Professional Documents

Culture Documents

RWRG0003 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0003

RWRG0003 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0003

Uploaded by

Bart JohnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RWRG0003 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0003

RWRG0003 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0003

Uploaded by

Bart JohnCopyright:

Available Formats

Roadranger Warranty Repair Guideline RWRG0003

RWRG0003 - Auxiliary Drive Gear Bearing Failure

Symptom(s) Bench Repair time for cleaning and bearing replacement 1.0

hour

• Growl noise only in low range, subsides in hi range

• Lever moves fore and aft during acceleration and PTO cover inspection per OEM SRT

deceleration

Shift Bar housing R&R per OEM SRT

• Lever jumps out (especially in reverse)

Repair level 2: Transmission R&R per OEM SRT

Cause Mainshaft overhaul bench time per OEM SRT

The auxiliary drive gear bearing can become pitted, loose and

ultimately fail. Worst-case scenario is when the bearing cage

breaks up. This can allow the Auxiliary Drive Gear to be thrust

Warranty Coding

fore and aft causing additional damage to the main or auxil- Part: 5566504

iary sections.

Complaint: Noise

Failure: Bearing failure

Repair Guideline

When the above complaint has been verified the transmission

main box should be inspected through a PTO opening. Warranty Disclaimer

If the failure is not the result of an accident, damage, negli-

There are two levels of repair for a failed Auxiliary Drive Gear

gence, abuse or misuse, improper installation or maintenance

Bearing:

or any other conditions described in the Limits and Exclusions

Level 1: If no bearing pieces are found through the PTO open- section of Warranty Manual TCWY0600, then Roadranger will

ing and the bearing cage is intact, pull auxiliary only to replace treat the condition as covered under its warranty. However,

the failed bearing. this conclusion does not necessarily mean that a defect in fact

exists. In all cases, Roadranger shall make the final determi-

Level 2: If bearing cage pieces or balls are found through the nation and interpretation as to the warrantability of the Prod-

PTO opening, the complete transmission should be removed. uct.

The mainshaft should be pulled, stripped down and inspected

for possible gear hub or washer damage. The main case

should be cleaned. The auxiliary section may only require

flushing but should be visually inspected for damage.

Note: Repair Strategy for Auxiliary section:

Visually inspect auxiliary countershaft front bearings for pit-

ting, spalling, or severe debris dent damage (detectable by

feel). These bearings are readily visible with the Auxiliary

removed. If there is no pitting on the rollers or races and the

races (cups) have only a dull polish, light scratching or slight

debris dents that cannot be detected with a fingernail while

going around the race (not across it), they can be reused. If

bearings are acceptable based on inspection, flush auxiliary

section and reinstall.

When pitting/spalling exists - disassemble auxiliary to replace

Auxiliary countershaft bearings and inspect remaining com-

ponents.

Warranty Labor

Repair level 1: Auxiliary R&R per OEM SRT

Page 1

You might also like

- 205-00 Drive Shaft System - General InformationDocument12 pages205-00 Drive Shaft System - General InformationPor PenglengNo ratings yet

- mm5L PDFDocument131 pagesmm5L PDFEdivaldoVeroneseNo ratings yet

- Angle Brooms 68iDocument22 pagesAngle Brooms 68iBart JohnNo ratings yet

- BS 05883 1996 (En)Document10 pagesBS 05883 1996 (En)Emanuele Mastrangelo100% (1)

- RWRG0001 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0001Document1 pageRWRG0001 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0001Bart JohnNo ratings yet

- RWRG0002 - Auxiliary Countershaft Bearing Failure: Roadranger Warranty Repair Guideline RWRG0002Document1 pageRWRG0002 - Auxiliary Countershaft Bearing Failure: Roadranger Warranty Repair Guideline RWRG0002Bart JohnNo ratings yet

- Rwrg0032en Us PDFDocument1 pageRwrg0032en Us PDFBart JohnNo ratings yet

- RWRG0032 - Output Looseness: Pre-Authorized Warranty Repair Guideline RWRG0032Document1 pageRWRG0032 - Output Looseness: Pre-Authorized Warranty Repair Guideline RWRG0032Bart JohnNo ratings yet

