Professional Documents

Culture Documents

Image 004

Image 004

Uploaded by

Vinay K0 ratings0% found this document useful (0 votes)

11 views1 pageOriginal Title

image004

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

11 views1 pageImage 004

Image 004

Uploaded by

Vinay KCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 1

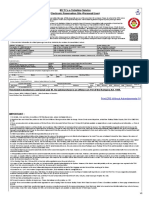

swe va 4as-2011

DIMENSIONING AND TOLERANCING PRINCIPLES

FOR GAGES AND FIXTURES.

1. GENERAL

1.1. Scope

This Standard presents the dasign practices for dimen-

stoning and tolerancing of gages and fiatures used for

the verification of maximum material condition {MMIC}

stze envelopes and viral condition boundaries gener

ated by geometnc tolerances controlled at MMC, and

datum features controlled at maximum material bound-

ary (MMB). Some examples of gages and fixtures used

to inspect workpteces using mgardloss. of foature size

(RFS) and regardless of material boundary (RMB) are

shown in Nonmandatory Appendix C

‘Mast of these practices focus on the design of recetver-

type gages that collect attribute data when used for the

Seen esipscecheciecel licen!

In accordance with ASME Y14 5-209, Some

Of fataring workploes for the collection of verses

data are shown, These practices represent examples of

product definitions allowed by ASME Y14.5, Since

ASME YI45 is nat a standard, ASME YI4.43

shows the practical embodiment ofthe theory displayed

in ASME Y145 by illustrating how the workpieces can

be fixtured and gaged for tolerance verification,

For gaging and fixturing principles and practices, see

sectionsd through 8 and Mandatory Appendices and IL.

1.2 Units

Tho International System of Units (SI) 4s featured 1s

this Standard as it commonly supersedes

US. Customary units specified on engineering draw-

ings. US. Customary units could equally well havebeen

used without projuilice to the principles established,

1.3 Figures

‘The figures in this Standard are in accordance with

ASME Vid 53-2000. The figures are imtended only as llas-

trations to aid the user in understanding the design

principles and methods of gaging and fxturing design

described in the text. Figures may show added detail

for emphasis orbe incompleteby intent. Numerical val-

tues of dimensions and tolerances are illustrative only

1.4 Reference to This Standard

Where are based on this Standard, it shall

bbe noted on the drawing or in a document referenced

Licensed to vinayksk041.

1

‘on the drawing. Reference te this Standard shall state

“Prepared in accordance with ASME 1443-2011."

2 REFERENCES:

The following revisions of American National

Standards form a part of thls Standard to the extent

‘specified herein. A more racent revision may be used

provided there is no conflict with the text of this

Standard. In the event of a conflict between the text of

this Standard and the references cited herein, the toxt

‘of tus Standard shall take precedence.

ASME 14.2, Preferred Metric Limits and Fits

ASME Bd6.1, Surface Texture (Surface Roughness,

‘Waviness, and Lay)

ASME B89.6.2, Temperatureand Humidity Environment

for Dimensional Measurement

ASME 8897.2, Dimensional Measurement Planning

ASME Y14.36M-1996, Surface Texture Symbols

ASME Y145-2009, Dimensioning and To

ASME Y145M-1904, Dimensioning and Tolerancing

ASME Y14.5.1M-1994, Mathematical Definition of

Dimensloning. and Tolerancing Principles

Publisher: The American Society of Mechanical

Eny (ASME), Three Park Avenue, New York,

NY 10016-5990, ASME Onder 2 Law

Drive, PO. Box 3900, Fairfield, NJ 07007-2000

(ewwasme.org)

3. DEFINITIONS:

3.41 General

The following, terms are defined as thelr use apples

tn this Standard. Some torms usad in this Standard are

repeated from ASME Y14.5-2009 or ASME Y14.5M-1904

‘and.are unique to those issues. In other cases, the terms

‘are common to several verstons of ASME YIA5 and no

datets shown,

32 Gaging

3.24 Actual Local Size

‘actual lacel size: the measured value of any individual

distance at any cross section of a featare of size

Last opened 4/30/20. Single user icense-only. Copying and networking prohibited

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- University of GreenwichDocument9 pagesUniversity of GreenwichVinay KNo ratings yet

- Lottery of BirthDocument1 pageLottery of BirthVinay KNo ratings yet

- Provence Alpes Côte D'azurDocument12 pagesProvence Alpes Côte D'azurVinay KNo ratings yet

- Shiva Aparadha Kshamapana StotramDocument3 pagesShiva Aparadha Kshamapana StotramVinay KNo ratings yet

- Eiffel Tower NewDocument24 pagesEiffel Tower NewVinay KNo ratings yet

- Chrysler BuildingDocument35 pagesChrysler BuildingVinay KNo ratings yet

- Art, Commonly Known As Cooper UnionDocument18 pagesArt, Commonly Known As Cooper UnionVinay KNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document2 pagesIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Vinay KNo ratings yet

- Data ExchangeDocument218 pagesData ExchangeVinay KNo ratings yet

- Job Description: We Are An Equal Opportunities EmployerDocument1 pageJob Description: We Are An Equal Opportunities EmployerVinay KNo ratings yet