Professional Documents

Culture Documents

Fire & Life Safety Design Considerations For The Tugun Bypass Tunnel

Fire & Life Safety Design Considerations For The Tugun Bypass Tunnel

Uploaded by

sulphurdioxideCopyright:

Available Formats

You might also like

- Sales and Purchase Agreement Ultra-Low Sulphur Diesel (En590 10Ppm)Document19 pagesSales and Purchase Agreement Ultra-Low Sulphur Diesel (En590 10Ppm)rodolfo molinaNo ratings yet

- Method Statement of Interlocking BlockDocument11 pagesMethod Statement of Interlocking BlockJulfikar Khan86% (7)

- Sample Documents For Crew EmploymentDocument45 pagesSample Documents For Crew EmploymentKrzysztof Majdzinski100% (2)

- Project Management.Document9 pagesProject Management.Mehak FatimaNo ratings yet

- Splintered City - SeattleDocument82 pagesSplintered City - SeattleSelurinhe100% (8)

- Volvo d12Document18 pagesVolvo d12ANH LÊ67% (6)

- cm04 09Document13 pagescm04 09Musharaf ShahNo ratings yet

- Fire Protection PDFDocument2 pagesFire Protection PDFsulphurdioxideNo ratings yet

- Rail Vehicle Peak Heat Release Rate Estimation: Problemy Kolejnictwa - Zeszyt 173 (Grudzień 2016)Document8 pagesRail Vehicle Peak Heat Release Rate Estimation: Problemy Kolejnictwa - Zeszyt 173 (Grudzień 2016)Devendran PoobalasingamNo ratings yet

- Hazards 26 Poster 17 Fracture Propagation in Dense Phase Co2 Pipelines From An Operator S PerspectiveDocument14 pagesHazards 26 Poster 17 Fracture Propagation in Dense Phase Co2 Pipelines From An Operator S PerspectiveAmmarul NafikNo ratings yet

- AJME - Aug2016 HDD AnalisisDocument11 pagesAJME - Aug2016 HDD AnalisisFelipeNo ratings yet

- Green Cable Tunnel Construction at Castle PeakDocument13 pagesGreen Cable Tunnel Construction at Castle PeakKwok Ho ChungNo ratings yet

- Airbus Structural Design ProjectsDocument2 pagesAirbus Structural Design ProjectsHugues de PayensNo ratings yet

- Turkstream Pipeline PrecommissioningDocument2 pagesTurkstream Pipeline PrecommissioningWayne BerreyNo ratings yet

- Fire Risk Assessment of Bridges From State of TheDocument21 pagesFire Risk Assessment of Bridges From State of TheMario StabileNo ratings yet

- PC NL Tunnels PDFDocument12 pagesPC NL Tunnels PDFfrank100% (1)

- A - SOAR and Research Priorities in Hydrogen SafetyDocument42 pagesA - SOAR and Research Priorities in Hydrogen SafetyAlexei KotchourkoNo ratings yet

- Tunnel Fire Protection: A Lost Formwork System, Using PROMATECT - HDocument24 pagesTunnel Fire Protection: A Lost Formwork System, Using PROMATECT - HDavid FonsecaNo ratings yet

- Ajme 4 4 4Document10 pagesAjme 4 4 4Ammarul NafikNo ratings yet

- PipelineDocument10 pagesPipelineHema S rashidNo ratings yet

- Book - Fires Assessing On The Cable Stayed Bridges - ArupDocument10 pagesBook - Fires Assessing On The Cable Stayed Bridges - ArupPhạm Thanh PhươngNo ratings yet

- 13 Water Control - Reasonable Sharing of Risk: Kjell O. BergeDocument5 pages13 Water Control - Reasonable Sharing of Risk: Kjell O. BergeماقوريNo ratings yet

- From Quarries To RoadsDocument3 pagesFrom Quarries To RoadsSetiady MaruliNo ratings yet

- Pipeline-Safety-Fact-Sheet PHMSA - Carbon CoalitionDocument2 pagesPipeline-Safety-Fact-Sheet PHMSA - Carbon Coalitionropi.saraNo ratings yet

- 2008 2 Fire Gas MappingDocument1 page2008 2 Fire Gas Mappingchetan_7927No ratings yet

- Application of CFD Techniques For Modelling Fire T PDFDocument10 pagesApplication of CFD Techniques For Modelling Fire T PDFIbrahim AhmedNo ratings yet

- 4.7 Construction PhilosophyDocument13 pages4.7 Construction PhilosophyPaidar Engineering and Energy Development Co.No ratings yet

- 1C 98engDocument57 pages1C 98engDavide AgnellaNo ratings yet

- Bridge Erection Techniques and Construction EquipmDocument2 pagesBridge Erection Techniques and Construction EquipmAbderrahmane SaidNo ratings yet

- 12.T-D Design Authority ExternalDocument12 pages12.T-D Design Authority Externalم.محمد القرشاوىNo ratings yet

- Carbon Capture Projects Funded by Energy DepartmentDocument5 pagesCarbon Capture Projects Funded by Energy DepartmentKUTNews100% (1)

- Psa / Pra / Qra: in TheDocument41 pagesPsa / Pra / Qra: in TheManlio CastroNo ratings yet

- Full ProjectDocument10 pagesFull ProjectIsmail HussainNo ratings yet

- Preview DW144Document8 pagesPreview DW144mendebour33% (3)

- Hydrogen HazopDocument19 pagesHydrogen HazopAdhi Sudrajat50% (2)

- Advanced Quality Assurance For Piling Works For The WICET Project in GladstoneDocument15 pagesAdvanced Quality Assurance For Piling Works For The WICET Project in GladstoneVetriselvan ArumugamNo ratings yet

- Gas Flare Design Debottlenecking Using Pinch AnalysisDocument25 pagesGas Flare Design Debottlenecking Using Pinch AnalysisRicardo BecNo ratings yet

- Fire Engineering DesignDocument13 pagesFire Engineering DesignPraful PatilNo ratings yet