- Rwrg0027en Us PDFDocument1 pageRwrg0027en Us PDFBart JohnNo ratings yet

- RWRG0027 - Input Shaft Breakage: Roadranger Warranty Repair Guideline RWRG0027Document1 pageRWRG0027 - Input Shaft Breakage: Roadranger Warranty Repair Guideline RWRG0027Bart JohnNo ratings yet

- RWRG0033 - Output Bearing Failure: Roadranger Warranty Repair Guideline RWRG0033Document2 pagesRWRG0033 - Output Bearing Failure: Roadranger Warranty Repair Guideline RWRG0033Bart JohnNo ratings yet

- RWRG0034 - Output Seal Leakage: Pre-Authorized Warranty Repair Guideline RWRG0034Document1 pageRWRG0034 - Output Seal Leakage: Pre-Authorized Warranty Repair Guideline RWRG0034Bart JohnNo ratings yet

- ZJ70DBS Drilling Rig NJ-15C2 Series Drilling Fluid Agitator User ManualDocument9 pagesZJ70DBS Drilling Rig NJ-15C2 Series Drilling Fluid Agitator User ManualAhmedNo ratings yet

- RWRG0040 - Low Range Synchronizer Failure: Pre-Authorized Warranty Repair Guideline RWRG0040Document1 pageRWRG0040 - Low Range Synchronizer Failure: Pre-Authorized Warranty Repair Guideline RWRG0040Bart JohnNo ratings yet

- RWRG0060 - Auxiliary Case To Main Case Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0060Document1 pageRWRG0060 - Auxiliary Case To Main Case Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0060Selvin Escobar RojasNo ratings yet

- RWRG0060 - Auxiliary Case To Main Case Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0060Document1 pageRWRG0060 - Auxiliary Case To Main Case Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0060Bart JohnNo ratings yet

- RWRG0004 - Clutch Housing Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0004Document2 pagesRWRG0004 - Clutch Housing Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0004Bart JohnNo ratings yet

- 205-00 Drive Shaft System - General Information PICKUP JMCDocument12 pages205-00 Drive Shaft System - General Information PICKUP JMCRusonegroNo ratings yet

- 205-04 - Front Drive HalfshaftsDocument12 pages205-04 - Front Drive HalfshaftsSofia AltuzarraNo ratings yet

- (TM) Ford Manual de Taller Ford Super Duty 2007 2008 en InglesDocument747 pages(TM) Ford Manual de Taller Ford Super Duty 2007 2008 en Inglesjuan carlos delgadoNo ratings yet

- rear axle suspension 单后桥悬架维修手册-enDocument10 pagesrear axle suspension 单后桥悬架维修手册-enlocario1No ratings yet

- RWRG0043 - High Range Synchronizer Failure: Pre-Authorized Warranty Repair Guideline RWRG0043Document1 pageRWRG0043 - High Range Synchronizer Failure: Pre-Authorized Warranty Repair Guideline RWRG0043Bart JohnNo ratings yet

- RWRG0031 - Splitter, Cylinder, Dry / Oil Ingestion On 13 - 18 SpeedsDocument2 pagesRWRG0031 - Splitter, Cylinder, Dry / Oil Ingestion On 13 - 18 SpeedsBart JohnNo ratings yet

- Rwrg0031en Us PDFDocument2 pagesRwrg0031en Us PDFBart JohnNo ratings yet

- OriginalDocument4 pagesOriginalRalph CordellNo ratings yet

- Trasmisión JAC 5 PDFDocument41 pagesTrasmisión JAC 5 PDFdavid.vaquerahotmail.com100% (2)

- Eaton Fuller Heavy-Duty Transmissions TRSM0996 EN-US: Service ManualDocument56 pagesEaton Fuller Heavy-Duty Transmissions TRSM0996 EN-US: Service Manualr reyesNo ratings yet

- Front Drive Halfshafts - : Item SpecificationDocument19 pagesFront Drive Halfshafts - : Item SpecificationJim LiebNo ratings yet

