine FrazierNo ratings yet

- Brick Basement Wall - Construction Procedure, Practical ConsiderationDocument7 pagesBrick Basement Wall - Construction Procedure, Practical Considerationvenkateswara rao PothinaNo ratings yet

- Aldo RossiDocument5 pagesAldo RossiGiulia Galli LavigneNo ratings yet

- Unit 16 Lighting LayoutDocument1 pageUnit 16 Lighting Layoutnikkoelbao96No ratings yet

- Blog - A Practical Approach To Level of Detail LOD - United BIM Inc.Document15 pagesBlog - A Practical Approach To Level of Detail LOD - United BIM Inc.Anthony NuñezNo ratings yet

- The 10 Most Famous Architects of All TimeDocument11 pagesThe 10 Most Famous Architects of All TimeCyril NitchezNo ratings yet

- NA To Sls en 1992-1-1 2013Document24 pagesNA To Sls en 1992-1-1 2013Gobidan NavanesanNo ratings yet

- Key Points:: RomanesqueDocument78 pagesKey Points:: Romanesqueeiro abainzaNo ratings yet

- Fl-Acp0led PDF PDFDocument3 pagesFl-Acp0led PDF PDFAndrea QuinoNo ratings yet

- Architectural, Structural & Mep Drawings FORDocument35 pagesArchitectural, Structural & Mep Drawings FORNana Barima100% (1)

- MIT OpenCourseWare - Architecture - 4.665 Contemporary Architecture and Critical Debate, Spring 2002 - ReadingsDocument5 pagesMIT OpenCourseWare - Architecture - 4.665 Contemporary Architecture and Critical Debate, Spring 2002 - Readingsdavid rockNo ratings yet