- Ocean Engineering: J. Calleya, R. Pawling, A. GreigDocument8 pagesOcean Engineering: J. Calleya, R. Pawling, A. GreigMaruf MuhammadNo ratings yet

- Document No.22 Public Safety-Application of Design CodesDocument8 pagesDocument No.22 Public Safety-Application of Design CodesafasfNo ratings yet

- Report3 Main Appendix ADocument46 pagesReport3 Main Appendix AhutuguoNo ratings yet

- Promat Promatect H Fire Resistant Cladding To Steel Ducts en My 2023 03Document20 pagesPromat Promatect H Fire Resistant Cladding To Steel Ducts en My 2023 03Shaun Tneh XuanNo ratings yet

- Tunnelling Railway TunnelsDocument2 pagesTunnelling Railway TunnelsLautaro LogaNo ratings yet

- Paper - Chevron Natural Gas Carbon Capture Technology Testing ProjectDocument10 pagesPaper - Chevron Natural Gas Carbon Capture Technology Testing ProjectendosporaNo ratings yet

- Fire Engineering - Technical Advisor-Peer Review 160611Document2 pagesFire Engineering - Technical Advisor-Peer Review 160611William HarrowNo ratings yet

- 02 - Content Page 1-28Document28 pages02 - Content Page 1-28ze kayNo ratings yet

- 4901 Ccs Roadmap Innovation and RDDocument9 pages4901 Ccs Roadmap Innovation and RDRashidNo ratings yet

- COWI Energy From WasteDocument8 pagesCOWI Energy From WasteEduardo TamargoNo ratings yet

- Parametric Fires For Structural DesignDocument17 pagesParametric Fires For Structural DesignCZengenhariaNo ratings yet

- XXI Paper 046Document10 pagesXXI Paper 046kkannan732153No ratings yet

- From Pore To Pipeline: Integrating Exploration and Production TechnologiesDocument1 pageFrom Pore To Pipeline: Integrating Exploration and Production TechnologiesPOWER.REGNo ratings yet

- Nuclear TankerDocument25 pagesNuclear TankerMRGEMEGP1No ratings yet

- Stress Analysis of A Gas Pipeline Installed Using HDD and Auger Bore TechniquesDocument8 pagesStress Analysis of A Gas Pipeline Installed Using HDD and Auger Bore TechniquesAmmarul NafikNo ratings yet

- The Glasgow Science Centre Tower ProjectDocument34 pagesThe Glasgow Science Centre Tower Projecthayet debbichNo ratings yet

- Epcm SKMDocument2 pagesEpcm SKMpentaxydNo ratings yet

- Nuclear Construction Lessons LearnedDocument22 pagesNuclear Construction Lessons LearnedLuciano PavonNo ratings yet

- SPE-38513-MS The Subsea Well Decommissioning ProjectDocument9 pagesSPE-38513-MS The Subsea Well Decommissioning ProjectÓscar MedinaNo ratings yet

- Offshore Renewables BrochureDocument24 pagesOffshore Renewables BrochureAhmed TahaNo ratings yet

- Tunel Fire ProtectionDocument14 pagesTunel Fire ProtectionThiago DuarteNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Design & Estimation Software: TECHNO Modular Switchboard System 2010Document1 pageDesign & Estimation Software: TECHNO Modular Switchboard System 2010sulphurdioxideNo ratings yet

- Techno Training Centre PDFDocument7 pagesTechno Training Centre PDFsulphurdioxideNo ratings yet

- Section 2 TECHNO Busbar SystemsDocument36 pagesSection 2 TECHNO Busbar SystemssulphurdioxideNo ratings yet

- Tesys Contactors: SelectionDocument6 pagesTesys Contactors: SelectionsulphurdioxideNo ratings yet

- Page 158 PDFDocument1 pagePage 158 PDFsulphurdioxideNo ratings yet

- Tesys Contactors: For Switching 3-Phase Capacitor Banks, Used For Power Factor CorrectionDocument2 pagesTesys Contactors: For Switching 3-Phase Capacitor Banks, Used For Power Factor CorrectionsulphurdioxideNo ratings yet

- 24505-EN (Web)Document6 pages24505-EN (Web)sulphurdioxideNo ratings yet

- Optimisation From The Inside Out: FeatureDocument4 pagesOptimisation From The Inside Out: FeaturesulphurdioxideNo ratings yet

- Tesys Contactors: For Utilisation Category Ac-1Document2 pagesTesys Contactors: For Utilisation Category Ac-1sulphurdioxideNo ratings yet

- Journal Issue II - 09 - Nakheel - Web - 0Document13 pagesJournal Issue II - 09 - Nakheel - Web - 0sulphurdioxideNo ratings yet

- Heat From Sewers AWA 2013Document6 pagesHeat From Sewers AWA 2013sulphurdioxideNo ratings yet

- 24564-EN (Web)Document2 pages24564-EN (Web)sulphurdioxideNo ratings yet

- Tesys Contactors: Selection GuideDocument2 pagesTesys Contactors: Selection GuidesulphurdioxideNo ratings yet

- Fire Protection PDFDocument2 pagesFire Protection PDFsulphurdioxideNo ratings yet

- Environmental Upgrade Agreements: Your Guide To Australia'S Finance Innovation For Building RetrofitsDocument51 pagesEnvironmental Upgrade Agreements: Your Guide To Australia'S Finance Innovation For Building RetrofitssulphurdioxideNo ratings yet

- NDY 9332v3Document8 pagesNDY 9332v3sulphurdioxideNo ratings yet

- Journal Issue II - 09 - Nakheel - Web - 0Document13 pagesJournal Issue II - 09 - Nakheel - Web - 0sulphurdioxideNo ratings yet

- ECOMarApr NDY Cover Story (A)Document6 pagesECOMarApr NDY Cover Story (A)sulphurdioxideNo ratings yet

- Data Centre Strategics Auckland Presentation - Mission Cirtical Power Quality (NDY) 20110525 - UPDATEDDocument33 pagesData Centre Strategics Auckland Presentation - Mission Cirtical Power Quality (NDY) 20110525 - UPDATEDsulphurdioxideNo ratings yet