- Guia de Embreagens LUKDocument36 pagesGuia de Embreagens LUKXman BrazilNo ratings yet

- 4 Wheel and Tire-N900 Series JMCDocument12 pages4 Wheel and Tire-N900 Series JMCRusonegroNo ratings yet

- RWRG0012 - Range Yoke Snap Ring Failure: Roadranger Warranty Repair Guideline RWRG0012Document1 pageRWRG0012 - Range Yoke Snap Ring Failure: Roadranger Warranty Repair Guideline RWRG0012Bart JohnNo ratings yet

- Honda S2000 Clutch BuzzDocument1 pageHonda S2000 Clutch BuzzWilliam KatzNo ratings yet

- MC 10147969 9999Document2 pagesMC 10147969 9999Karol GórskiNo ratings yet

- Manual Transmission: Section 5BDocument48 pagesManual Transmission: Section 5BJose Luis Rodriguez CruzNo ratings yet

- Torque Specifications Description NM LB-FTDocument6 pagesTorque Specifications Description NM LB-FTCamilo RamosNo ratings yet

- SMP Rotary FeederDocument5 pagesSMP Rotary FeederMELCO JITPLNo ratings yet

- Alternadores Delco RemyDocument21 pagesAlternadores Delco RemyosmeNo ratings yet

- Single-Reduction Forward Differential Carriers On Tandem and Tridem AxlesDocument132 pagesSingle-Reduction Forward Differential Carriers On Tandem and Tridem AxlesGlez BaNo ratings yet

- Differential+carrier New ModelDocument24 pagesDifferential+carrier New ModelTimkenNo ratings yet

- Replace GearboxDocument23 pagesReplace GearboxOvidijus JankauskasNo ratings yet

- LC6T55(英)Document40 pagesLC6T55(英)eduvalennNo ratings yet

- Corona RT 46 160Document120 pagesCorona RT 46 160Rimbert100% (2)

- SECTION 1.20: SpecificationsDocument26 pagesSECTION 1.20: SpecificationsLUISA FERNANDA TORRES MANOSALVANo ratings yet

- Single-Reduction Differential Carriers: Single Rear Drive Axles, Rear-Rear Tandem Drive Axles and Front Drive Steer AxlesDocument94 pagesSingle-Reduction Differential Carriers: Single Rear Drive Axles, Rear-Rear Tandem Drive Axles and Front Drive Steer AxlesTavyLocNo ratings yet

- 2005 RG Diesel SMDocument333 pages2005 RG Diesel SMMFNo ratings yet

- Installation: "Drop-In" Fork Lowering Kit Installation Instructions 02-08 VTX1800C/N/R/S/TDocument2 pagesInstallation: "Drop-In" Fork Lowering Kit Installation Instructions 02-08 VTX1800C/N/R/S/TGheorghe DanielNo ratings yet

- Rboat Davit MAINTENANCE MANUAL PDFDocument14 pagesRboat Davit MAINTENANCE MANUAL PDFAnoop AnupNo ratings yet

- PV776-20 006112 PDFDocument6 pagesPV776-20 006112 PDFJhosepNo ratings yet

- copling system 2 syz三一集团信息服务系统Document4 pagescopling system 2 syz三一集团信息服务系统Al FadilNo ratings yet

- Corona RT 46 164 SimpleDocument94 pagesCorona RT 46 164 SimpleRimbert100% (1)

- Replace Left Hand Pulse Ring (Fittings Rear Axle 1)Document26 pagesReplace Left Hand Pulse Ring (Fittings Rear Axle 1)Ovidijus JankauskasNo ratings yet

- Release Bearing Noise With Pedal UpDocument2 pagesRelease Bearing Noise With Pedal UpKB JongNo ratings yet

- SECTION 205-01 DriveshaftDocument6 pagesSECTION 205-01 DriveshaftDhewy AuLia Part IINo ratings yet

- YATB2015-010-M SD60 Shift DelayDocument3 pagesYATB2015-010-M SD60 Shift DelayLin LinNo ratings yet

- 204-01 - Front SuspensionDocument26 pages204-01 - Front SuspensionSofia AltuzarraNo ratings yet