- What Is The Real Power Of: Frank ItaliaDocument4 pagesWhat Is The Real Power Of: Frank ItaliasulphurdioxideNo ratings yet

- 034-036 - Security Feature ADocument3 pages034-036 - Security Feature AsulphurdioxideNo ratings yet

- Building On Solid (Rubber) Footings: 036 AcousticsDocument3 pagesBuilding On Solid (Rubber) Footings: 036 AcousticssulphurdioxideNo ratings yet

- 52-55 WHD Lores 0Document4 pages52-55 WHD Lores 0sulphurdioxideNo ratings yet

- UPS Topologies - Project Performance Comparisons 2010Document43 pagesUPS Topologies - Project Performance Comparisons 2010sulphurdioxideNo ratings yet

- Paper - 215 Adelaie Street - NABERS UpgradeDocument14 pagesPaper - 215 Adelaie Street - NABERS UpgradesulphurdioxideNo ratings yet

- MarutisuzukiDocument13 pagesMarutisuzukiUtkarsh PandeNo ratings yet

- Cement Production Output and Prices Trends in Mozambique: Daniel BaloiDocument6 pagesCement Production Output and Prices Trends in Mozambique: Daniel BaloiMustafa YılmazNo ratings yet

- Economy of India Under The British RajDocument7 pagesEconomy of India Under The British RajTintoAnilNo ratings yet

- Preliminary Report MH 17Document34 pagesPreliminary Report MH 17REZA FAHLEFINo ratings yet

- Consignment Process in SAP SDDocument9 pagesConsignment Process in SAP SDHarish KumarNo ratings yet

- Phil Rabbit Bus Vs Iac - LawphilDocument9 pagesPhil Rabbit Bus Vs Iac - LawphilQueenie SabladaNo ratings yet

- Blackspots Proforma-II ModifiedDocument2 pagesBlackspots Proforma-II ModifiedPhani PitchikaNo ratings yet

- WMU Ship First Seafarers Adjustment of Records On Work and Rest Hours Baumler Bhatia Kitada 2020Document10 pagesWMU Ship First Seafarers Adjustment of Records On Work and Rest Hours Baumler Bhatia Kitada 2020Captain ChemicalNo ratings yet

- Department of Transportation Department Order - 2017-009 PDFDocument3 pagesDepartment of Transportation Department Order - 2017-009 PDFPortCallsNo ratings yet

- Cable Overloading ReportDocument39 pagesCable Overloading ReportVasu IyerNo ratings yet

- MAN Maxicosi Mobi 2011 LR ENSVNOFI PDFDocument56 pagesMAN Maxicosi Mobi 2011 LR ENSVNOFI PDFAnonymous NM63QfBNo ratings yet

- NPCCDocument233 pagesNPCCvasan980No ratings yet

- AGB Purlin BrochureDocument50 pagesAGB Purlin BrochureMelissa GrahamNo ratings yet

- Manual h25 30da enDocument90 pagesManual h25 30da enpaulNo ratings yet

- Lufkin Reverse MarkDocument6 pagesLufkin Reverse MarkFabian Andres Torres BolañosNo ratings yet

- A Review of Motion Planning TechniquesDocument19 pagesA Review of Motion Planning TechniquesfafNo ratings yet

- 2021-2022 Fleet GuideDocument1 page2021-2022 Fleet GuideJuan KuriNo ratings yet

- Specs BicicletasDocument14 pagesSpecs BicicletasEdwin Javier Garavito HernándezNo ratings yet

- Atr72 QBDocument65 pagesAtr72 QBraiday8490% (10)

- What Is DTS-iDocument8 pagesWhat Is DTS-iGaurao WarungaseNo ratings yet

- IGNITECH Price List Units UsdDocument1 pageIGNITECH Price List Units Usdronal552No ratings yet

- Final Report: AIB/AAI/CAS.062 Air Accident Investigation Bureau of Singapore Ministry of Transport SingaporeDocument28 pagesFinal Report: AIB/AAI/CAS.062 Air Accident Investigation Bureau of Singapore Ministry of Transport SingaporeMorgen GumpNo ratings yet

- Products - Battery Storage - Storage Battery SystemDocument6 pagesProducts - Battery Storage - Storage Battery SystemJ Adan Solis SchroederNo ratings yet

- Dita Pramudia (19202244049) Plagiarism WritingDocument2 pagesDita Pramudia (19202244049) Plagiarism WritingDita PramudiaNo ratings yet

- Clutch: Automobile PowertrainDocument2 pagesClutch: Automobile PowertrainHarish Padmanaban100% (1)

Fire & Life Safety Design Considerations For The Tugun Bypass Tunnel

Fire & Life Safety Design Considerations For The Tugun Bypass Tunnel

Uploaded by

sulphurdioxideOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fire & Life Safety Design Considerations For The Tugun Bypass Tunnel

Fire & Life Safety Design Considerations For The Tugun Bypass Tunnel

Uploaded by

sulphurdioxideCopyright:

Available Formats

The Tugun Bypass viewed from the northern interchange at Currumbin, QLD

Fire & Life Safety Design Considerations

for the Tugun Bypass Tunnel

By Rob Bartlett, Senior Associate, Norman Disney & Young

T

he design fire size for a road tunnel has far- dangerous goods were permitted to travel through. With

reaching implications on the design and costs the introduction of tunnel projects such as the Tugun

associated with the tunnel structure and the fire Bypass project having parameters outside these usual

and life safety systems. This article highlights the process norms, the standardisation of design criteria was no

of determining the design fire size for road tunnel longer a valid option. An alternative approach was

projects, what the approach was previously, and how a necessary which took into consideration the unique risks

risk review process, as used on the Tugun Bypass project, associated with each project.

has significant benefits in obtaining a lower cost, tailored,

Prior to the design of the Sydney Harbour tunnel in 1992,

fire and life safety solution which meets the broad

little consideration was given to fire and life safety design

requirements of the project stakeholders.

in Australian road tunnels. The design of the Sydney

The design fire size for a tunnel has direct influence on Harbour tunnel fire and life safety systems was based on

the fire engineering analysis, the tunnel structural design limited US and PIARC data available at the time. In

(or its resistance to failure due to fire) and the design of 2001, the Australasian Fire Authorities Council produced

the fire and life safety systems such as the tunnel the “Fire Safety Guidelines for Road Tunnels” [1]. This

ventilation, fire detection and fire protections systems. document included relevant fire safety issues designed to

provide information and guidelines to those Fire Brigades

Until recently, the maximum tunnel design fire size had

who may be involved in providing comment or

traditionally been quantified in the design criteria of

requirements to road tunnel developers.

client briefs for road tunnel projects and was typically

rated at 50MW. This was based on the fact that most Tunnels up to 2006 were ‘fire engineered’ mainly for

tunnels within Australia were located in urban areas, the smoke management and egress provisions in line with the

speed limit was generally limited to 80km/hr, and no designated maximum design fire size. Since 2006, the risk

AUSTRALIAN TUNNELLING NEWS 39 Australasian Tunnelling Society

Fire & Life Safety Design Considerations for the Tugun Bypass Tunnel

review process has enhanced the fire engineering process lower heat release rates, and generally tenable conditions

and considers the maximum credible fire scenarios unique with the exception of visibility. The outcomes of the fire

to the project location and operating parameters. events in both the Sydney Harbour Tunnel and Melbourne

City Link Tunnel reinforce these conclusions.

In May this year I attended the Tunnel Fire Safety &

Ventilation Conference in Graz, Austria, and following the The Tugun Bypass project involved the design and

conference was a guest at the PIARC Ventilation Working construction of 7km of new motorway between Tweed

Group Meetings held at the Graz University of Heads NSW and Currumbin QLD, including a 340m long

Technology. It was interesting to observe that of the 20 or tunnel. The objective of the project was to improve

more countries represented in the PIARC Ventilation interstate travel through the Gold Coast and relieve the

Working Group, each had various local Authority impact of traffic congestion on the local roads at Tugun.

requirements to follow either a performance based or The project was designed and constructed under the

prescriptive based approach to fire engineering. This PacificLink Alliance between Queensland Main Roads,

group is currently working on a technical report titled, SMEC and Abigroup. ’Best for project‘ thinking was

“Design Fire Characteristics for Road Tunnels”, in relation encouraged by the Alliance at every level and across all

to determining the design fire size for road tunnel projects. aspects of the project. As a sub-consultant to SMEC,

Norman Disney & Young was engaged for the design of

The aim of the report is to provide information and case the tunnel and motorway services. The project was very

studies to enable decision-making around the available successful in opening to the public six months ahead of

options rather than advocating a performance based the contract schedule, whilst maintaining total costs below

approach over a prescriptive based approach. There was a the original project budget.

strong emphasis by the group on the importance of basing

the report on solid research and the results from recently The project was unique in that:

executed tunnel fire tests. • the route was located across the NSW/QLD border,

thereby doubling the number of stakeholder and

interest groups involved

• part of it was constructed below the extension of the

main runway of the Gold Coast Airport

• the posted speed limit was 100km/h, higher than most

in the country, and

• most classes of dangerous goods (except explosives

and flammable gases) were permitted to travel

through.

The original project brief issued at the time of tender

prescribed that the tunnel and services were to be

designed to accommodate the effects of a maximum

100MW design fire. However, given the unique parameters

of the project, the Scope of Works and Technical Criteria

[7] issued at the time of contract award was amended to

shift the responsibility for determination of the design

fire size to the Alliance team.

Fire testing of the smoke control system in the 2.4km long The contract stated that, “The mechanical ventilation and

Kirchdorf S35 Tunnel (20km north of Graz, Austria), May 2010,

smoke control systems must be capable of fully functional

just prior to opening.

continuous operation for the range of fire events up to and

To touch on the outcomes and conclusions from a number including a 50MW design fire as a minimum. The design

of full scale tunnel fire tests, we were able to see from the fire must meet this minimum requirement and must address

Runehamar [2], Memorial [3] and Reppafjord Tunnel fire the requirements necessary for the nature of goods that will

tests [4] that uncontrolled tunnel fires (or those where no be permitted in the tunnel.”

fire suppression is applied) result in poor visibility, very The design team needed to be able to identify the full

high temperatures and heat release rates, and significant range of possible fire risks and threats, right from the

impact on the integrity of the tunnel structure. These tests minute to the unmanageable, and review their

also showed that heat release rates in excess of 200MW corresponding consequences in some sort of orderly

could be generated from a fully developed non-dangerous fashion. A process was needed that clearly demonstrated

goods fire. the project team had exercised its duty of care to all

stakeholders, and ultimately, to the public.

By comparison, the results of the Benelux [5] and Piota

Negra Tunnel fire tests [6] showed us that controlled Given the large number of stakeholders involved, a Risk

tunnel fires — or fires where fire suppression is activated Review Workshop Process was decided upon as the

— result in cooler tunnel temperatures, limited visibility, vehicle to achieve this, and we acknowledge the good

Australasian Tunnelling Society 40 AUSTRALIAN TUNNELLING NEWS

The Tugun Bypass Tunnel constructed under the extension of the main runway of the Gold Coast Airport.

AUSTRALIAN TUNNELLING NEWS 41 Australasian Tunnelling Society

Fire & Life Safety Design Considerations for the Tugun Bypass Tunnel

work done by Risk Consultant, Risk & Reliability operating the deluge system on some types of dangerous

Consultants (or R2A) in assisting in the facilitation of goods which reacted with water.

these workshops. With over 20 stakeholder groups The probability of each fire scenario was assessed,

involved from both sides of the state border, separate (whether “credible” or not), and whether systems or

briefing sessions were held with each of the individual procedures could be put in place to mitigate the risks. For

stakeholder groups, including: example, it was agreed that design to accommodate an

• Design and construction team members aircraft misjudging the runway, colliding with the tunnel

and bursting into flames was unwarranted, as the

• Local Councils

likelihood of such was extremely low.