- Rear Drive Halfshafts - : Item SpecificationDocument26 pagesRear Drive Halfshafts - : Item SpecificationKent WaiNo ratings yet

- Dodge Nitro KA - 2007 - ClutchDocument29 pagesDodge Nitro KA - 2007 - ClutcheephantomNo ratings yet

- 271-New Soil Compactor SD110Document6 pages271-New Soil Compactor SD110Imam MuhhudaNo ratings yet

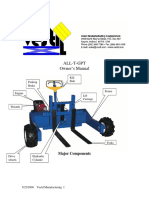

- ALL-T ManualDocument10 pagesALL-T ManualDBKNo ratings yet

- 2 Front Axle, Front Suspension-N900 Series JMCDocument41 pages2 Front Axle, Front Suspension-N900 Series JMCRusonegroNo ratings yet

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Bobcat: Status: State: Endangered Federal: Not ListedDocument3 pagesBobcat: Status: State: Endangered Federal: Not ListedBart JohnNo ratings yet

- Service Bulletin - Product: Driver Instructions TRDR0950 GET 2 KNOW VideosDocument2 pagesService Bulletin - Product: Driver Instructions TRDR0950 GET 2 KNOW VideosBart JohnNo ratings yet

- Tmib0320en UsDocument1 pageTmib0320en UsBart JohnNo ratings yet

- Tcwy0900en-Us 0120 PDFDocument34 pagesTcwy0900en-Us 0120 PDFBart JohnNo ratings yet

- Bobcat PDFDocument2 pagesBobcat PDFBart JohnNo ratings yet

- RWRG0027 - Input Shaft Breakage: Roadranger Warranty Repair Guideline RWRG0027Document1 pageRWRG0027 - Input Shaft Breakage: Roadranger Warranty Repair Guideline RWRG0027Bart JohnNo ratings yet

- RWRG0034 - Output Seal Leakage: Pre-Authorized Warranty Repair Guideline RWRG0034Document1 pageRWRG0034 - Output Seal Leakage: Pre-Authorized Warranty Repair Guideline RWRG0034Bart JohnNo ratings yet

- Eaton Warranty Manual: TCWY0600Document50 pagesEaton Warranty Manual: TCWY0600Bart JohnNo ratings yet

- Rwrg0032en Us PDFDocument1 pageRwrg0032en Us PDFBart JohnNo ratings yet

- RWRG0038 - Transmission Overheating: Roadranger Warranty Repair Guideline RWRG0038Document1 pageRWRG0038 - Transmission Overheating: Roadranger Warranty Repair Guideline RWRG0038Bart JohnNo ratings yet

- Rwrg0031en Us PDFDocument2 pagesRwrg0031en Us PDFBart JohnNo ratings yet

- RWRG0060 - Auxiliary Case To Main Case Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0060Document1 pageRWRG0060 - Auxiliary Case To Main Case Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0060Bart JohnNo ratings yet

- RWRG0031 - Splitter, Cylinder, Dry / Oil Ingestion On 13 - 18 SpeedsDocument2 pagesRWRG0031 - Splitter, Cylinder, Dry / Oil Ingestion On 13 - 18 SpeedsBart JohnNo ratings yet

- RWRG0033 - Output Bearing Failure: Roadranger Warranty Repair Guideline RWRG0033Document2 pagesRWRG0033 - Output Bearing Failure: Roadranger Warranty Repair Guideline RWRG0033Bart JohnNo ratings yet

- Rwrg0027en Us PDFDocument1 pageRwrg0027en Us PDFBart JohnNo ratings yet

- RWRG0040 - Low Range Synchronizer Failure: Pre-Authorized Warranty Repair Guideline RWRG0040Document1 pageRWRG0040 - Low Range Synchronizer Failure: Pre-Authorized Warranty Repair Guideline RWRG0040Bart JohnNo ratings yet

- RWRG0032 - Output Looseness: Pre-Authorized Warranty Repair Guideline RWRG0032Document1 pageRWRG0032 - Output Looseness: Pre-Authorized Warranty Repair Guideline RWRG0032Bart JohnNo ratings yet