• Road Authorities

Following the stakeholder briefing sessions, a workshop

• Airport Authorities was held with all external stakeholders to test the credible

• Fire Brigades, including local commands fire scenarios identified and the proposed precautions.

• Environmental departments, and The sessions were also used to canvass the wider

stakeholder group on whether there were any other

• Dangerous goods departments.

credible fire scenarios needed to be considered by the

These briefings enabled each group to be given a plain design and construction team. Each of the fire scenarios

english explanation of the project and its requirements, and identified were systematically reviewed in detail by the

sought specific feedback on the potential risks and fire and stakeholders, and profiling sheets were prepared which

life safety issues important to that group. It also provided recorded the group’s comments on the severity of each

an opportunity for each group to raise issues of concern or threat, along with the expected precautions or controls.

opportunity outside of fire and life safety. Minutes were The outcomes from the stakeholder workshop were also

kept for each meeting and all issues raised were fed into a used as input into the Incident Management Plans and to

central risk register, and non-fire and life safety issues — the Safety Integrity Levels (SIL) determination exercise

such as environmental, safety and operational issues — for the Information, Communication & Technology

were passed on to the relevant design group for Systems. Separate SIL Level workshops were conducted

consideration and inclusion in the design process. and attended by the design team, the technology

providers, the proponent and the end users (operators)

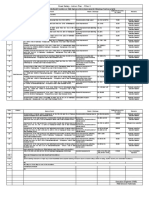

A preliminary fire scenario and impact review matrix (or which looked at:

vulnerability matrix) was prepared for discussion with the

stakeholders which listed out all of the foreseeable fire • the probability of occurrence of the scenario

threats down one side, and the various entities which • in situ control barriers to identify or avert a major

could be impacted by those threats across the top. A tunnel fire event before it happens (such as normal

preliminary assessment was undertaken of the extent of traffic management, CCTV coverage or contact from

consequences for each fire scenario, graded from no the public at the early stage of a hazard), and

impact up to multiple fatalities [refer Table 1]. Of • the potential sequence of events in terms of decision

significant concern was the impact and magnitude of making, response, and fire or control system activation

potential dangerous goods fires, and the effect of times.

Table 1 — Sample Fire Scenario/Impact Review Matrix

Incident Local

Public Response Residents Environment Infrastructure

Motorcycle X X – – –

Vehicle Fire XX XX – X X

Bus Fire XXX XXX – X XX

Non-Dangerous Goods Heavy

XXX XXX – XX XX

Goods Vehicle Fire

Dangerous Goods — Flammable

XXX XXX XX XX XXX

Gas Heavy Goods Vehicle Fire

Dangerous Goods — Toxic Gas

XXX XXX X X –

Heavy Goods Vehicle Fire

XXX Potential extreme consequence event

XX Potential major consequence event

X Potential moderate consequence event

– No vulnerability detected

Australasian Tunnelling Society 42 AUSTRALIAN TUNNELLING NEWS

By looking at the combined effect of these items, the

project team was able to logically establish that, to achieve

the required levels of system reliability stated in the

project brief, it was only the tunnel control and monitoring

system which was required to be formally SIL rated, not

the entire traffic management system or the fire protection

system, which saved significant costs to the project.

The preliminary risk evaluation process initially

established 35 tunnel fire threat scenarios. Following the

individual stakeholder briefings and the fire issues risk

workshop involving all stakeholders, 13 credible fire

scenarios were determined. Similarities within these

thirteen credible fire scenarios permitted detailed fire

engineering analysis of seven credible fire scenarios.

Four controlled tunnel fire scenarios were analysed —

with the deluge system activated — and yielded predicted

fire heat release rates in the order of 7MW. Three (3)

maximum test cases analysed the effect of a heavy goods

vehicle entering the tunnel with a fully developed non-

dangerous goods fire on board. These test cases yielded Smoke testing in the Tugun Bypass Tunnel, March 2008.

the maximum predicted fire size of 100MW.

Other outcomes of the risk review process identified: room to discuss the issues and address the concerns of

• it is best to activate the deluge system on the fire others with factual responses. Ultimately, the risk review

early (even if the vehicle contains dangerous goods) workshops are a vehicle for joint acceptance of the range

to minimise the likelihood of the fire penetrating the of fire risk events, and to confirm the appropriateness of

packaging and exposing the dangerous goods load the precautions proposed to be put in place to mitigate

those risks.

• historically, the majority of fires have been limited to

single vehicles, and were the result of a vehicle impact With agreement on credible tunnel fire scenarios, the fire

• flammable liquid fuel fires are limited by the pool size engineering analysis and design of the tunnel fire and life

which is dependent on the amount of fuel, the slope of safety and control systems can be tailored to the unique

the road and the capacity of the drainage system, and circumstances of a project. The result is cost-effective

solutions at the desired level of safety and reliability

• a high quality traffic management system and well acceptable to all stakeholders.

thought out Incident Management Plans are vital

to the prevention, detection and management of References:

fire incident scenarios, and minimisation of their

[1] Australasian Fire Authorities Council, ‘Fire Safety

consequences.

Guidelines for Road Tunnels’, Issue 1, 10 September 2001.

In summary, the greatest fire and life safety risks [2] Haukur Ingason and Anders Lönnermark SP, ‘Large-scale

associated with large infrastructure projects have low Fire Tests in the Runehamar Tunnel’, from the Swedish

probability but extreme consequences if they occur. By National Testing and Research Institute — Tunnelling &

undertaking a risk review process, all of the project Trenchless Construction, October 2004.

stakeholders are brought together at the initial stages to [3] Massachussetts Highway Department and Federal

quantify and categorise the risks. By harnessing the Highway Administrations, ‘Memorial Tunnel Fire

experience of the design and construction team and all of Ventilation Test Program; Test Report’, United States of

the relevant government, emergency services, America, November 1995.

environmental and specialist risk departments, it positions [4] Eureka Project EU 499 Firetun, Verlang und

the expertise for dealing with these risks at the forefront. Vertriebsgescllschaft, ‘Fires in Transport Tunnels; Report

on Full Scale Tests,’ Dusseldorf, November 1995.

The individual stakeholder briefings enable each group to

understand the fire safety issues that may affect them, [5] Ir. J.W Huijben — Bouwdienst Rijkswaterstaat Centre for

Tunnel Safety, ‘Tests on Fire Detection Systems and

and enables their concerns to be put on the table and

Sprinkler in a Tunnel,’ presented at the International

addressed early in the process. It is also a way of taking on Tunnel Conference (ITC), 2-4 December, 2002, in Basel.

board wider project issues, ideas, and suggestions which

[6] Emilio Cafaro, leader of GRF-DENER-C, Energy

would not necessarily be captured in a wider forum

Department, and Politecnico di Torino and Mario

because of time limitations.

Masiero for Silvani, ‘Testing Tunnel Fire Mitigation

The combined stakeholder workshops provide a vehicle Systems’, Tunnels & Tunnelling International, June 2004.

for due diligence as each group comes to the workshop [7] Roads and Traffic Authority, ‘Pacific Highway Tugun

informed, and familiar with the objectives of the risk Bypass, Exhibit A, Final Scope of Works and Technical

assessment process. All the necessary expertise is in the Criteria — Appendix 48’, 9 February 2006.

AUSTRALIAN TUNNELLING NEWS 43 Australasian Tunnelling Society

You might also like

- Sales and Purchase Agreement Ultra-Low Sulphur Diesel (En590 10Ppm)Document19 pagesSales and Purchase Agreement Ultra-Low Sulphur Diesel (En590 10Ppm)rodolfo molinaNo ratings yet

- Method Statement of Interlocking BlockDocument11 pagesMethod Statement of Interlocking BlockJulfikar Khan86% (7)

- Sample Documents For Crew EmploymentDocument45 pagesSample Documents For Crew EmploymentKrzysztof Majdzinski100% (2)

- Project Management.Document9 pagesProject Management.Mehak FatimaNo ratings yet

- Splintered City - SeattleDocument82 pagesSplintered City - SeattleSelurinhe100% (8)

- Volvo d12Document18 pagesVolvo d12ANH LÊ67% (6)

- cm04 09Document13 pagescm04 09Musharaf ShahNo ratings yet

- Fire Protection PDFDocument2 pagesFire Protection PDFsulphurdioxideNo ratings yet

- Rail Vehicle Peak Heat Release Rate Estimation: Problemy Kolejnictwa - Zeszyt 173 (Grudzień 2016)Document8 pagesRail Vehicle Peak Heat Release Rate Estimation: Problemy Kolejnictwa - Zeszyt 173 (Grudzień 2016)Devendran PoobalasingamNo ratings yet

- Hazards 26 Poster 17 Fracture Propagation in Dense Phase Co2 Pipelines From An Operator S PerspectiveDocument14 pagesHazards 26 Poster 17 Fracture Propagation in Dense Phase Co2 Pipelines From An Operator S PerspectiveAmmarul NafikNo ratings yet

- AJME - Aug2016 HDD AnalisisDocument11 pagesAJME - Aug2016 HDD AnalisisFelipeNo ratings yet

- Green Cable Tunnel Construction at Castle PeakDocument13 pagesGreen Cable Tunnel Construction at Castle PeakKwok Ho ChungNo ratings yet

- Airbus Structural Design ProjectsDocument2 pagesAirbus Structural Design ProjectsHugues de PayensNo ratings yet

- Turkstream Pipeline PrecommissioningDocument2 pagesTurkstream Pipeline PrecommissioningWayne BerreyNo ratings yet

- Fire Risk Assessment of Bridges From State of TheDocument21 pagesFire Risk Assessment of Bridges From State of TheMario StabileNo ratings yet

- PC NL Tunnels PDFDocument12 pagesPC NL Tunnels PDFfrank100% (1)

- A - SOAR and Research Priorities in Hydrogen SafetyDocument42 pagesA - SOAR and Research Priorities in Hydrogen SafetyAlexei KotchourkoNo ratings yet

- Tunnel Fire Protection: A Lost Formwork System, Using PROMATECT - HDocument24 pagesTunnel Fire Protection: A Lost Formwork System, Using PROMATECT - HDavid FonsecaNo ratings yet

- Ajme 4 4 4Document10 pagesAjme 4 4 4Ammarul NafikNo ratings yet

- PipelineDocument10 pagesPipelineHema S rashidNo ratings yet

- Book - Fires Assessing On The Cable Stayed Bridges - ArupDocument10 pagesBook - Fires Assessing On The Cable Stayed Bridges - ArupPhạm Thanh PhươngNo ratings yet

- 13 Water Control - Reasonable Sharing of Risk: Kjell O. BergeDocument5 pages13 Water Control - Reasonable Sharing of Risk: Kjell O. BergeماقوريNo ratings yet

- From Quarries To RoadsDocument3 pagesFrom Quarries To RoadsSetiady MaruliNo ratings yet

- Pipeline-Safety-Fact-Sheet PHMSA - Carbon CoalitionDocument2 pagesPipeline-Safety-Fact-Sheet PHMSA - Carbon Coalitionropi.saraNo ratings yet

- 2008 2 Fire Gas MappingDocument1 page2008 2 Fire Gas Mappingchetan_7927No ratings yet

- Application of CFD Techniques For Modelling Fire T PDFDocument10 pagesApplication of CFD Techniques For Modelling Fire T PDFIbrahim AhmedNo ratings yet

- 4.7 Construction PhilosophyDocument13 pages4.7 Construction PhilosophyPaidar Engineering and Energy Development Co.No ratings yet

- 1C 98engDocument57 pages1C 98engDavide AgnellaNo ratings yet

- Bridge Erection Techniques and Construction EquipmDocument2 pagesBridge Erection Techniques and Construction EquipmAbderrahmane SaidNo ratings yet