- RWRG0006 - Air Module Failure: Roadranger Warranty Repair Guideline RWRG0006Document1 pageRWRG0006 - Air Module Failure: Roadranger Warranty Repair Guideline RWRG0006Bart JohnNo ratings yet

- RWRG0043 - High Range Synchronizer Failure: Pre-Authorized Warranty Repair Guideline RWRG0043Document1 pageRWRG0043 - High Range Synchronizer Failure: Pre-Authorized Warranty Repair Guideline RWRG0043Bart JohnNo ratings yet

- RWRG0042 - Air Filter Regulator Failure: Pre-Authorized Warranty Repair Guideline RWRG0042Document1 pageRWRG0042 - Air Filter Regulator Failure: Pre-Authorized Warranty Repair Guideline RWRG0042Bart JohnNo ratings yet

- RWRG0004 - Clutch Housing Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0004Document2 pagesRWRG0004 - Clutch Housing Gasket Leak: Pre-Authorized Warranty Repair Guideline RWRG0004Bart JohnNo ratings yet

- RWRG0002 - Auxiliary Countershaft Bearing Failure: Roadranger Warranty Repair Guideline RWRG0002Document1 pageRWRG0002 - Auxiliary Countershaft Bearing Failure: Roadranger Warranty Repair Guideline RWRG0002Bart JohnNo ratings yet

- RWRG0012 - Range Yoke Snap Ring Failure: Roadranger Warranty Repair Guideline RWRG0012Document1 pageRWRG0012 - Range Yoke Snap Ring Failure: Roadranger Warranty Repair Guideline RWRG0012Bart JohnNo ratings yet

- RWRG0001 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0001Document1 pageRWRG0001 - Auxiliary Drive Gear Bearing Failure: Roadranger Warranty Repair Guideline RWRG0001Bart JohnNo ratings yet

- Eaton Warranty Guide TCWY0900 EN-USDocument34 pagesEaton Warranty Guide TCWY0900 EN-USBart JohnNo ratings yet

- RWRG0007 - Internal Heat Exchange (Cooler) Failure: Pre-Authorized Warranty Repair Guideline RWRG0007Document2 pagesRWRG0007 - Internal Heat Exchange (Cooler) Failure: Pre-Authorized Warranty Repair Guideline RWRG0007Bart JohnNo ratings yet

- Eaton Ultrashift Plus Transmissions Trdr0941 En-Us: Features, ContinuedDocument2 pagesEaton Ultrashift Plus Transmissions Trdr0941 En-Us: Features, ContinuedBart JohnNo ratings yet

- Eaton Fuller Heavy-Duty Transmissions TRDR0400: Driver InstructionsDocument24 pagesEaton Fuller Heavy-Duty Transmissions TRDR0400: Driver InstructionsBart JohnNo ratings yet

- Eaton Ultrashift Plus Transmissions Trdr0941 En-Us: Features, ContinuedDocument2 pagesEaton Ultrashift Plus Transmissions Trdr0941 En-Us: Features, ContinuedBart JohnNo ratings yet

- Practice Problems 2012Document5 pagesPractice Problems 2012Anonymous Fj3YPHNo ratings yet

- Adolescent Reproductive Health Albay S.Y. 2022-2023: Region V-Bicol Division: School: District: Period/Date: Grade LevelDocument1 pageAdolescent Reproductive Health Albay S.Y. 2022-2023: Region V-Bicol Division: School: District: Period/Date: Grade LevelPamela Rose Baraquiel-BelardoNo ratings yet

- MFG Fiberglass Column Forms Product SheetDocument3 pagesMFG Fiberglass Column Forms Product SheetAboalmaail AlaminNo ratings yet

- Ultrastructure of The Dentin Adhesive Interface After Acidbase Challenge 2004Document8 pagesUltrastructure of The Dentin Adhesive Interface After Acidbase Challenge 2004Mohamed OudaNo ratings yet

- Homework 1 Modulo 8Document6 pagesHomework 1 Modulo 8Eliab OrellanaNo ratings yet