- 12.T-D Design Authority ExternalDocument12 pages12.T-D Design Authority Externalم.محمد القرشاوىNo ratings yet

- Carbon Capture Projects Funded by Energy DepartmentDocument5 pagesCarbon Capture Projects Funded by Energy DepartmentKUTNews100% (1)

- Psa / Pra / Qra: in TheDocument41 pagesPsa / Pra / Qra: in TheManlio CastroNo ratings yet

- Full ProjectDocument10 pagesFull ProjectIsmail HussainNo ratings yet

- Preview DW144Document8 pagesPreview DW144mendebour33% (3)

- Hydrogen HazopDocument19 pagesHydrogen HazopAdhi Sudrajat50% (2)

- Advanced Quality Assurance For Piling Works For The WICET Project in GladstoneDocument15 pagesAdvanced Quality Assurance For Piling Works For The WICET Project in GladstoneVetriselvan ArumugamNo ratings yet

- Gas Flare Design Debottlenecking Using Pinch AnalysisDocument25 pagesGas Flare Design Debottlenecking Using Pinch AnalysisRicardo BecNo ratings yet

- Fire Engineering DesignDocument13 pagesFire Engineering DesignPraful PatilNo ratings yet

- Ocean Engineering: J. Calleya, R. Pawling, A. GreigDocument8 pagesOcean Engineering: J. Calleya, R. Pawling, A. GreigMaruf MuhammadNo ratings yet

- Document No.22 Public Safety-Application of Design CodesDocument8 pagesDocument No.22 Public Safety-Application of Design CodesafasfNo ratings yet

- Report3 Main Appendix ADocument46 pagesReport3 Main Appendix AhutuguoNo ratings yet

- Promat Promatect H Fire Resistant Cladding To Steel Ducts en My 2023 03Document20 pagesPromat Promatect H Fire Resistant Cladding To Steel Ducts en My 2023 03Shaun Tneh XuanNo ratings yet

- Tunnelling Railway TunnelsDocument2 pagesTunnelling Railway TunnelsLautaro LogaNo ratings yet

- Paper - Chevron Natural Gas Carbon Capture Technology Testing ProjectDocument10 pagesPaper - Chevron Natural Gas Carbon Capture Technology Testing ProjectendosporaNo ratings yet

- Fire Engineering - Technical Advisor-Peer Review 160611Document2 pagesFire Engineering - Technical Advisor-Peer Review 160611William HarrowNo ratings yet

- 02 - Content Page 1-28Document28 pages02 - Content Page 1-28ze kayNo ratings yet

- 4901 Ccs Roadmap Innovation and RDDocument9 pages4901 Ccs Roadmap Innovation and RDRashidNo ratings yet

- COWI Energy From WasteDocument8 pagesCOWI Energy From WasteEduardo TamargoNo ratings yet

- Parametric Fires For Structural DesignDocument17 pagesParametric Fires For Structural DesignCZengenhariaNo ratings yet

- XXI Paper 046Document10 pagesXXI Paper 046kkannan732153No ratings yet

- From Pore To Pipeline: Integrating Exploration and Production TechnologiesDocument1 pageFrom Pore To Pipeline: Integrating Exploration and Production TechnologiesPOWER.REGNo ratings yet

- Nuclear TankerDocument25 pagesNuclear TankerMRGEMEGP1No ratings yet

- Stress Analysis of A Gas Pipeline Installed Using HDD and Auger Bore TechniquesDocument8 pagesStress Analysis of A Gas Pipeline Installed Using HDD and Auger Bore TechniquesAmmarul NafikNo ratings yet

- The Glasgow Science Centre Tower ProjectDocument34 pagesThe Glasgow Science Centre Tower Projecthayet debbichNo ratings yet

- Epcm SKMDocument2 pagesEpcm SKMpentaxydNo ratings yet

- Nuclear Construction Lessons LearnedDocument22 pagesNuclear Construction Lessons LearnedLuciano PavonNo ratings yet

- SPE-38513-MS The Subsea Well Decommissioning ProjectDocument9 pagesSPE-38513-MS The Subsea Well Decommissioning ProjectÓscar MedinaNo ratings yet

- Offshore Renewables BrochureDocument24 pagesOffshore Renewables BrochureAhmed TahaNo ratings yet

- Tunel Fire ProtectionDocument14 pagesTunel Fire ProtectionThiago DuarteNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Applicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsFrom EverandApplicability of IAEA Safety Standards to Non-Water Cooled Reactors and Small Modular ReactorsNo ratings yet

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Design & Estimation Software: TECHNO Modular Switchboard System 2010Document1 pageDesign & Estimation Software: TECHNO Modular Switchboard System 2010sulphurdioxideNo ratings yet

- Techno Training Centre PDFDocument7 pagesTechno Training Centre PDFsulphurdioxideNo ratings yet

- Section 2 TECHNO Busbar SystemsDocument36 pagesSection 2 TECHNO Busbar SystemssulphurdioxideNo ratings yet

- Tesys Contactors: SelectionDocument6 pagesTesys Contactors: SelectionsulphurdioxideNo ratings yet

- Page 158 PDFDocument1 pagePage 158 PDFsulphurdioxideNo ratings yet

- Tesys Contactors: For Switching 3-Phase Capacitor Banks, Used For Power Factor CorrectionDocument2 pagesTesys Contactors: For Switching 3-Phase Capacitor Banks, Used For Power Factor CorrectionsulphurdioxideNo ratings yet

- 24505-EN (Web)Document6 pages24505-EN (Web)sulphurdioxideNo ratings yet

- Optimisation From The Inside Out: FeatureDocument4 pagesOptimisation From The Inside Out: FeaturesulphurdioxideNo ratings yet

- Tesys Contactors: For Utilisation Category Ac-1Document2 pagesTesys Contactors: For Utilisation Category Ac-1sulphurdioxideNo ratings yet

- Journal Issue II - 09 - Nakheel - Web - 0Document13 pagesJournal Issue II - 09 - Nakheel - Web - 0sulphurdioxideNo ratings yet