- EnerMech TrainingDocument4 pagesEnerMech TrainingZulhilmi ZalizanNo ratings yet

- Titration of Vinegar Lab ReportDocument8 pagesTitration of Vinegar Lab ReportIbrahim Abdulkadir JumaNo ratings yet

- Behavioral Pathology in Alzheimers Disease Rating Scale Behavead 1997Document3 pagesBehavioral Pathology in Alzheimers Disease Rating Scale Behavead 1997Filly ZhangNo ratings yet

- Caf-6 TaxDocument4 pagesCaf-6 TaxaskermanNo ratings yet

- Fungi: Galactomannan and 1,3-β - Glucan Testing for the Diagnosis of Invasive AspergillosisDocument8 pagesFungi: Galactomannan and 1,3-β - Glucan Testing for the Diagnosis of Invasive AspergillosisntnquynhproNo ratings yet

- Jaggery Making: How To Make Jaggery?Document5 pagesJaggery Making: How To Make Jaggery?Subham BhattacharyaNo ratings yet

- King Propose Volume 1Document225 pagesKing Propose Volume 1Lorenzo FaddaNo ratings yet

- Problem Set No.1Document3 pagesProblem Set No.1paolo sulitNo ratings yet

- Elements, Compounds and Mixtures: Gen. ScienceDocument31 pagesElements, Compounds and Mixtures: Gen. ScienceMadhavi KapadiaNo ratings yet

- TAD 1630 GE: Genset Engine - Gen PacDocument2 pagesTAD 1630 GE: Genset Engine - Gen PacselfyNo ratings yet

- Latihan Autocad KIMI-A2 - PlanDocument1 pageLatihan Autocad KIMI-A2 - PlanMuhd HakimieNo ratings yet

- Stainless Steel Grade 410Document5 pagesStainless Steel Grade 410Rajesh N Priya Gopinathan100% (2)

- Audi A6 EuroncapDocument3 pagesAudi A6 EuroncapcarbasemyNo ratings yet

- Router7031 NS-01-002 CNV AllAccessGuideDocument20 pagesRouter7031 NS-01-002 CNV AllAccessGuideAHMAD FUADNo ratings yet

- 02 IVD-R Deep-Dive Deck NewDocument215 pages02 IVD-R Deep-Dive Deck Newrajiveacharya100% (1)

- Diagnosisofmyasthenia Gravis: Mamatha Pasnoor,, Mazen M. Dimachkie,, Constantine Farmakidis,, Richard J. BarohnDocument14 pagesDiagnosisofmyasthenia Gravis: Mamatha Pasnoor,, Mazen M. Dimachkie,, Constantine Farmakidis,, Richard J. BarohnLilisNo ratings yet

- 26 Jan 21Document156 pages26 Jan 21Aj YangNo ratings yet

- 3.0 Chapter 3 LECTURE NOTESDocument6 pages3.0 Chapter 3 LECTURE NOTESNhư Hoàng Thụy TâmNo ratings yet

- Psychology and The Challenges of Life 13th Edition Nevid Solutions ManualDocument73 pagesPsychology and The Challenges of Life 13th Edition Nevid Solutions Manualbrianwoodsnjyoxepibt100% (14)

- Letter To Parents (RVHS Incident)Document2 pagesLetter To Parents (RVHS Incident)dontspreadaboutmeNo ratings yet

- New and Future Developments in Sustainable Agriculture Advances in Microbe Based Biostimulants Harikesh Bahadur Singh Download PDF ChapterDocument52 pagesNew and Future Developments in Sustainable Agriculture Advances in Microbe Based Biostimulants Harikesh Bahadur Singh Download PDF Chaptersamantha.lara160100% (6)

- After Activity Report Oplan Paalala 201Document12 pagesAfter Activity Report Oplan Paalala 201Jaimee Marie PeraltaNo ratings yet

- Thematic Apperception Test 8Document8 pagesThematic Apperception Test 8api-610105652No ratings yet

- Titan Aviation 30000l Semi Trailer Refueller PDFDocument4 pagesTitan Aviation 30000l Semi Trailer Refueller PDFcloudysunNo ratings yet