- Heat From Sewers AWA 2013Document6 pagesHeat From Sewers AWA 2013sulphurdioxideNo ratings yet

- 24564-EN (Web)Document2 pages24564-EN (Web)sulphurdioxideNo ratings yet

- Tesys Contactors: Selection GuideDocument2 pagesTesys Contactors: Selection GuidesulphurdioxideNo ratings yet

- Fire Protection PDFDocument2 pagesFire Protection PDFsulphurdioxideNo ratings yet

- Environmental Upgrade Agreements: Your Guide To Australia'S Finance Innovation For Building RetrofitsDocument51 pagesEnvironmental Upgrade Agreements: Your Guide To Australia'S Finance Innovation For Building RetrofitssulphurdioxideNo ratings yet

- NDY 9332v3Document8 pagesNDY 9332v3sulphurdioxideNo ratings yet

- Journal Issue II - 09 - Nakheel - Web - 0Document13 pagesJournal Issue II - 09 - Nakheel - Web - 0sulphurdioxideNo ratings yet

- ECOMarApr NDY Cover Story (A)Document6 pagesECOMarApr NDY Cover Story (A)sulphurdioxideNo ratings yet

- Data Centre Strategics Auckland Presentation - Mission Cirtical Power Quality (NDY) 20110525 - UPDATEDDocument33 pagesData Centre Strategics Auckland Presentation - Mission Cirtical Power Quality (NDY) 20110525 - UPDATEDsulphurdioxideNo ratings yet

- What Is The Real Power Of: Frank ItaliaDocument4 pagesWhat Is The Real Power Of: Frank ItaliasulphurdioxideNo ratings yet

- 034-036 - Security Feature ADocument3 pages034-036 - Security Feature AsulphurdioxideNo ratings yet

- Building On Solid (Rubber) Footings: 036 AcousticsDocument3 pagesBuilding On Solid (Rubber) Footings: 036 AcousticssulphurdioxideNo ratings yet

- 52-55 WHD Lores 0Document4 pages52-55 WHD Lores 0sulphurdioxideNo ratings yet

- UPS Topologies - Project Performance Comparisons 2010Document43 pagesUPS Topologies - Project Performance Comparisons 2010sulphurdioxideNo ratings yet

- Paper - 215 Adelaie Street - NABERS UpgradeDocument14 pagesPaper - 215 Adelaie Street - NABERS UpgradesulphurdioxideNo ratings yet

- MarutisuzukiDocument13 pagesMarutisuzukiUtkarsh PandeNo ratings yet

- Cement Production Output and Prices Trends in Mozambique: Daniel BaloiDocument6 pagesCement Production Output and Prices Trends in Mozambique: Daniel BaloiMustafa YılmazNo ratings yet

- Economy of India Under The British RajDocument7 pagesEconomy of India Under The British RajTintoAnilNo ratings yet

- Preliminary Report MH 17Document34 pagesPreliminary Report MH 17REZA FAHLEFINo ratings yet

- Consignment Process in SAP SDDocument9 pagesConsignment Process in SAP SDHarish KumarNo ratings yet

- Phil Rabbit Bus Vs Iac - LawphilDocument9 pagesPhil Rabbit Bus Vs Iac - LawphilQueenie SabladaNo ratings yet

- Blackspots Proforma-II ModifiedDocument2 pagesBlackspots Proforma-II ModifiedPhani PitchikaNo ratings yet

- WMU Ship First Seafarers Adjustment of Records On Work and Rest Hours Baumler Bhatia Kitada 2020Document10 pagesWMU Ship First Seafarers Adjustment of Records On Work and Rest Hours Baumler Bhatia Kitada 2020Captain ChemicalNo ratings yet

- Department of Transportation Department Order - 2017-009 PDFDocument3 pagesDepartment of Transportation Department Order - 2017-009 PDFPortCallsNo ratings yet

- Cable Overloading ReportDocument39 pagesCable Overloading ReportVasu IyerNo ratings yet

- MAN Maxicosi Mobi 2011 LR ENSVNOFI PDFDocument56 pagesMAN Maxicosi Mobi 2011 LR ENSVNOFI PDFAnonymous NM63QfBNo ratings yet

- NPCCDocument233 pagesNPCCvasan980No ratings yet

- AGB Purlin BrochureDocument50 pagesAGB Purlin BrochureMelissa GrahamNo ratings yet

- Manual h25 30da enDocument90 pagesManual h25 30da enpaulNo ratings yet

- Lufkin Reverse MarkDocument6 pagesLufkin Reverse MarkFabian Andres Torres BolañosNo ratings yet

- A Review of Motion Planning TechniquesDocument19 pagesA Review of Motion Planning TechniquesfafNo ratings yet

- 2021-2022 Fleet GuideDocument1 page2021-2022 Fleet GuideJuan KuriNo ratings yet

- Specs BicicletasDocument14 pagesSpecs BicicletasEdwin Javier Garavito HernándezNo ratings yet

- Atr72 QBDocument65 pagesAtr72 QBraiday8490% (10)

- What Is DTS-iDocument8 pagesWhat Is DTS-iGaurao WarungaseNo ratings yet

- IGNITECH Price List Units UsdDocument1 pageIGNITECH Price List Units Usdronal552No ratings yet

- Final Report: AIB/AAI/CAS.062 Air Accident Investigation Bureau of Singapore Ministry of Transport SingaporeDocument28 pagesFinal Report: AIB/AAI/CAS.062 Air Accident Investigation Bureau of Singapore Ministry of Transport SingaporeMorgen GumpNo ratings yet

- Products - Battery Storage - Storage Battery SystemDocument6 pagesProducts - Battery Storage - Storage Battery SystemJ Adan Solis SchroederNo ratings yet

- Dita Pramudia (19202244049) Plagiarism WritingDocument2 pagesDita Pramudia (19202244049) Plagiarism WritingDita PramudiaNo ratings yet

- Clutch: Automobile PowertrainDocument2 pagesClutch: Automobile PowertrainHarish Padmanaban100% (1)